ASTM D6376-05

(Test Method)Standard Test Method for Determination of Trace Metals in Petroleum Coke by Wavelength Dispersive X-Ray Fluorescence Spectroscopy

Standard Test Method for Determination of Trace Metals in Petroleum Coke by Wavelength Dispersive X-Ray Fluorescence Spectroscopy

SCOPE

1.1 This test method covers the X-ray fluorescence spectrometric determination of total sulfur and trace metals in samples of raw or calcined petroleum coke. Elements determined using this test method are listed in Table 1.

1.2 Detection limits, sensitivity, and optimal element ranges will vary with matrices, spectrometer type, analyzing crystal, and other instrument conditions and parameters.

1.3 All analytes are determined as the element and reported as such. These include all elements listed in Table 1. This test method may be applicable to additional elements or concentration ranges if sufficient standards are available to produce proper calibration equations.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

AnAmerican National Standard

Designation:D6376–05

Standard Test Method for

Determination of Trace Metals in Petroleum Coke by

1

Wavelength Dispersive X-ray Fluorescence Spectroscopy

This standard is issued under the fixed designation D6376; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

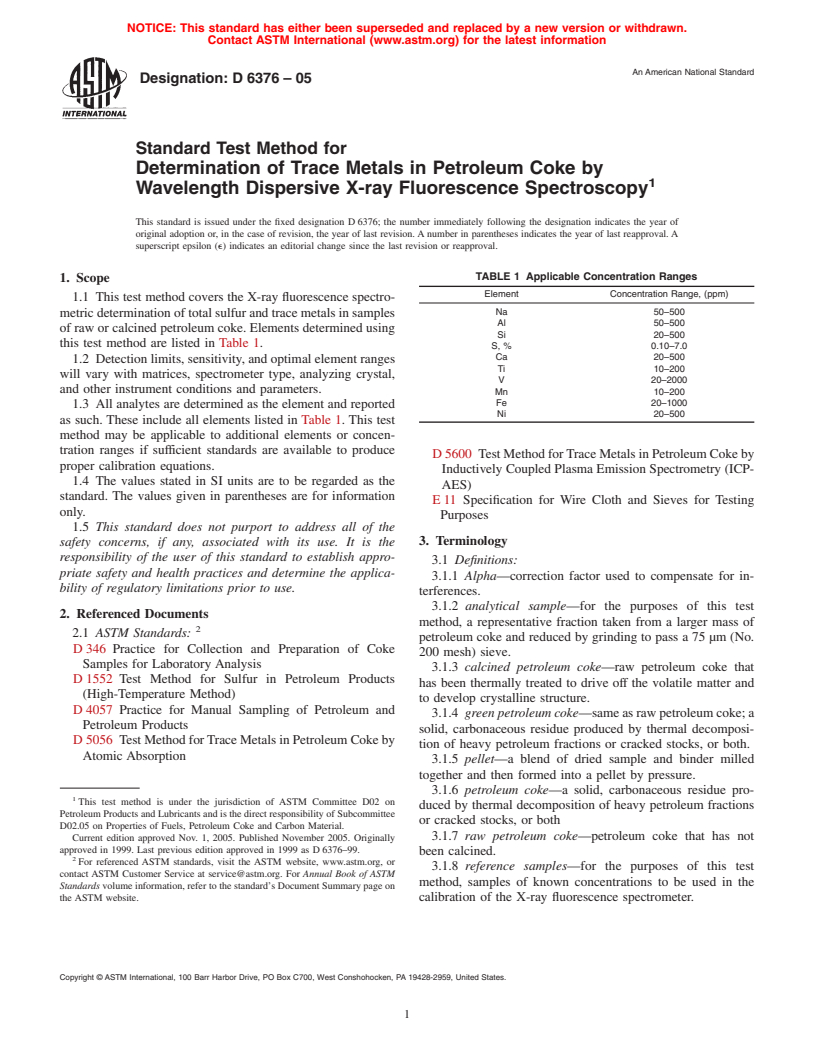

TABLE 1 Applicable Concentration Ranges

1. Scope

Element Concentration Range, (ppm)

1.1 This test method covers the X-ray fluorescence spectro-

Na 50–500

metricdeterminationoftotalsulfurandtracemetalsinsamples

Al 50–500

of raw or calcined petroleum coke. Elements determined using

Si 20–500

this test method are listed in Table 1.

S, % 0.10–7.0

Ca 20–500

1.2 Detectionlimits,sensitivity,andoptimalelementranges

Ti 10–200

will vary with matrices, spectrometer type, analyzing crystal,

V 20–2000

and other instrument conditions and parameters.

Mn 10–200

Fe 20–1000

1.3 All analytes are determined as the element and reported

Ni 20–500

as such. These include all elements listed in Table 1. This test

method may be applicable to additional elements or concen-

tration ranges if sufficient standards are available to produce

D5600 TestMethodforTraceMetalsinPetroleumCokeby

proper calibration equations.

InductivelyCoupledPlasmaEmissionSpectrometry(ICP-

1.4 The values stated in SI units are to be regarded as the

AES)

standard. The values given in parentheses are for information

E11 Specification for Wire Cloth and Sieves for Testing

only.

Purposes

1.5 This standard does not purport to address all of the

3. Terminology

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3.1 Definitions:

priate safety and health practices and determine the applica-

3.1.1 Alpha—correction factor used to compensate for in-

bility of regulatory limitations prior to use.

terferences.

3.1.2 analytical sample—for the purposes of this test

2. Referenced Documents

method, a representative fraction taken from a larger mass of

2

2.1 ASTM Standards:

petroleum coke and reduced by grinding to pass a 75 µm (No.

D346 Practice for Collection and Preparation of Coke

200 mesh) sieve.

Samples for Laboratory Analysis

3.1.3 calcined petroleum coke—raw petroleum coke that

D1552 Test Method for Sulfur in Petroleum Products

has been thermally treated to drive off the volatile matter and

(High-Temperature Method)

to develop crystalline structure.

D4057 Practice for Manual Sampling of Petroleum and

3.1.4 green petroleum coke—sameasrawpetroleumcoke;a

Petroleum Products

solid, carbonaceous residue produced by thermal decomposi-

D5056 TestMethodforTraceMetalsinPetroleumCokeby

tion of heavy petroleum fractions or cracked stocks, or both.

Atomic Absorption

3.1.5 pellet—a blend of dried sample and binder milled

together and then formed into a pellet by pressure.

3.1.6 petroleum coke—a solid, carbonaceous residue pro-

1

This test method is under the jurisdiction of ASTM Committee D02 on

duced by thermal decomposition of heavy petroleum fractions

PetroleumProductsandLubricantsandisthedirectresponsibilityofSubcommittee

or cracked stocks, or both

D02.05 on Properties of Fuels, Petroleum Coke and Carbon Material.

3.1.7 raw petroleum coke—petroleum coke that has not

Current edition approved Nov. 1, 2005. Published November 2005. Originally

approved in 1999. Last previous edition approved in 1999 as D6376–99.

been calcined.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3.1.8 reference samples—for the purposes of this test

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

method, samples of known concentrations to be used in the

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. calibration of the X-ray fluorescence spectrometer.

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D6376–05

4. Summary of Test Method of the sulfur effect on each metallic element and apply in

appropriate correction.

4.1 A representative sample of petroleum coke is dried to

constantmassat110 610°Candthencrushedtopassa75µm

7. Apparatus

(No. 200 mesh) sieve. A weighed portion of this analytical

7.1 Balance, capable of weighing 50 6 0.01 g.

sample is mixed with stearic acid, or other suitable binder, and

7.2 Hydraulic Press, capable of exerting a force of not less

thenmilledandcompressedintoasmall,smoothpelletsuitable

than 276 MPa (40 000 psi).

for analysis. The pellet is irradiated by an X-ray beam. The

7.3 Mill or Grinder, capable

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.