ASTM F3004-13e1

(Test Method)Standard Test Method for Evaluation of Seal Quality and Integrity Using Airborne Ultrasound

Standard Test Method for Evaluation of Seal Quality and Integrity Using Airborne Ultrasound

SIGNIFICANCE AND USE

5.1 This method allows for the evaluation of seal quality by passing an ultrasound signal through the sealed area of a package or item. Poorly sealed areas will not transmit as much ultrasonic energy as properly sealed areas.

5.2 This method relies on quantitative analysis of ultrasound signal strength, providing a non-subjective approach to assessing package seal quality and detecting defects.

5.3 This technique has been used for inspecting a variety of materials including flexible pouch seals, rigid tray seals and other packaging components such as affixed valves. The precision and bias for any specific package and seal configuration needs to be individually determined and validated.

5.4 The C-Scan approach is useful for laboratory applications or off-line seal inspection. The L-Scan approach can be used for on-line, real time inspection of seal quality. The sensitivity of either approach to detect a given defect size and level of severity needs to be individually determined.

5.5 Sound waves propagate at different speeds through different materials generally moving faster through more dense materials. The acoustic impedance (expressed as g/cm2·μs) is the product of density (g/cm3) and velocity (cm/μs). Of particular importance is the extreme difference between the impedance of air and that of any solid material. Any gap or poorly bonded area can be readily detected.

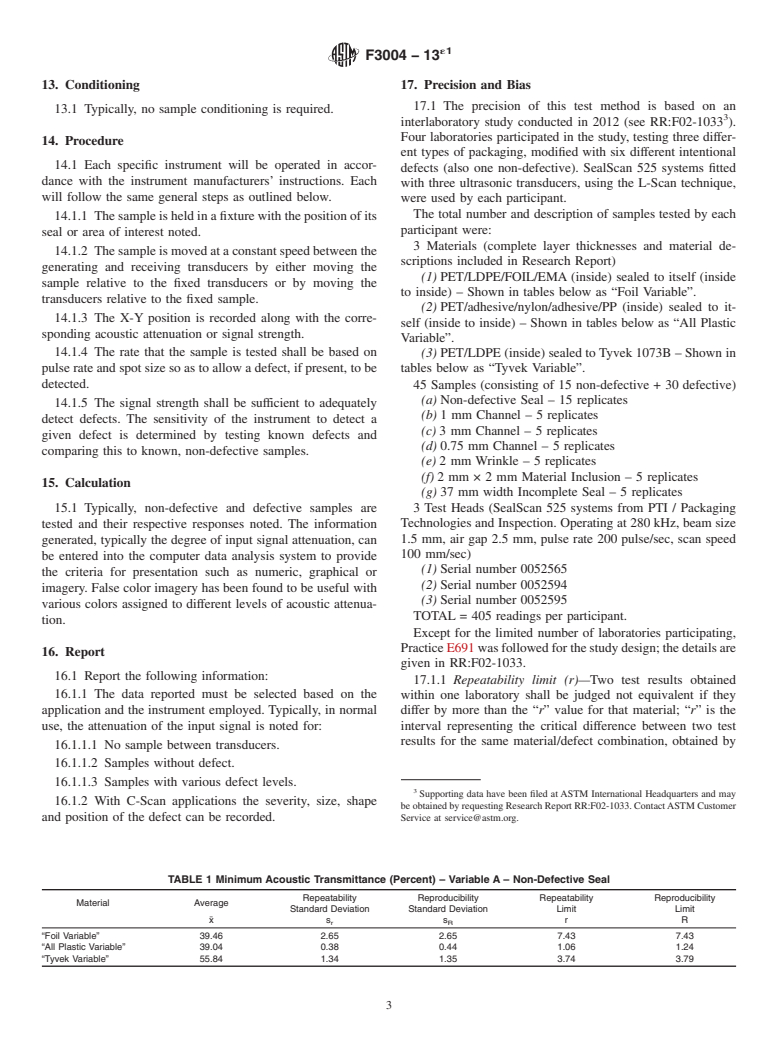

Material

Velocity

(cm/μsec)

Density

(g/cm3)

Acoustic

Impedance

(g/cm2-μsec)

Air (20°C, 1 bar)

0.0344

0.00119

0.000041

Water (20°C)

0.148

1.0

0.148

Polyethylene

0.267

1.1

0.294

Aluminum

0.632

2.7

1.710

SCOPE

1.1 This standard method describes the technology and testing procedures that can be used to detect seal defects in the size range of 1 mm and characterize seal quality in a variety of packaging styles using airborne ultrasound technology.

1.2 This test method does not purport to be the only method for measurement of seal quality.

1.3 Heat seals and other package components can be tested in flexible, semi-rigid and rigid packages. Only the precision and bias for flexible package seals were evaluated in a recent ILS included in the method. The precision and bias for any specific package needs to be individually determined.

1.4 On-line, real time inspection of seals can be considered particularly in the L-Scan mode.

1.5 This method provides a non-destructive, quantitative, non-subjective approach to flexible package seal inspection.

1.6 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: F3004 − 13

Standard Test Method for

Evaluation of Seal Quality and Integrity Using Airborne

1

Ultrasound

This standard is issued under the fixed designation F3004; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—Reference to RR:F02-1033 was added editorially in April 2014.

1. Scope E691Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

1.1 This standard method describes the technology and

testing procedures that can be used to detect seal defects in the

3. Terminology

sizerangeof1mmandcharacterizesealqualityinavarietyof

packaging styles using airborne ultrasound technology. 3.1 Definitions:

3.1.1 acoustic impedance—the product of a material’s den-

1.2 Thistestmethoddoesnotpurporttobetheonlymethod

sity and its acoustic velocity.

for measurement of seal quality.

3.1.2 airborne ultrasound—non-contact,non-destructiveul-

1.3 Heat seals and other package components can be tested

trasound technology that allows materials to be scanned and

in flexible, semi-rigid and rigid packages. Only the precision

analyzed without physical contact with the transducers. No

and bias for flexible package seals were evaluated in a recent

coupling is used other than air.

ILS included in the method. The precision and bias for any

specific package needs to be individually determined.

3.1.3 ultrasonic attenuation—the decay rate of the wave as

it propagates through a material. It is the combined effect of

1.4 On-line, real time inspection of seals can be considered

particularly in the L-Scan mode. scattering and absorption.

1.5 This method provides a non-destructive, quantitative, 3.1.4 ultrasound—sound with frequencies greater than the

non-subjective approach to flexible package seal inspection.

upper limit of human hearing which is approximately 20 kHz.

Typical industrial applications use much higher frequencies in

1.6 The values stated in SI units are to be regarded as

the 1–100 MHz range.

standard. No other units of measurement are included in this

standard.

3.1.5 ultrasound C-Scan—multiple L-Scans which accumu-

lates data to describe an area of interest in both X and Y

1.7 This standard does not purport to address all of the

dimensions.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3.1.6 ultrasound L-Scan—a single linear scan across one

priate safety and health practices and determine the applica-

direction over the area of interest.

bility of regulatory limitations prior to use.

4. Summary of Test Method

2. Referenced Documents

4.1 Ultrasound has been used for inspecting a wide variety

2

2.1 ASTM Standards:

of materials as well as human health issues, based on sending

E177Practice for Use of the Terms Precision and Bias in

and receiving ultrasonic sound waves. Airborne Ultrasound

ASTM Test Methods

(ABUS) is a non-contact ultrasound technology that allows

packages to be scanned and analyzed without making any

contact with the ultrasonic transducers. Unlike contact

1

ThistestmethodisunderthejurisdictionofASTMCommitteeF02onFlexible

ultrasound, ABUS does not use liquid or gel coupling to

Barrier Packaging and is the direct responsibility of Subcommittee F02.40 on

propagate sound. It may be critical to production processes to

Package Integrity.

analyze a bond without changing the characteristics of the

Current edition approved Aug. 1, 2013. Published September 2013. DOI:

10.1520/F3004-13E01.

package or product in any way which may affect salability.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

ABUS is capable of testing packaging where continuous and

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

complete bonding between two materials is essential or, if the

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. bond is limited, the degree of bonding.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

F3004 − 13

4.2 ABUS is similar to most ultrasound applications in

Acoustic

Velocity Density

Material Impedance

3

principle; however it uses air to propagate ultrasonic waves.

(cm/µsec) (g/cm )

2

(g/cm -µsec)

The ABUS technology uses the transmission of ultrasonic

Air (20°C, 1 bar) 0.0344 0.00119 0.000041

waves to create a representative data image, allowing for Water (20°C) 0.148 1.0 0.148

Polyethylene 0.267 1.1 0.294

quantitative evaluation of the quality of bonded materi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.