ASTM A494/A494M-00

(Specification)Standard Specification for Castings, Nickel and Nickel Alloy

Standard Specification for Castings, Nickel and Nickel Alloy

SCOPE

1.1 This specification covers nickel, nickel-copper, nickel-copper-silicon, nickel-molybdenum, nickel-chromium, and nickel-molybdenum-chromium alloy castings for corrosion-resistant service.

1.2 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification. Inch-pound units are applicable for material ordered to Specification A494 and SI units for material ordered to Specification A494M.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: A 494/A494M – 00 An American National Standard

Standard Specification for

Castings, Nickel and Nickel Alloy

This standard is issued under the fixed designation A 494/A494M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E 354 Test Methods for Chemical Analysis of High-

Temperature, Electrical, Magnetic, and Other Similar Iron,

1.1 This specification covers nickel, nickel-copper, nickel-

Nickel, and Cobalt Alloys

copper-silicon, nickel-molybdenum, nickel-chromium, and

2.2 Military Standards:

nickel-molybdenum-chromium alloy castings for corrosion-

NAVSEA T9074–AS-GIB-010/271 Requirements for Non-

resistant service.

destructive Testing Methods

1.2 The values stated in either inch-pound units or SI units

NAVSEA S9074–AR-GIB-010/2718 Requirements for Fab-

are to be regarded separately as standard. Within the text, the

rication Welding and Inspection, and Casting Inspection

SI units are shown in brackets. The values stated in each

and Repair for Machinery, Piping, and Pressure Vessels

system are not exact equivalents; therefore, each system must

be used independently of the other. Combining values from the

3. Terminology

two systems may result in nonconformance with the specifi-

3.1 Definitions:

cation. Inch-pound units are applicable for material ordered to

3.1.1 master heat—a single furnace charge of refined alloy

Specification A 494 and SI units for material ordered to

which may either be poured directly into castings or into remelt

Specification A 494M.

alloy for individual melts.

2. Referenced Documents 3.1.2 melts—a single furnace charge poured into castings.

When master heats are used to prepare melts, a melt analysis

2.1 ASTM Standards:

shall be reported.

A 370 Test Methods and Definitions for Mechanical Testing

of Steel Products

4. General Conditions for Delivery

A 488/A488M Practice for Steel Castings, Welding, Quali-

4.1 Material furnished to this specification shall conform to

fications of Procedures and Personnel

the requirements of Specification A 781/A 781M, including

A 732/A732M Specification for Castings, Investment, Car-

any supplementary requirements that are indicated in the

bon and Low–Alloy Steel for General Application, and

3 purchase order. Failure to comply with the general require-

Cobalt Alloy for High Strength at Elevated Temperatures

ments of Specification A 781/A 781M constitutes nonconfor-

A 781/A781M Specification for Castings, Steel and Alloy,

3 mance with this specification. In case of conflict between the

Common Requirements, for General Industrial Use

requirements of this specification and Specification A 781/

E 8 Test Methods for Tension Testing of Metallic Materials

A 781M, this specification shall prevail.

E 29 Practice for Using Significant Digits in Test Data to

Determine Conformance with Specifications

5. Ordering Information

E 30 Test Methods for Chemical Analysis of Steel, Cast

6 5.1 Orders for castings to this specification should include

Iron, Open-Hearth Iron, and Wrought Iron

the following information:

E 38 Methods for Chemical Analysis of Nickel-Chromium

7 5.1.1 Quantity, in pieces, and

and Nickel-Chromium-Iron Alloys

5.1.2 Grade designation (Table 1) and class (Table 2).

E 76 Test Methods for Chemical Analysis of Nickel-Copper

6 5.2 The purchaser shall specify any of the following infor-

Alloys

mation required to describe adequately the desired material:

5.2.1 Heat treat condition (see 6.1 and 6.2),

This specification is under the jurisdiction of ASTM Committee A-1 on Steel,

5.2.2 Repair welding (see 11)

Stainless Steel, and Related Alloys and is the direct responsibility of Subcommittee

A01.18 on Castings. 5.2.3 Source inspection requirements, if any (see Specifica-

Current edition approved Mar. 10, 2000. Published May 2000. Originally

tion A 781/A 781M),

published as B 332 – 58 T. Redesignated as A 494 in 1963. Last previous edition

5.2.4 Marking-for-identification requirements, if any (see

A 494/A 494M – 99.

13.1), and

Annual Book of ASTM Standards, Vol 01.03.

Annual Book of ASTM Standards, Vol 01.02.

5.2.5 Supplementary requirements desired, including the

Annual Book of ASTM Standards, Vol 03.01.

Annual Book of ASTM Standards, Vol 14.02.

6 8

Annual Book of ASTM Standards, Vol 03.05. Available from DODSSP, Building 4/Section D, 700 Robbins Avenue Phila-

Discontinued, see 1989 Annual Book of ASTM Standards, Vol 03.05. delphia, PA 19111–5098

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

A 494/A494M

TABLE 1 Chemical Requirements

TABLE 2 Heat Treat Requirements

Grade Heat Treatment

CZ-100, M-35-1, M-35-2, CY-40 Class 1, M-30H, M-30C, As cast

M-25S Class 1, CY5SnBiM

A

M-25S, Class 2 Load into furnace at 600°F [315°C] maximum. Heat to 1600°F [870°C] and hold

for 1 h plus an additional 30 min for each ½ in. [13 mm] of cross section over 1

B C

in. Cool to 1300°F [705°C] and hold at temperature for 30 min then quench in

oil to room temperature.

M-25S, Class 3 Load into furnace at 600°F [315°C] maximum. Heat slowly to 1100°F [605°C] and

hold to develop maximum hardness. Furnace or air cool to room temperature.

N-12MV, N-7M Heat to 2000°F [1095°C] minimum, hold for sufficient time to heat castings to

temperature, quench in water or rapid cool by other means.

CW-12MW, CW-6M, CW-6MC, CW-2M Heat to 2150°F [1175°C] minimum, hold for sufficient time to heat castings to

temperature, quench in water or rapid cool by other means.

CY-40, Class 2 Heat to 1900°F [1040°C] minimum, hold for sufficient time to heat castings to

temperature, quench in water or rapid cool by other means.

CX2MW (N26022) Heat to 2200°F [1205°C] minimum, hold for sufficient time to heat castings to

temperature, quench in water or rapid air cool by other means.

CU5MCuC (N28820) Heat to 2100°F [1150°C] minimum, hold for sufficient time to heat castings to

temperature, quench in water. Stabilize at 1725–1815°F [940–990°C], hold for

sufficient time to heat castings to temperature, quench in water or rapid cool by

other means.

A

M-25S, while machinable in the “as cast” condition, is capable of being solution treated for improved machinability. It may be subsequently age hardened to the

hardness specified in Table 3 and finished machined or ground.

B

For cross sections over 6 in. [125 mm] it may be necessary to increase the hold time if maximum softness is desired.

C

For maximum softness and the least variation in hardness levels, castings should be transferred from an oven at 1600°F [870°C] to a second oven at 1300°F [705°C].

standards of acceptance. requirements prescribed in Table 1.

7.2 An analysis of each master heat shall be made by the

6. Heat Treatment

manufacturer to determine the percentages of the elements

6.1 Castings shall be heat treated in accordance with the

specified in Table 1. The analysis shall be made from a

requirements in Table 2.

representative sample taken during the pouring of the master

heat. Chemical composition shall be reported to the purchaser

NOTE 1—Proper heat treatment of these alloys is usually necessary to

or his representative.

enhance corrosion resistance and, in some cases, to meet mechanical

properties. Minimum heat treat temperatures are specified; however, it is

7.3 Test Methods E 76 or Test Methods E 354 shall be used

sometimes necessary to heat treat at higher temperatures, hold for some

for referee purposes. Test Methods E 30 or Methods E 38 shall

minimum time at temperature, and then rapidly cool the castings in order

be used if Test Methods E 76 or Test Methods E 354 do not

to enhance the corrosion resistance and meet mechanical properties.

include a method for some element present in the material.

6.2 When Class 1 is specified, grades CY40 and M-25S

8. Tensile Properties

shall be supplied in the as-cast condition. When Class 2 is

8.1 One tension test shall be made from each master heat

specified, grades CY40 and M-25S shall be supplied in the

except for grades M-25S and CY5SnBiM when the master heat

solution-treated condition. When Class 3 is specified, grade

is used to pour the castings. One tension test shall be made

M-25S shall be supplied in the age-hardened condition.

from each melt except for grades M-25S and CY5SnBiM. Test

7. Chemical Composition

results shall conform to the tensile requirements specified in

7.1 These alloys shall conform to the chemical composition Table 3. Test bars shall be poured in special blocks from the

A 494/A494M

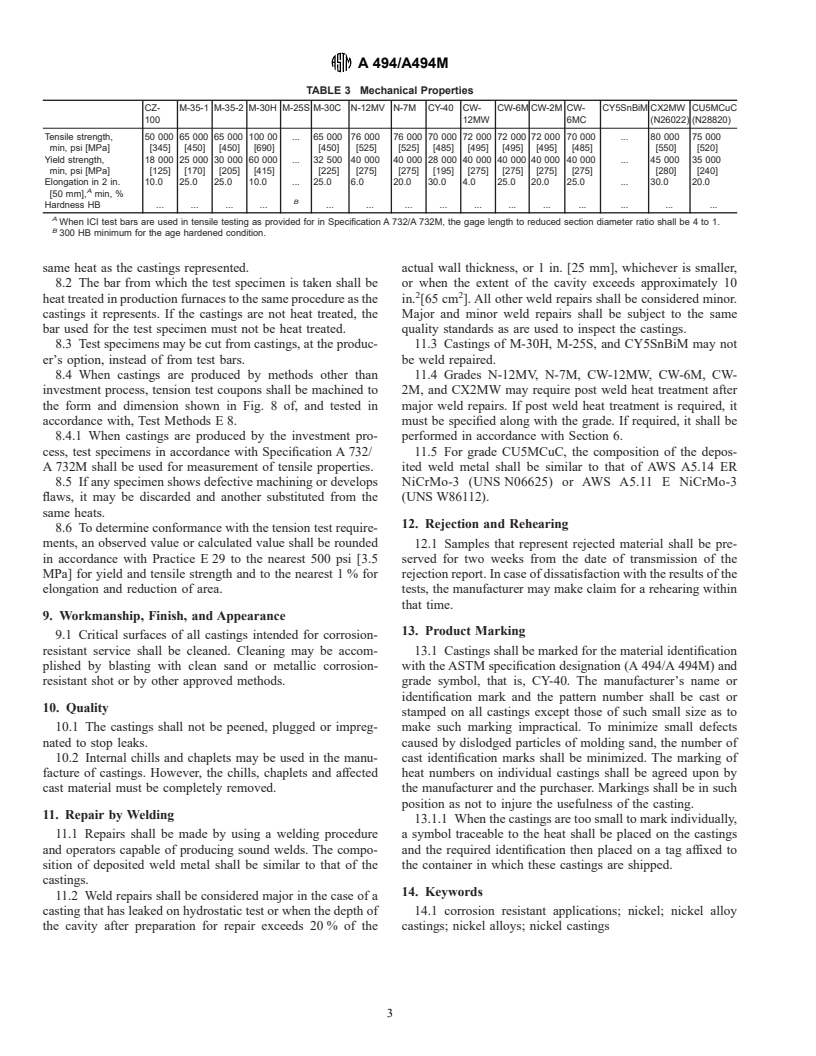

TABLE 3 Mechanical Properties

CZ- M-35-1 M-35-2 M-30H M-25S M-30C N-12MV N-7M CY-40 CW- CW-6M CW-2M CW- CY5SnBiM CX2MW CU5MCuC

100 12MW 6MC (N26022) (N28820)

Tensile strength, 50 000 65 000 65 000 100 00 . 65 000 76 000 76 000 70 000 72 000 72 000 72 000 70 000 . 80 000 75 000

min, psi [MPa] [345] [450] [450] [690] [450] [525] [525] [485] [495] [495] [495] [485] [550] [520]

Yield strength, 18 000 25 000 30 000 60 000 . 32 500 40 000 40 000 28 000 40 000 40 000 40 000 40 000 . 45 000 35 000

min, psi [MPa] [125] [170] [205] [415] [225] [275] [275] [195] [275] [275] [275] [275] [280] [240]

Elongation in 2 in. 10.0 25.0 25.0 10.0 . 25.0 6.0 20.0 30.0 4.0 25.0 20.0 25.0 . 30.0 20.0

A

[50 mm], min, %

B

Hardness HB . . . . . . . . . . . . . . .

A

When ICI test bars are used in tensile testing as provided for in Specification A 732/A 732M, the gage length to reduced section diameter ratio shall be 4 to1.

B

300 HB minimum for the age hardened condition.

same heat as the castings represented. actual wall thickness, or 1 in. [25 mm], whichever is smaller,

8.2 The bar from which the test specimen is taken shall be or when the extent of the cavity exceeds approximately 10

2 2

heat treated in production furnaces to the same procedure as the in. [65 cm ]. All other weld repairs shall be considered minor.

castings it represents. If the castings are not heat treated, the Major and minor weld repairs shall be subject to the same

bar used for the test specimen must not be heat treated. quality standards as are used to inspect the castings.

8.3 Test specimens may be cut from castings, at the produc- 11.3 Castings of M-30H, M-25S, and CY5SnBiM may not

er’s option, instead of from test bars. be weld repaired.

8.4 When castings are produced by methods other than 11.4 Grades N-12MV, N-7M, CW-12MW, CW-6M, CW-

investment process, tension test coupons shall be machined to 2M, and CX2MW may require post weld heat treatment after

the form and dimension shown in Fig. 8 of, and tested in major weld repairs. If post weld heat treatment is required, it

accordance with, Test Methods E 8. must be specified along with the grade. If required, it shall be

8.4.1 When castings are produced by the investment pro- performed in accordance with Section 6.

cess, test specimens in accordance with Specification A 732/ 11.5 For grade CU5MCuC, the composition of the depos-

A 732M shall be used for measurement of tensile properties. ited weld metal shall be similar to that of AWS A5.14 ER

8.5 If any specimen shows defective machining or develops NiCrMo-3 (UNS N06625) or AWS A5.11 E NiCrMo-3

flaws, it may be discarded and another substituted from the (UNS W86112).

same heats.

12. Rejection and Rehearing

8.6 To determine conformance with the tension test require-

ments, an observed value or calculated value shall be rounded 12.1 Samples that represent rejected material shall be pre-

in accordance with Practice E 29 to the nearest 500 psi [3.5 served for two weeks from the date of transmission of the

MPa] for yield and tensile strength and to the nearest 1 % for rejection report. In case of dissatisfaction with the results of the

elongation and reduction of area.

tests, the manufacturer may make claim for a rehearing within

that time.

9. Workmanship, Finish, and Appearance

13. Product Marking

9.1 Critical surfaces of all castings intended for corrosion-

resistant service shall be cleaned. Cleaning may be accom-

13.1 Castings shall be marked for the material identification

plished by blasting with clean sand or metallic corrosion- with the ASTM specification designation (A 494/A 494M) and

resistant shot or by other approved methods.

grade symbol, that is, CY-40. The manufacturer’s name or

identification mark and the pattern number shall be cast or

10. Quality

stamped on all castings except those of such small size as to

10.1 The castings shall not be peened, plugged or impreg- make such marking impractical. To minimize small defects

nated to stop leaks. caused by dislodged particles of molding sand, the number of

10.2 Internal chills and chaplets may be used in the manu- cast identification marks shall be minimized. The marking of

facture of castings. However, the chills, chaplets and affected heat numbers on individual castings shall be agreed upon by

cast material must be completely removed. the manufacturer and the purchaser. Markings shall be in such

position as not to injure the usefulness of the casting.

11. Repair by Welding

13.1.1 When the castings are too small to mark individually,

11.1 Repairs shall be made by using a welding procedure a symbol traceable to the heat shall be placed on the castings

and operators capable of producing sound welds. The compo- and the required identification then placed on a tag affixed to

sition of deposited weld metal shall be similar to that of the the container in which these castings are shipped.

castings.

14. Keywords

11.2 Weld repairs shall be considered major in the case of a

casting that has leaked on hydrostatic test or when the depth of 14.1 corrosion resistant applications; nickel; nickel alloy

the cavity after preparation for repair exceeds 20 % of the castings; nickel alloys; nickel castings

A 494/A494M

SUPPLEMENTARY REQUIREMENTS

The following supplementary requirements shall not apply unless specified in the purchase order. A

list of standard supplementary requirements for use at the option of the purchaser is included in

Specification A 781/A 781M. Those which are ordinarily considered for use with this specification are

given below; others enumerated in Specification A 781/A 781M may be used with this specification

upon agreement between the manufacturer and the purchaser.

S2. Radiographic Examination

S3. Liquid Penetrant Examination

S6. Certification

S10. Hardness Tests

S10.1 When composition M-25S material is ordered with a

hardness maximum or range in the as-cast or solution treated

condition, hardness tests shall be made in accordance with Test

Me

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.