ASTM E1289-08

(Specification)Standard Specification for Reference Specimen for Sound Transmission Loss

Standard Specification for Reference Specimen for Sound Transmission Loss

ABSTRACT

This specification describes the construction and installation of standard reference specimens for quality control of laboratory sound transmission loss measurements. The reference specimen is composed of framed steel panels. The required materials for fabrication and installation are as follows: galvanized sheets, frame, and panels. Four kinds of installation may be done: Installation A using a single layer reference specimen, Installation B using double layer reference specimen with a common plate, Installation C using double layer reference specimen with separate plates-empty cavity, and Installation D using double layer reference specimen with separate plates and added layer of sound-absorbing material in the cavity.

SCOPE

1.1 This specification describes the construction and installation of standard reference specimens for quality control of laboratory sound transmission loss measurements using Test Method E 90.

1.2 Laboratories may choose to construct and test all of the reference specimens described here or only a subset. Specific specimens may be required by a test method or an accrediting agency.

1.3 &si-value;

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E1289 −08

StandardSpecification for

1

Reference Specimen for Sound Transmission Loss

This standard is issued under the fixed designation E1289; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

1. Scope

Blind rivets—diameter, 3.2 mm ( ⁄8 in. ).

Duct tape, 50 mm (2 in.) wide.

1.1 This specification describes the construction and instal-

Drywall screws, Type W—length, 32 mm (1.25 in.).

lation of standard reference specimens for quality control of Bolts #10–24 —25 mm (1 in.) long with appropriate nuts and washers.

Fasteners, to hold wood frame to the perimeter of the test opening.

laboratory sound transmission loss measurements using Test

Non-hardening, caulking,

Method E90.

Nominal 2 by 4 in. wood framing, approximately 40 by 90 mm.

NOTE 1—The quantity and length of each component needed depends

1.2 Laboratories may choose to construct and test all of the

on the size of the laboratory test opening.

reference specimens described here or only a subset. Specific

NOTE 1—To simplify cleaning, the wood framing used to support the

specimens may be required by a test method or an accrediting

steel panels may be painted.

agency.

4.1.2 The weight of each component of the reference

1.3 The values stated in SI units are to be regarded as

specimen and the assembled specimen shall be measured and

standard. The values given in parentheses are for information

kept on record. In addition, the thickness of each of the steel

only.

panels shall be measured in six locations. (See Appendix X1.)

2. Referenced Documents

4.2 Assembly:

2

2.1 ASTM Standards: 4.2.1 Galvanized Sheets—The length of each galvanized

C634 Terminology Relating to Building and Environmental sheet shall be a few millimetres less than the height of the

Acoustics laboratory test opening. The total width of all the sheets shall

E90 Test Method for Laboratory Measurement of Airborne be a few millimetres less than the width of the laboratory test

Sound Transmission Loss of Building Partitions and opening. This may require that one or more sheets be cut

Elements lengthwise.The intent is that, when installed, the panels fill the

test opening completely.

3. Terminology

4.2.2 Frame—Cut steel right angles to size to form a frame

3.1 Definitions—For definitions of terms used in this for each sheet; the frame shall have the same outside dimen-

specification, see Terminology C634. sions as the sheets. Notch and weld the steel angles to form the

four corners of the frame as shown in Fig. 1. Alternatively,

4. Construction of Reference Specimen

miter the angles and weld similarly. Smooth corners after

4.1 General: welding.

4.1.1 The reference specimen is composed of framed steel 4.2.3 Panels—Construct a panel by riveting steel sheets to

panels. The required materials for fabrication and installation the frames as follows:0

are as follows: 4.2.3.1 Drill holes at 100 mm (4 in.) on-center around the

perimeterofthesheetsfortheinstallationoftheblindrivets.To

Galvanized steel sheets—width, 1220 mm (4 ft); nominal thickness, 0.63 mm

2

(24 gauge). The weight of the sheets shall be 5.1 ± 0.7 kg/m (1.05 ± 0.15 lb/

ensure proper alignment of the sheets with the frame, it is

2

ft ).

recommended to drill a few holes and then install rivets to hold

1

Steel right angles with 25-mm (1-in.) flanges—metal thickness, 3.2 mm ( ⁄8 in.).

the sheet in place. Once this is done, the remaining holes may

be drilled and the rivets installed. Position these holes to avoid

1

This specification is under the jurisdiction of ASTM Committee E33 on conflict with the clearance holes described in 4.2.3.2.

Building and Environmental Acoustics and is the direct responsibility of Subcom-

5

4.2.3.2 Drill 4 mm ( ⁄32 inch) diameter holes through the

mittee E33.03 on Sound Transmission.

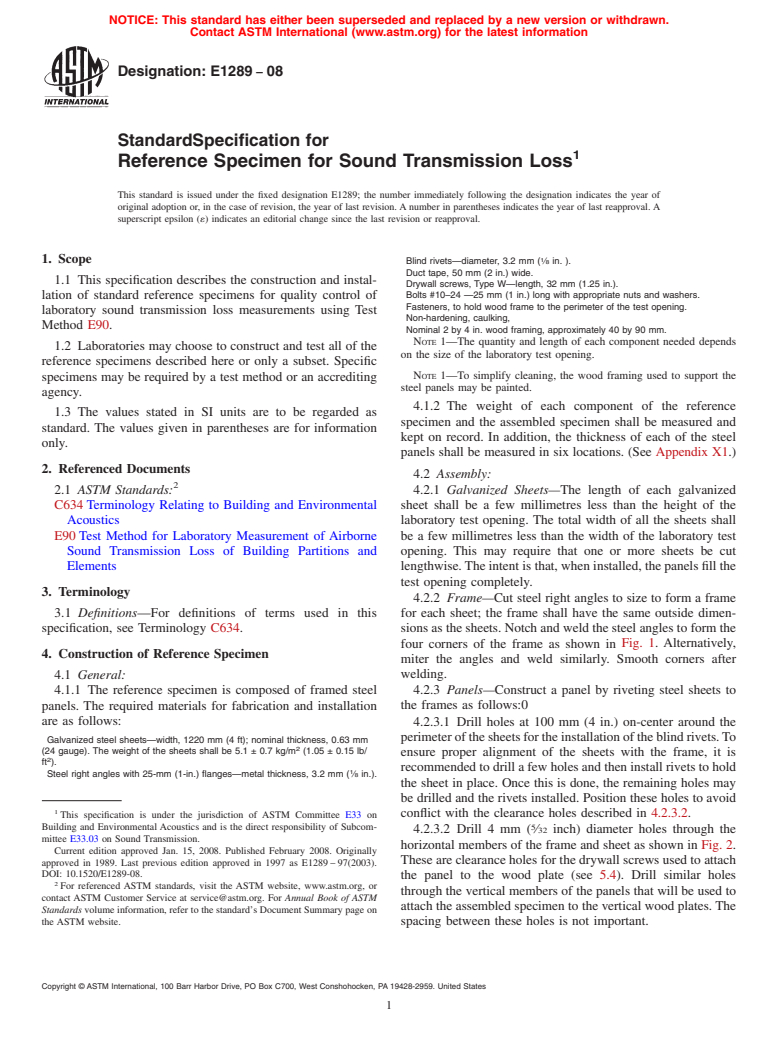

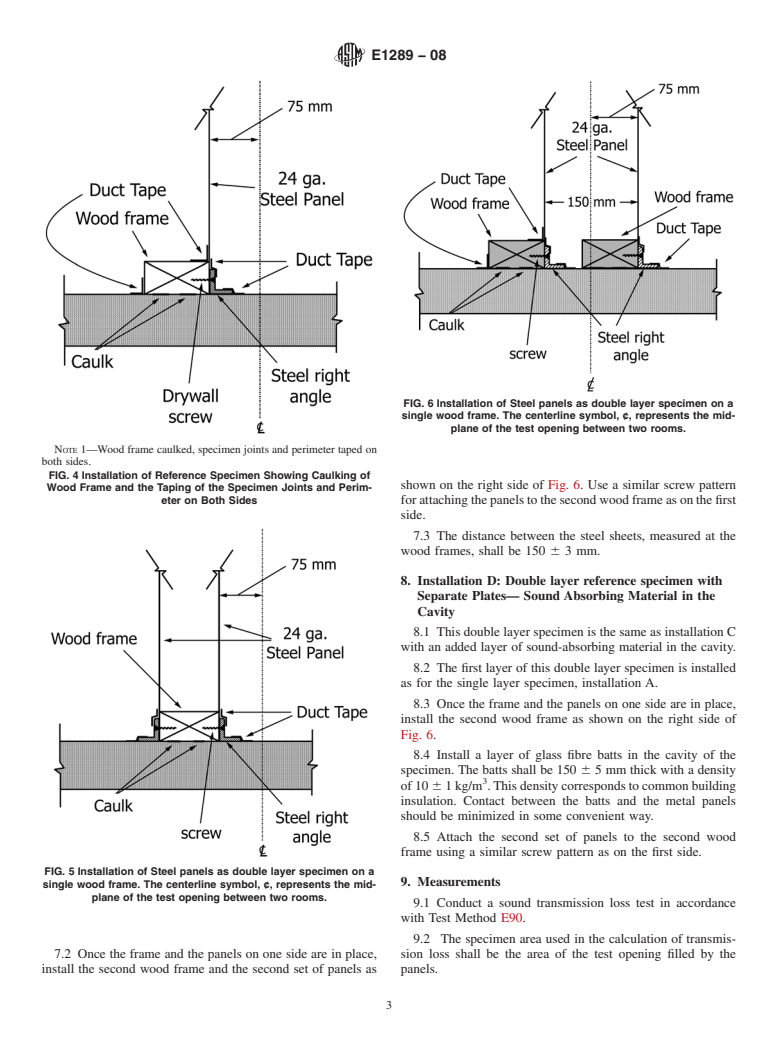

horizontal members of the frame and sheet as shown in Fig. 2.

Current edition approved Jan. 15, 2008. Published February 2008. Originally

These are clearance holes for the drywall screws used to attach

approved in 1989. Last previous edition approved in 1997 as E1289 – 97(2003).

DOI: 10.1520/E1289-08.

the panel to the wood plate (see 5.4). Drill similar holes

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

through the vertical members of the panels that will be used to

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

attach the assembled specimen to the vertical wood plates. The

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. spacing between these holes is not important.

Copyright © ASTM International, 100 Barr Harbor Drive, PO

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.