ASTM F1701-12(2018)

(Specification)Standard Specification for Unused Rope with Special Electrical Properties

Standard Specification for Unused Rope with Special Electrical Properties

ABSTRACT

This specification covers the requirements, sizes, construction, tests, and procedures for unused ropes for use by electrical utilities and related industries on energized lines operating at voltages higher than a certain value. Electrical test shall be performed in order to determine the rope's electrical conductivity and resistivity to water. Physical properties such as hardness, diameter, breaking strength, elongation, and melt point shall be determined as well. Rope and strands shall be free from kinks, strand knots, and darting yarns or loose ends (inside yarns which project through cover yarns of strand at intervals along the rope).

SCOPE

1.1 This specification covers the requirements, sizes, construction, tests, and procedures for unused ropes for use by electrical utilities and related industries on energized lines operating at voltages higher than 1 kV.

1.2 This specification covers the minimum electrical, mechanical, and physical properties guaranteed by the manufacturer and the detailed procedures by which such properties are to be determined. The purchaser has the option to perform or have performed any of these tests in order to verify the guarantee. Claims for failure to meet the specification are subject to verification by the manufacturer.

1.3 The rope to which this specification applies is designed to be used in a clean and dry condition, on or near energized lines.

1.4 A margin of safety shall be allowed between the maximum voltage and working distances on which it is used and the test voltage and lengths at which it is tested.

1.5 It is common practice for the user of this type of equipment to prepare complete instructions and regulations to govern in detail the correct and safe use of such equipment.

1.6 The use and maintenance of this equipment is beyond the scope of this specification.

1.7 The values stated in SI units are to be regarded as the standard.

1.8 The following safety hazards caveat pertains only to the test method portion, Section 11, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. The test levels used in this standard are for testing under laboratory conditions and are not to be regarded as safe use levels.

1.9 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:F1701 −12 (Reapproved 2018)

Standard Specification for

Unused Rope with Special Electrical Properties

This standard is issued under the fixed designation F1701; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.9 This international standard was developed in accor-

dance with internationally recognized principles on standard-

1.1 This specification covers the requirements, sizes,

ization established in the Decision on Principles for the

construction, tests, and procedures for unused ropes for use by

Development of International Standards, Guides and Recom-

electrical utilities and related industries on energized lines

mendations issued by the World Trade Organization Technical

operating at voltages higher than 1 kV.

Barriers to Trade (TBT) Committee.

1.2 This specification covers the minimum electrical,

2. Referenced Documents

mechanical, and physical properties guaranteed by the manu-

facturer and the detailed procedures by which such properties

2.1 ASTM Standards:

are to be determined. The purchaser has the option to perform

C1500 Test Method for Nondestructive Assay of Plutonium

or have performed any of these tests in order to verify the

by Passive Neutron Multiplicity Counting

guarantee. Claims for failure to meet the specification are

D1125 Test Methods for Electrical Conductivity and Resis-

subject to verification by the manufacturer.

tivity of Water

D4268 Test Methods for Testing Fiber Ropes (Withdrawn

1.3 The rope to which this specification applies is designed

2002)

to be used in a clean and dry condition, on or near energized

E4 Practices for Force Verification of Testing Machines

lines.

F711 Specification for Fiberglass-Reinforced Plastic (FRP)

1.4 A margin of safety shall be allowed between the

Rod and Tube Used in Live Line Tools

maximum voltage and working distances on which it is used

2.2 IEEE Standards:

and the test voltage and lengths at which it is tested.

IEEE Std 4 Standard Techniques for High Voltage Testing

1.5 It is common practice for the user of this type of

2.3 Other Standard:

equipment to prepare complete instructions and regulations to

Cordage Institute CI-1301 Polypropylene Fiber Rope

govern in detail the correct and safe use of such equipment.

3-Strand and 8-Strand Constructions (April 1999)

1.6 The use and maintenance of this equipment is beyond

3. Terminology

the scope of this specification.

3.1 General—The terms used in this specification are com-

1.7 The values stated in SI units are to be regarded as the

mon to and well known by the industries that will be using

standard.

them.

1.8 The following safety hazards caveat pertains only to the

4. Ordering Information

test method portion, Section 11, of this specification: This

standarddoesnotpurporttoaddressallofthesafetyconcerns,

4.1 Orders for rope under this specification should include

ifany,associatedwithitsuse.Itistheresponsibilityoftheuser

the following information:

of this standard to establish appropriate safety, health, and

4.2 Manufacturer’s designation of the rope.

environmental practices and determine the applicability of

4.3 Length of Coil or Reel:

regulatory limitations prior to use. The test levels used in this

standard are for testing under laboratory conditions and are not

to be regarded as safe use levels.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

1 3

This specification is under the jurisdiction of ASTM Committee F18 on The last approved version of this historical standard is referenced on

Electrical Protective Equipment for Workers and is the direct responsibility of www.astm.org.

Subcommittee F18.35 on Tools & Equipment. Available from Institute of Electrical and Electronics Engineers, Inc. (IEEE),

Current edition approved Oct. 1, 2018. Published October 2018. Originally 445 Hoes Ln., P.O. Box 1331, Piscataway, NJ 08854-1331.

approved in 1996. Last previous edition approved in 2012 as F1701-12. DOI: Available from The Cordage Institute, 994 Old Eagle School Rd., Suite 1019,

10.1520/F1701-12R18. Wayne, PA 19087.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1701−12 (2018)

4.3.1 Lengths—Each package shall be continuous through- 11. Test Methods and Performance Requirements

out without splices or knots. Ends shall be taped, heat sealed,

11.1 The ropes complying with these specifications shall

or served to prevent unraveling.

undergo two different tests, electrical and mechanical/physical,

and are to be termed “nonconductive” rope. Samples of rope

5. Physical Properties

selected in accordance with Section 8 from every production

5.1 Hardness—Refer to 11.5. lot (single finished production length) shall be tested and each

reel identified by lot (see 15.3).

5.2 Diameter, Break Strength, and Elongation—Refer to

11.1.1 The test sequence is (1) visual (Refer to Section 7;

11.5.

(2) dry electrical (Refer to 11.3); (3) wet electrical (Refer to

11.4); (4) mechanical/physical (Refer to 11.5).

6. Mechanical Properties

11.2 Caution—It is recommended that the test apparatus be

6.1 Theprimarymechanicalpropertyofropeisthebreaking

designed to afford the operator full protection in performance

strength. Minimum breaking strengths, and associated nominal

of his duties. Reliable means of deenergizing and grounding

design characteristics (dimensions, mass, and acceptable varia-

the high-voltage circuit shall be provided.

tions) of ropes are available from manufacturer or the Cordage

11.3 Electrical Test Procedure Dry Test—This is a dry

Institute.

specimen test to be used on new rope prior to wet test.

11.3.1 Specimen for Test—When selected in accordance

7. Workmanship, Finish, and Appearance

with Section 8, the test specimen shall be at least 1.8 m (6 ft)

7.1 All sizes of rope shall be evenly laid and well balanced

long so that when the rope is held in a vertical position, there

in accordance with best rope making workmanship. Rope and

willbe1.0m(3ft)ofropefreefromknots,eyes,orsplices(see

strandsshallbefreefromkinks,strandknots,anddartingyarns

Fig. 1).

or loose ends (inside yarns which project through cover yarns

11.3.2 Handling of Specimen—When the rope is handled, it

of strand at intervals along the rope).

shall always be outside the test footage (see Fig. 1).

11.3.3 Electrodes:

8. Sampling and Number of Tests or Retests

11.3.3.1 The electrodes shall be designed to shield out the

8.1 Composition of Batch to be Sampled—Samples shall be majority of stray capacitive currents.

taken from a homogeneous batch consisting of ropes of the 11.3.3.2 The electrodes and configuration shall be the same

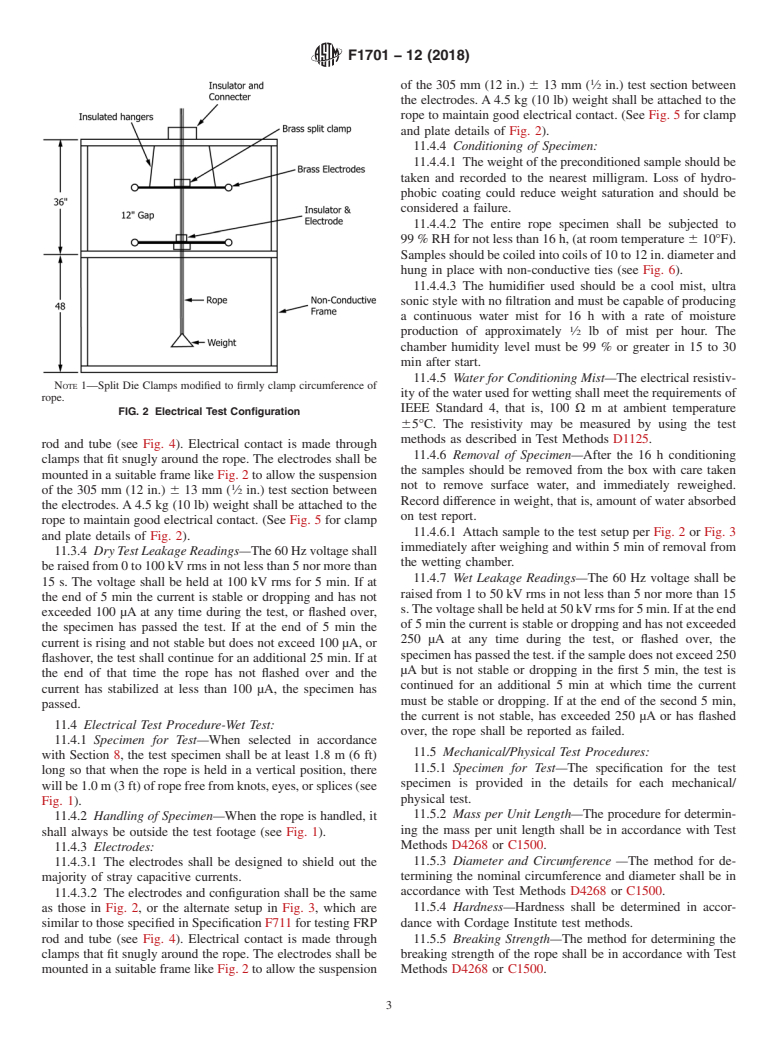

samesizeandsamedimensionsandwhichhavebeensubjectto as those in Fig. 2, or the alternate setup in Fig. 3, which are

the same series of manufacturing operations and the same similar to those specified in Specification F711 for testing FRP

checking procedure.

8.2 Selecting the Samples—Take at random from the batch

the minimum number of samples, S, obtained from the follow-

ing equation:

=

S 5 0.4 N

where N = number of coils making up the batch.

Where the calculated value of S is not a whole number, the

numberobtainedshallberoundedtothenearestwholenumber.

For example, 27.5 and 30.35 shall be rounded to 28 and 30,

respectively. Where S < 1, take one sample length.

8.2.1 Specimen Selection Location—For testing of rope

shipped in reel lengths, specimens shall be selected from each

end. One specimen shall be selected from the outside end and

one from the inside (drum) end. This will require a re-reeling

of the rope.

8.3 Single-finished production runs of greater than 1828 m

(6000 ft) tests shall be conducted at the beginning and end of

the finished production length.

9. Specimen Preparation

9.1 Specimen preparation is included as a part of each test

method. The ends of each rope specimen shall be heat sealed.

10. Recommended Working Load

10.1 Manufacturers furnishing rope under this specification

shall specify a recommended maximum working load. FIG. 1 Test Footage for Electrical Test

F1701−12 (2018)

of the 305 mm (12 in.) 6 13 mm ( ⁄2 in.) test section between

the electrodes.A4.5 kg (10 lb) weight shall be attached to the

rope to maintain good electrical contact. (See Fig. 5 for clamp

and plate details of Fig. 2).

11.4.4 Conditioning of Specimen:

11.4.4.1 The weight of the preconditioned sample should be

taken and recorded to the nearest milligram. Loss of hydro-

phobic coating could reduce weight saturation and should be

considered a failure.

11.4.4.2 The entire rope specimen shall be subjected to

99 % RH for not less than 16 h, (at room temperature 6 10°F).

Samplesshouldbecoiledint

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.