ASTM D7216-05

(Test Method)Standard Test Method for Determining Automotive Engine Oil Compatibility with Typical Seal Elastomers

Standard Test Method for Determining Automotive Engine Oil Compatibility with Typical Seal Elastomers

SCOPE

1.1 This test method covers quantitative procedures for the evaluation of the compatibility of automotive engine oils with four reference elastomers typical of those used in the sealing materials in contact with these oils. Compatibility is evaluated by determining the changes in volume, Durometer A hardness and tensile properties when the elastomer specimens are immersed in the oil for a specified time and temperature.

1.2 Effective sealing action requires that the physical properties of elastomers used for any seal have a high level of resistance to the liquid or oil in which they are immersed. When such a high level of resistance exists, the elastomer is said to be compatible with the liquid or oil.Note 1

The user of this test method should be proficient in the use of Test Methods D 412 (tensile properties), D 471 (effect of rubber immersion in liquids), D 2240 (Durometer hardness), and D 5662 (gear oil compatibility with typical oil seal elastomers), all of which are involved in the execution of the operations of this test method.

1.3 This test method provides a preliminary or first order evaluation of oil/elastomer compatibility only. Because seals may be subjected to static or dynamic loads, or both, and they may operate over a range of conditions, a complete evaluation of the potential sealing performance of any elastomer-oil combination in any service condition usually requires tests additional to those described in this test method.

1.4 The four reference elastomer formulations specified in this test method were chosen to be representative of those used in heavy-duty diesel engines. The procedures described in this test method can, however, also be used to evaluate the compatibility of automotive engine oils with different elastomer types/formulations or different test durations and temperatures to those employed in this test method.Note 2

In such cases, the precision and bias statement in Section does not apply. In addition to agreeing acceptable limits of precision, where relevant, the user and supplier should also agree: (1) test temperatures and immersion times to be used; (2) the formulations and typical properties of the elastomers; and (3) the sourcing and quality control of the elastomer sheets.Note 3

The TMC may also issue Information Letters on this matter.

1.5 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.7 This test method is arranged as follows:SectionScopeReferenced DocumentsTerminologySummary of Test MethodSignificance and UseApparatusReference MaterialsProcedureCalculationsTMC 1006 Reference Oil TestingReportPrecision and BiasKeywordsFormulations and Physical Properties for the Reference Elastomers

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D7216–05

Standard Test Method for

Determining Automotive Engine Oil Compatibility with

Typical Seal Elastomers

This standard is issued under the fixed designation D 7216; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Any properly equipped laboratory, without outside assistance, can use the test method described in

this standard. However, the ASTM Test Monitoring Center (TMC) provides a reference oil (TMC

1006) and an assessment of the test results obtained with this oil and the reference elastomers. By

these means, the laboratory will know whether their use of the test method gives results statistically

similar to those obtained by other laboratories.

The TMC also use the reference oil results on different batches of elastomers from different

laboratories to update continually the total and within-laboratory standard deviation estimates. Some

specifications, for example, Specification D 4485, use the updated TMC standard deviation estimates,

pertainingatthetimetestoilsareevaluated,toadjustspecificationlimitsfortheeffectsoftheindustry

test variability.

Various agencies require that a laboratory utilize the TMC services in seeking qualification of oils

against specifications. For example, the U.S. Army imposes such a requirement in connection with

several Army engine lubricating oil specifications.

Accordingly, this test method is written for use by laboratories that utilize the TMC services.

Laboratories that choose not to use those services may simply ignore those portions of the test method

that refer to the TMC.

This test method may be modified by means of information letters issued by the TMC. In addition,

the TMC may issue supplementary memoranda related to this test method.

1. Scope When such a high level of resistance exists, the elastomer is

said to be compatible with the liquid or oil.

1.1 This test method covers quantitative procedures for the

evaluation of the compatibility of automotive engine oils with

NOTE 1—The user of this test method should be proficient in the use of

four reference elastomers typical of those used in the sealing Test Methods D 412 (tensile properties), D 471 (effect of rubber immer-

sion in liquids), D 2240 (Durometer hardness), and D 5662 (gear oil

materials in contact with these oils. Compatibility is evaluated

compatibilitywithtypicaloilsealelastomers),allofwhichareinvolvedin

by determining the changes in volume, Durometer A hardness

the execution of the operations of this test method.

and tensile properties when the elastomer specimens are

1.3 This test method provides a preliminary or first order

immersed in the oil for a specified time and temperature.

evaluation of oil/elastomer compatibility only. Because seals

1.2 Effective sealing action requires that the physical prop-

erties of elastomers used for any seal have a high level of may be subjected to static or dynamic loads, or both, and they

may operate over a range of conditions, a complete evaluation

resistance to the liquid or oil in which they are immersed.

of the potential sealing performance of any elastomer-oil

combination in any service condition usually requires tests

additional to those described in this test method.

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

1.4 The four reference elastomer formulations specified in

D02.B0 on Automotive Lubricants.

this test method were chosen to be representative of those used

Current edition approved Nov. 1, 2005. Published January 2006.

2 in heavy-duty diesel engines. The procedures described in this

ASTM Test Monitoring Center, 6555 Penn Avenue, Pittsburgh, PA 15206.

www.astmtmc.cmu.edu test method can, however, also be used to evaluate the

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D7216–05

compatibility of automotive engine oils with different elas- 3.1.1 automotive, adj—descriptive of equipment associated

tomer types/formulations or different test durations and tem- with self-propelled machinery, usually vehicles driven by

peratures to those employed in this test method. internal combustion engines. D4175

3.1.2 candidate oil, n—an oil that is intended to have the

NOTE 2—In such cases, the precision and bias statement in Section 12

performance characteristics necessary to satisfy a specification

does not apply. In addition to agreeing acceptable limits of precision,

and is to be tested against that specification. D4175

where relevant, the user and supplier should also agree: (1) test tempera-

tures and immersion times to be used; (2) the formulations and typical

3.1.3 elastomer, n—a natural or synthetic polymer having

propertiesoftheelastomers;and (3)thesourcingandqualitycontrolofthe

the rubber-like property of substantially recovering its size and

elastomer sheets.

shape after removal of a deforming force. D4175

NOTE 3—The TMC may also issue Information Letters on this matter.

3.1.4 engine oil, n—a liquid that reduces friction or wear, or

1.5 The values stated in SI units are to be regarded as the

both,betweenthemovingpartswithinanengine;removesheat

standard. The values given in parentheses are for information

particularly from the underside of pistons; and serves as

only.

combustion gas sealant for the piston rings.

1.6 This standard does not purport to address all of the

3.1.4.1 Discussion—It may contain additives to enhance

safety concerns, if any, associated with its use. It is the

certain properties. Inhibition of engine rusting, deposit forma-

responsibility of the user of this standard to establish appro-

tion, valve train wear, oil oxidation and foaming are examples.

priate safety and health practices and determine the applica-

D4175

bility of regulatory limitations prior to use.

3.1.5 formulation, n—the specific chemical composition

1.7 This test method is arranged as follows:

used in manufacturing a seal elastomer or a reference oil.

Section

Scope 1 D5662

Referenced Documents 2

3.1.6 hardness, n—of an elastomer, the resistance to defor-

Terminology 3

mation or indentation.

Summary of Test Method 4

Significance and Use 5

3.1.6.1 Discussion—In this test method the hardness of an

Apparatus 6

elastomer is measured with a Shore Durometer A (see Test

Reference Materials 7

Procedure 8

Method D 2240). D4175

Calculations 9

3.1.7 heavy-duty engine, n—in internal; combustion engine

TMC 1006 Reference Oil Testing 10

Report 11 types,onethatisdesignedtoallowoperationcontinuouslyator

Precision and Bias 12

close to its peak output.

Keywords 13

3.1.7.1 Discussion—This type of engine is typically in-

Formulations and Physical Properties for the Reference Elastomers Annex A1

stalled in large trucks and busses as well as farm, industrial,

2. Referenced Documents

and construction equipment. D4485

2.1 ASTM Standards:

3.1.8 non-reference oil, n—any oil other than a reference

D 297 Test Methods for Rubber Products—Chemical

oil,suchasaresearchformulation,commercialoilorcandidate

Analysis

oil. D4175

D 412 Test Methods for Vulcanized Rubber and Thermo-

3.1.9 reference oil, n—an oil of known performance char-

plastic Elastomers—Tension

acteristics, used as a basis for comparison.

D 471 Test Method for Rubber Property—Effect of Liquids

3.1.9.1 Discussion—Reference oils are used to calibrate

D 1193 Specification for Reagent Water

testing facilities, to compare the performance of other oils, or

D 1566 Terminology Relating to Rubber

to evaluate other materials (such as seals) that interact with

D 2240 Test Method for Rubber Property—Durometer

oils. D4175

Hardness

3.1.10 tensile strength, n—the maximum tensile stress ap-

D 4175 Terminology Relating to Petroleum, Petroleum

plied in stretching a specimen to rupture. D1566

Products, and Lubricants

3.1.11 test oil, n—any oil subjected to evaluation in an

D 4485 Specification for Performance of Engine Oils

established procedure. D4175

D 5662 Test Method for Determining Automotive Gear Oil

3.1.12 ultimate elongation, n—the elongation at which rup-

Compatability with Typical Oil Seal Elastomers

E29 Practice for Using Significant Digits in Test Data to ture occurs in the application of continued tensile stress.

D1566

Determine Conformance with Specifications

E 178 Practice for Dealing With Outlying Observations

3.2 Definitions of Terms Specific to This Standard:

3.2.1 compatibility, n—of an engine oil/elastomer combina-

3. Terminology

tion, a characteristic that signifies a complete or high-level of

3.1 Definitions:

resistance of the elastomer to deleterious effects imparted by

contact with, or immersion in, the oil.

3.2.1.1 Discussion—The phrase “high compatibility” indi-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

cates that after contact or immersion, the elastomer properties

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

are maintained at or near their initial level. The terms “lack of

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. compatibility” and “low compatibility” indicate that after

D7216–05

contact or immersion, the elastomer properties are adversely fore, incorporate effects of variations in the properties of the

affected to an extent that could be detrimental to sealing reference elastomers on the test variability.

performance.

5.4 This test method is suitable for specification compliance

3.2.2 immersion test, n—an operation to evaluate compat- testing, quality control, referee testing, and research and

ibility by determining the effect of a liquid on elastomer test

development.

specimens submerged in the liquid for a specified time and at

5.5 The reference elastomers, reference oil and the physical

a specified temperature.

properties involved in this test method address the specific

3.2.2.1 Discussion—The effect of the liquid is evaluated by requirements of engine oils. Although other tests exist for

the difference in (typical) elastomer physical properties pre-

compatibility of elastomers with liquids, these are considered

and post-immersion. too generalized for engine oils.

3.2.3 reference elastomer, n—an elastomer compound pre-

pared using a specified formulation; its immersion test prop-

6. Apparatus

erties with selected oils have been well established by the use

6.1 The testing equipment as specified in Test Methods

of recognized and accepted testing and documentation proce-

D 412, D 471, D 2240, and D 5662 is required for the use of

dures.

this test method.

6.2 Balance—Use any commercially available balance ca-

4. Summary of Test Method

pableofweighingtothenearest0.1mg.Equipthebalancewith

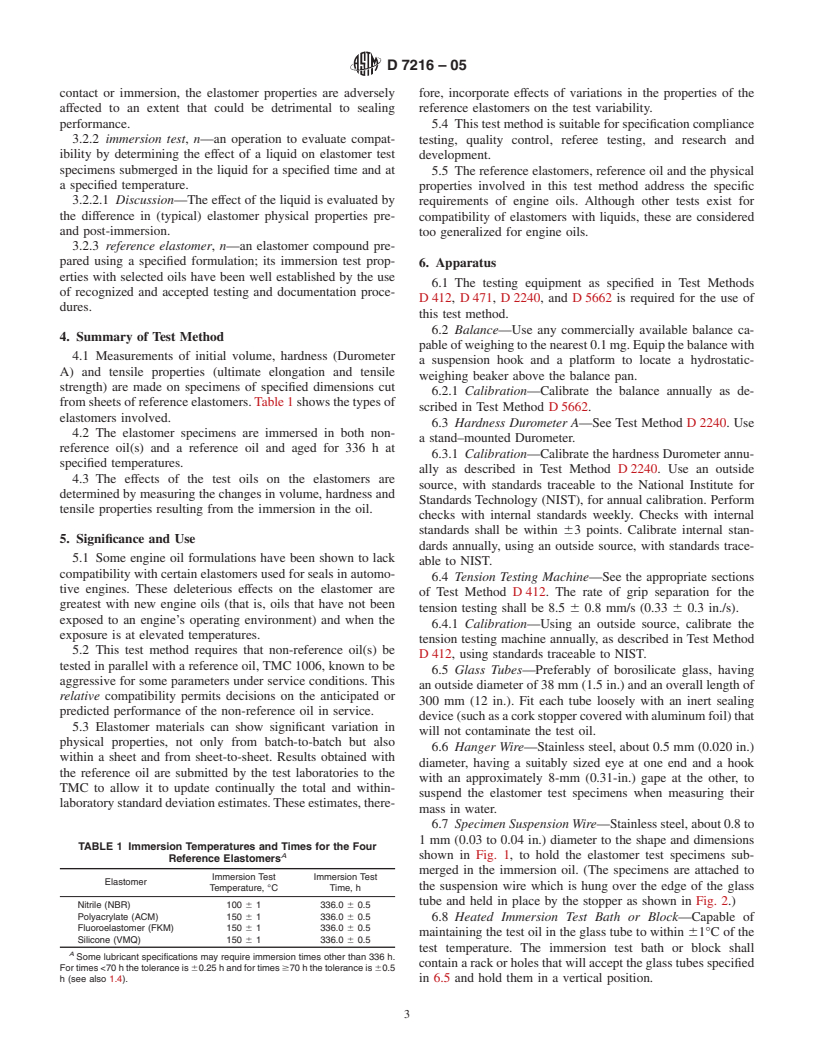

4.1 Measurements of initial volume, hardness (Durometer

a suspension hook and a platform to locate a hydrostatic-

A) and tensile properties (ultimate elongation and tensile

weighing beaker above the balance pan.

strength) are made on specimens of specified dimensions cut

6.2.1 Calibration—Calibrate the balance annually as de-

fromsheetsofreferenceelastomers.Table1showsthetypesof

scribed in Test Method D 5662.

elastomers involved.

6.3 Hardness Durometer A—See Test Method D 2240. Use

4.2 The elastomer specimens are immersed in both non-

a stand–mounted Durometer.

reference oil(s) and a reference oil and aged for 336 h at

6.3.1 Calibration—Calibrate the hardness Durometer annu-

specified temperatures.

ally as described in Test Method D 2240. Use an outside

4.3 The effects of the test oils on the elastomers are

source, with standards traceable to the National Institute for

determined by measuring the changes in volume, hardness and

Standards Technology (NIST), for annual calibration. Perform

tensile properties resulting from the immersion in the oil.

checks with internal standards weekly. Checks with internal

standards shall be within 63 points. Calibrate internal stan-

5. Significance and Use

dards annually, using an outside source, with standards trace-

5.1 Some engine oil formulations have been shown to lack

able to NIST.

compatibility with certain elastomers used for seals in automo-

6.4 Tension Testing Machine—See the appropriate sections

tive engines. These deleterious effects on the elastomer are

of Test Method D 412. The rate of grip separation for the

greatest with new engine oils (that is, oils that have not been

tension testing shall be 8.5 6 0.8 mm/s (0.33 6 0.3 in./s).

exposed to an engine’s operating environment) and when the

6.4.1 Calibration—Using an outside source, calibrate the

exposure is at elevated temperatures.

tension testing machine annually, as described in Test Method

5.2 This test method requires that non-reference oil(s) be

D 412, using standards traceable to NIST.

tested in parallel with a reference oil, TMC 1006, known to be

6.5 Glass Tubes—Preferably of borosilicate glass, having

aggressive for some parameters under service conditions. This

an outside diameter of 38 mm (1.5 in.) and an overall length of

relative compatibility permits decisions on the anticipated or

300 mm (12 in.). Fit each tube loosely with an inert sealing

predicted performance of the non-reference oil in service.

device(suchasacorkstoppercoveredwithaluminumfoil)that

5.3 Elastomer materials can show significant variation in

will not contaminate the test oil.

physical properties, not only from batch-to-batch but also

6.6 Hanger Wire—Stainless steel, about 0.5 mm (0.020 in.)

within a sheet and from sheet-to-sheet. Results obtained with

diameter, having a suitably sized eye at one end and a hook

the reference oil are submitted by the test laboratories to the

with an approximately 8-mm (0.31-in.) gape at the other, to

TMC to allow it to update continually the total and within-

suspend the elastomer test specimens when measuring their

laboratorystandarddeviationestimates.Theseestimates,there-

mass in water.

6.7 Specimen Suspension Wire—Stainlesssteel,about0.8to

1 mm (0.03 to 0.04 in.) diameter to the shape and dimensions

TABLE 1 Immersion Temperatures and Times for the Four

A

shown in Fig. 1, to hold the elastomer test specimens sub-

Reference Elastomers

merged in the immersion oil. (The specimens are attached to

Immersion Test Immersion Test

Elastomer

the suspension wire which is hung over the edge of the glass

Temperature, °C Time, h

tube and held in place by the stopper as shown in Fig. 2.)

Nitrile (NBR) 100 6 1 336.0 6 0.5

Polyacrylate (ACM) 150 6 1 336.0 6 0.5

6.8 Heated Immersion Test Bath or Block—Capabl

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.