ASTM E910-95

(Test Method)Standard Test Method for Application and Analysis of Helium Accumulation Fluence Monitors for Reactor Vessel Surveillance, E706 (IIIC)

Standard Test Method for Application and Analysis of Helium Accumulation Fluence Monitors for Reactor Vessel Surveillance, E706 (IIIC)

SCOPE

1.1 This test method describes the concept and use of helium accumulation for neutron fluence dosimetry for reactor vessel surveillance. Although this test method is directed toward applications in vessel surveillance, the concepts and techniques are equally applicable to the general field of neutron dosimetry. The various applications of this test method for reactor vessel surveillance are as follows:

1.1.1 Helium accumulation fluence monitor (HAFM) capsules,

1.1.2 Unencapsulated, or cadmium or gadolinium covered, radiometric monitors (RM) and HAFM wires for helium analysis,

1.1.3 Charpy test block samples for helium accumulation, and

1.1.4 Reactor vessel (RV) wall samples for helium accumulation.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 910 – 95

Standard Test Method for

Application and Analysis of Helium Accumulation Fluence

Monitors for Reactor Vessel Surveillance, E706 (IIIC)

This standard is issued under the fixed designation E 910; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E 482 Guide for Application of Neutron Transport Methods

for Reactor Vessel Surveillance, E 706 (IID)

1.1 This test method describes the concept and use of

E 560 Practice for Extrapolating Reactor Vessel Surveil-

helium accumulation for neutron fluence dosimetry for reactor

lance Dosimetry Results, E 706 (IC)

vessel surveillance. Although this test method is directed

E 693 Practice for Characterizing Neutron Exposures in

toward applications in vessel surveillance, the concepts and

Ferritic Steels in Terms of Displacements Per Atom (DPA),

techniques are equally applicable to the general field of neutron

E 706 (ID)

dosimetry. The various applications of this test method for

E 706 Master Matrix for Light-Water Reactor Pressure

reactor vessel surveillance are as follows:

Vessel Surveillance Standards

1.1.1 Helium accumulation fluence monitor (HAFM) cap-

E 844 Guide for Sensor Set Design and Irradiation for

sules,

Reactor Surveillance, E 706 (IIC)

1.1.2 Unencapsulated, or cadmium or gadolinium covered,

E 853 Practice for Analysis and Interpretation of Light-

radiometric monitors (RM) and HAFM wires for helium

Water Reactor Surveillance Results, E 706 (IA)

analysis,

E 854 Test Method for Application and Analysis of Solid

1.1.3 Charpy test block samples for helium accumulation,

State Track Recorder (SSTR) Monitors for Reactor Sur-

and

veillance, E 706 (IIIB)

1.1.4 Reactor vessel (RV) wall samples for helium accumu-

E 900 Guide for Predicting Neutron Radiation Damage to

lation.

Reactor Vessel Materials, E 706 (IIF)

1.2 This standard does not purport to address all of the

E 944 Guide for Application of Neutron Spectrum Adjust-

safety concerns, if any, associated with its use. It is the

ment Methods in Reactor Surveillance, (IIA)

responsibility of the user of this standard to establish appro-

E 1005 Test Method for Application and Analysis of Radio-

priate safety and health practices and determine the applica-

metric Monitors for Reactor Vessel Surveillance, E 706

bility of regulatory limitations prior to use.

(IIIA)

2. Referenced Documents E 1018 Guide for Application of ASTM Evaluated Nuclear

Data File (ENDF/A)—Cross Section and Uncertainty File,

2.1 ASTM Standards:

E 706 (IIB)

C 859 Terminology Relating to Nuclear Materials

IE Damage Correlations for Reactor Vessel Surveillance

E 170 Terminology Relating to Radiation Measurements

IIE Benchmark Testing of Reactor Vessel Surveillance

and Dosimetry

IIID Application and Analysis of Damage Monitors for

E 184 Practice for Effects of High-Energy Neutron Radia-

Reactor Vessel Surveillance

tion on the Mechanical Properties of Metallic Materials,

IIIE Application and Analysis of Temperature Monitors for

E 706 (IB)

Reactor Vessel Surveillance

E 244 Test Method for Atom Percent Fission in Uranium

and Plutonium Fuel (Mass Spectrometric Method)

3. Terminology

E 261 Test Method for Determining Neutron Fluence Rate,

3.1 Definitions—For definition of terms used in this test

Fluence, and Spectra by Radioactivation Techniques

method, refer to Terminology C 859 and E 170. For terms not

defined therein, reference may be made to other published

This test method is under the jurisdiction of ASTM Committee E-10 on Nuclear

glossaries.

Technology and Applicationsand is the direct responsibility of Subcommittee

E10.05on Nuclear Radiation Metrology.

Current edition approved April 15, 1995. Published June 1995. Originally

published as E 910 – 82. Last previous edition E 910 – 89.

2 5

Annual Book of ASTM Standards, Vol 12.01. The roman numeral-alphabetical designation before the title indicates that this

Annual Book of ASTM Standards, Vol 12.02. standard is currently in process of being drafted and that a brief description of its

Annual Book of ASTM Standards, Vol 12.02. The roman numeral-alphabetical contents may be found in Matrix E 706.

designation at the end of this title indicates that a brief description of this standard See Dictionary of Scientific Terms, 3rd Edition, Sybil P. Parker, Ed., McGraw

may be found in Matrix E 706. Hill, Inc.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

E 910

FIG. 1 Helium Accumulation Fluence Monitor Capsule

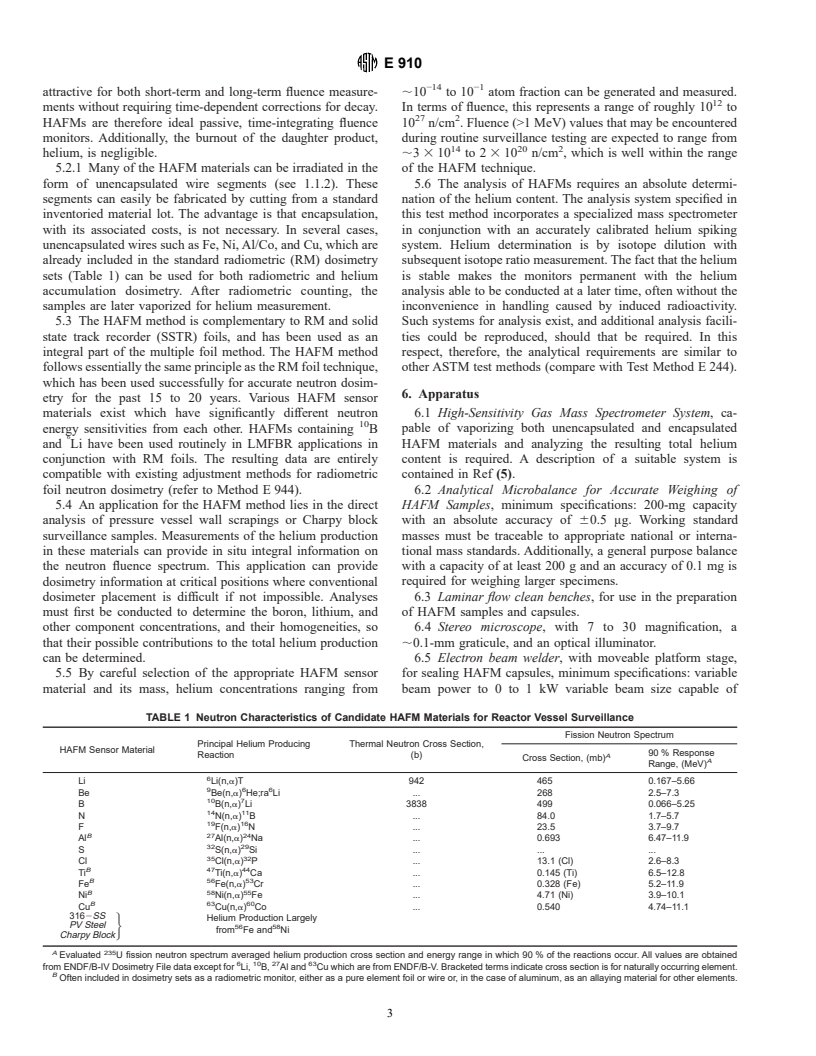

4. Summary of the HAFM Test Method 4.4 The He concentration in the HAFM, in general terms, is

proportional to the incident neutron fluence. Consideration

4.1 Helium accumulation fluence monitors (HAFMs) are

must, however, be made for such factors as HAFM material

passive neutron dosimeters that have a measured reaction

burnup, neutron self-shielding and flux depression, a-recoil,

product that is helium. The monitors are placed in the reactor

and neutron gradients. Corrections for these effects are dis-

locations of interest, and the helium generated through (n,a)

cussed more fully in Section 13. Generally, they total less than

reactions accumulates and is retained in the HAFM (or HAFM

5 % of the measured helium concentration. Since the individual

capsule) until the time of removal, perhaps several years later.

corrections are usually known to within 50 %, the total error

The helium is then measured very precisely by high-sensitivity

from these corrections amounts to #2 %. Sources of uncer-

gas mass spectrometry (1, 2). The neutron fluence is then

tainty also lie in the HAFM material mass, isotopic composi-

directly obtained by dividing the measured helium concentra-

tion, and mass spectrometric helium analysis. As indicated in

tion by the spectrum-averaged cross section. Competing he-

Section 13, however, these uncertainties generally contribute

lium producing reactions, such as (g,a) do not, except possibly

for Be(g,a), affect the HAFM results. The range of helium less than 1 % of the total uncertainty for routine analyses.

concentrations that can be accurately measured in irradiated

4.5 Applying the above corrections to the measured HAFM

−13 −1

HAFMs extends from ;10 to 10 atom fraction. This range

helium concentration, the total incident neutron fluence (over

permits the HAFMs to be tested in low fluence environments

the energy range of sensitivity of the HAFM) can be obtained

yet to work equally well for high fluence situations.

directly from a knowledge of the spectrum-integrated total

4.2 Typically, HAFMs are either individual small solid

helium production cross section for the particular irradiation

samples, such as wire segments (3) or miniature encapsulated

environment. At the present time, the uncertainty in the derived

samples of small crystals of powder (4), as shown in Fig. 1. As

neutron fluence is mainly due to uncertainty in the spectrum-

with radiometric dosimetry, different materials are used to

integrated cross section of the HAFM sensor material rather

provide different energy sensitivity ranges. Encapsulation is

than the combined uncertainties in the helium determination

necessary for those HAFM materials and reactor environment

process. This situation is expected to improve as the cross

combinations where sample melting, sample contamination, or

sections are more accurately measured, integrally tested in

loss of generated helium could possibly occur. Additionally,

benchmark facilities (6), and reevaluated.

encapsulation generally facilitates the handling and identifica-

tion of the HAFM both prior to and following irradiation. The

5. Significance and Use

contents of HAFM capsules typically range from 0.1 to 10 mg.

5.1 The HAFM test method is one of several available

4.3 Following irradiation, encapsulated HAFMs are cleaned

passive neutron dosimetry techniques (see, for example, Meth-

and identified in preparation for helium analysis. Helium

ods E 854 and E 1005). This test method can be used in

analysis is then accomplished by vaporizing both the capsule

combination with other dosimetry methods, or, if sufficient data

and its contents and analyzing the helium in the resulting gases

are available from different HAFM sensor materials, as an

in a high sensitivity mass spectrometer system (5). The amount

4 4 3

alternative dosimetry test method. The HAFM method yields a

of He is determined by measuring the He-to- He isotopic

direct measurement of total helium production in an irradiated

ratio in the sample gases subsequent to the addition of an

accurately calibrated amount of He “spike.” Unencapsulated sample. Absolute neutron fluence can then be inferred from

this, assuming the appropriate spectrum integrated total helium

HAFMs, for example, pure element wires, are usually etched to

remove a predetermined layer of outer material before helium production cross section. Alternatively, a calibration of the

composite neutron detection efficiency for the HAFM method

analysis (3). This eliminates corrections for both cross con-

tamination between samples and a-recoil into or out of the may be obtained by exposure in a benchmark neutron field

sample during the irradiation. where the fluence and spectrum averaged cross section are both

known (see Matrix E 706 IIE).

5.2 HAFMs have the advantage of producing an end prod-

The boldface numbers in parentheses refer to the list of references appended to

this test method. uct, helium, which is stable, making the HAFM method very

E 910

−14 −1

attractive for both short-term and long-term fluence measure- ;10 to 10 atom fraction can be generated and measured.

ments without requiring time-dependent corrections for decay. In terms of fluence, this represents a range of roughly 10 to

27 2

HAFMs are therefore ideal passive, time-integrating fluence 10 n/cm . Fluence (>1 MeV) values that may be encountered

monitors. Additionally, the burnout of the daughter product, during routine surveillance testing are expected to range from

14 20 2

helium, is negligible. ;3 3 10 to 2 3 10 n/cm , which is well within the range

5.2.1 Many of the HAFM materials can be irradiated in the of the HAFM technique.

form of unencapsulated wire segments (see 1.1.2). These 5.6 The analysis of HAFMs requires an absolute determi-

segments can easily be fabricated by cutting from a standard nation of the helium content. The analysis system specified in

inventoried material lot. The advantage is that encapsulation, this test method incorporates a specialized mass spectrometer

with its associated costs, is not necessary. In several cases, in conjunction with an accurately calibrated helium spiking

unencapsulated wires such as Fe, Ni, Al/Co, and Cu, which are system. Helium determination is by isotope dilution with

already included in the standard radiometric (RM) dosimetry subsequent isotope ratio measurement. The fact that the helium

sets (Table 1) can be used for both radiometric and helium is stable makes the monitors permanent with the helium

accumulation dosimetry. After radiometric counting, the analysis able to be conducted at a later time, often without the

samples are later vaporized for helium measurement. inconvenience in handling caused by induced radioactivity.

5.3 The HAFM method is complementary to RM and solid Such systems for analysis exist, and additional analysis facili-

state track recorder (SSTR) foils, and has been used as an ties could be reproduced, should that be required. In this

integral part of the multiple foil method. The HAFM method respect, therefore, the analytical requirements are similar to

follows essentially the same principle as the RM foil technique, other ASTM test methods (compare with Test Method E 244).

which has been used successfully for accurate neutron dosim-

6. Apparatus

etry for the past 15 to 20 years. Various HAFM sensor

materials exist which have significantly different neutron 6.1 High-Sensitivity Gas Mass Spectrometer System, ca-

energy sensitivities from each other. HAFMs containing B pable of vaporizing both unencapsulated and encapsulated

and Li have been used routinely in LMFBR applications in HAFM materials and analyzing the resulting total helium

conjunction with RM foils. The resulting data are entirely content is required. A description of a suitable system is

compatible with existing adjustment methods for radiometric contained in Ref (5).

foil neutron dosimetry (refer to Method E 944). 6.2 Analytical Microbalance for Accurate Weighing of

5.4 An application for the HAFM method lies in the direct HAFM Samples, minimum specifications: 200-mg capacity

analysis of pressure vessel wall scrapings or Charpy block with an absolute accuracy of 60.5 μg. Working standard

surveillance samples. Measurements of the helium production masses must be traceable to appropriate national or interna-

in these materials can provide in situ integral information on tional mass standards. Additionally, a general purpose balance

the neutron fluence spectrum. This application can provide with a capacity of at least 200 g and an accuracy of 0.1 mg is

dosimetry information at critical positions where conventional required for weighing larger specimens.

dosimeter placement is difficult if not impossible. Analyses 6.3 Laminar flow clean benches, for use in the preparation

must first be conducted to determine the boron, lithium, and of HAFM samples and capsules.

other component concentrations, and their homogeneities, so 6.4 Stereo microscope, with 7 to 30 magnification, a

;0.1-mm graticule, and an optical illuminator.

that their possible contributions to the total helium production

can be determined. 6.5 Electron beam welder, with moveable platform stage,

for sealing HAFM capsules, minimum specifications: variable

5.5 By careful selection of the appropriate HAFM sensor

material and its mass, helium concentrations ranging from beam power to 0 to 1 kW variable beam size capable of

TABLE 1 Neutron Characteristics of Candidate HAFM Materials for Reactor Vessel Surveillance

Fission Neutron Spectrum

Principal Helium Producing Thermal Neutron Cross Section,

HAFM Sensor Material

90 % Response

Reaction (b) A

Cross Section, (mb)

A

Range, (MeV)

Li Li(n,a)T 942 465 0.167–5.66

9 6 6

Be Be(n,a) He;ra Li . 268 2.5–7.3

10 7

B B(n,a) Li 3838 499 0.066–5.25

14 11

N N(n,a) B . 84.0 1.7–5.7

19 16

F F(n,a) N . 23.5 3.7–9.7

B 27 24

Al Al(n,a) Na . 0.693 6.47–11.9

32 29

S S(n,a) Si . . .

35 32

Cl Cl(n,a) P . 13.1 (Cl) 2.6–8.3

B 47 44

Ti

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.