ASTM C1410-05a

(Specification)Standard Specification for Cellular Melamine Thermal and Sound-Absorbing Insulation

Standard Specification for Cellular Melamine Thermal and Sound-Absorbing Insulation

ABSTRACT

This specification covers cellular melamine thermal and sound-absorbing insulation for use in industrial environments operating within the specified temperature range. Some applications of the thermal insulation materials covered by this standard are subject to building codes for fire performance. A vapor retarder is required when the insulation materials are used for cold surface applications where water vapor condense and may cause a decrease in thermal performance. Open-cell melamine foam is produced when a pentane blowing agent is used to foam a melamine-aldehyde precondensate. Melamine thermal insulation is furnished in three types according to shape and two grades according to facing. The typical facing materials are aluminum foil, aluminized mylar, polyvinylchloride, and polyvinylfluoride. All materials should conform to the required values of oxygen index, specific optical smoke density, surface burning characteristics, density, tensile strength, percent elongation, indentation force deflection, and thermal conductivity.

SCOPE

1.1 This specification covers the type, physical properties, and dimensions of open-cell melamine foam intended for use as thermal and sound-absorbing insulation for temperatures from -40 to 350°F (-40 to 177°C) in industrial environments.

1.2 The use of thermal insulation materials covered by this specification may be governed by building codes that address fire performance.

1.3 The use of an appropriate vapor retarder is required on cold surface applications where water vapor could condense and cause a decrease in thermal performance. Refer to Practice C755 for selection of vapor retarders. Facings shall be agreed upon between the purchaser and the manufacturer or supplier. This specification addresses the foam alone.

1.4 The values stated in inch-pounds are to be regarded as the standard. The SI units given in parentheses are provided for information only and may be approximate.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation: C1410 – 05a

Standard Specification for

1

Cellular Melamine Thermal and Sound-Absorbing Insulation

This standard is issued under the fixed designation C1410; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope C356 Test Method for Linear Shrinkage of Preformed

High-Temperature Thermal Insulation Subjected to Soak-

1.1 This specification covers the type, physical properties,

ing Heat

and dimensions of open-cell melamine foam intended for use

C390 Practice for Sampling and Acceptance of Thermal

as thermal and sound-absorbing insulation for temperatures

Insulation Lots

from −40 to +350°F (−40 to +177°C) in industrial environ-

C423 Test Method for Sound Absorption and Sound Ab-

ments.

sorption Coefficients by the Reverberation Room Method

1.2 Some uses of thermal insulation materials covered by

C518 Test Method for Steady-State Thermal Transmission

this specification are governed by building codes that address

Properties by Means of the Heat Flow Meter Apparatus

fire performance.

C585 Practice for Inner and Outer Diameters of Thermal

1.3 The use of an appropriate vapor retarder is required on

Insulation for Nominal Sizes of Pipe and Tubing

cold surface applications where water vapor condense and

C755 Practice for Selection of Water Vapor Retarders for

cause a decrease in thermal performance. Refer to Practice

Thermal Insulation

C755 for selection of vapor retarders. Facings shall be agreed

C1045 PracticeforCalculatingThermalTransmissionProp-

upon between the purchaser and the manufacturer or supplier.

erties Under Steady-State Conditions

1.4 The values stated in inch-pounds are to be regarded as

C1104/C1104M Test Method for Determining the Water

thestandard.TheSIunitsgiveninparenthesesareprovidedfor

Vapor Sorption of Unfaced Mineral Fiber Insulation

information only and are approximate.

C1363 Test Method for Thermal Performance of Building

1.5 This standard does not purport to address all of the

Materials and Envelope Assemblies by Means of a Hot

safety concerns, if any, associated with its use. It is the

Box Apparatus

responsibility of the user of this standard to establish appro-

D2863 Test Method for Measuring the Minimum Oxygen

priate safety and health practices and determine the applica-

Concentration to Support Candle-Like Combustion of

bility of regulatory limitations prior to use.

Plastics (Oxygen Index)

2. Referenced Documents

D3574 Test Methods for Flexible Cellular Materials—Slab,

2

Bonded, and Molded Urethane Foams

2.1 ASTM Standards:

E84 Test Method for Surface Burning Characteristics of

C168 Terminology Relating to Thermal Insulation

Building Materials

C177 Test Method for Steady-State Heat Flux Measure-

E176 Terminology of Fire Standards

ments and Thermal Transmission Properties by Means of

E662 Test Method for Specific Optical Density of Smoke

the Guarded-Hot-Plate Apparatus

Generated by Solid Materials

C335 Test Method for Steady-State Heat Transfer Proper-

E795 PracticesforMountingTestSpecimensDuringSound

ties of Pipe Insulation

Absorption Tests

E800 Guide for Measurement of Gases Present or Gener-

ated During Fires

1

This specification is under the jurisdiction of ASTM Committee C16 on

E2231 Practice for Specimen Preparation and Mounting of

Thermal Insulation and is the direct responsibility of Subcommittee C16.22 on

Pipe and Duct Insulation Materials to Assess Surface

Organic and Nonhomogeneous Inorganic Thermal Insulation.

Burning Characteristics

Current edition approved May 1, 2005. Published May 2005. Originally

approved in 1998. Last previous edition approved in 1998 as C1014–05. DOI:

2.2 Boeing Standards:

10.1520/C1410-05A. 3

Boeing Specification Support Standard 72396

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

3

the ASTM website. The Boeing Company, Boeing Technology Services, Seattle , WA.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

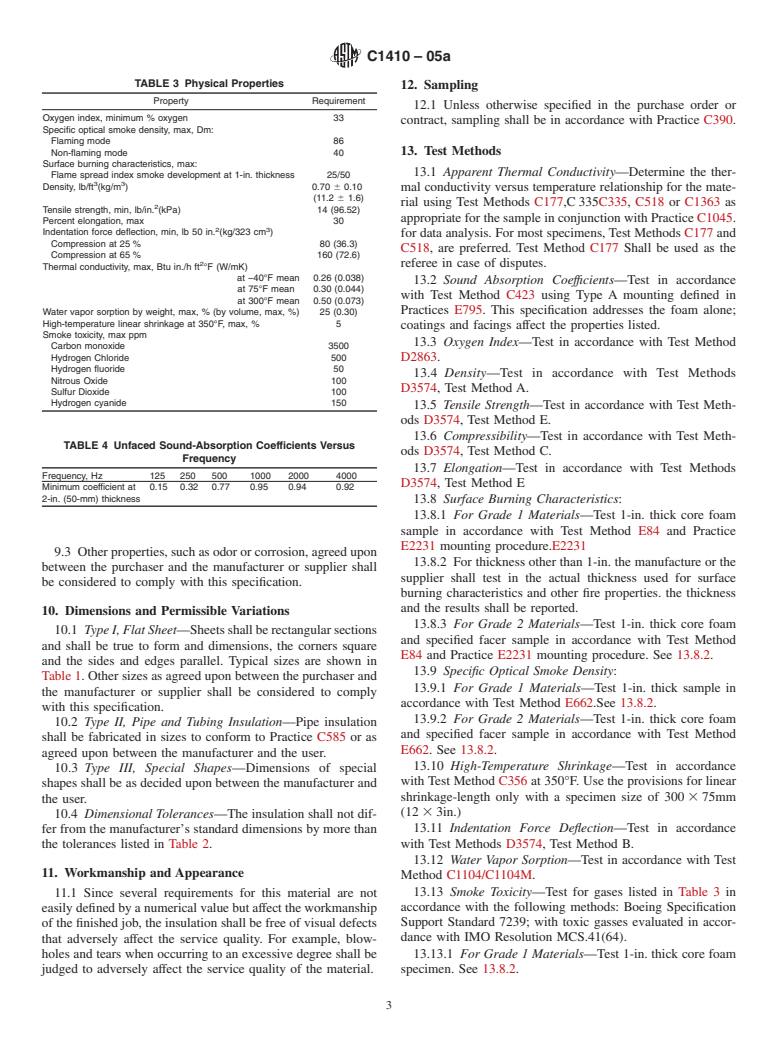

C1410 – 05a

TABLE 1 Common Dimensions TABLE 2 Insulation Tolerances

Type I Type II Type Type I Type II

1

Width, in. (mm) 12 to 50 (305 to 1270) N/A Width, in. (mm) 6 ⁄4 (6.4) N/A

1 1

Length, in. (mm) 48 to 100 (1219 to 2540) 36 or 48 (914 or 1219) Length, in. (mm) 6 ⁄4 (6.4) 6 ⁄8 (3.2) −0

1 1 1 1

Thickness, in. (mm) ⁄4 to 20 (6.4 to 508) ⁄2 to 5 (12.7 to 127) Thickness, in. (mm) 6 ⁄8 (3.2) or 2 % 6 ⁄8 (3.2) –0 or 2 %

whichever

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.