ASTM F711-02(2007)

(Specification)Standard Specification for Fiberglass-Reinforced Plastic (FRP) Rod and Tube Used in Live Line Tools

Standard Specification for Fiberglass-Reinforced Plastic (FRP) Rod and Tube Used in Live Line Tools

ABSTRACT

This specification covers the technical characteristics of and test methods for insulating rods and foam-filled tubes made from fiberglass-reinforced plastic (FRP) that are intended for use in live line tools. This specification does not include insulating foam-filled tubes and rods made from other materials, as well as fittings and attachments to the rods and foam-filled tubes for complete tools are not covered in this specification. The rods and tubes shall undergo four types of tests, namely: design test, sample test, routine test, and acceptance test. Tests shall be conducted to evaluate the following mechanical and electrical properties: wicking, bending deflection, horizontal crush, tension, shear, compression, modulus of elasticity, and mechanical aging; and dielectric current and leakage.

SCOPE

1.1 This specification covers insulating rods and foam-filled tubes made from fiberglass-reinforced plastic (FRP) that are intended for use in live line tools.

1.2 This specification does not include insulating foam-filled tubes and rods from other materials. Specifications for fittings and attachments to rods and foam-filled tubes for complete tools are not covered in this specification.

1.3 This specification establishes the technical characteristics that the tubes and rods must satisfy.

The following safety hazards caveat pertains only to the test method portion, Section 12, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F711 −02(Reapproved 2007)

Standard Specification for

Fiberglass-Reinforced Plastic (FRP) Rod and Tube Used in

Live Line Tools

ThisstandardisissuedunderthefixeddesignationF711;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.2 design test—atypeoftestmadeonasampletreatedas

representative of an industrial product. These tests will not

1.1 Thisspecificationcoversinsulatingrodsandfoam-filled

generally be repeated in quantity production.

tubes made from fiberglass-reinforced plastic (FRP) that are

3.1.3 insulating tubes and rods—fiberglass-reinforced plas-

intended for use in live line tools.

tic (FRP) products manufactured using processes so that the

1.2 This specification does not include insulating foam-

tubes and rods produced will meet the electrical and mechani-

filled tubes and rods from other materials. Specifications for

cal tests prescribed in this specification.

fittings and attachments to rods and foam-filled tubes for

3.1.4 interior foam-filled tube—homogeneous unicellular

complete tools are not covered in this specification.

thermosetting foam filling with closed cells blown with non-

1.3 This specification establishes the technical characteris-

combustible gases. The foam filling shall be bonded to the

tics that the tubes and rods must satisfy.

interior tube wall. The foam filling should be free of voids,

1.4 The following safety hazards caveat pertains only to the

separations, holes, cracks, etc.

test method portion, Section 12, of this specification.This

3.1.5 routine test—a type of test made regularly on produc-

standard does not purport to address all of the safety concerns,

tion material.

if any, associated with its use. It is the responsibility of the user

3.1.6 visual inspection—a visual check made to detect

of this standard to establish appropriate safety and health

constructional defects.

practices and determine the applicability of regulatory limita-

tions prior to use.

4. Ordering Information

4.1 Outside Diameter Sizes—Foam-filled FRP tube and

2. Referenced Documents

solid FRP rod shall meet the outside diameter dimensions

2.1 ASTM Standards:

shown in Table 1.The tolerances shown will assist in ensuring

D149Test Method for Dielectric Breakdown Voltage and

interchangeability with interfacing equipment.

DielectricStrengthofSolidElectricalInsulatingMaterials

4.2 Inspection of the material shall be agreed upon between

at Commercial Power Frequencies

the purchaser and the seller as part of the purchase contract.

D638Test Method for Tensile Properties of Plastics

D695Test Method for Compressive Properties of Rigid

5. Materials and Manufacture

Plastics

5.1 Except for those test methods leading to destruction,

neither the FRP tube, foam, or the bond between them shall

3. Terminology

deteriorate during the prescribed mechanical and electrical

3.1 Definitions of Terms Specific to This Standard:

tests of this specification.

3.1.1 acceptance test—a type of test made at the option of

6. Physical Requirements

the purchaser.

6.1 The materials shall conform to the diameters prescribed

in Table 1 for tube and rod.

This specification is under the jurisdiction of ASTM Committee F18 on

6.2 The standard sizes listed by nominal diameter are

Electrical Protective Equipment for Workers and is the direct responsibility of

recommended and do not preclude the manufacture of other

Subcommittee F18.35 on Tools & Equipment.

sizes or shapes.

Current edition approved Oct. 1, 2007. Published October 2007. Originally

approved in 1981. Last previous edition approved in 2002 as F711–02. DOI:

7. Weight

10.1520/F0711-02R07.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

7.1 It has not been found necessary to specify the weight of

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

the product produced under this specification in order for it to

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. comply with performance requirements.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F711−02 (2007)

TABLE 1 Standard Tube and Rod Outside Diameters

routine tube

routine rod

Nominal Diameter Min Diameter Max Diameter

TYPE

in. (mm) in. (mm) in. (mm)

10.2 Electrical:

Tube 1 (25.4) 0.98 (24.9) 1.02 (25.9)

Test Type Material

1 ⁄4 (31.8) 1.22 (31.0) 1.27 (32.3)

Dielectric current (leakage) design rod

1 ⁄2 (38.1) 1.47 (37.3) 1.53 (38.9)

(before moisture conditioning) design tube

1 ⁄4 (44.5) 1.73 (43.9) 1.78 (45.2)

Dielectric current (leakage) design rod

2 (50.8) 1.97 (50.0) 2.04 (51.8)

(after moisture conditioning) design tube

2 ⁄2 (63.5) 2.47 (62.7) 2.54 (64.5)

Withstand (either method 1 or 2) routine rod

3 (76.2) 2.97 (75.3) 3.04 (77.2)

routine tube

Rod ⁄8 (9.5) 0.369 (9.4) 0.385 (9.8)

⁄2 (12.7) 0.490 (12.4) 0.510 (13.0)

11. Number of Tests and Samples (Three each)

⁄8 (15.9) 0.610 (15.5) 0.635 (16.1)

⁄4 (19.1) 0.720 (18.3) 0.765 (19.4)

11.1 Tubes:

11.1.1 Wicking Test—Three samples, each 1-in. (25-mm)

long.

8. Workmanship, Finish, and Appearance

11.1.2 Bending Deflection Test—8ft,5in.(2.6m)orlonger.

See Fig. 13.

8.1 The external surface shall be uniform, symmetrical, and

11.1.3 Horizontal Crush Test—Three diameters long. See

free of abrasions, scratches, blemishes, and surface defects.

Fig. 14.

8.2 Any defect that may capture an impurity or impair the

11.1.4 Tension Test—12-in. (300-mm) long, prepared in

dielectric integrity of the product shall be cause for rejection.

accordance with Fig. 1 and Test Method D638.

8.3 FRP rod or tube material after which a finish coating,

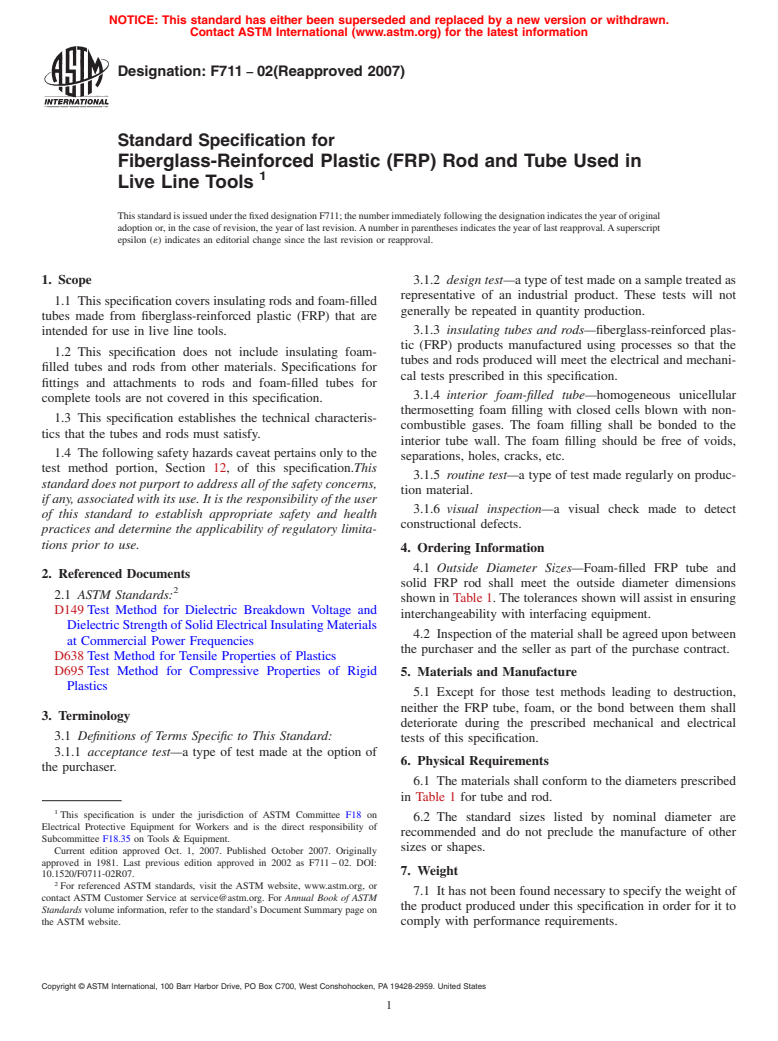

11.1.5 Shear Test—4-in. (100-mm) long, prepared in accor-

such as paint, is applied must meet all physical, electrical, and

dance with Fig. 2.

mechanical requirements.

11.1.6 Electrical Tests—12-in. (300-mm) long, prepared in

accordance with Section 12.

9. Sampling

11.2 Rod:

9.1 Design Test—Perform the test on a minimum of three

samples only when changes are made to a new or existing

design of the product that may affect the mechanical and

electrical characteristics.

9.1.1 The design test will be used to qualify a specific item

and normally will not be repeated during production.

9.2 Sample Test—A test specimen shall consist of one or

more items, dependent on 1% of the lot being tested.

9.2.1 Alotisrepresentedeitherbyallitemsproducedinone

production run or in one shipment.

9.2.2 Lots of new, unused items shall have test specimens

selected at random.

9.3 Routine Test—Performthetestonallpiecesdeliveredto

the purchaser.

9.4 Acceptance Test—A test made at the option of the

purchaser.

10. Conduct of Tests on Samples

10.1 Mechanical:

Test Type Material

Wicking design tube

Bending deflection design tube

Horizontal crush design tube

acceptance tube

Tension design tube

design rod

Shear design tube

Compression design rod

Modulus of elasticity (tension) design rod

Mechanical aging (flexure) design tube

design rod

Visual design tube

design rod

acceptance tube

acceptance rod

Dimensional acceptance tube

acceptance rod

FIG. 1 Tension Test

F711−02 (2007)

12. Test Methods

12.1 Visual Inspection—Make a visual check to detect

manufacturing defects (for example, evidence of faulty bond-

ing between fibers and resin, air bubbles, foreign bodies, or

particles).

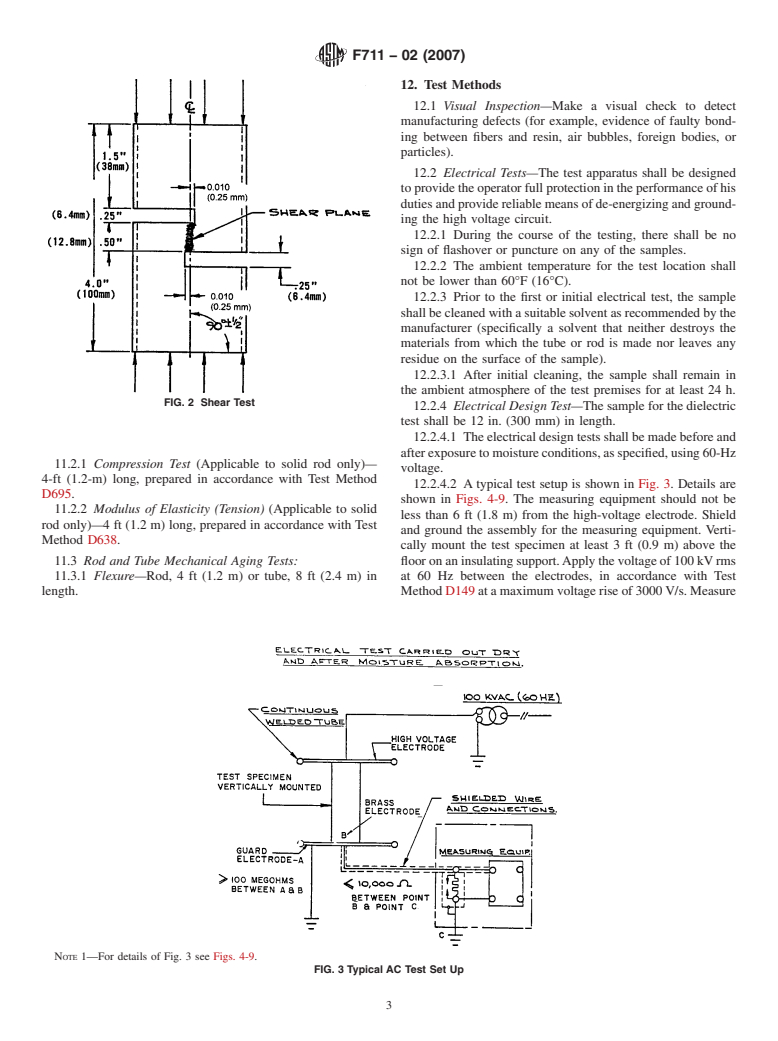

12.2 Electrical Tests—The test apparatus shall be designed

toprovidetheoperatorfullprotectionintheperformanceofhis

dutiesandprovidereliablemeansofde-energizingandground-

ing the high voltage circuit.

12.2.1 During the course of the testing, there shall be no

sign of flashover or puncture on any of the samples.

12.2.2 The ambient temperature for the test location shall

not be lower than 60°F (16°C).

12.2.3 Prior to the first or initial electrical test, the sample

shallbecleanedwithasuitablesolventasrecommendedbythe

manufacturer (specifically a solvent that neither destroys the

materials from which the tube or rod is made nor leaves any

residue on the surface of the sample).

12.2.3.1 After initial cleaning, the sample shall remain in

the ambient atmosphere of the test premises for at least 24 h.

FIG. 2 Shear Test

12.2.4 Electrical Design Test—Thesampleforthedielectric

test shall be 12 in. (300 mm) in length.

12.2.4.1 Theelectricaldesigntestsshallbemadebeforeand

afterexposuretomoistureconditions,asspecified,using60-Hz

11.2.1 Compression Test (Applicable to solid rod only)—

voltage.

4-ft (1.2-m) long, prepared in accordance with Test Method

12.2.4.2 A typical test setup is shown in Fig. 3. Details are

D695.

shown in Figs. 4-9. The measuring equipment should not be

11.2.2 Modulus of Elasticity (Tension) (Applicable to solid

less than 6 ft (1.8 m) from the high-voltage electrode. Shield

rod only)—4 ft (1.2 m) long, prepared in accordance with Test

and ground the assembly for the measuring equipment. Verti-

Method D638.

cally mount the test specimen at least 3 ft (0.9 m) above the

11.3 Rod and Tube Mechanical Aging Tests: flooronaninsulatingsupport.Applythevoltageof100kVrms

11.3.1 Flexure—Rod, 4 ft (1.2 m) or tube, 8 ft (2.4 m) in at 60 Hz between the electrodes, in accordance with Test

length. MethodD149atamaximumvoltageriseof3000V/s.Measure

NOTE 1—For details of Fig. 3 see Figs. 4-9.

FIG. 3Typical AC Test Set Up

F711−02 (2007)

FIG. 4 Assembly Detail

FIG. 5 Electrode Detail

the current passing over or through the test specimen in rms (b)Upon completion of the before-moisture conditioning

values by passing it through a known resistance.

electricaltest(I1),thesampleshallthenbeplacedinasuitable

(a)The current I1 is the maximum dielectric current

chamber and undergo the following conditioning prior to the

measured with an alternating voltage of 100 kV rms 60 Hz

after-moisture conditioning electrical test, (I2).

applied between the electrodes for 1 min.

F711−02 (2007)

FIG. 6 Electrode Cap Detail

FIG. 8 Nylon Electrode Support Detail

FIG. 9 Brass Screw Detail

FIG. 7 Brass Electrode Detail

12.2.4.3 Test Results—The currents (I1) measured shall be

less than the values in Table 2. The difference between I1 and

I2 shall be less than 20 µA.

Time: 168 h

Temperature: 23 ± 4°C

12.2.5 Electrical Withstand Routine Tests—EitherMethod1

Relative humidity: 93 %, or greater

or Method 2 shall be used to perform the routine electrical

(c)After moisture conditioning and a light wiping with a withstand test for both FRP rods and FRP foam-filled tubes.

drycloth,thecurrent I2ismeasuredunderthesameconditions 12.2.5.1 Electrical Withstand Acceptance Test (Method 1)

as was I1. Without Dielectric Current Monitoring—The typical test setup

(d)Locate the specimen in the same relative position to is shown in Fig. 10. Horizontally mount the test specimen at

earth;thehigh-potentialendofthesampleshallbethesamefor least 3 ft (0.9 m) above the floor on an insulating support. The

both tests. electrodes shall be spaced 12 in. apart.

F711−02 (2007)

A

TABLE 2 Flexure Forces and Leakage Current

Leakage

Outside Diameter Flexure Forces

Current, I1

TYPE

in. (mm) lbf (N) µA

Tube 1 (25.4) 220 (978.6) 5

1 ⁄4 (31.8) 270 (1201.0) 6

1 ⁄2 (38.1) 370 (1645.8) 8

1 ⁄4 (44.5) 550 (2446.5) 9

2 (50.8) 670 (2980.3) 10

2 ⁄2 (63.5) 1680 (7473.0) 12

3 (76.2) 3030 (13 478.1) 14

Rod ⁄8 (9.5) 50 (222.4) 6

⁄2 (12.7) 150 (667.2) 6

⁄8 (15.9) 375 (1668.0) 6

⁄4 (19.1) 800 (3058.6) 6

A

Values listed for maximum I1 are based on pole constructed of a relatively thin

wallandfilledinternallywithfoam.Somespecialapplicationsrequireathickerwall,

denser foam, or different materials, which could change the dielectric constant of

the test setup and consequently I1. Tubes such as these will still meet the

requirements of this specification if the dry leakage is less than twice the listed

maximum value of I1 in the table.

FIG. 11 Typical Test Set-Up

FIG. 10 Typical Test Arrangement for Electrical Withstand Accep-

tance Test

(a)During the electrical withstand acceptance test, the

tubesorrodsshallbesubjectedtoanalternatingvoltageof100

kV rms at power frequency in accordance with Test Method

D149 at a maximum voltage rise of 3000V/s.The test voltage

shall be applied between electrodes for 5 min.

FIG. 12 Typical Test Set-Up

(b)During the course of the testing, there shall be no sign

of flashover, puncture, tracking, or erosion on the surface of

any sample. There shall be no perceptible temperature rise of

drive so that intentional action on the part of the operator is

any sample.

required to reset the equipment.

12.2.5.2 Electrical Withstand Test (Method 2) With Dielec-

(b) Acceptableriseaboveambientoflessthan I1aslisted

tric Current Monitoring—The typical test set-up is shown in

in Table 2. During the course of the testing, there shall be no

Figs.11and12.Thenecessaryequipmentshouldbeadequately

sign of flashover, puncture, tracking, or erosion on the surface

shielded to provide accurate readings. The test fixture should

of any sample.

be enclosed for worker protection and equipped with an

exhaust fan to provide a stable atmosphere. A motor drive 12.3 Mechanical Testing of FRP Tube:

should be utilized to ensure a uniform rate of feed. The feed 12.3.1 Bending Deflection Test (design)—A tube 8 ft 5 in.

rateshouldbeproportionaltotheresponsetimeofthemetering (2.6 m) or longer shall be placed in a testing device such that

circuit; that is, it shall be run slowly enough that maximum the overhang arm is 60 in. (1.5 m) in length, and the distance

readings are obtained. At no time should this rate of feed between supports is as shown in Fig. 13.

exceed 40 ft/min. 12.3.1.1 The support shall be of the pole clamp-type (ap-

(a) With 6-in. electrode spacing, the applied voltage will proximately 4-in. (100-mm) long) with the back clamp tight-

be 50 kV. The equipment shall be designed such that a ened to hold specimen in place while the front clamp remains

flashover, excessive dielectric current will disable the motor loose and serves only as a fulcrum. Both clamps shall be free

F711−02 (2007)

FIG. 13 Bending Deflection Test

FIG. 14 Crush Test

to pivot as load (in Table 3) is applied 60 in. (1.5 m) from

TABLE 4 Crush Minimums

center of front clamping device (see Fig. 13).

Diameter Min Crush Strength

12.3.1.2 The deflection of each tube tested shall not exceed

in. (mm) lbf (N)

the value specified in Table 3.

1 (25) 650 (2891)

12.3.2 Horizontal Crus

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.