ASTM D2737-03

(Specification)Standard Specification for Polyethylene (PE) Plastic Tubing

Standard Specification for Polyethylene (PE) Plastic Tubing

ABSTRACT

This specification covers polyethylene (PE) tubing pressure-rated for water. Included here are criteria for classifying PE plastic tubing materials and PE plastic tubing, and requirements and test methods for materials, workmanship, dimensions, bond strength, carbon black, density,.sustained pressure, hydrostatic burst pressure, and environmental stress cracking. Quality-assurance-passed products shall be marked accordingly as specified.

SCOPE

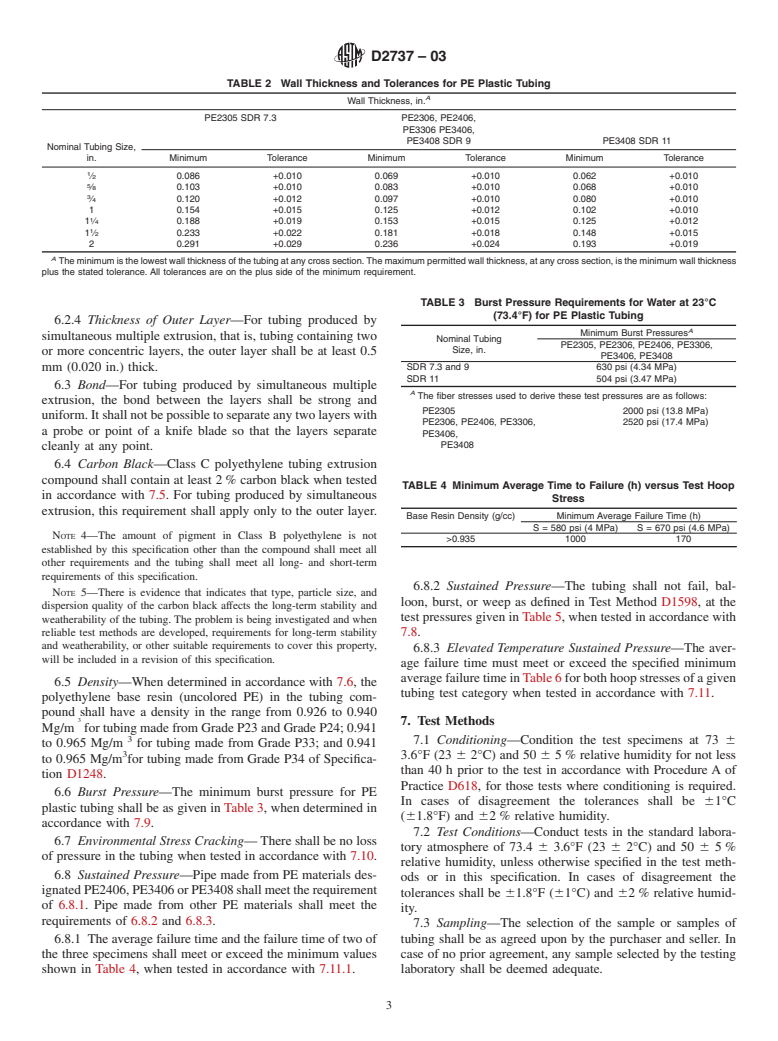

1.1 This specification covers polyethylene (PE) tubing pressure rated for water (see appendix). Included are criteria for classifying PE plastic tubing materials and PE plastic tubing, and requirements and test methods for materials, workmanship, dimensions, sustained pressure, burst pressure, and environmental stress cracking. This specification differs from the pipe specifications in their outside diameters. Methods of marking are also given.

1.2 The text of this specification references notes, footnotes, and appendixes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the specification.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

Note 1—PE plastic tubing is often used with fittings that require flaring the tubing. The technique used to make the flare is highly important to produce leak-free joints. For further information, refer to Practice D 3140.

1.4 The following safety hazards caveat pertains only to the test methods portion, Section 7, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D2737 – 03

Standard Specification for

1

Polyethylene (PE) Plastic Tubing

This standard is issued under the fixed designation D2737; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope by Extrusion Plastometer

D1248 Specification for Polyethylene Plastics Extrusion

1.1 This specification covers polyethylene (PE) tubing pres-

Materials for Wire and Cable

sure rated for water (see appendix). Included are criteria for

D1505 Test Method for Density of Plastics by the Density-

classifying PE plastic tubing materials and PE plastic tubing,

Gradient Technique

andrequirementsandtestmethodsformaterials,workmanship,

D1598 Test Method for Time-to-Failure of Plastic Pipe

dimensions, sustained pressure, burst pressure, and environ-

Under Constant Internal Pressure

mental stress cracking. This specification differs from the pipe

D1599 TestMethodforResistancetoShort-TimeHydraulic

specifications in their outside diameters. Methods of marking

Pressure of Plastic Pipe, Tubing, and Fittings

are also given.

D1600 Terminology for Abbreviated Terms Relating to

1.2 The text of this specification references notes, footnotes,

Plastics

and appendixes which provide explanatory material. These

D1603 Test Method for Carbon Black Content in Olefin

notesandfootnotes(excludingthoseintablesandfigures)shall

Plastics

not be considered as requirements of the specification.

D2122 Test Method for Determining Dimensions of Ther-

1.3 The values stated in inch-pound units are to be regarded

moplastic Pipe and Fittings

as the standard. The values given in parentheses are for

D2837 TestMethodforObtainingHydrostaticDesignBasis

information only.

forThermoplastic Pipe Materials or Pressure Design Basis

NOTE 1—PEplastictubingisoftenusedwithfittingsthatrequireflaring

for Thermoplastic Pipe Products

the tubing. The technique used to make the flare is highly important to

D3140 Practice for Flaring Polyolefin Pipe and Tubing

produce leak-free joints. For further information, refer to Practice D3140.

D3350 Specification for Polyethylene Plastics Pipe and

1.4 The following safety hazards caveat pertains only to the

Fittings Materials

test methods portion, Section 7, of this specification: This

F412 Terminology Relating to Plastic Piping Systems

standard does not purport to address all of the safety concerns,

2.2 NSF Standard:

if any, associated with its use. It is the responsibility of the user

Standard No. 14 for Plastic Piping Components and Related

of this standard to establish appropriate safety and health 3

Materials

practices and determine the applicability of regulatory limita-

tions prior to use. 3. Terminology

3.1 Definitions: Definitions are in accordance with Termi-

2. Referenced Documents

nology F412 and abbreviations are in accordance with Termi-

2

2.1 ASTM Standards:

nologyD1600,unlessotherwisespecified.Theabbreviationfor

D618 Practice for Conditioning Plastics for Testing

polyethylene plastic is PE.

D792 Test Methods for Density and Specific Gravity (Rela-

3.2 Definitions of Terms Specific to This Standard:

tive Density) of Plastics by Displacement

3.2.1 hydrostatic design stress—the estimated maximum

D1238 Test Method for Melt Flow Rates of Thermoplastics

tensile stress the material is capable of withstanding continu-

ously with a high degree of certainty that failure of the pipe

will not occur. This stress is circumferential when internal

1

This specification is under the jurisdiction ofASTM Committee F17 on Plastic

hydrostatic water pressure is applied.

Piping Systems and is the direct responsibility of Subcommittee F17.26 on Olefin

3.2.2 pressure rating (PR)—the estimated maximum water

Based Pipe.

Current edition approved Aug. 10, 2003. Published September 2003. Originally

pressure the pipe is capable of withstanding continuously with

approved in 1968. Last previous edition approved in 2001 as D2737 – 01. DOI:

ahighdegreeofcertaintythatfailureofthepipewillnotoccur.

10.1520/D2737-03.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from the National Sanitation Foundation, P.O. Box 1468,AnnArbor,

the ASTM website. MI 48106.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D2737 – 03

TABLE 1 Outside Diameters and Tole

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.