ASTM C1128-01(2008)

(Guide)Standard Guide for Preparation of Working Reference Materials for Use in Analysis of Nuclear Fuel Cycle Materials

Standard Guide for Preparation of Working Reference Materials for Use in Analysis of Nuclear Fuel Cycle Materials

SIGNIFICANCE AND USE

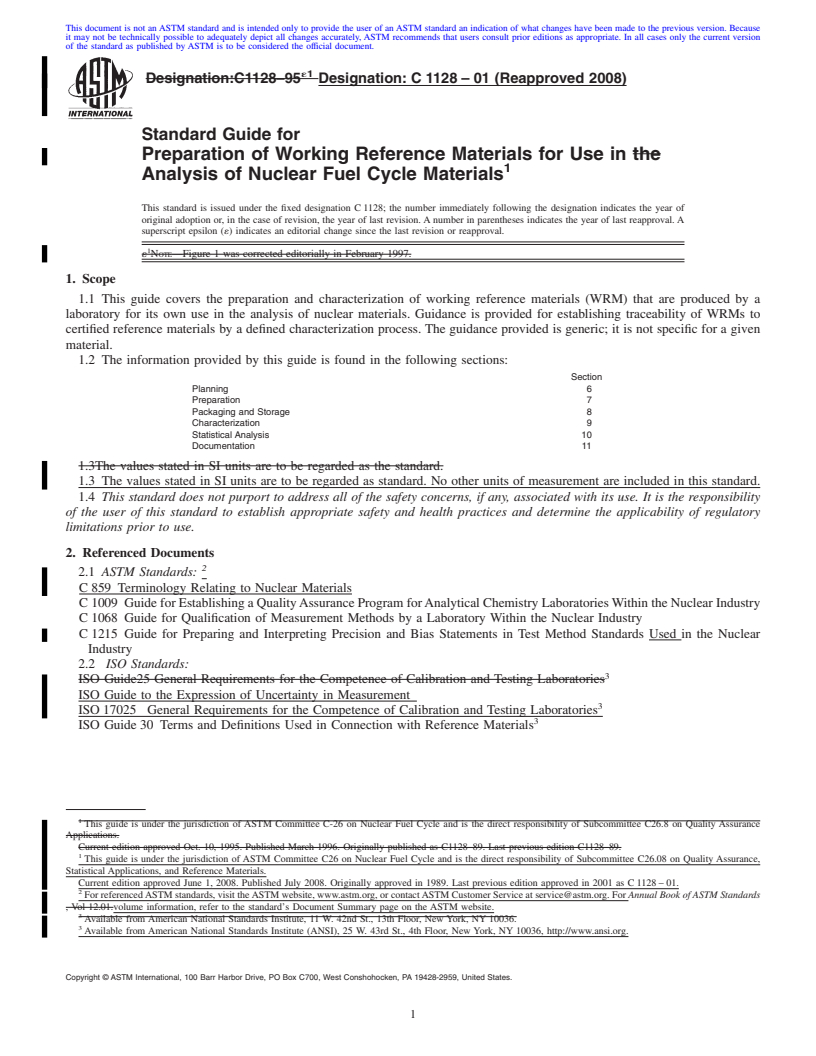

Certified reference materials (CRMs) prepared from nuclear materials are generally of high purity, possessing chemical stability or reproducible stoichiometry. Usually they are certified using the most unbiased and precise measurement methods available, often with more than one laboratory being involved in making certification measurements. CRMs are generally used on a national or international level, and they are at the top of the metrological hierarchy of reference materials. A graphical representation of a national nuclear measurement system is shown in Fig. 3.

Working reference materials (WRMs) need to have quality characteristics that are similar to CRMs, although the rigor used to achieve those characteristics is not usually as stringent as for CRMs. Where possible, CRMs are often used to calibrate the methods used for establishing the concentration values (reference values) assigned to WRMs, thus providing traceability to CRMs as required by ISO 17025. A WRM is normally prepared for a specific application.

Because of the importance of having highly reliable measurement data from nuclear materials, particularly for control and accountability purposes, CRMs are sometimes used for calibration when available. However, CRMs prepared from nuclear materials are not always available for specific applications. Thus, there may be a need for a laboratory to prepare WRMs from nuclear materials. Also, CRMs are often too expensive, or their supply is too limited for use in the quantities needed for long-term, routine use. When properly prepared, WRMs will serve equally well as CRMs for most applications, and using WRMs will preserve supplies of CRMs.

Difficulties may be encountered in the preparation of RMs from nuclear materials because of the chemical and physical properties of the materials. Chemical instabilities, problems in ensuring stoichiometry, and radioactivity are factors involved, with all three factors being involved with some materials. Those preparing ...

SCOPE

1.1 This guide covers the preparation and characterization of working reference materials (WRM) that are produced by a laboratory for its own use in the analysis of nuclear materials. Guidance is provided for establishing traceability of WRMs to certified reference materials by a defined characterization process. The guidance provided is generic; it is not specific for a given material.

1.2 The information provided by this guide is found in the following sections:

Section Planning 6 Preparation 7 Packaging and Storage 8 Characterization 9 Statistical Analysis10 Documentation11

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1128 − 01(Reapproved 2008)

Standard Guide for

Preparation of Working Reference Materials for Use in

Analysis of Nuclear Fuel Cycle Materials

This standard is issued under the fixed designation C1128; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope a Laboratory Within the Nuclear Industry

C1215Guide for Preparing and Interpreting Precision and

1.1 This guide covers the preparation and characterization

Bias Statements in Test Method Standards Used in the

of working reference materials (WRM) that are produced by a

Nuclear Industry

laboratory for its own use in the analysis of nuclear materials.

2.2 ISO Standards:

Guidance is provided for establishing traceability ofWRMs to

ISO Guide to the Expression of Uncertainty in Measure-

certified reference materials by a defined characterization

ment

process.The guidance provided is generic; it is not specific for

ISO17025General Requirements for the Competence of

a given material.

Calibration and Testing Laboratories

1.2 The information provided by this guide is found in the

ISO Guide30Terms and Definitions Used in Connection

following sections: 3

with Reference Materials

Section

Planning 6

3. Terminology

Preparation 7

3.1 Definitions of Terms Specific to This Standard:

Packaging and Storage 8

Characterization 9

3.1.1 certified reference material (CRM) —a reference ma-

Statistical Analysis 10

terial with one or more property values that are certified by a

Documentation 11

technically valid procedure, accompanied by or traceable to a

1.3 The values stated in SI units are to be regarded as

certificate or other documentation that is issued by a certifying

standard. No other units of measurement are included in this

body (as defined by ISO Guide30). A certifying body is a

standard.

technically competent body (organization or firm, public or

1.4 This standard does not purport to address all of the

private) that issues a reference material certificate (as defined

safety concerns, if any, associated with its use. It is the

by ISO Guide30). A reference material certificate is a docu-

responsibility of the user of this standard to establish appro-

ment certifying one or more property values for a certified

priate safety and health practices and determine the applica-

reference material, stating that the necessary procedures have

bility of regulatory limitations prior to use.

been carried out to establish their validity (as defined by ISO

Guide30).

2. Referenced Documents

3.1.2 reference material (RM) —amaterialorsubstanceone

2.1 ASTM Standards:

or more properties of which are sufficiently well established to

C859Terminology Relating to Nuclear Materials

be used for the calibration of an apparatus, the assessment of a

C1009Guide for Establishing a QualityAssurance Program

measurement method, or assigning values to materials (as

forAnalytical Chemistry Laboratories Within the Nuclear

defined by ISO Guide30). A reference material may be

Industry

referred to in this guide also as a standard, such as calibration

C1068Guide for Qualification of Measurement Methods by

standard or control standard.

3.1.3 working reference material (WRM) —a RM usually

prepared by a single laboratory for its own use as a calibration

This guide is under the jurisdiction ofASTM Committee C26 on Nuclear Fuel

standard, as a control standard, or for the qualification of a

Cycle and is the direct responsibility of Subcommittee C26.08 on Quality

Assurance, Statistical Applications, and Reference Materials.

measurementmethod(seeGuideC1068)asindicatedinFig.1.

CurrenteditionapprovedJune1,2008.PublishedJuly2008.Originallyapproved

in 1989. Last previous edition approved in 2001 as C1128–01. DOI: 10.1520/

C1128-01R08. Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 4th Floor, New York, NY 10036, http://www.ansi.org.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM See C859 for other terms specific to the nuclear fuel cycle.

Standards volume information, refer to the standard’s Document Summary page on It is important that a well defined uncertainty in the stated value(s) be given in

the ASTM website. the certificate.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1128 − 01 (2008)

FIG. 1 Quality Assurance of Analytical Laboratory Data

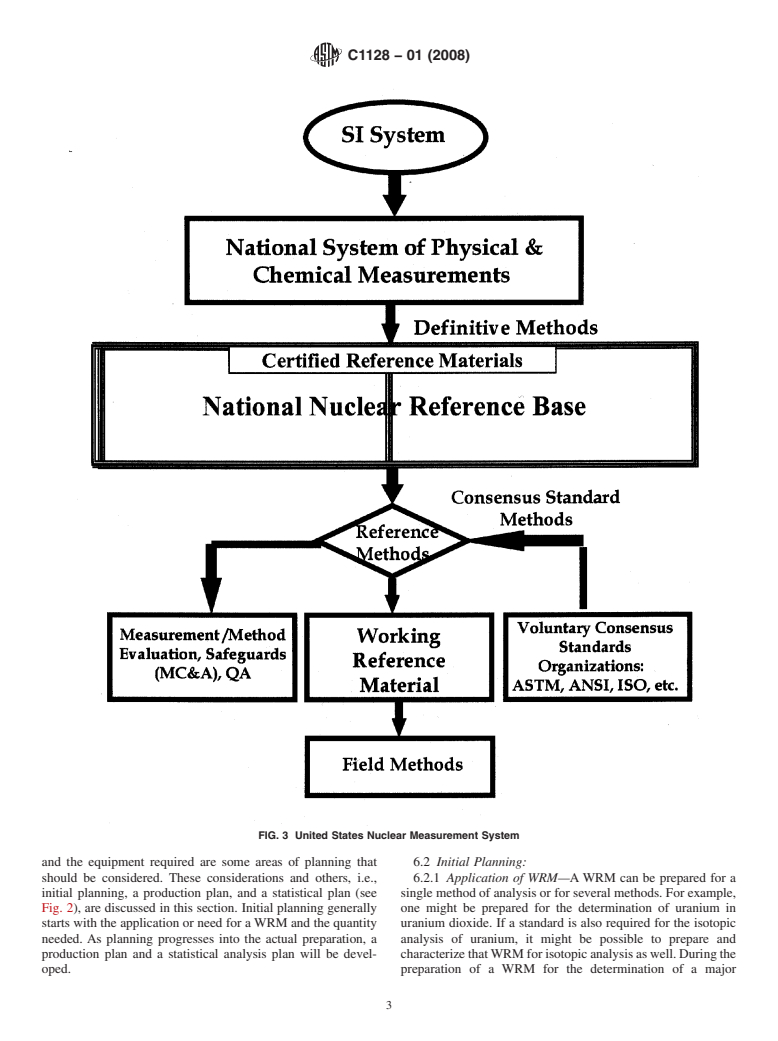

4. Summary of Guide

4.1 This guide covers the preparation of WRMs from

nuclear fuel cycle materials. These materials are compounds

and metal of uranium and plutonium, absorber materials such

asboroncarbide,andcladdingmaterialssuchaszirconiumand

stainless steel. The criteria governing the preparation of reli-

ableWRMs are identified and discussed. Because this guide is

FIG. 2 Producing a Working Reference Material

generic, requirements and detailed information for specific

nuclear materials are not given.Aflow diagram to illustrate an

from nuclear materials are not always available for specific

approach to producing WRMs is given in Fig. 2.

applications. Thus, there may be a need for a laboratory to

prepare WRMs from nuclear materials. Also, CRMs are often

5. Significance and Use

too expensive, or their supply is too limited for use in the

5.1 Certified reference materials (CRMs) prepared from

quantities needed for long-term, routine use. When properly

nuclear materials are generally of high purity, possessing

prepared, WRMs will serve equally well as CRMs for most

chemical stability or reproducible stoichiometry. Usually they

applications, and using WRMs will preserve supplies of

are certified using the most unbiased and precise measurement

CRMs.

methods available, often with more than one laboratory being

5.4 Difficulties may be encountered in the preparation of

involved in making certification measurements. CRMs are

RMs from nuclear materials because of the chemical and

generallyusedonanationalorinternationallevel,andtheyare

physical properties of the materials. Chemical instabilities,

at the top of the metrological hierarchy of reference materials.

problems in ensuring stoichiometry, and radioactivity are

A graphical representation of a national nuclear measurement

factors involved, with all three factors being involved with

system is shown in Fig. 3.

some materials. Those preparing WRMs from nuclear materi-

5.2 Working reference materials (WRMs) need to have

als must be aware of how these factors affect preparation, as

quality characteristics that are similar to CRMs, although the

well as being aware of the other criteria governing the

rigor used to achieve those characteristics is not usually as

preparation of reliable WRMs.

stringent as for CRMs. Where possible, CRMs are often used

tocalibratethemethodsusedforestablishingtheconcentration 6. Planning

values (reference values) assigned to WRMs, thus providing

6.1 Producing a WRM requires forethought to ensure the

traceability to CRMs as required by ISO 17025. A WRM is

credibility of the completed WRM. Planning also ensures that

normally prepared for a specific application.

the necessary resources are available. Time, funding, and

5.3 Because of the importance of having highly reliable materials can be wasted easily without thorough planning.

measurement data from nuclear materials, particularly for Planning should include developing an outline or general

control and accountability purposes, CRMs are sometimes scheme for preparing the WRM. The intended use of the

used for calibration when available. However, CRMs prepared WRM, the sources available for obtaining needed materials,

C1128 − 01 (2008)

FIG. 3 United States Nuclear Measurement System

and the equipment required are some areas of planning that 6.2 Initial Planning:

should be considered. These considerations and others, i.e., 6.2.1 Application of WRM—AWRM can be prepared for a

initial planning, a production plan, and a statistical plan (see singlemethodofanalysisorforseveralmethods.Forexample,

Fig. 2), are discussed in this section. Initial planning generally one might be prepared for the determination of uranium in

starts with the application or need for aWRM and the quantity uranium dioxide. If a standard is also required for the isotopic

needed. As planning progresses into the actual preparation, a analysis of uranium, it might be possible to prepare and

production plan and a statistical analysis plan will be devel- characterizethatWRMforisotopicanalysisaswell.Duringthe

oped. preparation of a WRM for the determination of a major

C1128 − 01 (2008)

constituent, it might be possible to add desired impurities and Appendix X1). Characterization may include the analysis of

to establish values for those impurities. Careful consideration starting materials for impurities and major constituents. It

should be given to the preparation of multi-purpose WRMs, should include a scheme for establishing the value to be

however, because they tend to be difficult to prepare and assigned (reference value) to each constituent of interest. In

characterize. planning for characterization, consideration must be given to

thedegreeofreliabilityrequiredforareferencevalue.Thiswill

6.2.2 Quantity—The quantity of WRM prepared will de-

involve planning for the statistical collection and analysis of

pend on such factors as the length of time required for its use,

characterization data (see 6.4).

the frequency of use, the amount of material available, and the

6.3.5 Packaging—Packaging of the WRM should be

WRM’santicipatedshelflife.Considerationshouldbegivento

planned.Decisionsneedtobemadeconcerning thedivisionof

the amount of WRM that will be needed for characterization

the WRM into portions, selecting containers, uniquely identi-

and for archival purposes. Needs may develop during the use

of a WRM such as the exchange of materials with another fying containers, sealing containers, and using additional

meanstoprotecttheintegrityoftheWRM.Itmaybenecessary

laboratory for an interlaboratory testing program. For this and

otherpossiblecontingencies,thepreparationofaquantityover to package some WRMs soon after preparation to preserve

integrity; in that case, packaging materials and equipment

the anticipated amount should be planned.

should be readied prior to material preparation. Inadequate

6.3 Production Plan—An outline that specifies how the

packaging may lead to loss of the WRM’s integrity through

WRM will be produced should be prepared during planning.

such consequences as contamination, evaporation, degradation

The subjects discussed in 6.2 and in this section should be

and absorption.

considered and addressed if appropriate. A preparation proce-

6.4 Statistical Plan—A statistical plan for characterization

dure should be written and included as a part of the production

should be developed during planning. Such a plan is necessary

plan(see7.4).Theproductionplanmustbeintegratedwiththe

to allow an uncertainty to be determined for each reference

statistical plan (see 6.4).

value.Thestatisticalplanestablisheshowcharacterizationwill

6.3.1 Materials—The selection of materials is an important

be done. It includes sampling of the WRM, the frequency and

part of planning because proper selection is critical to achiev-

number of measurements to be made of the WRM, any

ingcredibleWRMs.Selectiondependsonavailability(source),

reference material to be measured with the WRM, and the

cost, chemical and physical properties, and stability or repro-

order of measurements (see 9.3 and 9.4). The validation or

ducible stoichiometry. The material selected for a WRM must

calibration of the measurement method to be used for charac-

beassimilaraspossibletothesamplematerialinchemicaland

terization may be addressed in the plan also (see 9.2.3). It is

physical properties, particularly in those that will affect the

essential to have a qualified statistician involved in developing

method of analysis. One way to achieve similarity in compo-

the plan, and the statistician should be brought into the

sition is to prepare the WRM material by the same or similar

planning process early (see Fig. 2). Developing a statistical

processusedtopreparethesamplematerial.Probablythemost

planisaniterativeprocessthatwillgoonthroughoutplanning,

important criterion for selection is stability. The WRM com-

and it must be integrated with the production plan (see 6.3).

position must be sufficiently stable to make the preparation of

the WRM cost effective, and the stability must be known well

7. WRM Preparation

enough to establish a shelf life with a high degree of confi-

7.1 The objective of preparation is to make physical and

dence.Somewhatunstablematerialswhosestoichiometriescan

chemical manipulations so as to produce a homogeneous and

be reproduced easily can be used for WRMs.

stable material in the form required for a WRM. For a given

6.3.2 Equipment—Generally,standardlaboratoryequipment

WRM, the physical and chemical manipulations that will be

will be involved in preparing a WRM. Analytical setups and

used depend on the starting material(s), the WRM form

instrumentation will be required, possibly to analyze starting

required, and the physical and chemical properties of the

materials for impurities and other constituents and certainly to

materials involved. Various aspects of preparation are dis-

analyze the prepared material during final characterization of

cussed in this section.

the WRM. Depending on packaging requirements, equipment

7.2 StartingMaterials—Thestartingmaterialsfortheprepa-

may be required for such things as sealing glass ampoules or

ration of WRMs may be the WRM forms desired or may be

packaging a WRM in a special atmosphere.

other materials that are processed into those forms. In the

6.3.3 Use—The degree of attention given to some steps in

former case, the starting material is process material. For

producing a WRM may vary depending on its planned use.

example, a batch of uranium dioxide pellets, boron carbide

Usually, WRMs are used for calibration and measurement

powder, or plutonium nitrate solution might be taken directly

control.Acommonapproachtoproducingacontrolstandardis

from a process run, treated as necessary, characterized, and

to take material from a batch of production material, treat it as

packaged as aWRM. In the latter case, various approaches are

necessarytoensurehomogeneity,andestablishinitialmeasure-

used to produce the form desired. For ex

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation:C1128–95 Designation:C1128–01 (Reapproved 2008)

Standard Guide for

Preparation of Working Reference Materials for Use in the

Analysis of Nuclear Fuel Cycle Materials

This standard is issued under the fixed designation C1128; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—Figure 1 was corrected editorially in February 1997.

1. Scope

1.1 This guide covers the preparation and characterization of working reference materials (WRM) that are produced by a

laboratory for its own use in the analysis of nuclear materials. Guidance is provided for establishing traceability of WRMs to

certified reference materials by a defined characterization process. The guidance provided is generic; it is not specific for a given

material.

1.2 The information provided by this guide is found in the following sections:

Section

Planning 6

Preparation 7

Packaging and Storage 8

Characterization 9

Statistical Analysis 10

Documentation 11

1.3The values stated in SI units are to be regarded as the standard.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

C859 Terminology Relating to Nuclear Materials

C1009 GuideforEstablishingaQualityAssuranceProgramforAnalyticalChemistryLaboratoriesWithintheNuclearIndustry

C1068 Guide for Qualification of Measurement Methods by a Laboratory Within the Nuclear Industry

C1215 Guide for Preparing and Interpreting Precision and Bias Statements in Test Method Standards Used in the Nuclear

Industry

2.2 ISO Standards:

ISO Guide25 General Requirements for the Competence of Calibration and Testing Laboratories

ISO Guide to the Expression of Uncertainty in Measurement

ISO17025 General Requirements for the Competence of Calibration and Testing Laboratories

ISO Guide30 Terms and Definitions Used in Connection with Reference Materials

This guide is under the jurisdiction of ASTM Committee C-26 on Nuclear Fuel Cycle and is the direct responsibility of Subcommittee C26.8 on Quality Assurance

Applications.

Current edition approved Oct. 10, 1995. Published March 1996. Originally published as C1128–89. Last previous edition C1128–89.

This guide is under the jurisdiction of ASTM Committee C26 on Nuclear Fuel Cycle and is the direct responsibility of Subcommittee C26.08 on Quality Assurance,

Statistical Applications, and Reference Materials.

Current edition approved June 1, 2008. Published July 2008. Originally approved in 1989. Last previous edition approved in 2001 as C1128–01.

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.ForAnnualBookofASTMStandards

, Vol 12.01.volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from American National Standards Institute, 11 W. 42nd St., 13th Floor, New York, NY 10036.

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C1128–01 (2008)

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 certified reference material (CRM) —a reference material with one or more property values that are certified by a

technicallyvalidprocedure,accompaniedbyortraceabletoacertificateorotherdocumentationthatisissuedbyacertifyingbody

(asdefinedbyISOGuide30).Acertifyingbodyisatechnicallycompetentbody(organizationorfirm,publicorprivate)thatissues

areferencematerialcertificate(asdefinedbyISOGuide30).SuchanorganizationcouldbetheNationalInstituteofStandardsand

Technology (NIST) or the New Brunswick Laboratory. A reference material certificate is a document certifying one or more

property values for a certified reference material, stating that the necessary procedures have been carried out to establish their

validity (as defined by ISO Guide30).Areference material certificate is a document certifying one or more property values for a

certified reference material, stating that the necessary procedures have been carried out to establish their validity (as defined by

ISO Guide30).

3.1.2 reference material (RM) —a material or substance one or more properties of which are sufficiently well established to be

used for the calibration of an apparatus, the assessment of a measurement method, or assigning values to materials (as defined by

ISO Guide30). A reference material may be referred to in this guide also as a standard, such as calibration standard or control

standard.

3.1.3 working reference material (WRM) —a RM usually prepared by a single laboratory for its own use as a calibration

standard, as a control standard, or for the qualification of a measurement method (see Guide C1068) as indicated in Fig. 1.

4. Summary of Guide

4.1 This guide covers the preparation of WRMs from nuclear fuel cycle materials. These materials are compounds and metal

of uranium and plutonium, absorber materials such as boron carbide, and cladding materials such as zirconium and stainless steel.

The criteria governing the preparation of reliableWRMs are identified and discussed. Because this guide is generic, requirements

anddetailedinformationforspecificnuclearmaterialsarenotgiven.AflowdiagramtoillustrateanapproachtoproducingWRMs

is given in Fig. 2.

5. Significance and Use

5.1 Certified reference materials (CRMs) prepared from nuclear materials are generally of high purity, possessing chemical

stability or reproducible stoichiometry. Usually they are certified using the most unbiased and precise measurement methods

available, often with more than one laboratory being involved in making certification measurements. CRMs are generally used on

It is important that some well defined indication of the uncertainty in the stated values be given in the certificate.

See C859 for other terms specific to the nuclear fuel cycle.

Based on NUREG-0118 (also designated LA-NUREG-6348), Preparation of Working Calibration and Test Materials: Plutonium Nitrate Solution, Nuclear Regulatory

Commission. Available from the Superintendent of Documents, U.S. Government Printing Office, Washington, DC 20402.

It is important that a well defined uncertainty in the stated value(s) be given in the certificate.

FIG. 1 Quality Assurance of Analytical Laboratory Data

C1128–01 (2008)

FIG. 2 Producing a Working Reference Material

a national or international level, and they are at the top of the metrological hierarchy of reference materials. A graphic

descriptiongraphical representation of the United Statesa national nuclear measurement system is shown in Fig. 3.

5.2 Workingreferencematerials(WRMs)needtohavequalitycharacteristicsthataresimilartoCRMs,althoughtherigorused

to achieve those characteristics is not usually as stringent as for CRMs. Where possible, CRMs are often used to calibrate the

methodsusedforestablishingtheconcentrationvalues(referencevalues)assignedtoWRMs,thusprovidingtraceabilitytoCRMs

as required by ISO 17025. A WRM is normally prepared for a specific application.

5.3 Because of the importance of having highly reliable measurement data from nuclear materials, particularly for control and

accountability purposes, CRMs are sometimes used for calibration when available. However, CRMs prepared from nuclear

materials are not always available for specific applications. Thus, there may be a need for a laboratory to prepare WRMs from

nuclearmaterials.Also,CRMsareoftentooexpensive,ortheirsupplyistoolimitedforuseinthequantitiesneededforlong-term,

routine use. When properly prepared, WRMs will serve equally well as CRMs for most applications, and using WRMs will

preserve supplies of CRMs.

5.4 Difficulties may be encountered in the preparation of RMs from nuclear materials because of the chemical and physical

properties of the materials. Chemical instabilities, problems in ensuring stoichiometry, and radioactivity are factors involved, with

all three factors being involved with some materials. Those preparing WRMs from nuclear materials must be aware of how these

factors affect preparation, as well as being aware of the other criteria governing the preparation of reliable WRMs.

6. Planning

6.1 Producing aWRM requires forethought before the work starts to ensure that the credibility of the completedWRM will be

established. WRM. Planning is also important to ensure ensures that the necessary resources are available. Time, funding, and

materials can be wasted easily without thorough planning, whichplanning. Planning should include developing an outline or

general scheme for preparing theWRM.The intended use of theWRM, the sources available for obtaining needed materials, and

the equipment required are some areas of planning that mustshould be considered. These considerations and others are discussed

in this section in terms ofothers, i.e., initial planning, a production plan, and a statistical plan (see Fig. 2), are discussed in this

section. Initial planning generally starts with the application or need for a WRM and the quantity needed.As planning progresses

into the actual preparation, a production plan and a statistical analysis plan will be developed.

C1128–01 (2008)

FIG. 3 United States Nuclear Measurement System

6.2 Initial Planning:

6.2.1 Application of WRM—AWRM can be prepared for a single method of analysis or for several methods. For example, one

might be prepared for the determination of uranium in uranium dioxide. If a standard is also required for the isotopic analysis of

uranium, it might be possible to prepare and characterize that WRM for isotopic analysis as well. In situations involving the

determination of impurities, it may or may not be desirable to prepare WRMs. Often, determinations of impurities do not require

highly reliable results, and the preparation of a WRM might not be cost effective.Areference material lower in the metrological

hierarchy could be adequate. On the other hand, during the preparation of a WRM for the determination of a major constituent,

it might be possible to add desired impurities and to establish values for those impurities.This would give a multi-purposeWRM.

C1128–01 (2008)

Careful consideration should be given to the preparation of multi-purpose WRMs, however, because they tend to be difficult to

prepare and characterize. —A WRM can be prepared for a single method of analysis or for several methods. For example, one

might be prepared for the determination of uranium in uranium dioxide. If a standard is also required for the isotopic analysis of

uranium,itmightbepossibletoprepareandcharacterizethatWRMforisotopicanalysisaswell.DuringthepreparationofaWRM

for the determination of a major constituent, it might be possible to add desired impurities and to establish values for those

impurities. Careful consideration should be given to the preparation of multi-purpose WRMs, however, because they tend to be

difficult to prepare and characterize.

6.2.2 Quantity—The quantity of WRM prepared will depend on such factors as the length of time required for its use, the

frequency of use, the amount of material available, and its theWRM’s anticipated shelf life. Consideration should be given to the

amount of WRM that will be needed for characterization and perhaps for archival purposes. Needs may develop during the use

of a WRM such as the exchange of materials with another laboratory for an interlaboratory testing program. For this and other

possible contingencies, the preparation of a quantity over the anticipated amount should be planned.

6.3 Production Plan—An outline should be prepared during planning that specifies how theWRM will be produced should be

preparedduringplanning.Thesubjectsdiscussedin6.2andinthissectionmustshouldbeconsideredandaddressedifappropriate.

A preparation procedure should be written and included as a part of the production plan (see 7.4). The production plan must be

integrated with the statistical plan (see 6.4).

6.3.1 Materials—The selection of materials is an important part of planning because proper selection is critical to achieving

credible WRMs. Selection depends on availability (source), cost, chemical and physical properties, and stability or reproducible

stoichiometry. The material selected for a WRM must be as similar as possible to the sample material in chemical and physical

properties, particularly in those that will affect the method of analysis. One way to achieve similarity in composition is to prepare

the WRM material by the same or similar process used to prepare the sample material. Probably the most important criterion for

selection is stability. The WRM composition must be sufficiently stable to make the preparation of the WRM cost effective, and

the stability must be known well enough to establish a shelf life with a high degree of confidence. Somewhat unstable materials

whose stoichiometries can be reproduced easily can be used for WRMs.

6.3.2 Equipment—Generally, standard laboratory equipment will be involved in preparing a WRM. Analytical setups and

instrumentationwillberequired,possiblytoanalyzestartingmaterialsforimpuritiesandotherconstituentsandcertainlytoanalyze

the prepared material during final characterization of the WRM. Depending on packaging requirements, equipment may be

required for such things as sealing glass ampoules or packaging a WRM in a special atmosphere.

6.3.3 Use—The degree of attention given to some steps in producing aWRM may vary depending on its planned use. Usually,

WRMs are used for calibration and measurement control.Acommon approach to producing a control standard is to take material

from a batch of production material, treat it as necessary to ensure homogeneity, and establish initial measurement control limits

b

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.