ASTM D2105-01

(Test Method)Standard Test Method for Longitudinal Tensile Properties of "Fiberglass" (Glass-Fiber-Reinforced Thermosetting-Resin) Pipe and Tube

Standard Test Method for Longitudinal Tensile Properties of "Fiberglass" (Glass-Fiber-Reinforced Thermosetting-Resin) Pipe and Tube

SCOPE

1.1 This test method covers the determination of the comparative longitudinal tensile properties of fiberglass pipe when tested under defined conditions of pretreatment, temperature, and testing machine speed. Both glass-fiber-reinforced thermosetting-resin pipe (RTRP) and glass-fiber-reinforced polymer mortar pipe (RPMP) are fiberglass pipes.

Note 1—For the purposes of this standard, polymer does not include natural polymer.

1.2 This test method is generally limited to pipe diameter of 6 in. (150 mm) or smaller. Larger sizes may be tested if required apparatus is available.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are provided for information purposes only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1—There is no similar or equivalent ISO standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D 2105–01

Standard Test Method for

Longitudinal Tensile Properties of “Fiberglass” (Glass-Fiber-

1

Reinforced Thermosetting-Resin) Pipe and Tube

This standard is issued under the fixed designation D 2105; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope * D 3567 Practice for Determining Dimensions of “Fiber-

glass” (Glass-Fiber-ReinforcedThermosetting-Resin) Pipe

1.1 This test method covers the determination of the com-

5

and Fittings

parative longitudinal tensile properties of fiberglass pipe when

6

E 4 Practices for Force Verification of Testing Machines

tested under defined conditions of pretreatment, temperature,

E 83 Practice for Verification and Classification of Exten-

and testing machine speed. Both glass-fiber-reinforced

6

someters

thermosetting-resin pipe (RTRP) and glass-fiber-reinforced

5

F 412 Terminology Relating to Plastic Piping Systems

polymer mortar pipe (RPMP) are fiberglass pipes.

NOTE 1—For the purposes of this standard, polymer does not include 3. Terminology

natural polymer.

3.1 General—Definitions are in accordance with Terminol-

1.2 This test method is generally limited to pipe diameter of

ogy D 883 and F 412 and abbreviations are in accordance with

6 in. (150 mm) or smaller. Larger sizes may be tested if

Terminology D 1600, unless otherwise indicated.

required apparatus is available.

3.2 Other definitions of terms and symbols relating to

1.3 The values stated in inch-pound units are to be regarded

tension testing of plastics appear in theAnnex to Test Methods

as the standard. The values given in parentheses are provided

D 638 and D 638M.

for information purposes only.

3.3 Definitions of Terms Specific to This Standard:

1.4 This standard does not purport to address all of the

3.3.1 aggregate—a siliceous sand conforming to the re-

safety concerns, if any, associated with its use. It is the

quirements of Specification C 33, except that the requirements

responsibility of the user of this standard to establish appro-

for gradation shall not apply.

priate safety and health practices and determine the applica-

3.3.2 exterior surface resin layer—a resin layer, with or

bility of regulatory limitations prior to use.

without filler or reinforcement, or both, applied to the exterior

surface of the pipe structural wall.

NOTE 2—There is no similar or equivalent ISO standard.

3.3.3 fiberglass pipe—a tubular product containing glass

2. Referenced Documents fiber reinforcement embedded in or surrounded by cured

thermosetting resin; the composite structure may contain

2.1 ASTM Standards:

2 aggregate, granular or platelet fillers, thixotropic agents, pig-

C 33 Specification for Concrete Aggregates

3

ments, or dyes; thermoplastic or thermosetting liners may be

D 618 Practice for Conditioning Plastics for Testing

3 included.

D 638 Test Method for Tensile Properties of Plastics

3.3.4 liner—the inner portion of the wall at least 0.005 in.

D 638M Test Method for Tensile Properties of Plastics

3 (0.13 mm) in thickness, as determined in 9.1.2, which does not

(Metric)

4

contribute to the strength in the determination of the hydro-

D 883 Terminology Relating to Plastics

static design basis.

D 1600 Terminology for Abbreviated Terms Relating to

4

3.3.5 reinforced polymer mortar pipe (RPMP)—a fiberglass

Plastics

pipe with aggregate.

3.3.6 reinforced thermosetting resin pipe (RTRP)—a fiber-

glass pipe without aggregate.

1

This test method is under the jurisdiction ofASTM Committee D20 on Plastics

3.3.7 reinforced wall thickness—the total wall thickness

and is the direct responsibility of Subcommittee D20.23 on Reinforced Plastic

minus the liner or exterior coating thickness, or both.

Piping Systems.

Current edition approved June 10, 2001. Published August 2001. Originally

published as D 2105 – 62T. Last previous edition D 2105 – 97.

2

Annual Book of ASTM Standards, Vol 04.02.

3 5

Annual Book of ASTM Standards, Vol 08.01. Annual Book of ASTM Standards, Vol 08.04.

4 6

Annual Book of ASTM Standards, Vols 08.01 and 08.04. Annual Book of ASTM Standards, Vol 03.01.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D 2105

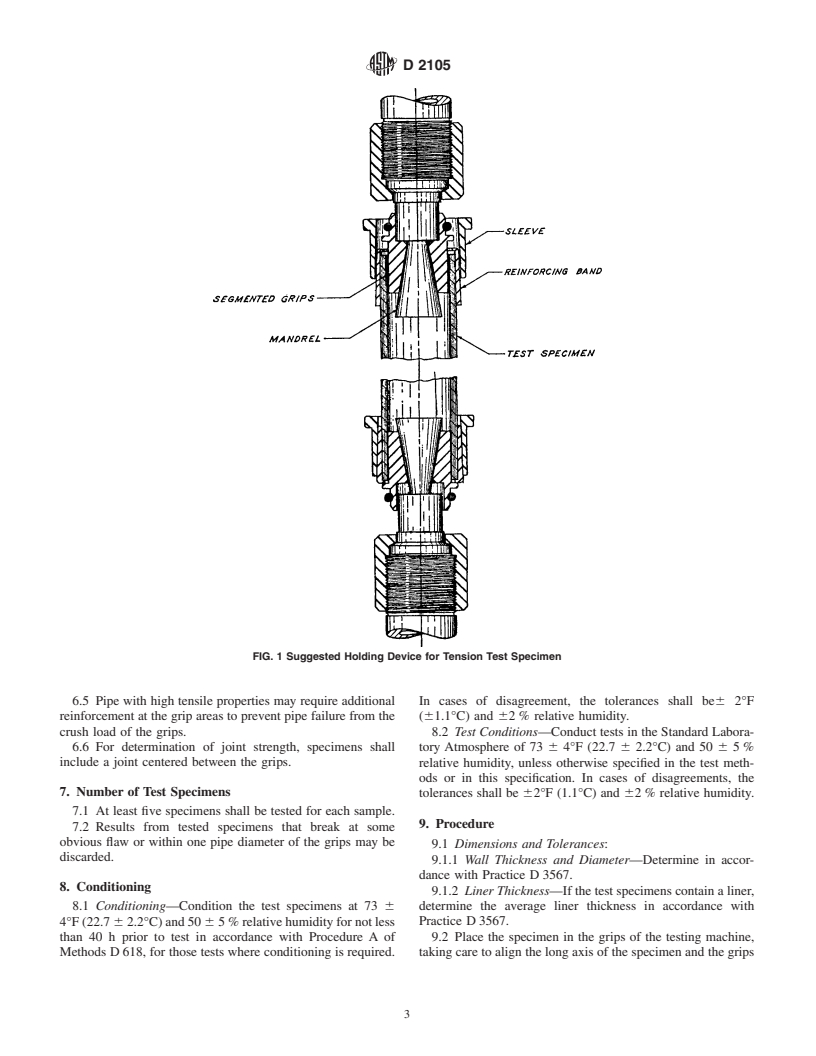

4. Significance and Use coincide with the direction of the applied pull through the

centerlineofthegripassembly.Thetestspecimenshallbeheld

4.1 Tensile properties include modulus of elasticity,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.