ASTM C307-18

(Test Method)Standard Test Method for Tensile Strength of Chemical-Resistant Mortar, Grouts, and Monolithic Surfacings

Standard Test Method for Tensile Strength of Chemical-Resistant Mortar, Grouts, and Monolithic Surfacings

SIGNIFICANCE AND USE

4.1 It is recognized that chemical-resistant mortars, grouts, and monolithic surfacings are not usually under tension when in service; however, such data are useful for purposes of determining the rate of cure and other properties.

4.2 This test method is not recommended for mortars, grouts, and monolithic surfacings containing aggregate greater than 1/4 in.

SCOPE

1.1 This test method covers the determination of tensile strength of cured chemical-resistant materials in the form of molded briquets. These materials include mortars, brick and tile grouts, machinery grouts, and monolithic surfacings. These materials shall be based on resin, silicate, silica, or sulfur binders.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C307 − 18

Standard Test Method for

Tensile Strength of Chemical-Resistant Mortar, Grouts, and

1

Monolithic Surfacings

This standard is issued under the fixed designation C307; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope E177 Practice for Use of the Terms Precision and Bias in

ASTM Test Methods

1.1 This test method covers the determination of tensile

E691 Practice for Conducting an Interlaboratory Study to

strength of cured chemical-resistant materials in the form of

Determine the Precision of a Test Method

molded briquets. These materials include mortars, brick and

tile grouts, machinery grouts, and monolithic surfacings. These

3. Terminology

materials shall be based on resin, silicate, silica, or sulfur

binders. 3.1 Definitions:

3.1.1 For definitions of terms used in this test method, see

1.2 The values stated in inch-pound units are to be regarded

Terminology C904.

as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only

4. Significance and Use

and are not considered standard.

4.1 It is recognized that chemical-resistant mortars, grouts,

1.3 This standard does not purport to address all of the

and monolithic surfacings are not usually under tension when

safety concerns, if any, associated with its use. It is the

in service; however, such data are useful for purposes of

responsibility of the user of this standard to establish appro-

determining the rate of cure and other properties.

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use. 4.2 This test method is not recommended for mortars,

1.4 This international standard was developed in accor-

grouts, and monolithic surfacings containing aggregate greater

1

dance with internationally recognized principles on standard-

than ⁄4 in.

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

5. Apparatus

mendations issued by the World Trade Organization Technical

5.1 Weighing Equipment, shall be capable of weighing

Barriers to Trade (TBT) Committee.

materials or specimens to 60.3 % accuracy.

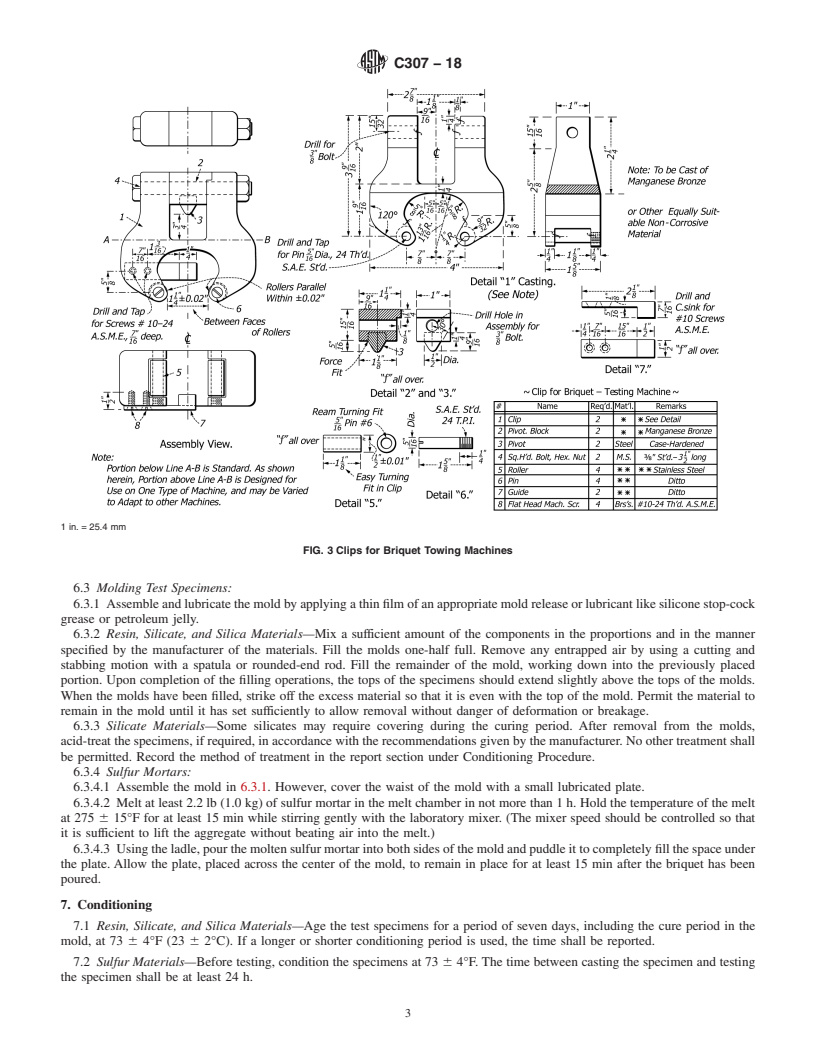

2. Referenced Documents 5.2 Specimen Molds—The molds for making briquet test

2

specimens shall be sufficiently rigid to prevent deformation

2.1 ASTM Standards:

during molding and shall be made of corrosion-resistant

C904 Terminology Relating to Chemical-Resistant Nonme-

material. Gang molds, when used, shall be of the type shown in

tallic Materials

Fig. 1. The dimensions of the briquet molds shall be the width

E4 Practices for Force Verification of Testing Machines

of the mold, between inside faces, at waist line of briquet, 1 in.

The width and the depth of the briquet mold at the waist line

1

This test method is under the jurisdiction of ASTM Committee D01 on Paint

shall be 1 in. 6 0.02in. (25mm 6 0.5mm). The molds shall

and Related Coatings, Materials, and Applications and is the direct responsibility of

conform to the dimensional requirements shown in Fig. 2.

Subcommittee D01.46 on Industrial Protective Coatings.

Current edition approved July 1, 2018. Published November 2018. Originally

5.3 Equipment for Mixing Materials, shall consist of a

published in 1953. Last previous edition approved in 2012 as C307 – 03 (2012).

container of suitable size, preferably corrosion resistant, and a

DOI: 10.1520/C0307-18.

2

strong, sturdy spatula, trowel, or mechanical mixer.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.4 The following additional equipment is required for

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. sulfur mortars.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C307 − 18

5.4.1 Melting Chamber, of sufficient volume and heat ca-

pacity to melt the mortar sample and maintain the temperature

3

of the melt between 260 and 290°F (127 and 143°C).

5.4.2 Laboratory Mixer, of such a type and speed to be

capable of lifting the aggregate without beating air into the

FIG. 1 Briquet Gang Mold

melt.

5.4.3 Ladle, of sufficient capacity to completely pour one

briquet.

5.5 Testing Machine, the testing machine shall be of any

type sufficient to provide the required load and the rate of

crosshead m

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C307 − 03 (Reapproved 2012) C307 − 18

Standard Test Method for

Tensile Strength of Chemical-Resistant Mortar, Grouts, and

1

Monolithic Surfacings

This standard is issued under the fixed designation C307; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 This test method covers the determination of tensile strength of cured chemical-resistant materials in the form of molded

briquets. These materials include mortars, brick and tile grouts, machinery grouts, and monolithic surfacings. These materials shall

be based on resin, silicate, silica, or sulfur binders.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

C904 Terminology Relating to Chemical-Resistant Nonmetallic Materials

E4 Practices for Force Verification of Testing Machines

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Terminology

3.1 Definitions:

3.1.1 For definitions of terms used in this test method, see Terminology C904.

4. Significance and Use

4.1 It is recognized that chemical-resistant mortars, grouts, and monolithic surfacings are not usually under tension when in

service; however, such data are useful for purposes of determining the rate of cure and other properties.

1

4.2 This test method is not recommended for mortars, grouts, and monolithic surfacings containing aggregate greater than ⁄4

in.

5. Apparatus

5.1 Weighing Equipment, shall be capable of weighing materials or specimens to 60.3 % accuracy.

5.2 Specimen Molds—The molds for making briquet test specimens shall be sufficiently rigid to prevent deformation during

molding and shall be made of corrosion-resistant material. Gang molds, when used, shall be of the type shown in Fig. 1. The

1

This test method is under the jurisdiction of ASTM Committee D01 on Paint and Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.46 on Industrial Protective Coatings.

Current edition approved Aug. 1, 2012July 1, 2018. Published September 2012November 2018. Originally published in 1953. Last previous edition approved in 20082012

as C307 – 03 (2008).(2012). DOI: 10.1520/C0307-03R12.10.1520/C0307-18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C307 − 18

FIG. 1 Briquet Gang Mold

dimensions of the briquet molds shall be the width of the mold, between inside faces, at waist line of briquet, 1 in. The width and

the depth of the briquet mold at the waist line shall be 1 in. 6 0.02in. (25mm 6 0.5mm). The molds shall conform to the

dimensional requirements shown in Fig. 2.

5.3 Equipment for Mixing Materials, shall consist of a container of suitable size, preferably corrosion resistant, and a strong,

sturdy spatula, trowel, or mechanical mixer.

5.4 The following additional equipment is required for sulfur mortars.

5.4.1 Melting Chamber, of sufficient volume and heat capacity to melt the mortar sample and maintain the temperature of the

3

melt b

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.