ASTM D2658-04

(Test Method)Standard Test Method for Determining Interior Dimensions of Fiberboard Boxes (Box Gage Method)

Standard Test Method for Determining Interior Dimensions of Fiberboard Boxes (Box Gage Method)

SIGNIFICANCE AND USE

The interior dimensions are important properties in the general construction of a box, and accurate methods of measurement are required for research work, routine control, and acceptance testing for conformance to specifications. For containers to carry and protect their contents effectively and efficiently, the containers must be of proper and uniform size. This method involves a degree of human judgment and assumes careful and accurate placement and reading of specified apparatus.

Method A, Measuring Lot of Boxes—determines if a lot (i.e., production run) is within specified tolerance for each dimension (length, width, and depth). A minimum of five specimens are measured. The test result for each dimension is the individual measurements of that dimension on all specimens. If any test result is outside of a specified tolerance, that box specimen should be re-measured using Method B to determine final test results.

Method B, Measuring Single Boxes—determines if one particular box is within specified tolerance for each dimension. The test result for each dimension is the average of all measurements of that dimension.

SCOPE

1.1 This test method covers the determination of the interior dimensions of regular slotted or special slotted styles of single-wall corrugated, double-wall corrugated, and solid fiberboard boxes.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D2658–04

Standard Test Method for

Determining Interior Dimensions of Fiberboard Boxes (Box

1

Gage Method)

This standard is issued under the fixed designation D2658; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2 Definitions of Terms Specific to This Standard:

3.2.1 depth—thedistancebetweentheinnermostsurfacesof

1.1 This test method covers the determination of the interior

the box measured perpendicular to the length and width.

dimensions of regular slotted or special slotted styles of

3.2.2 interior dimensions—the shortest distances between

single-wall corrugated, double-wall corrugated, and solid fi-

opposite walls.

berboard boxes.

3.2.3 length—the larger of the two dimensions of the open

1.2 This standard does not purport to address all of the

face.

safety concerns, if any, associated with its use. It is the

3.2.4 regular slotted—one-piece box with all flaps the same

responsibility of the user of this standard to establish appro-

length and outer flaps meeting. Inner flaps may or may not

priate safety and health practices and determine the applica-

meet, but do not overlap.

bility of regulatory limitations prior to use.

3.2.5 special slotted—one-piece box with all flaps meeting

2. Referenced Documents or not meeting but not overlapping.

2

3.2.6 width—the lesser of the two dimensions of the open

2.1 ASTM Standards:

face.

D585 Practice for Sampling and Accepting a Single Lot of

Paper, Paperboard, Fiberboard, and Related Product

4. Significance and Use

D685 Practice for Conditioning Paper and Paper Products

4.1 The interior dimensions are important properties in the

for Testing

general construction of a box, and accurate methods of

D996 Terminology of Packaging and Distribution Environ-

measurement are required for research work, routine control,

ments

and acceptance testing for conformance to specifications. For

D4332 Practice for Conditioning Containers, Packages, or

containers to carry and protect their contents effectively and

Packaging Components for Testing

efficiently, the containers must be of proper and uniform size.

E691 Practice for Conducting an Interlaboratory Study to

This method involves a degree of human judgment and

Determine the Precision of a Test Method

assumes careful and accurate placement and reading of speci-

2.2 ANSI Standard:

fied apparatus.

B46.1 Surface Texture Surface Roughness, Waviness and

3 4.2 Method A, Measuring Lot of Boxes—determines if a lot

Lay

(i.e., production run) is within specified tolerance for each

3. Terminology dimension (length, width, and depth). A minimum of five

specimens are measured. The test result for each dimension is

3.1 Definitions—General terms in this test method are

the individual measurements of that dimension on all speci-

defined in Terminology D996.

mens. If any test result is outside of a specified tolerance, that

box specimen should be re-measured using Method B to

1

This test method is under the jurisdiction of ASTM Committee D10 on

determine final test results.

Packaging and is the direct responsibility of Subcommittee D10.27 on Paper and

4.3 Method B, Measuring Single Boxes—determines if one

Paperboard Products.

Current edition approved Dec. 1, 2004. Published December 2004. Originally particular box is within specified tolerance for each dimension.

approved in 1967. Last previous edition approved in 1999 as D2658 – 94 (1999).

The test result for each dimension is the average of all

DOI: 10.1520/D2658-04.

measurements of that dimension.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3

Available from American National Standards Institute, 25 W. 43rd St., 4th

Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

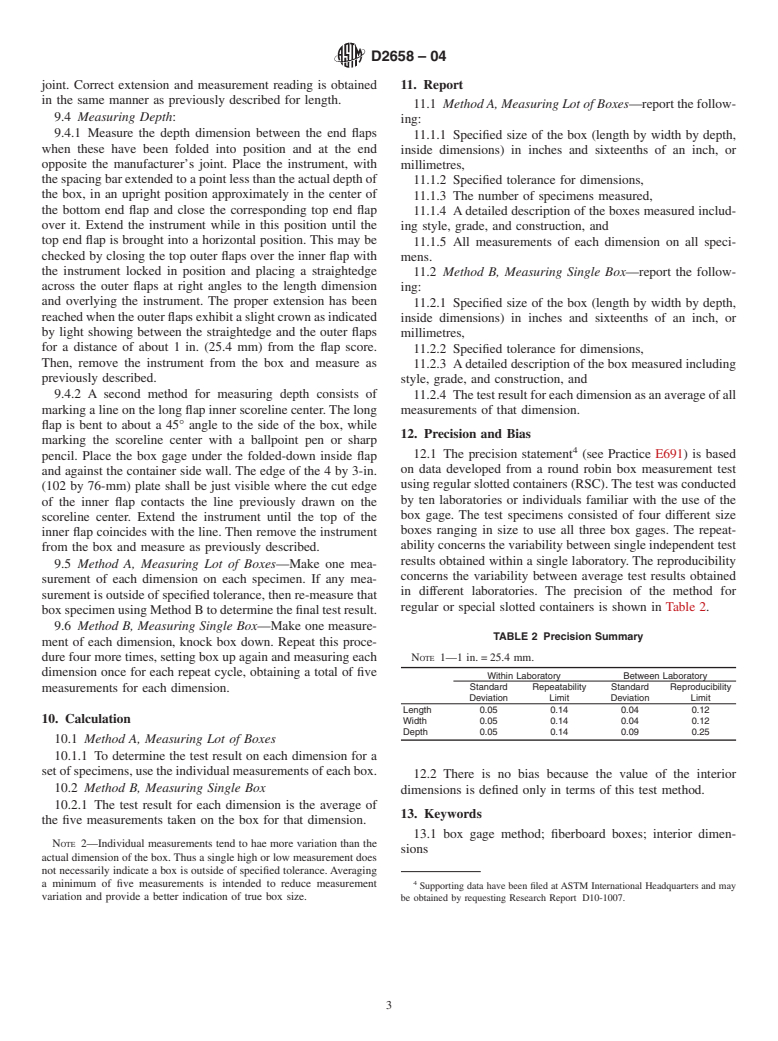

D2658–04

5. Apparatus 7. Test Specimens

5.1 Measuring Equipment, consisting of two flat metal 7.1 Method A, Measuring Lot of Boxes—

plates mounted on each end and at right angles to a telescoping

7.1.1 In no instance shall fewer than five specimens be

spacing bar (Fig. 1). measured and taken as representative of the lot.

5.1.1 Metal Plates— The metal plates shall be not less than

7.1.2 For large lots, a formal sampling plan is advised.

3

⁄16 in. (4.76 mm) thick and shall have length and width

Application of Practice D585 is suggested.

dimensions of 4 by 3 in. (102 by 76 mm) w

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.