ASTM D5835-95(2007)

(Practice)Standard Practice for Sampling Stationary Source Emissions for the Automated Determination of Gas Concentrations

Standard Practice for Sampling Stationary Source Emissions for the Automated Determination of Gas Concentrations

ABSTRACT

This practice presents the procedures and equipment that will permit, within certain limits, representative sampling of stationary source emissions for the automated determination of gas concentrations of effluent gas streams. This application is limited to the determination of oxygen (O2), carbon dioxide (CO2), carbon monoxide (CO), sulfur dioxide (SO2), nitric oxide (NO), nitrogen dioxide (NO2) and total oxides of nitrogen (NOx). Although velocity measurements are required to determine the mass flow rates of gases, this is, however, not included in this practice. This practice describes representative sampling of gases in a duct, both by extractive and non-extractive methods. In extractive sampling, gases are conditioned to remove aerosols, particulate matter, and other interfering substances before being conveyed to the instruments. In non-extractive sampling, the measurements are made in-situ; therefore, no sample conditioning except filtering is required.

SCOPE

1.1 This practice covers procedures and equipment that will permit, within certain limits, representative sampling for the automated determination of gas concentrations of effluent gas streams. The application is limited to the determination of oxygen (O2), carbon dioxide (CO2), carbon monoxide (CO), sulfur dioxide (SO 2), nitric oxide (NO), nitrogen dioxide (NO2) and total oxides of nitrogen (NOx).

1.2 Velocity measurements are required to determine the mass flow rates of gases. This is not included in this practice.

1.3 There are some combustion processes and situations that may limit the applicability of this practice. Where such conditions exist, caution and competent technical judgment are required, especially when dealing with any of the following:

1.3.1 Corrosive or highly reactive components,

1.3.2 High vacuum, high pressure, or high temperature gas streams,

1.3.3 Wet flue gases,

1.3.4 Fluctuations in velocity, temperature, or concentration due to uncontrollable variation in the process,

1.3.5 Gas stratification due to the non-mixing of gas streams,

1.3.6 Measurements made using environmental control devices, and

1.3.7 Low levels of gas concentrations.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For more specific safety precautions, refer to 5.1.4.8, 5.2.1.6, and 6.2.2.1.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5835 − 95(Reapproved 2007)

Standard Practice for

Sampling Stationary Source Emissions for the Automated

Determination of Gas Concentrations

This standard is issued under the fixed designation D5835; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This practice covers procedures and equipment that

D1356 Terminology Relating to Sampling and Analysis of

will permit, within certain limits, representative sampling for

Atmospheres

the automated determination of gas concentrations of effluent

D1608 Test Method for Oxides of Nitrogen in Gaseous

gas streams. The application is limited to the determination of

Combustion Products (Phenol-Disulfonic Acid Proce-

oxygen (O ), carbon dioxide (CO ), carbon monoxide (CO),

2 2

dures)

sulfurdioxide(SO ),nitricoxide(NO),nitrogendioxide(NO )

2 2

D3154 Test Method for Average Velocity in a Duct (Pitot

and total oxides of nitrogen (NO ).

x

Tube Method)

1.2 Velocity measurements are required to determine the

2.2 Other Document:

mass flow rates of gases. This is not included in this practice.

40 CFR Part 60, Standards of Performance for Stationary

1.3 Therearesomecombustionprocessesandsituationsthat

Sources, Appendix A, Test Methods 2, 3, 3a, 6, 6c, 7, 7e,

may limit the applicability of this practice. Where such

and 10

conditions exist, caution and competent technical judgment are

required, especially when dealing with any of the following:

3. Terminology

1.3.1 Corrosive or highly reactive components,

3.1 Definitions:

1.3.2 High vacuum, high pressure, or high temperature gas

3.1.1 For definitions of terms used in this practice, refer to

streams,

Terminology D1356.

1.3.3 Wet flue gases,

4. Summary of Practice

1.3.4 Fluctuations in velocity, temperature, or concentration

due to uncontrollable variation in the process,

4.1 This practice describes representative sampling of gases

1.3.5 Gas stratification due to the non-mixing of gas

in a duct, including both extractive and non-extractive sam-

streams,

pling. In extractive sampling, these gases are conditioned to

1.3.6 Measurements made using environmental control

remove aerosols, particulate matter, and other interfering

devices, and substances before being conveyed to the instruments. In

1.3.7 Low levels of gas concentrations. non-extractive sampling, the measurements are made in-situ;

therefore, no sample conditioning except filtering is required.

1.4 This standard does not purport to address all of the

4.1.1 Extractive Sampling—Extractive sampling includes

safety concerns, if any, associated with its use. It is the

extraction of the sample, removal of interfering materials, and

responsibility of the user of this standard to establish appro-

maintenance of the gas concentration throughout the sampling

priate safety and health practices and determine the applica-

system for subsequent analysis by appropriate instrumentation

bility of regulatory limitations prior to use. For more specific

(see Fig. 1).

safety precautions, refer to 5.1.4.8, 5.2.1.6, and 6.2.2.1.

4.2 Non-extractive Sampling—Non-extractive sampling

doesnotinvolveremovalofasample,andsamplingisconfined

to the gas stream in the stack or duct (see Figs. 2 and 3).

This practice is under the jurisdiction ofASTM Committee D22 on Air Quality

and is the direct responsibility of Subcommittee D22.03 on Ambient Atmospheres

and Source Emissions.

Current edition approved April 1, 2007. Published June 2007. Originally For referenced ASTM standards, visit the ASTM website, www.astm.org, or

approved in 1995. Last previous edition approved in 2001 as D5835 - 95(2001). contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

DOI: 10.1520/D5835-95R07. Standards volume information, refer to the standard’s Document Summary page on

This practice is based on ISO 10396, “Stationary source emissions—Sampling the ASTM website.

fortheautomateddeterminationofgasconcentrations,”availablefromInternational Available from Supt. of Documents, U.S. Government Printing Office,

Organization for Standardization, Casa Postale 56, CH-1211, Geneva, Switzerland. Washington, DC 20402.

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959. United States

D5835 − 95 (2007)

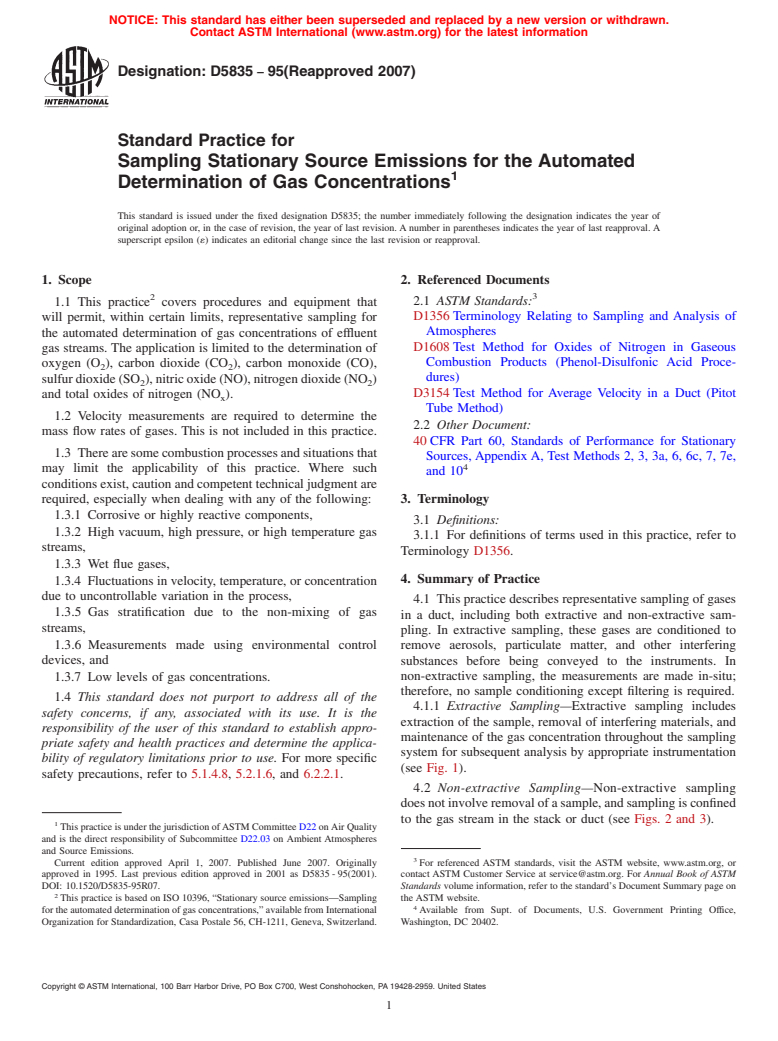

NOTE—Key:

1 Baffle 13 Heater

2 In-stack Filter 14 Refrigeration Unit

3 Tee 15 Water Discharge

4 Probe 16 Vacuum Gage

5 Sampling Port 17 Bypass Valve

6 Cap 18 Pump

7 Pressure Gage 19 Sampling Line (Heating Optional)

8 To Zero and Span Gases 20 Manifold

9 Heat-traced Sampling Line 21 ToAnalyzer(s)

10 Temperature Controller (Line) 22 Rotameter

11 Temperature Controller (Box) 23 Vent

12 Filter

FIG. 1 Extractive Sampling and Conditioning System

5. Representative Factors 5.1.3 Where there are difficulties due to the nature of the

source as noted in 5.1.2, establish the concentration profile for

5.1 Nature of the Source:

each operating condition and to determine the best sampling

5.1.1 The representativeness of the determination of gas-

location.

eous concentration in enclosed gas streams depends on several

5.1.3.1 Some sources may have more variability in process

factors:

(for example, cyclic variation) and, consequently, any time

5.1.1.1 The heterogeneity of the process stream, such as

dependent measurement may be less representative of the

variations in concentration, temperature, or velocity across the

average concentration if a full cycle of variability is not

duct caused by moisture or gas stratification,

sampled.

5.1.1.2 Gas leakage or air infiltration and continuous gas

5.1.4 Before any measurements are carried out, it is neces-

reactions, and

sary to become familiar with the pertinent operating character-

5.1.1.3 Random errors due to the finite nature of the sample

istics of the process from which emissions are to be sampled

and the sampling procedure adopted to obtain a representative

and determined. These operating characteristics include, but

sample.

are not necessarily limited to, the following:

5.1.2 Representativeness may be difficult to achieve for the

5.1.4.1 Mode of process operation (cyclic, batch charging,

following reasons:

or continuous),

5.1.2.1 Nature of the source (for example, cyclic,

5.1.4.2 Process feed rates and composition,

continuous, or batch),

5.1.4.3 Fuel rates and composition,

5.1.2.2 Concentration level of the gas,

5.1.4.4 Normal operating gas temperatures and pressures,

5.1.2.3 Size of the source, and

5.1.2.4 Configuration of the duct network where samples 5.1.4.5 Operating and removal efficiency of the pollution

are extracted. control equipment,

D5835 − 95 (2007)

It is important that the sampling location be removed from any

obstructions that will seriously disturb the gas flow in the duct

or stack. The pollutant can have cross sectional variation. The

concentrationatvariouspointsofthecross-sectionshallfirstbe

checked, in order to assess the homogeneity of the flow and to

detect any infiltration of air or gas stratification, etc. If a

preliminary analysis of cross-section at measurements taken

indicates more than 6 15 % variation in concentrations, and if

an alternative acceptable location is not available, multi-point

sampling is recommended.

5.2.2.2 Multi-point sampling may be achieved either by

moving the probe from point to point or having a probe with

multiple access ports. Usually, the cross sectional concentra-

tion of gaseous pollutants is uniform, because of the diffusion

and turbulent mixing. If so, it is only necessary to sample at

one point within the stack or duct to determine the average

concentration. Extract gas samples near the center of the stack

sampling site. When using nonextractive systems, obtain a

concentration as representative as possible, but ensure that the

instrument location is representative.

5.3 Gas Concentration, Velocity, and Temperature Profile—

Before commencing sampling, determine if there are any

spatial or temporal fluctuations in the gas concentrations by

conducting a preliminary survey of the gas concentration,

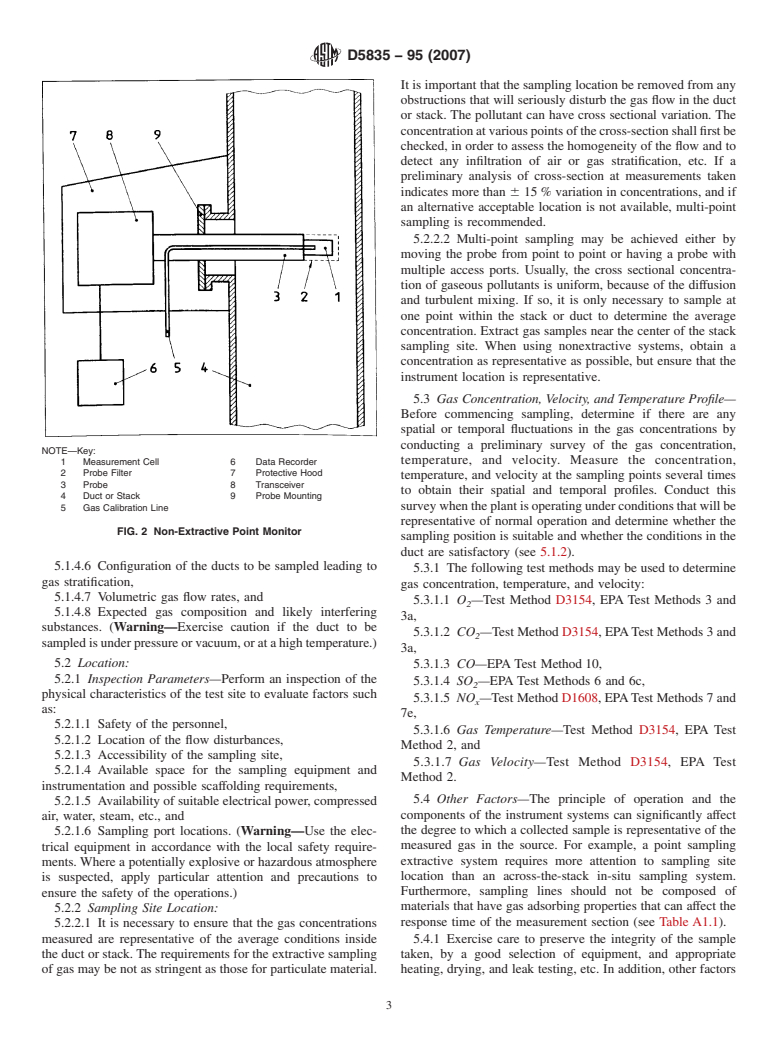

NOTE—Key:

temperature, and velocity. Measure the concentration,

1 Measurement Cell 6 Data Recorder

2 Probe Filter 7 Protective Hood

temperature, and velocity at the sampling points several times

3 Probe 8 Transceiver

to obtain their spatial and temporal profiles. Conduct this

4 Duct or Stack 9 Probe Mounting

surveywhentheplantisoperatingunderconditionsthatwillbe

5 Gas Calibration Line

representative of normal operation and determine whether the

FIG. 2 Non-Extractive Point Monitor

sampling position is suitable and whether the conditions in the

duct are satisfactory (see 5.1.2).

5.1.4.6 Configuration of the ducts to be sampled leading to

5.3.1 The following test methods may be used to determine

gas stratification,

gas concentration, temperature, and velocity:

5.1.4.7 Volumetric gas flow rates, and

5.3.1.1 O —Test Method D3154, EPA Test Methods 3 and

5.1.4.8 Expected gas composition and likely interfering

3a,

substances. (Warning—Exercise caution if the duct to be

5.3.1.2 CO —Test Method D3154, EPATest Methods 3 and

sampledisunderpressureorvacuum,oratahightemperature.)

3a,

5.2 Location: 5.3.1.3 CO—EPA Test Method 10,

5.2.1 Inspection Parameters—Perform an inspection of the

5.3.1.4 SO —EPA Test Methods 6 and 6c,

physical characteristics of the test site to evaluate factors such

5.3.1.5 NO —Test Method D1608, EPATest Methods 7 and

x

as:

7e,

5.2.1.1 Safety of the personnel,

5.3.1.6 Gas Temperature—Test Method D3154, EPA Test

5.2.1.2 Location of the flow disturbances,

Method 2, and

5.2.1.3 Accessibility of the sampling site,

5.3.1.7 Gas Velocity—Test Method D3154, EPA Test

5.2.1.4 Available space for the sampling equipment and

Method 2.

instrumentation and possible scaffolding requirements,

5.4 Other Factors—The principle of operation and the

5.2.1.5 Availability of suitable electrical power, compressed

components of the instrument systems can significantly affect

air, water, steam, etc., and

the degree to which a collected sample is representative of the

5.2.1.6 Sampling port locations. (Warning—Use the elec-

measured gas in the source. For example, a point sampling

trical equipment in accordance with the local safety require-

extractive system requires more attention to sampling site

ments. Where a potentially explosive or hazardous atmosphere

location than an across-the-stack in-situ sampling system.

is suspected, apply particular attention and precautions to

Furthermore, sampling lines should not be composed of

ensure the safety of the operations.)

materials that have gas adsorbing properties that can affect the

5.2.2 Sampling Site Location:

response time of the measurement section (see Table A1.1).

5.2.2.1 It is necessary to ensure that the gas concentrations

measured are representative of the average conditions inside 5.4.1 Exercise care to preserve the integrity of the sample

the duct or stack. The requirements for the extractive sampling taken, by a good selection of equipment, and appropriate

of gas may be not as stringent as those for particulate material. heating, drying, and leak testing, etc. In addition, other factors

D5835 − 95 (2007)

NOTE—Key:

1 Lamp 7 Electronic Module

2 TransmitterAssembly 8 Data Recorder

3 Internal Gas Calibration Cell 9 Stack or Duct

4 ReceiverAssembly 10 Alignment/Calibration Pipe

5 Protective Windows 11 PurgeAir Blower

6 Detector 12 Gas Calibration Line

FIG. 3 Non-Extractive Path Monitor

such as corrosion, synergies, reaction with components, subject to corrosion by oxidizing gases and may be porous to

decomposition, and adsorption might affect the integrity of a hydrogen. Thus, it is preferable to have stainless steel or

sample. chromium steels that can be used up to 900°C. Other special

steels or alloys can be used above this temperature. Heat the

6. Equipment

probe if condensation occurs in its interior and cool it with an

6.1 Recommended construction materials are described in air or water jacket when sampling in very hot gases. Electri-

Annex A1. cally ground metal probes since high voltages are easily

generated in dry gas streams, causing particulate matter to be

6.2 Components of Extractive Sampling Equipment:

collected on the probe surface. Grounding is particularly

6.2.1 Primary Filter—The filter medium shall be con-

important when employed in an explosive atmosphere.

structed of an appropriate alloy (such as a specific stainless

6.2.2.2 Refractory Probes (see Annex A1), generally made

steel cast alloy), quartz borosilicate, ceramics, or another

of vitreous silica, porcelain, mullite or recrystallized alumina.

suitable material. A filter that retains particles greater than 10

They are fragile and may warp at high temperatures; with the

µm is recommended. A secondary filter might be required as

exception of silica, they may also crack from thermal shock.

well (see 6.2.4). The filter medium may be located outside the

Borosilicate glass probes can withstand temperatures up to

ductoratthetipofthesampleprobe(6.2.2).Ifplacedatthetip

500°Candvitreoussilicaprobesupto1000°C.Somerefractors

of the probe, a deflector plate may be added to prevent particle

of advanced ceramic materials can withstand temperatures

build-up on the leading edge of the filter. This will prevent

higher than 1000°C.

blockage of the filter. Avoid contamination of the filter with

6.2.3 Heated Sampling Line Connected to Moisture Re-

particulate matter where condensate may react with gases,

moval Assembly:

resulting in erroneous result.

6.2.3.1 Thesamplinglineshallbemadeofstainlesssteel,or

6.2.2 Probe:

Polytetrafluoroethylene (PTFE).

6.2.2.1 Metal Probes—The choice of the metal depends

basicallyonthephysicalandchemicalpropertiesofthesample 6.2.3.2 The tube diameter shall be adequate to provide a

and on the nature of the gas to be determined. Mild steel is flow rate that is sufficient to feed the monitors, bearing in mind

D5835 − 95 (2007)

the sampling line length and the pressure characteristics of the 6.2.6.3 Dilution may be used to reduce the water concen-

sampling pump (6.2.5) used. tration to a level where water removal may not be necessary.

6.2.3.3 Maintain the sampling line at a temperature of at 6.2.7 Analyzer Sampling Line:

least 15°C above the water and acid dew-point temperature of

6.2.7.1 The part of the sampling line associated with the

the sampled gas. Monitor the temperature.

analyzershallbemadeofani

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.