ASTM A1082/A1082M-12

(Specification)Standard Specification for High Strength Precipitation Hardening and Duplex Stainless Steel Bolting for Special Purpose Applications

Standard Specification for High Strength Precipitation Hardening and Duplex Stainless Steel Bolting for Special Purpose Applications

ABSTRACT

This specification covers high strength stainless steel bolting for special purpose applications such as pressure vessels. Several grades of precipitation-hardened and duplex (ferritic-austenitic) stainless steels are covered. Selection will depend upon design, service conditions, mechanical properties and characteristics related to the application. Bolting supplied to this specification shall conform to the requirements of Specification A962/A962M. These requirements include test methods, finish, thread dimensions, marking, terminology, testing, certification, optional supplementary requirements, and others. Bars shall be produced in accordance with Specifications A276/A276M, A479/A479M or A564/A564M as applicable while the fasteners shall be produced in accordance with this specification and the requirements of A962/A962M.

SCOPE

1.1 This specification covers high strength stainless steel bolting for special purpose applications such as pressure vessels. Several grades of precipitation-hardened and duplex (ferritic-austenitic) stainless steels are covered. Selection will depend upon design, service conditions, mechanical properties and characteristics related to the application.

1.2 The following referenced general requirements are indispensable for application of this specification: Specification A962/A962M.

1.3 Supplementary Requirements are provided for use at the option of the purchaser. The Supplementary Requirements shall only apply when specified individually by the purchaser in the purchase order or contract.

1.4 This specification is expressed in both inch-pound units and in SI units; however, unless the purchase order or contract specifies the applicable “M” specification designation (SI units), the inch-pound units shall apply.

1.5 The values stated in either SI units or inch-pound units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A1082/A1082M −12

StandardSpecification for

High Strength Precipitation Hardening and Duplex Stainless

Steel Bolting for Special Purpose Applications

This standard is issued under the fixed designation A1082/A1082M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This specification covers high strength stainless steel

A276/A276M Specification for Stainless Steel Bars and

bolting for special purpose applications such as pressure

Shapes

vessels. Several grades of precipitation-hardened and duplex

A370 Test Methods and Definitions for Mechanical Testing

(ferritic-austenitic) stainless steels are covered. Selection will

of Steel Products

depend upon design, service conditions, mechanical properties

A479/A479M Specification for Stainless Steel Bars and

and characteristics related to the application.

Shapes for Use in Boilers and Other Pressure Vessels

1.2 The following referenced general requirements are in- A564/A564M Specification for Hot-Rolled and Cold-

Finished Age-Hardening Stainless Steel Bars and Shapes

dispensable for application of this specification: Specification

A959/A959M Guide for Specifying Harmonized Standard

A962/A962M.

Grade Compositions for Wrought Stainless Steels

1.3 Supplementary Requirements are provided for use at the

A962/A962M Specification for Common Requirements for

option of the purchaser. The Supplementary Requirements

Bolting Intended for Use at Any Temperature from Cryo-

shall only apply when specified individually by the purchaser

genic to the Creep Range

in the purchase order or contract.

2.2 ASNT Documents:

ASNT SNT-TC-1A Recommended Practice for Personnel

1.4 This specification is expressed in both inch-pound units

Qualification and Certification in Nondestructive Testing

and in SI units; however, unless the purchase order or contract

specifies the applicable “M” specification designation (SI

3. Ordering Information

units), the inch-pound units shall apply.

3.1 The inquiry and order shall indicate the following, as

required, to describe the desired material adequately:

1.5 The values stated in either SI units or inch-pound units

3.1.1 Quantity (weight or number of pieces),

are to be regarded separately as standard. Within the text, the

3.1.2 Description of item (bars, bolts, nuts, etc.),

SI units are shown in brackets. The values stated in each

3.1.3 UNS Designation or Type (see Table 1),

system may not be exact equivalents; therefore, each system

3.1.4 Heat-Treat Condition (see 7.1.1),

shall be used independently of the other. Combining values

3.1.5 Dimension/Threads, etc. (see the section in Specifica-

from the two systems may result in non-conformance with the

tion A962/A962M titled “Workmanship, Finish, and

standard.

Appearance”), and

1.6 This standard does not purport to address all of the

3.1.6 Supplementary Requirements, if any.

safety concerns, if any, associated with its use. It is the

4. Common Requirements

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

4.1 Bolting supplied to this specification shall conform to

bility of regulatory limitations prior to use.

the requirements of Specification A962/A962M. These re-

quirements include test methods, finish, thread dimensions,

1 2

This specification is under the jurisdiction of ASTM Committee A01 on Steel, For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

A01.22 on Steel Forgings and Wrought Fittings for PipingApplications and Bolting Standards volume information, refer to the standard’s Document Summary page on

Materials for Piping and Special Purpose Applications. the ASTM website.

Current edition approved Nov. 15, 2012. Published December 2012. DOI: AvailablefromAmericanSocietyforNondestructiveTesting(ASNT),P.O.Box

10.1520/A1082/A1082M-12. 28518, 1711 Arlingate Ln., Columbus, OH 43228-0518, http://www.asnt.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A1082/A1082M−12

A

TABLE 1 Chemical Requirements

UNS

B

Type Carbon Manganese Phosphorus Sulfur Silicon Chromium Nickel Molybdenum Nitrogen Other Elements

B

Designation

Duplex (Ferritic-Austenitic) Grades

S31100 { 0.06 1.00 0.045 0.030 1.00 25.0-27.0 6.0-7.0{{ Ti 0.25

S31260 { 0.030 1.00 0.030 0.030 0.75 24.0-26.0 5.5-7.5 2.5-3.5 0.10-0.30 Cu 0.20-0.80,

W 0.10-0.50

S31803 { 0.030 2.00 0.030 0.020 1.00 21.0-23.0 4.5-6.5 2.5-3.5 0.08-0.20 {

S32101 { 0.040 4.0-6.0 0.040 0.030 1.00 21.0-22.0 1.35-1.70 0.10-0.80 0.20-0.25 Cu 0.10-0.80

S32202 { 0.030 2.00 0.040 0.010 1.00 21.5-24.0 1.0-2.80 0.45 0.18-0.26 {

S32205 2205 0.030 2.00 0.030 0.020 1.00 22.0-23.0 4.5-6.5 3.0-3.5 0.14-0.20

S32304 2304 0.030 2.50 0.040 0.030 1.00 21.5-24.5 3.0-5.5 0.05-0.60 0.05-0.20 Cu 0.05-0.60

S32506 { 0.030 1.00 0.040 0.015 0.90 24.0-26.0 5.5-7.2 3.0-3.5 0.08-2.0 W 0.05-0.30

S32550 255 0.040 1.50 0.040 0.030 1.00 24.0-27.0 4.5-6.5 2.9-3.9 0.10-0.25 Cu 1.50-2.50

S32750 2507 0.030 1.20 0.035 0.020 0.80 24.0-26.0 6.0-8.0 3.0-5.0 0.24-0.32 Cu 0.50

S32760 { 0.030 1.00 0.030 0.010 1.00 24.0-26.0 6.0-8.0 3.0-4.0 0.20-0.30 Cu 0.50-1.00,

W 0.50-1.00,

%Cr+3.3x%Mo

+16x%N$40

S32906 { 0.030 0.80-1.50 0.030 0.030 0.50 28.0-30.0 5.8-7.5 1.50-2.60 0.30-0.40 Cu 0.80

S32950 { 0.030 2.00 0.035 0.010 0.60 26.0-29.0 3.5-5.2 1.00-2.50 0.15-0.35

S39277 { 0.025 0.80 0.025 0.002 0.80 24.0-26.0 6.5-8.0 3.0-4.0 0.23-.033 Cu 1.20-2.00,

W 0.80-1.20

Precipitation Hardening Grades

S15700 632 0.09 1.00 0.040 0.030 1.00 14.0-16.0 6.5-7.7 2.00-3.00 { Al 0.75-1.50

S17400 630 0.07 1.00 0.040 0.030 1.00 15.0-17.0 3.0-5.0{{ Cu 3.0-5.0,

Cb +Ta 0.15-0.45

S17600 635 0.08 1.00 0.040 0.030 1.00 16.0-17.5 6.0-7.5{{ Al 0.40,

Ti 0.40-1.20

S17700 631 0.09 1.00 0.040 0.030 1.00 16.0-18.0 6.5-7.7{{ Al 0.75-1.50

S35500 634 0.10-0.15 0.50-1.25 0.040 0.030 0.50 15.0-16.0 4.0-5.0 2.5-3.2 0.07-0.13 Cb 0.10-0.50

A

Maximum or range unless otherwise indicated.

B

See Guide A959/A959M.

A

TABLE 2 Solution Treatment and Mechanical Property Requirements for PH Grades

Mechanical Property Requirements in the Solution Treated Condition

Elongation

D

Solution Hardness

UNS

Tensile in 2” Reduction

B,C

Type Treatment

Yield Strength

Designation

Strength [50 mm] of Area,

°F [°C]

ksi [MPa] Rockwell, Brinell,

ksi [MPa] or 4D, min. %

maximum maximum

min. %

S15700 632 {{{{{ 100 HRB 269

S17400 630 Cool to below {{{{ 38 HRC 363

90 [32]

S17600 635 Air Cool 120 [825] 75 [515] 10 45 32 HRC 302

S17700 631 {{{{{ 98 HRB 229

S35500 634 Hold at# -100 {{{{{ 363

[-73] for at

least 3 hours

A

Values shown are minimums or ranges unless maximum is indicated.

B

1900 [1040] ± 25°F [15°C].

C

Quenched in water unless the table specifies another media.

D

Either Rockwell or Brinell testing is permitted unless thickness is below ⁄2 ” in which case Rockwell is preferred.

marking, terminology, testing, certification, optional supple- shall be at the option of the manufacturer unless otherwise

mentary requirements, and others. Failure to comply with the specified in the purchase order or contract.

requirements of Specification A962/A962M constitutes non-

5.2 Fasteners shall be produced in accordance with this

conformance with this specification. In case of conflict be-

specification and the requirements of A962/A962M.

tween the requirements of this specification and Specification

6. Chemical Composition

A962/A962M, this specification shall prevail.

6.1 Each alloy shall conform to the chemical composition

5. Materials and Manufacture

requirements prescribed in Table 1.

5.1 Bars shall be produced in accordance with Specifica-

7. Heat Treatment

tions A276/A276M, A479/A479M or A564/A564M as appli-

cable. Finish (hot or cold, ground, rough turned, drawn, etc.) 7.1 Precipitation Hardening (PH) Stainless Steels:

A1082/A1082M−12

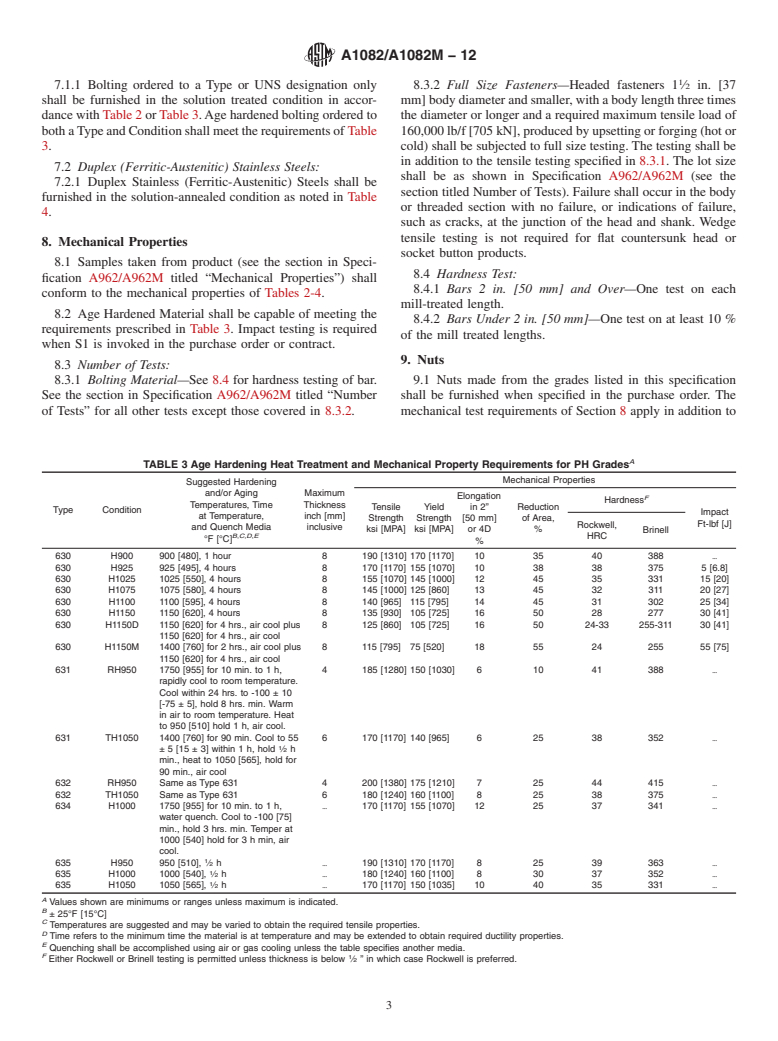

7.1.1 Bolting ordered to a Type or UNS designation only 8.3.2 Full Size Fasteners—Headed fasteners 1 ⁄2 in. [37

shall be furnished in the solution treated condition in accor- mm] body diameter and smaller, with a body length three times

dance with Table 2 or Table 3.Age hardened bolting ordered to the diameter or longer and a required maximum tensile load of

bothaTypeandConditionshallmeettherequirementsofTable 160,000 lb/f [705 kN], produced by upsetting or forging (hot or

3. cold) shall be subjected to full size testing. The testing shall be

in addition to the tensile testing specified in 8.3.1. The lot size

7.2 Duplex (Ferritic-Austenitic) Stainless Steels:

shall be as shown in Specification A962/A962M (see the

7.2.1 Duplex Stainless (Ferritic-Austenitic) Steels shall be

section titled Number of Tests). Failure shall occur in the body

furnished in the solution-annealed condition as noted in Table

or threaded section with no failure, or indications of failure,

4.

such as cracks, at the junction of the head and shank. Wedge

tensile testing is not required for flat countersunk head or

8. Mechanical Properties

socket button products.

8.1 Samples taken from product (see the section in Speci-

8.4 Hardness Test:

fication A962/A962M titled “Mechanical Properties”) shall

8.4.1 Bars 2 in. [50 mm] and Over—One test on each

conform to the mechanical properties of Tables 2-4.

mill-treated length.

8.2 Age Hardened Material shall be capable of meeting the

8.4.2 Bars Under 2 in. [50 mm]—One test on at least 10 %

requirements prescribed in Table 3. Impact testing is required

of the mill treated lengths.

when S1 is invoked

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.