ASTM D3704-96(2001)

(Test Method)Standard Test Method for Wear Preventive Properties of Lubricating Greases Using the (Falex) Block on Ring Test Machine in Oscillating Motion

Standard Test Method for Wear Preventive Properties of Lubricating Greases Using the (Falex) Block on Ring Test Machine in Oscillating Motion

SCOPE

1.1 This test method covers the determination of wear properties of lubricating greases by means of the Falex block-on-ring friction and wear test machine.

1.2 The values stated in SI units are to be regarded as standard except where equipment is supplied using inch-pound units and would then be regarded as standard. The metric equivalents of inch-pound units given in such cases in the body of the standard may be approximate.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D3704–96 (Reapproved 2001)

Standard Test Method for

Wear Preventive Properties of Lubricating Greases Using

the (Falex) Block on Ring Test Machine in Oscillating

Motion

This standard is issued under the fixed designation D 3704; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope external force, one body moves or tends to move relative to the

other. G40

1.1 This test method covers the determination of wear

3.1.3 kinetic coeffıcient of friction, n—the coefficient of

properties of lubricating greases by means of the Falex

friction under conditions of macroscopic relative motion be-

block-on-ring friction and wear test machine.

tween two bodies. G40

1.2 The values stated in SI units are to be regarded as

3.1.4 wear, n—damage to a solid surface, generally involv-

standard except where equipment is supplied using inch-pound

ingprogressivelossofmaterial,duetorelativemotionbetween

units and would then be regarded as standard. The metric

that surface and a contacting substance or substances. G40

equivalents of inch-pound units given in such cases in the body

of the standard may be approximate.

4. Summary of Test Method

1.3 This standard does not purport to address all of the

4.1 The tester is operated with a steel test ring oscillating

safety concerns, if any, associated with its use. It is the

against a steel test block. Test speed, load, angle of oscillation,

responsibility of the user of this standard to establish appro-

time and specimen surface finish and hardness can be varied to

priate safety and health practices and determine the applica-

simulate field conditions.

bility of regulatory limitations prior to use

4.2 The width of the wear scar, developed on the test block

2. Referenced Documents from contact with the oscillating test ring, is measured.

2.1 ASTM Standards:

5. Significance and Use

D 1403 Test Method for Cone Penetration of Lubricating

5.1 This test method is used to differentiate between greases

Grease Using One-Quarter and One-Half Scale Cone

2 having high, medium, and low wear preventive properties

Equipment

using oscillating motion. The user of this method should

D 2714 Test Method for Calibration and Operation of the

2 determine to his own satisfaction whether results of this test

Falex Block-on-Ring Friction and Wear Testing Machine

procedure correlate with field performance or other bench test

3. Terminology machines.

3.1 Definitions:

6. Apparatus

3.1.1 coeffıcient of friction, µ or f, n—in tribology, the

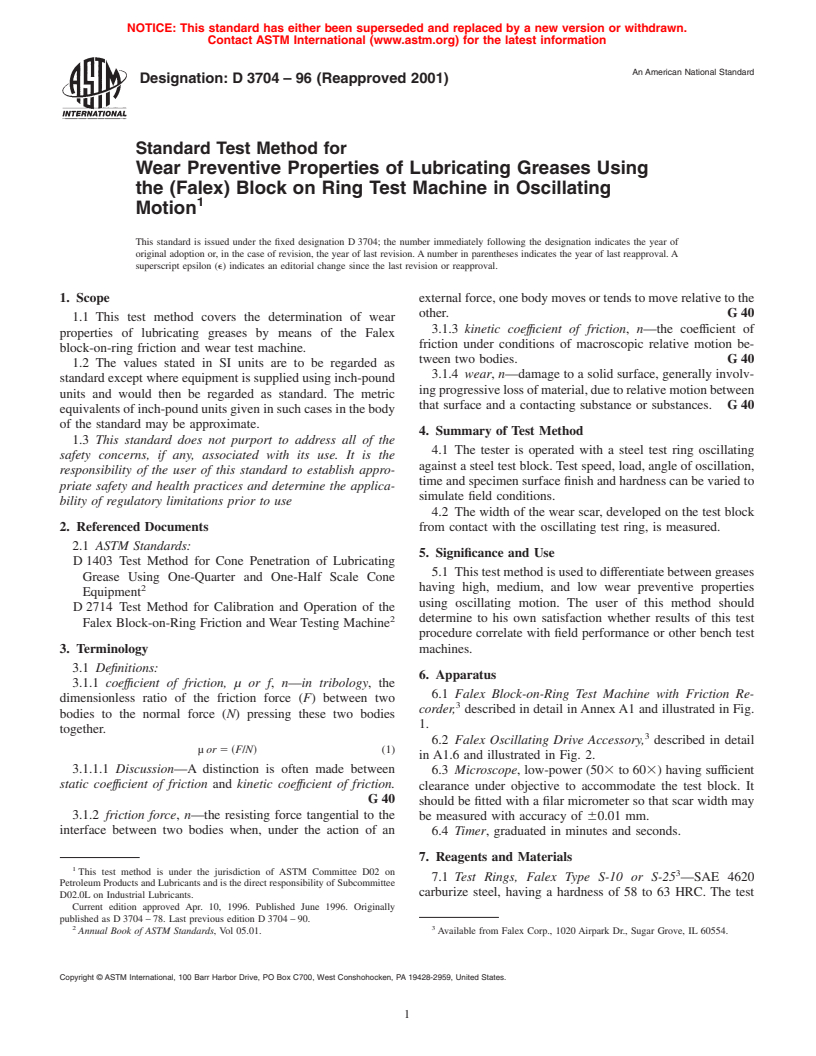

6.1 Falex Block-on-Ring Test Machine with Friction Re-

dimensionless ratio of the friction force (F) between two

corder, described in detail inAnnexA1 and illustrated in Fig.

bodies to the normal force (N) pressing these two bodies

1.

together.

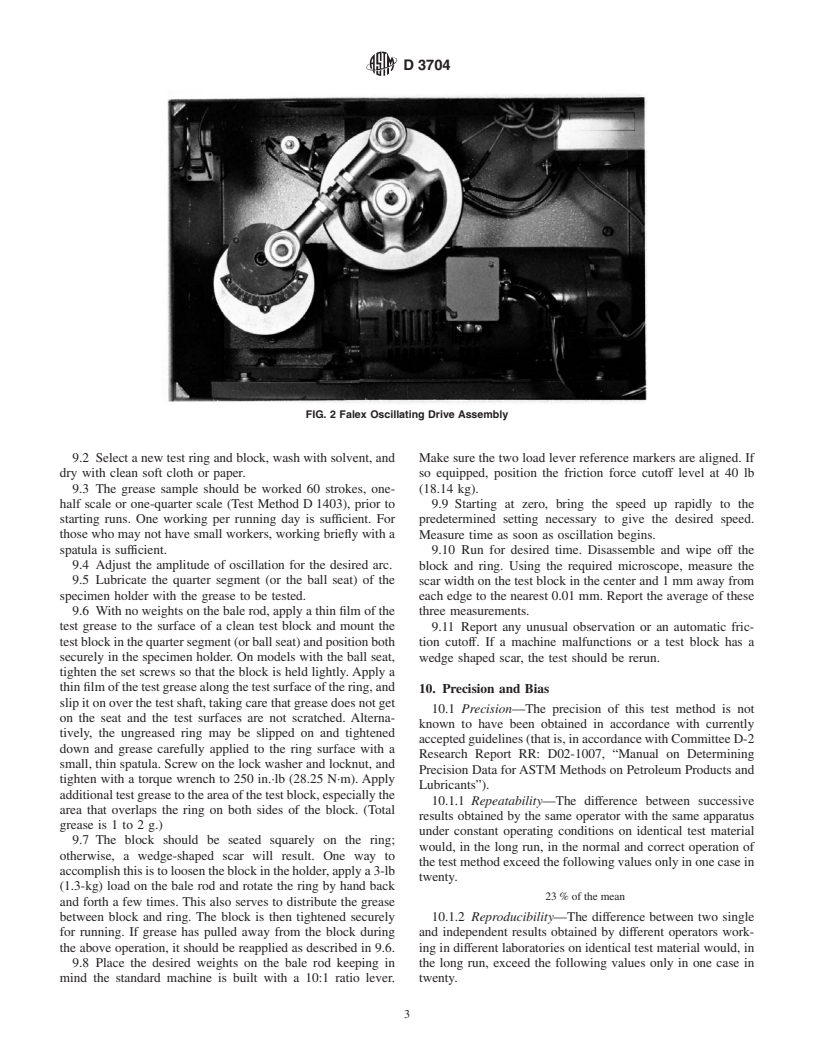

6.2 Falex Oscillating Drive Accessory, described in detail

µ or 5 ~F/N! (1)

in A1.6 and illustrated in Fig. 2.

3.1.1.1 Discussion—A distinction is often made between

6.3 Microscope, low-power (503 to 603) having sufficient

static coeffıcient of friction and kinetic coeffıcient of friction.

clearance under objective to accommodate the test block. It

G40

should be fitted with a filar micrometer so that scar width may

3.1.2 friction force, n—the resisting force tangential to the

be measured with accuracy of 60.01 mm.

interface between two bodies when, under the action of an

6.4 Timer, graduated in minutes and seconds.

7. Reagents and Materials

This test method is under the jurisdiction of ASTM Committee D02 on

7.1 Test Rings, Falex Type S-10 or S-25 —SAE 4620

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

carburize steel, having a hardness of 58 to 63 HRC. The test

D02.0L on Industrial Lubricants.

Current edition approved Apr. 10, 1996. Published June 1996. Originally

published as D 3704 – 78. Last previous edition D 3704 – 90.

2 3

Annual Book of ASTM Standards, Vol 05.01. Available from Falex Corp., 1020 Airpark Dr., Sugar Grove, IL 60554.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D3704

FIG. 1 Falex Block on Ring Test Machine

FIG. 1 Falex Ring and Block Test Machine (continued)

due to possible toxic effects. Each user should select a solvent that can

ring has a width of 8.15 mm (0.321 in.), a diameter of 35 mm

meethisapplicablesafetystandardsandstillthoroughlycleanthemachine

(1.3775 in.) and a maximum radial run out of 0.013 mm

parts.

(0.0005 in.). The surface roughness of the S-10 ring shall be

0.15–0.30 µm (6 to 12 µin.) rms. The surface roughness of the

8. Calibration and Standardization

S-25 ring shall be 0.51 to 0.71 µm (22 to 28 µin.) rms.

8.1 Run Test Method D 2714 calibration procedure to en-

7.2 Test Blocks, Falex Type H-30 or H-60 —SAE 01 tool

sure good mechanical operation of test equipment.

steel having two ground test surfaces of 0.10–0.20 µm (4 to 8

µin.) rms. The test block has a width 6.35 mm (0.250 in.) and

9. Procedure

a 15.76 mm (0.620 in.) length. The H-30 test block has a

9.1 Before each test, clean the apparatus with appropriate

hardness of HRC 27 to 33. The H-60 test block has a hardness

solvent chosen in 7.3 and blow dry.

of HRC 58 to 63.

7.3 Solvent, non-film forming, nonchlorinated.

NOTE 1—Solvents formerly used in this test method were eliminated Consult instruction manual for proper operation.

D3704

FIG. 2 Falex Oscillating Drive Assembly

9.2 Select a new test ring and block, wash with solvent, and Make sure the two load lever reference markers are aligned. If

dry with clean soft cloth or paper. so equipped, position the friction force cutoff level at 40 lb

9.3 The grease sample should be worked 60 strokes, one- (18.14 kg).

half scale or one-quarter scale (Test Method D 1403), prior to

9.9 Starting at zero, bring the speed up rapidly to the

starting runs. One working per running day is sufficient. For predetermined setting necessary to give the desired speed.

those who may not have small workers, working briefly with a

Measure time as soon as oscillation begins.

spatula is sufficient. 9.10 Run for desired time. Disassemble and wipe off the

9.4 Adjust the amplitude of oscillation for the desired arc.

block and ring. Using the required microscope, measure the

9.5 Lubricate the quarter segment (or the ball seat) of the scar width on the test block in the center and 1 mm away from

specimen holder with the grease to be tested.

each edge to the nearest 0.01 mm. Report the average of these

9.6 With no weights on the bale rod, apply a thin film of the three measurements.

test grease to the surface of a clean test block and mount the

9.11 Report any unusual observation or an automatic fric-

testblockinthequartersegment(orballseat)andpositionboth tion cutoff. If a machine malfunctions or a test block has a

securely in the specimen holder. On models with the ball seat,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.