ASTM D5030/D5030M-21

(Test Method)Standard Test Methods for Density of In-Place Soil and Rock Materials by the Water Replacement Method in a Test Pit

Standard Test Methods for Density of In-Place Soil and Rock Materials by the Water Replacement Method in a Test Pit

SIGNIFICANCE AND USE

5.1 These test methods can be used to determine the in-place density of compacted soil and rock materials in construction of earth embankments, road fills, and structure backfill. For construction control, the test methods can be used as the basis for acceptance of material compacted to a specified density or to a percentage of a maximum density determined by a standard laboratory compaction test method such as determined from Test Methods D698 or D1557, subject to the limitations discussed in 1.4.

5.2 These test methods can be used to determine in-place density of natural soil deposits, aggregates, soil mixtures, or other similar material.

Note 1: The quality of the result produced by these test methods are dependent on the competence of the personnel performing them and the suitability of the equipment and facilities used. Agencies that meet the criteria of Practice D3740 are generally considered capable of competent and objective testing/sampling/inspection/etc. Users of these test methods are cautioned that compliance with Practice D3740 does not in itself assure reliable results. Reliable results depend on many factors; Practice D3740 provides a means of evaluating some of those factors.

SCOPE

1.1 These test methods cover the determination of the in-place density of soil and rock materials using water to fill a lined test pit to determine the volume of the test pit. The use of the word “rock” in these test methods is used to imply that the material being tested will typically only contain particles larger than 3 in. [75 mm].

1.2 These test methods are best suited for test pits with a volume between approximately 3 and 100 ft3 [0.08 and 3 m3]. In general, the materials tested would have maximum particle sizes over 5 in. [125 mm]. These test methods may be used for larger sized excavations if desirable.

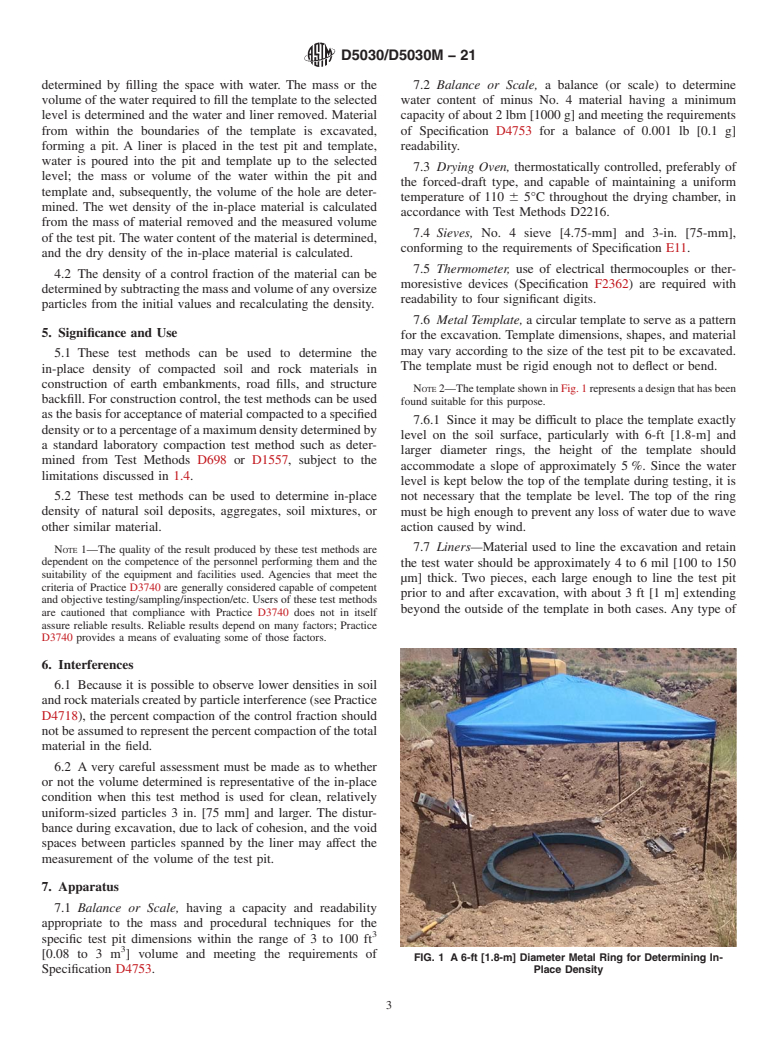

1.2.1 This procedure is usually performed using circular metal templates with inside diameters of 3 ft [0.9 m] or more. Other shapes or materials may be used providing they meet the requirements of these test methods and the guidelines given in Annex A1 for the minimum volume of the test pit.

1.2.2 Test Method D4914 may be used as an alternative method. Its use, however, is usually only practical for volume determination of test pits between approximately 1 and 6 ft3 [0.03 and 0.2 m3].

1.2.3 Test Method D1556 or Test Method D2167 is usually used to determine the volume of test holes smaller than 1 ft3 [0.03 m3].

1.3 The two procedures are described as follows:

1.3.1 Procedure A—In-Place Density and Density of Total Material (Section 12).

1.3.2 Procedure B—In-Place Density and Density of Control Fraction (Section 13).

1.4 Selection of Procedure:

1.4.1 Procedure A is used when the in-place density of the total material is to be determined. Procedure A can also be used to determine percent compaction or percent relative density when the maximum particle size present in the in-place material being tested does not exceed the maximum particle size allowed in the laboratory compaction test (Test Methods D698, D1557, D4253, D4254, and D7382). For Test Methods D698 and D1557 only, the density determined in the laboratory compaction test may be corrected for larger particle sizes in accordance with, and subject to the limitations of, Practice D4718.

1.4.2 Procedure B is used when percent compaction or percent relative density is to be determined and the in-place material contains particles larger than the maximum particle size allowed in the laboratory compaction test methods previously described or when Practice D4718 is not applicable for the laboratory compaction test method. Then, the material is considered to consist of two fractions, or portions. The material obtained from the in-place density test is physically divided into a control fraction and an oversize fraction based on a designated sieve size. The density of the control fraction is calculated and ...

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D5030/D5030M − 21

Standard Test Methods for

Density of In-Place Soil and Rock Materials by the Water

1

Replacement Method in a Test Pit

This standard is issued under the fixed designation D5030/D5030M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* size allowed in the laboratory compaction test (Test Methods

D698, D1557, D4253, D4254, and D7382). For Test Methods

1.1 These test methods cover the determination of the

D698andD1557only,thedensitydeterminedinthelaboratory

in-place density of soil and rock materials using water to fill a

compaction test may be corrected for larger particle sizes in

lined test pit to determine the volume of the test pit.The use of

accordance with, and subject to the limitations of, Practice

the word “rock” in these test methods is used to imply that the

D4718.

materialbeingtestedwilltypicallyonlycontainparticleslarger

1.4.2 Procedure B is used when percent compaction or

than 3 in. [75 mm].

percent relative density is to be determined and the in-place

1.2 These test methods are best suited for test pits with a

material contains particles larger than the maximum particle

3 3

volume between approximately 3 and 100 ft [0.08 and 3 m ].

size allowed in the laboratory compaction test methods previ-

In general, the materials tested would have maximum particle

ously described or when Practice D4718 is not applicable for

sizes over 5 in. [125 mm]. These test methods may be used for

the laboratory compaction test method. Then, the material is

larger sized excavations if desirable.

consideredtoconsistoftwofractions,orportions.Thematerial

1.2.1 This procedure is usually performed using circular

obtained from the in-place density test is physically divided

metal templates with inside diameters of 3 ft [0.9 m] or more.

into a control fraction and an oversize fraction based on a

Other shapes or materials may be used providing they meet the

designated sieve size. The density of the control fraction is

requirements of these test methods and the guidelines given in

calculated and compared with the density(ies) established by

Annex A1 for the minimum volume of the test pit.

the laboratory compaction test method(s).

1.2.2 Test Method D4914 may be used as an alternative

1.4.3 Often, the control fraction is the minus No. 4 [4.75-

method. Its use, however, is usually only practical for volume

mm] sieve size material for cohesive or nonfree-draining

3

determination of test pits between approximately 1 and 6 ft

materials and the minus 3-in. [75-mm] sieve size material for

3

[0.03 and 0.2 m ].

cohesionless, free-draining materials.While other sizes may be

1.2.3 Test Method D1556 or Test Method D2167 is usually

3 3

used for the control fraction such as ⁄8, ⁄4-in. [9.5, 19-mm],

3

used to determine the volume of test holes smaller than 1 ft

these test methods have been prepared using only the No. 4

3

[0.03 m ].

[4.75-mm] and the 3-in. [75-mm] sieve sizes for clarity.

1.3 The two procedures are described as follows:

1.5 Any soil and rock material can be tested, provided that

1.3.1 Procedure A—In-Place Density and Density of Total

the material being tested has sufficient cohesion or particle

Material (Section 12).

attractiontomaintainstablesidewallsduringexcavationofthe

1.3.2 Procedure B—In-Place Density and Density of Con-

test pit and through completion of this test. It should also be

trol Fraction (Section 13).

firmenoughnottodeformorsloughduetotheminorpressures

exerted while digging the hole and filling it with water.

1.4 Selection of Procedure:

1.4.1 Procedure A is used when the in-place density of the

1.6 These test methods are generally limited to material in

totalmaterialistobedetermined.ProcedureAcanalsobeused

an unsaturated or partially saturated condition above the

to determine percent compaction or percent relative density

ground water table and is not recommended for materials that

when the maximum particle size present in the in-place

are soft or friable (crumble easily) or in a moisture condition

material being tested does not exceed the maximum particle

such that water seeps into the excavated hole. The accuracy of

the test may be affected for materials that deform easily or that

may undergo volume change in the excavated hole from

1

These test methods are under the jurisdiction ofASTM Committee D18 on Soil

standing or walking near the hole while performing the test.

and Rock and is the direct responsibility of

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D5030/D5030M − 13a D5030/D5030M − 21

Standard Test Methods for

Density of In-Place Soil and Rock in Place Materials by the

1

Water Replacement Method in a Test Pit

This standard is issued under the fixed designation D5030/D5030M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 These test methods cover the determination of the in-place density of soil and rock materials using water to fill a lined test

pit to determine the volume of the test pit. The use of the word “rock” in these test methods is used to imply that the material being

tested will typically only contain particles larger than 3 in. [75 mm].

3 3

1.2 These test methods are best suited for test pits with a volume between approximately 3 and 100 ft [0.08 and 2.833 m ]. In

general, the materials tested would have maximum particle sizes over 5 in. [125 mm]. These test methods may be used for larger

sized excavations if desirable.

1.2.1 This procedure is usually performed using circular metal templates with inside diameters of 3 ft [0.9 m] or more. Other

shapes or materials may be used providing they meet the requirements of these test methods and the guidelines given in Annex

A1 for the minimum volume of the test pit.

1.2.2 Test Method D4914 may be used as an alternative method. Its use, however, is usually only practical for volume

3 3

determination of test pits between approximately 1 and 6 ft [0.03 and 0.170.2 m ].

3 3

1.2.3 Test Method D1556 or Test Method D2167 is usually used to determine the volume of test holes smaller than 1 ft [0.03 m ].

1.3 The two procedures are described as follows:

1.3.1 Procedure A—In-Place Density and Density of Total Material (Section 12).

1.3.2 Procedure B—In-Place Density and Density of Control Fraction (Section 13).

1.4 Selection of Procedure:

1.4.1 Procedure A is used when the in-place density of the total material is to be determined. Procedure A can also be used to

determine percent compaction or percent relative density when the maximum particle size present in the in-place material being

tested does not exceed the maximum particle size allowed in the laboratory compaction test (Test Methods D698, D1557, D4253,

D4254, D4564, and D7382). For Test Methods D698 and D1557 only, the density determined in the laboratory compaction test

may be corrected for larger particle sizes in accordance with, and subject to the limitations of, Practice D4718.

1

These test methods are under the jurisdiction of ASTM Committee D18 on Soil and Rock and is the direct responsibility of Subcommittee D18.08 on Special and

Construction Control Tests.

Current edition approved Nov. 15, 2013May 15, 2021. Published December 2013June 2021. Originally approved in 1989. Last previous edition approved in 2013 as D5030

– 13.13a. DOI: 10.1520/D5030_D5030M-13A.10.1520/D5030_D5030M-21.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D5030/D5030M − 21

1.4.2 Procedure B is used when percent compaction or percent relative density is to be determined and the in-place material

contains particles larger than the maximum particle size allowed in the laboratory compaction test methods previously described

or when Practice D4718 is not applicable for the laboratory compaction test. Then test method. Then, the material is considered

to consist of two fractions, or portions. The material obtained from the in-place density test is physically divided into a control

fraction and an oversize fraction based on a designated sieve size. The density of the control fraction is calculated and compared

with the density(ies) established by the laboratory compaction test(s). test method(s).

1.4.3 Normally,Often, the control fraction is the minus No. 4 [4.75-mm] sieve size material for cohesive or nonfree-draining

materials and the minus 3-in. [75-mm] sieve size material for cohesionless, free-draining materials. While other sizes are may be

3 3

used for the control fraction such as ⁄8, ⁄4-in. [9.5, 19-mm], these test methods have been prepared using only the No. 4 [4.75-mm]

and the 3-in. [75-mm] sieve sizes for clarity.

1.5 Any soil and rock material can be tested, provide

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.