ASTM D7544-09

(Specification)Standard Specification for Pyrolysis Liquid Biofuel

Standard Specification for Pyrolysis Liquid Biofuel

ABSTRACT

This specification details the physical and chemical requirements for pyrolysis liquid biofuels produced from biomass that are intended for use in industrial burners equipped to handle these types of fuels. The type of biofuel covered here is not intended for use in residential heaters, small commercial boilers, engines, or marine applications. It shall remain uniform in medium-term storage and shall not separate into layers due to gravity. Properly sampled test specimens shall undergo test procedures to determine their adherence to the following requirements: gross heat of combustion, water content, pyrolysis solids content, kinematic viscosity, density, sulfur content, ash content, pH, flash point, and pour point.

SCOPE

1.1 This specification covers a pyrolysis liquid biofuel produced from biomass intended for use in industrial burners equipped to handle these types of fuels. This type of biofuel is not intended for use in residential heaters, small commercial boilers, engines, or marine applications.

Note 1—For information on the significance of the physical, chemical, and performance properties identified in this specification, see Appendix X1.

1.2 This specification is for use in contracts for the purchase of pyrolysis liquid biofuel and for guidance of consumers of this type of fuel.

1.3 Nothing in this specification should preclude observance of national or local regulations, which may be more restrictive.

Note 2—The generation and dissipation of static electricity may create problems in the handling of pyrolysis liquid biofuel. For more information on the subject, see Guide D 4865.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4.1 Exception—BTU units are included for information only in 3.5.1.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7544 – 09

Standard Specification for

Pyrolysis Liquid Biofuel

This standard is issued under the fixed designation D7544; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D240 Test Method for Heat of Combustion of Liquid

Hydrocarbon Fuels by Bomb Calorimeter

1.1 This specification covers a pyrolysis liquid biofuel

D396 Specification for Fuel Oils

produced from biomass intended for use in industrial burners

D445 Test Method for Kinematic Viscosity of Transparent

equipped to handle these types of fuels. This type of biofuel is

and Opaque Liquids (and Calculation of Dynamic Viscos-

not intended for use in residential heaters, small commercial

ity)

boilers, engines, or marine applications.

D482 Test Method for Ash from Petroleum Products

NOTE 1—For information on the significance of the physical, chemical,

D4052 Test Method for Density and Relative Density of

and performance properties identified in this specification, see Appendix

Liquids by Digital Density Meter

X1.

D4057 Practice for Manual Sampling of Petroleum and

1.2 This specificationisforuseincontractsforthe purchase

Petroleum Products

of pyrolysis liquid biofuel and for guidance of consumers of

D4177 Practice for Automatic Sampling of Petroleum and

this type of fuel.

Petroleum Products

1.3 Nothinginthisspecificationshouldprecludeobservance

D4294 Test Method for Sulfur in Petroleum and Petroleum

of national or local regulations, which may be more restrictive.

Products by Energy Dispersive X-ray Fluorescence Spec-

trometry

NOTE 2—The generation and dissipation of static electricity may create

problemsinthehandlingofpyrolysisliquidbiofuel.Formoreinformation D4865 Guide for Generation and Dissipation of Static

on the subject, see Guide D4865.

Electricity in Petroleum Fuel Systems

D5854 PracticeforMixingandHandlingofLiquidSamples

1.4 The values stated in SI units are to be regarded as

of Petroleum and Petroleum Products

standard. No other units of measurement are included in this

D6469 Guide for Microbial Contamination in Fuels and

standard.

Fuel Systems

1.4.1 Exception—BTU units are included for information

E70 Test Method for pH of Aqueous Solutions With the

only in 3.5.1.

Glass Electrode

1.5 This standard does not purport to address all of the

E203 Test Method forWater UsingVolumetric Karl Fischer

safety concerns, if any, associated with its use. It is the

Titration

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

3. Terminology

bility of regulatory limitations prior to use.

3.1 Definitions of Terms Specific to This Standard:

2. Referenced Documents 3.2 bulk fuel, n—fuel in the storage facility in quantities

over 190 L.

2.1 ASTM Standards:

3.3 char, n—fine carbonaceous powder that is separated

D93 Test Methods for Flash Point by Pensky-Martens

from the vapors of biomass during pyrolysis.

Closed Cup Tester

3.3.1 Discussion—Pyrolysis liquid biofuel contains uni-

D97 Test Method for Pour Point of Petroleum Products

formly suspended char.

3.4 fuel degradation products, n—those materials that are

This specification is under the jurisdiction of ASTM Committee D02 on

formed in fuel during extended storage or exposure to high

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

temperatures.

D02.E0 on Burner, Diesel, Non-Aviation Gas Turbine, and Marine Fuels.

3.4.1 Discussion—During storage, reactive organic com-

Current edition approved June 15, 2009. PublishedAugust 2009. DOI: 10.1520/

D7544-09.

pounds in pyrolysis liquid can act together to form larger

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

molecules (fuel degradation products), which can become

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

insoluble or increase the fuel viscosity, or both.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D7544 – 09

TABLE 1 Detailed Requirements for Pyrolysis Liquid Biofuels

Property Test Method Specification Units

Gross Heat of Combustion D240 15 min MJ/kg

Water Content E203 30 max mass %

Pyrolysis Solids Content Annex A1 2.5 max mass %

A 2

Kinematic Viscosity at 40°C D445 125 max mm /s

Density at 20°C D4052 1.1–1.3 kg/dm

Sulfur Content D4294 0.05 max mass %

Ash Content D482 0.25 max mass %

pH E70 Report .

Flash Point D93, Procedure B 45 min °C

Pour Point D97 –9 max °C

A

Without filtering.

3.5 industrial burner, n—device which produces heat for 5. Detailed Requirements

industrial use through the combustion of liquid fuels.

5.1 The pyrolysis liquid biofuel specified shall conform to

3.5.1 Discussion—Industrial burners are typically designed

the detailed requirements shown in Table 1.

for one of two applications: (1) industrial furnaces—integral

5.2 The properties selected for limitation are those that are

components of manufacturing processes that provide direct

believed to be of the greatest significance in obtaining accept-

heating; for example, in aggregate, cement, lime, or phosphate

able performance of the burner.

kilns; coke ovens; or blast, smelting, melting, refining, or

drying ovens and (2) industrial boilers—large indirect heating

6. Sampling

units which transfer thermal energy to water or other fluids or

gases for use in heating in industrial settings, power generation

6.1 Review all intended test methods prior to sampling to

andinmanufacturingprocesses.Theseboilerscanbeclassified

understand the importance and effects of sampling technique,

as utility/large industrial boilers with a heat input greater than

proper containers, and special handling required for each test

105 GJ/h (100 3 106 BTU/h) or small industrial boilers with

method. See Table 2.

a heat input of between 10.5 to 105 GJ/h (10 to 100 3

6.2 As indicated in 4.1, during medium-term storage, py-

106 BTU/h).

rolysis liquid biofuel shall remain uniform and not separate

3.6 long-term storage—storage of fuel for longer than 3

into layers. Note, however, that separation may occur during

months after it is received by the user.

long-term storage. Therefore, samples should be well mixed

3.7 medium-term storage—storage of fuel for up to 3

when transferring from the primary sampling process or

months after it is received by the user.

container, or both, to another container or analytical apparatus,

3.7.1 Discussion—Itisrecommendedthatfuelbeconsumed

or both. Sampling from an active circulation loop or a well

within 6 months of receipt. mixedoragitatedtankispreferred.RefertoPracticeD5854for

more guidance on mixing and handling samples.

3.8 pyrolysis, n—chemical decomposition of organic mate-

rials by heating in the absence of oxygen.

6.3 Sample Size—A minimum of 1 L is recommended.

3.9 pyrolysis liquid biofuel, n—liquid product from the

pyrolysis of biomass. 7. Test Methods

3.9.1 Discussion—Pyrolysisliquidbiofueliscomprisedofa

7.1 The requirements enumerated in this specification shall

complex mixture of the decomposition products of ligno-

be determined in accordance with the following test methods:

cellulosic biomass including highly oxygenated organic com-

7.1.1 Gross Heat of Combustion—Test Method D240.

pounds. It is produced from the pyrolysis of biomass, followed

7.1.2 Water Content—Test Method E203.

by the rapid condensation of its vapors.

7.1.3 Pyrolysis Solids Content—See Annex A1.

3.10 pyrolysissolids,n—solidparticlescontainedwithinthe

pyrolysis liquid biofuel. 7.1.4 Kinematic Viscosity—Test Method D445.

3.10.1 Discussion—Pyrolysissolidsiscomprisedofashand

7.1.5 Density—Test Method D4052.

char.

7.1.6 Sulfur—Test Method D4294.

7.1.7 Ash Content—Test Method D482.

4. General Requirements

7.1.8 pH—Test Method E70.

4.1 The pyrolysis liquid biofuel specified in this specifica-

7.1.9 Flash Point—Test Method D93.

tion shall remain uniform in medium-term storage and not

7.1.10 Pour Point—Test Method D97.

separate by gravity into layers.

NOTE 3—Long-term storage or equipment down time can necessitate 8. Keywords

circulation of pyrolysis liquid biofuel in-tank to prevent such separation.

8.1 pyrolysis liquid biofuel; bio-oil; pyrolysis oil; pyoil;

The buyer and seller should agree on any requirements for long-term

py-oil; bio-crude-oil; bio-fuel-oil; wood liquids; burner fuel;

storage. If minor separation occurs during medium-term storage, mild

agitation or product circulation should reverse such separation. renewable energy; alternative energy; fuel oils; furnace oils

D7544 – 09

TABLE 2 Typical Sampling Procedures for Containers

Type of Container Procedure

Storage tanks that are well-mixed by circulation or agitation Automatic or Manual Pipeline Sampling

Tank cars, tank trucks, or ship tanks Dipper Sampling or All-Level Sampling

ANNEX

(Mandatory Information)

A1. TEST METHOD FOR PYROLYSIS SOLIDS CONTENT IN PYROLYSIS LIQUIDS BY FILTRATION OF SOLIDS IN

METHANOL

A1.1 Scope A1.4.6 Filter Holders, borosilicate glass.

A1.4.7 Filter Membrane,binderfreeglassmicrofiber,1µm.

A1.1.1 This test method describes a filtration procedure for

A1.4.8 Weighing Dish, aluminum.

determining the pyrolysis solids content of pyrolysis liquid. It

A1.4.9 Balance,capableofweighingtothenearest0.0001 g

is intended for the analysis of pyrolysis liquid with all ranges

(0.1 mg) with a range of 300 g.

of pyrolysis solids concentrations.

A1.4.10 Vacuum.

A1.1.2 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this

standard.

A1.5 Reagents and Solvents

A1.1.3 This standard does not purport to address all of the

A1.5.1 Purity of Reagents

safety concerns, if any, associated with its use. It is the

Reagent grade chemicals shall be used in all tests. Unless

responsibility of the user of this standard to establish appro-

otherwise indicated, it is intended that all reagents shall

priate safety and health practices and determine the applica-

conform to the specifications of the Committee on Analytical

bility of regulatory limitations prior to use. Material Safety

Reagents of the American Chemical Society, where such

Data Sheets are available for reagents and materials. Review

specifications are available. Other grades may be used, pro-

them for hazards prior to usage.

vided it is first ascertained that the reagent is of sufficiently

A1.1.4 For Referenced Documents, see Section 2.

high purity to permit its use without lessening the accuracy of

A1.1.5 For Terminology, see Section 3.

the determination. If an industrial grade reagent is used, it shall

be filtered using 0.45 µm filter paper prior to use.

A1.2 Summary of Test Method

A1.5.2 Ethanol, reagent grade (Warning—Flammable.

A1.2.1 Apyrolysis liquid sample is dissolved in a methanol

Toxic. Can be harmful or fatal if ingested or inhaled. Avoid

and dichloromethane solution (1:1), which is then filtered

skin contact.)

through a vacuum filter system. After filtering, the filtrand is

A1.5.3 Methanol (MeOH), reagent grade (Warning—

washed with the solvent until the filtrate is clear. The filter is

Flammable. Toxic. Can be harmful or fatal if ingested or

removed, dried and weighed. The pyrolysis solids content is

inhaled. Avoid skin contact.)

calculated based on the original pyrolysis liquid sample.

A1.5.4 Dichloromethane (DCM), reagent grade

(Warning—Flammable. Toxic. Can be harmful or fatal if

A1.3 Significance and Use

ingested or inhaled. Avoid skin contact.)

A1.3.1 Pyrolysis liquid can be produced to various char

A1.5.5 Filter Paper, 1 µm pore size, binder free glass

concentrations. Increasing pyrolysis solids content can affect

microfiber.

the pyrolysis liquid biofuel handling, atomization, and storage

stability in a negative manner.

A1.6 Sampling

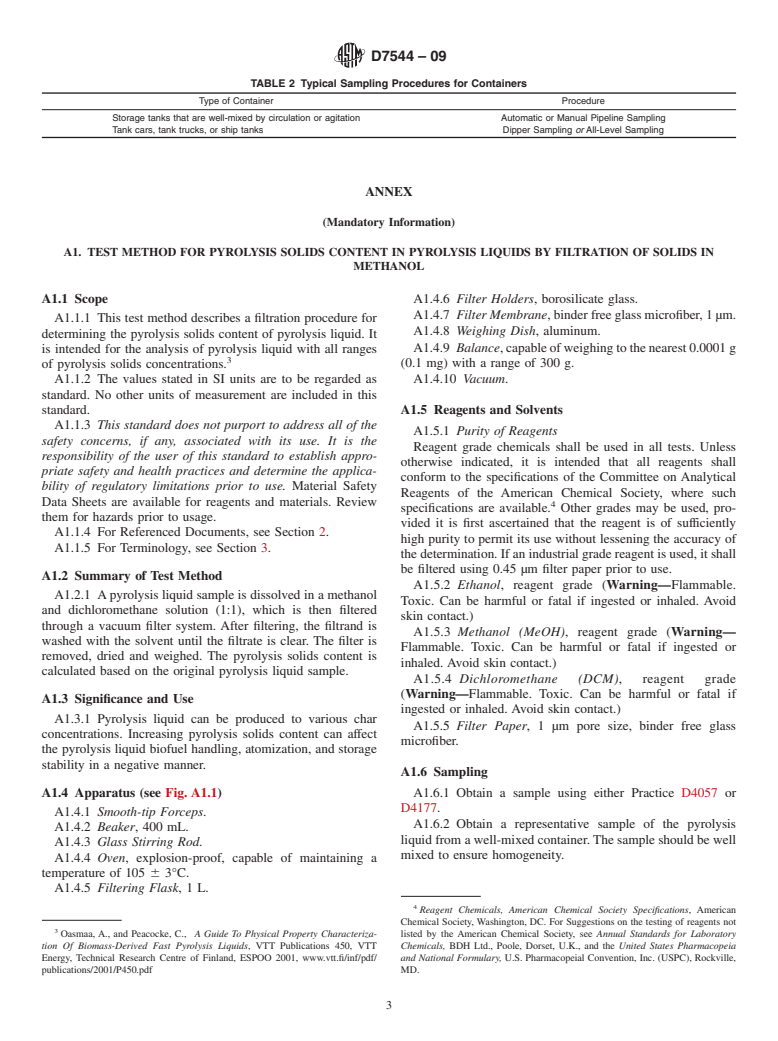

A1.4 Apparatus (see Fig. A1.1) A1.6.1 Obtain a sample using either Practice D4057 or

D4177.

A1.4.1 Smooth-tip Forceps.

A1.6.2 Obtain a representative sample of the pyrolysis

A1.4.2 Beaker, 400 mL.

liquid from a well-mixed container.The sample should be well

A1.4.3 Glass Stirring Rod.

mixed to ensure homogeneity.

A1.4.4 Oven, explosion-proof, capable of maintaining a

temperature of 105 6 3°C.

A1.4.5 Filtering Flask,1L.

Reagent Chemicals, American Chemical Society Specifications, American

Chemical Society, Washington, DC. For Suggestions on the testing of reagents not

Oasmaa, A., and Peacocke, C., A Guide To Physical Property Characteriza- listed by the American Chemical Society, see Annual Standards for Laboratory

tion Of Biomass-Derived Fast Pyrolysis Liquids, VTT Publications 450, VTT Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

Energy, Technical Research Centre of Finland, ESPOO 2001, www.vtt.fi/inf/pdf/ and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

publications/2001/P450.pdf MD.

D7544 – 09

FIG. A1.1 Paper Filtration Apparatus

D7544 – 09

A1.7 Procedure A1.8 Calculation

A1.8.1 Calculate the pyrolysis solids content of the pyroly-

A1.7.1 Dry a clean filter membrane for 15 min in a

sis liquid sample in accordance with Eq A1.1.

desiccator, place in a labeled aluminum weighing dish, and

weigh to the nearest 0.1 mg. PS

pyrolysis solids ~wt %!5 3 100% (A1.1)

PL

A1.7.2 Place a 400 mL beaker on the balance, and tare it.

A1.7.3 Vigorouslyshakethesamplebyhandforaminimum

of 15 s.

pyrolysis solids = pyrolysis solids content, wt%,

A1.7.4 Using a disposable pipette, weigh approximately 15 PS = pyrolysis solids retained on 1 µm filter

g of pyrolysis liquid sample into the beaker. Record the weight paper (g), and

PL = pyrolysis liquid sample taken for analy-

to the nearest 0.1 mg.

sis (g).

A1.7.5 Add approximately 100 to 200 mL MeOH-DCM

solution (1:1) into the beaker and stir the mixture vigorously to

A1.9 Report

dissolve the pyrolysis liquid in the solvent.

A1.9.1 Report the pyrolysis oil solids content to two sig-

A1.7.6 Mountthefilteronadryholderandapplyavacuum.

nificant figures.

Mount and securely clamp the filter funnel to the filter holder.

A1.10 Precision and Bias

A1.7.7 Use methanol to wash the filter paper to properly

A1.10.1 This interim precision statement represents repli-

seal the latter to the bottom of the funnel.

cateanalysesperformedintwolaboratoriesovertensuccessive

A1.7.8 Filter the solution through the vacuum filter system

days by the same analyst on the same day on the sam

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.