ASTM D7312-10

(Test Method)Standard Test Method for Determining the Permanent Shear Strain and Complex Shear Modulus of Asphalt Mixtures Using the Superpave Shear Tester (SST) (Withdrawn 2019)

Standard Test Method for Determining the Permanent Shear Strain and Complex Shear Modulus of Asphalt Mixtures Using the Superpave Shear Tester (SST) (Withdrawn 2019)

SIGNIFICANCE AND USE

The test procedures and associated analysis techniques described in this method can be used to determine complex shear modulus and permanent shear strain of asphalt mixtures. The shear frequency sweep test at constant height can be used to determine the complex shear modulus of a mixture. The repeated shear test at constant height can be used to determine permanent shear strain under repeated loading.

Note 4—The complex shear modulus is used to characterize the shear behavior of the mixture, and the permanent shear strain relates to pavement rutting.

SCOPE

1.1 This standard provides performance-related test procedures for the determination of stiffness complex shear modulus and permanent shear strain of asphalt mixtures using the Superpave Shear Tester (SST). This standard is applicable to the testing and analysis of modified and unmodified asphalt mixtures.

1.2 This standard is applicable to specimens prepared in a laboratory or cored from a pavement for post-construction analysis. It is intended for use with specimens having the following minimum dimensions:

WITHDRAWN RATIONALE

This standard provided performance-related test procedures for the determination of stiffness complex shear modulus and permanent shear strain of asphalt mixtures using the Superpave Shear Tester (SST).

Formerly under the jurisdiction of Committee D04 on Road and Paving Materials, this test method was withdrawn in January 2019 in accordance with section 10.6.3 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7312 − 10

Standard Test Method for

Determining the Permanent Shear Strain and Complex

Shear Modulus of Asphalt Mixtures Using the Superpave

1

Shear Tester (SST)

This standard is issued under the fixed designation D7312; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.4 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this

1.1 This standard provides performance-related test proce-

standard.

dures for the determination of stiffness complex shear modulus

1.5 This standard does not purport to address all of the

and permanent shear strain of asphalt mixtures using the

safety concerns, if any, associated with its use. It is the

Superpave Shear Tester (SST). This standard is applicable to

responsibility of the user of this standard to establish appro-

the testing and analysis of modified and unmodified asphalt

priate safety and health practices and determine the applica-

mixtures.

bility of regulatory limitations prior to use.

1.2 This standard is applicable to specimens prepared in a

laboratory or cored from a pavement for post-construction

2. Referenced Documents

analysis. It is intended for use with specimens having the

2

following minimum dimensions: 2.1 ASTM Standards:

D75 Practice for Sampling Aggregates

Nominal Maximum Aggregate Specimen Specimen

Size in Asphalt Mixture Diameter Height

D140 Practice for Sampling Bituminous Materials

D979 Practice for Sampling Bituminous Paving Mixtures

19 mm 150 mm 50 mm

D2041 Test Method for Theoretical Maximum Specific

12.5 mm, 9.5 mm, 4.75 mm 150 mm 38 mm

Gravity and Density of Bituminous Paving Mixtures

NOTE 1—Nominal maximum aggregate size is defined in AASHTO

D2726 Test Method for Bulk Specific Gravity and Density

R35 as one sieve larger than the first sieve to retain more than 10 % of the

of Non-Absorptive Compacted Asphalt Mixtures

total aggregate.Asphalt mixtures with a nominal maximum aggregate size

greater than 19 mm can be tested using this procedure, but it is not D3203 Test Method for Percent Air Voids in Compacted

recommended. The larger aggregate sizes may significantly interfere with

Dense and Open Bituminous Paving Mixtures

the material response, thereby affecting the repeatability of the test.

D3549 Test Method for Thickness or Height of Compacted

NOTE 2—The SST shall accommodate test specimens of 150 mm in

Bituminous Paving Mixture Specimens

diameter and 50 mm in height. The specimen height of 50 mm is

D5361 Practice for Sampling Compacted Bituminous Mix-

preferred, but may not be available in roadway cores where layer

tures for Laboratory Testing

thickness may be less. If the specimen height is less than 50 mm, use

platen to platen fixturing (Linear Variable Differential Transformers

D6752 Test Method for Bulk Specific Gravity and Density

(LVDTs) or extensometers). Specimen heights less than 38 mm cannot be

of Compacted Bituminous Mixtures Using Automatic

tested because of equipment constraints.

Vacuum Sealing Method

NOTE 3—The diameter-to-height ratio for shear test specimens should

D6857 Test Method for Maximum Specific Gravity and

be 3:1 or greater. This effectively eliminates the use of 100 mm diameter

specimens (because of minimum height requirement for testing discussed Density of Bituminous Paving Mixtures UsingAutomatic

in Note 2).

Vacuum Sealing Method

D6925 Test Method for Preparation and Determination of

1.3 The between laboratory reproducibility of this test

the Relative Density ofAsphalt Mix Specimens by Means

methodhasnotbeendetermined,thereforethisstandardshould

of the Superpave Gyratory Compactor

not be used for acceptance or rejection of a material for

E1 Specification for ASTM Liquid-in-Glass Thermometers

purchasing purposes.

E4 Practices for Force Verification of Testing Machines

1

This test method is under the jurisdiction of ASTM Committee D04 on Road

2

and Paving Materials and is the direct responsibility of Subcommittee D04.26 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Fundamental/Mechanistic Tests. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved Dec. 1, 2010. Published December 2010. Originally Standards volume information, refer to the standard’s Document Summary page on

approved 2007. Last published in 2007 as D7312–07. DOI: 10.1520/D7312-10. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

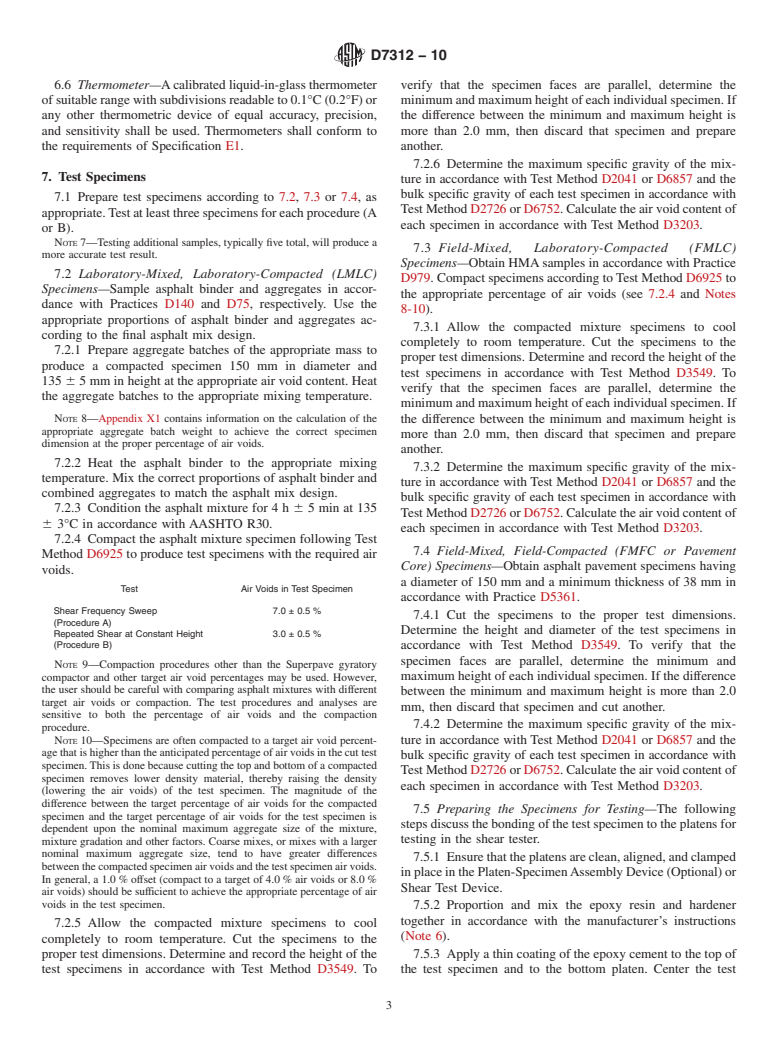

D7312 − 10

3

2.2 AASHTO Standards

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.