ASTM C1534-02

(Specification)Standard Specification for Flexible Polymeric Foam Sheet Insulation Used as a Thermal and Sound Absorbing Liner for Duct Systems

Standard Specification for Flexible Polymeric Foam Sheet Insulation Used as a Thermal and Sound Absorbing Liner for Duct Systems

SCOPE

1.1 This specification covers the composition, dimensions, and physical properties of flexible unfaced foam sheet, used to insulate interior surfaces of HVAC ducts, plenums and equipment used for the distribution of conditioned air with a temperature of up to 250°F (121°C).

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are in SI, and are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

Designation: C 1534 – 02

Standard Specification for

Flexible Polymeric Foam Sheet Insulation Used as a

Thermal and Sound Absorbing Liner for Duct Systems

This standard is issued under the fixed designation C 1534; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Properties from Steady-State Heat Flux Measurements

C 1071 Specification for Fibrous Glass Duct Lining Insula-

1.1 This specification covers the composition, dimensions,

tion (Thermal and Sound Absorbing Material)

and physical properties of flexible unfaced foam sheet, used to

C 1104 Test Method for Determining the Water Vapor

insulate interior surfaces of HVAC ducts, plenums and equip-

Sorption of Unfaced Mineral Fiber Insulation

ment used for the distribution of conditioned air with a

C 1114 TestMethodforSteady-StateThermalTransmission

temperature of up to 250°F (121°C).

Properties by Means of the Thin-Heater Apparatus

1.2 The values stated in inch-pound units are to be regarded

C 1304 Test Method for Assessing the Odor Emission of

as the standard. The values given in parentheses are in SI, and

Thermal Insulation Materials

are for information only.

C 1338 Test Method for Determining the Fungi Resistance

1.3 This standard does not purport to address all of the

of Insulation Materials and Facings

safety concerns, if any, associated with its use. It is the

E 84 Test Method for Surface Burning Characteristics of

responsibility of the user of this standard to establish appro-

Building Materials

priate safety and health practices and determine the applica-

E 176 Terminology of Fire Standards

bility of regulatory requirements prior to use.

G 21 Practice for Determining Resistance of Synthetic

2. Referenced Documents Polymer Materials to Fungi

G 22 Practice for Determining Resistance of Plastics to

2.1 ASTM Standards:

Bacteria

C 168 Terminology Relating to Thermal Insulating Mate-

rial

3. Terminology

C 177 Test Method for Steady-State Heat Flux Measure-

3.1 The definitions of terms used in this specification shall

ments and Thermal Transmission Properties by Means of

be in accordance with Terminologies C 168, C 634, and E 176.

the Guarded-Hot-Plate Apparatus

In case of any conflicts, Terminology C 168 shall be the

C 209 Test Methods for Cellulosic Fiber Insulating Board

authority.

C 390 Criteria for Sampling and Acceptance of Preformed

3.2 Definitions of Terms Specific to This Standard:

Thermal Insulation Lots

3.2.1 closed cell foam—a foam comprised of predominately

C 411 Test Method for Hot-Surfaced Performance of High

individual non interconnecting cells.

Temperature Thermal Insulation

3.2.2 flexible cellular—a cellular material that will not

C 423 Test Method for Sound Absorption and Sound Ab-

rupture within 60 s when a specimen 1 3 1 3 8 in. in length

sorption Coefficients by the Reverberation Room Method

(25 3 25 3 200 mm) is bent around a 1 in. (25 mm) diameter

C 518 Test Method for Steady-State Heat Flux Measure-

mandrelatauniformrateofonelapin5sintheformofahelix

ments and Thermal Transmission Properties by Means of

2 at a temperature between 65 and 85°F (18 and 29°C).

the Heat Flow Meter Apparatus

3.2.3 open cell foam—a foam made porous by interconnect-

C 634 Terminology Relating to Environmental Acoustics

ing cells.

C 665 Specification for Mineral-Fiber Blanket Thermal In-

sulation for Light Frame Construction and Manufactured

4. Classification

Housing

4.1 The flexible polymeric insulations of this specification

C 1045 Practice for Calculating Thermal Transmission

are classified into Types I and II. Type I is a closed flexible

foam. Type II is an open cell flexible foam.

NOTE 1—The primary difference between Type I and Type II materials

This specification is under the jurisdiction of ASTM Committee C16 on

Thermal Insulation and is the direct responsibility of Subcommittee C16.22 on

Organic and Non-Homogenous Inorganic Thermal Insulations.

Current edition approved July 10, 2002. Published September 2002. Annual Book of ASTM Standards, Vol 04.07.

2 4

Annual Book of ASTM Standards, Vol 04.06. Annual Book of ASTM Standards, Vol 14.04.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

C1534–02

are: Type I materials exhibit lower water absorption properties and Type

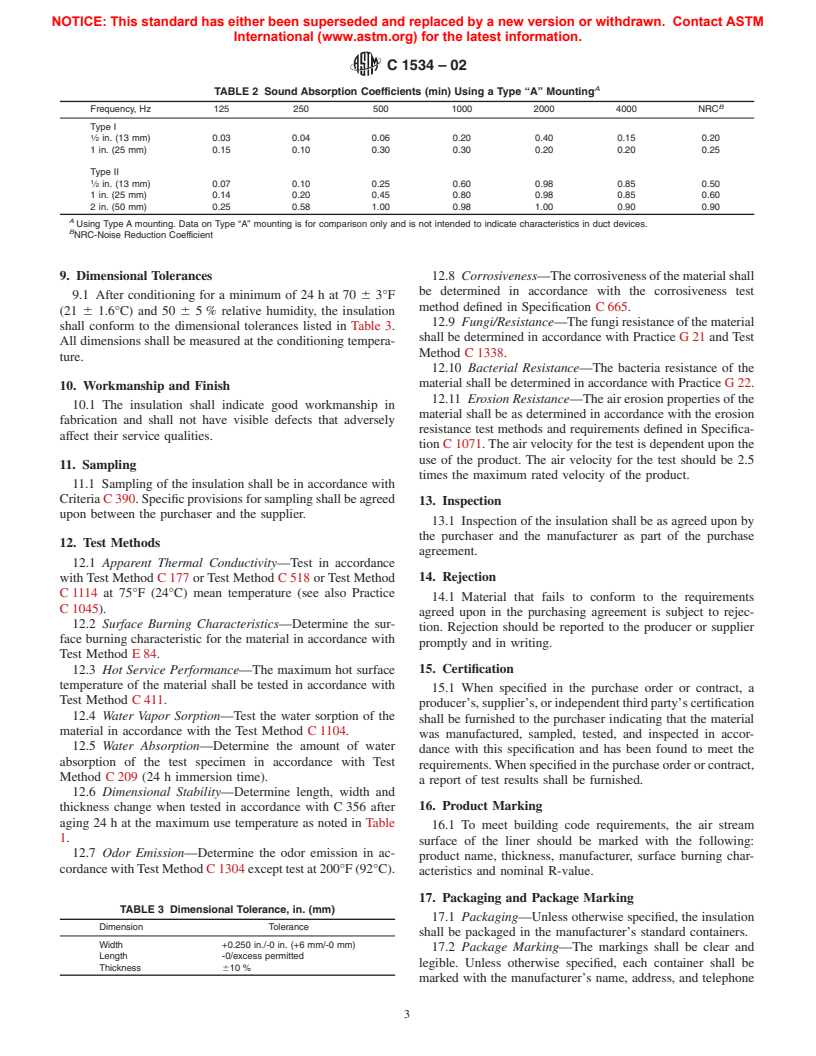

7.6 Dimensional Stability—Shall be tested in accordance

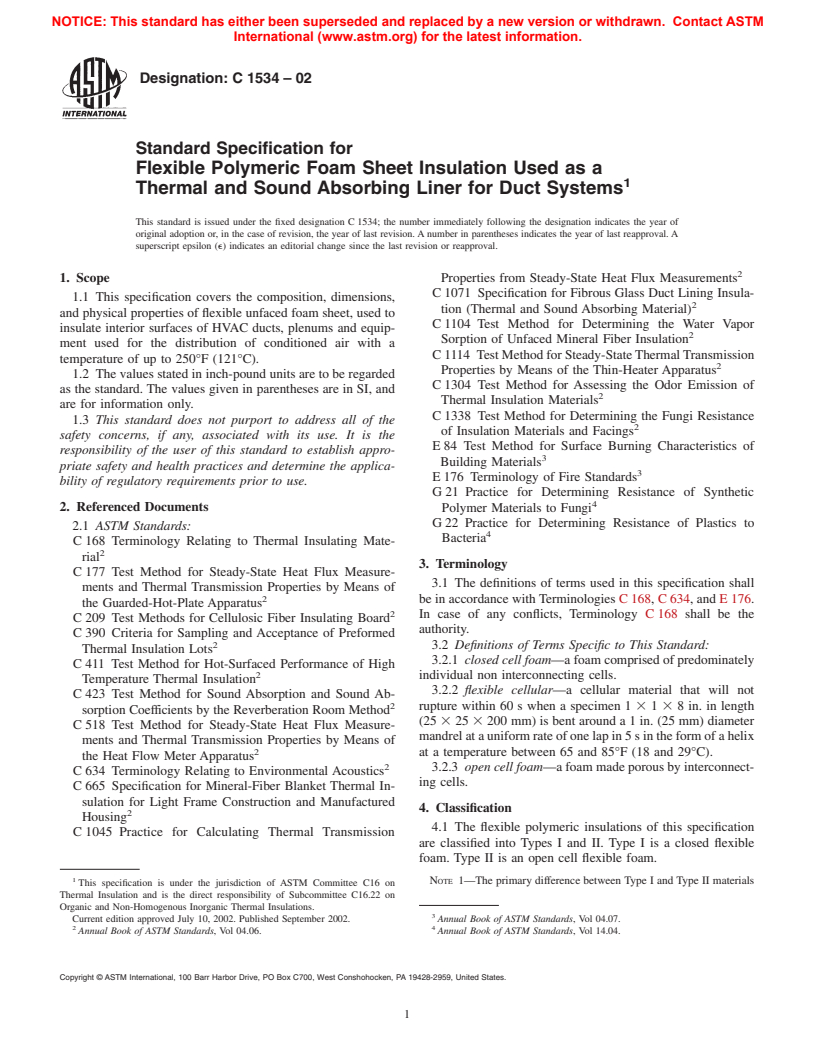

II materials have greater acoustical properties as noted in Tables 1 and 2.

with 12.6.

7.7 Odor Emission—There shall be no detectable odor of

5. Materials

objectionable nature when tested in accordance with 12.7.

5.1 These products shall be made of a homogeneous blend

7.8 Corrosiveness—No corrosion shall be noted when

of natural or synthetic polymeric materials that may be

tested in accordance with 12.8.

modified with various thermoplastic or thermosetting resins,

7.9 Fungi Resistance—When tested in accordance with

plasticizers, modifiers, antioxidants, curatives, blowing agents

12.9, the test specimens shall show no fungal growth.

and other additives.

7.10 Bacteria Resistance—When tested in accordance with

5.2 Flexible, polymeric cellular thermal insulations shall be

12.10 the test specimens shall show no bacteria growth.

ofuniformcoredensity.Eventhoughtheseinsulationmaterials

7.11 Erosion Resistance—The product shall show no evi-

may have a smooth skin surface or coating on one or both

dence of delamination or continued erosion when air is passed

sides, they are to be considered homogeneous for the purposes

through typical duct sections when tested in accordance with

of determining thermal performance.

12.11.

6. Ordering Information

7.12 Sound Absorption Coeffıcient—When tested in accor-

dance with Test Method C 423 using an “A” mounting, the

6.1 Specific installation, insulation type, thickness, length,

insulation shall have sound absorption coefficient and NRC not

and width suited for the intended use shall be agreed upon by

less than that indicated in Table 2.

the purchaser and supplier.

7. Physical Properties—See Tables 1 and 2 for Summary

8. Qualification and Inspection Requirements

of Requirements

8.1 Qualification Requirements—The following require-

7.1 Apparent Thermal Conductivity—The material shall be

ments shall be used for purposes of initial material qualifica-

tested for apparent thermal conductivity at 75°F (24°C) mean

tion:

temperature in accordance with 12.1. The thermal conductivity

8.1.1 Apparent thermal conductivity,

for the average of any four randomly selected samples, shall

8.1.2 Surface burning characteristics,

not be more than 0.30 Btu-in./h-sq ft°F (0.043 W/m-K) when

8.1.3 Hot surface performance,

tested in accordance with 12.1. See Table 1.

8.1.4 Water vapor sorption,

NOTE 2—Consult the local or state building codes for the minimum

8.1.5 Water absorption,

installed thermal resistance, R-value, required to be installed.

8.1.6 Odor emission,

7.2 Surface Burning Characteristics—Shall be in accor-

8.1.7 Corrosiveness,

dance with 12.2. See Table 1 and Note 1 for requirements.

8.1.8 Fungi resistance,

7.3 Hot Surface Performance—The insulation shall have no

8.1.9 Bacterial resistance,

evidence of flaming, glowing, smoldering, visible smoke,

8.1.10 Sound absorption coefficient, and

delamination, cracking, warpage, melting, dripp

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.