ASTM D4511-00(2006)

(Test Method)Standard Test Method for Hydraulic Conductivity of Essentially Saturated Peat

Standard Test Method for Hydraulic Conductivity of Essentially Saturated Peat

SIGNIFICANCE AND USE

Values of hydraulic conductivity determined by this test method may be useful in making rough preliminary estimates of the initial rates of drainage and compression of peat deposits when the only effective stress increase on the deposit is that resulting from a moderate, gradual lowering of the water table.

Even under light, sustained loads, peat will undergo dramatic volume changes that influence (decrease) the hydraulic conductivity of the deposit by several orders of magnitude. This test method does not offer provisions for the determination of the relationship between hydraulic conductivity and the void ratios corresponding to increasing stress levels. Therefore, this test method is not suitable for applications involving grade increases, such as embankment construction or placement of access berms alongside drainage ditches.

Undisturbed specimens from apparently homogeneous peat deposits at the same location often exhibit significantly different hydraulic conductivity properties due to variations in material composition and sampling procedure.

Note 1—The quality of the result produced by this standard is dependent on the competence of the personnel performing it, and the suitability of the equipment and facilities used. Agencies that meet the criteria of Practice D 3740 are generally considered capable of competent and objective testing/sampling/inspection/etc. Users of this standard are cautioned that compliance with Practice D 3740 does not in itself ensure reliable results. Reliable results depend on many factors; Practice D 3740 provides a means of evaluating some of those factors.

SCOPE

1.1 This test method covers the determination of the hydraulic conductivity (permeability) of essentially saturated, intact cylindrical specimens of peat when the hydraulic conductivity is greater than 1 10-7 m/s (1 10-5 cm/s). During the test, the specimens are contained in the core holder, or in right, regular cylindrical sections cut from the sampling tube in which they were originally obtained in the field.

1.2 Hydraulic conductivity is calculated on the basis of the measured constant flow rate through the specimen under constant head. For verification, flow rate determinations may be made at two or more values of constant head with corresponding calculations of hydraulic conductivity.

1.3 The values stated in SI units are to be regarded as the standard.

1.4 All observed and calculated values shall conform to the guide for significant digits and rounding established in Practice D6026.

1.4.1 The procedures used to specify how data are collected/recorded and calculated in this standard are regarded as the industry standard. In addition, they are representative of the significant digits that should generally be retained. The procedures used do not consider material variation, purpose for obtaining the data, special purpose studies, or any considerations for the user's objectives, and it is common practice to increase or reduce significant digits of reported data to be commensurate with these considerations. It is beyond the scope of this standard to consider significant digits used in analysis methods for engineering design.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D4511–00 (Reapproved 2006)

Standard Test Method for

Hydraulic Conductivity of Essentially Saturated Peat

This standard is issued under the fixed designation D4511; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

1.1 This test method covers the determination of the hy- 2.1 ASTM Standards:

draulic conductivity (permeability) of essentially saturated, D653 Terminology Relating to Soil, Rock, and Contained

intact cylindrical specimens of peat when the hydraulic con- Fluids

−7 −5

ductivityisgreaterthan1 310 m/s(1 310 cm/s).During D1587 PracticeforThin-WalledTubeSamplingofSoilsfor

the test, the specimens are contained in the core holder, or in Geotechnical Purposes

right,regularcylindricalsectionscutfromthesamplingtubein D2434 Test Method for Permeability of Granular Soils

which they were originally obtained in the field. (Constant Head)

1.2 Hydraulic conductivity is calculated on the basis of the D2974 TestMethodsforMoisture,Ash,andOrganicMatter

measured constant flow rate through the specimen under of Peat and Other Organic Soils

constant head. For verification, flow rate determinations may D3740 Practice for Minimum Requirements for Agencies

be made at two or more values of constant head with Engaged in Testing and/or Inspection of Soil and Rock as

corresponding calculations of hydraulic conductivity. Used in Engineering Design and Construction

1.3 The values stated in SI units are to be regarded as the D4220 Practices for Preserving and Transporting Soil

standard. Samples

1.4 All observed and calculated values shall conform to the D4753 Guide for Evaluating, Selecting, and Specifying

guideforsignificantdigitsandroundingestablishedinPractice Balances and Standard Masses for Use in Soil, Rock, and

D6026. Construction Materials Testing

1.4.1 Theproceduresusedtospecifyhowdataarecollected/ D6026 PracticeforUsingSignificantDigitsinGeotechnical

recorded and calculated in this standard are regarded as the Data

industry standard. In addition, they are representative of the 2.2 NRC Document:

significant digits that should generally be retained. The proce- Peat Testing Manual

dures used do not consider material variation, purpose for

3. Terminology

obtaining the data, special purpose studies, or any consider-

ations for the user’s objectives, and it is common practice to 3.1 Definitions—For common definitions of terms in this

standard, refer to Terminology D653.

increase or reduce significant digits of reported data to be

commensuratewiththeseconsiderations.Itisbeyondthescope 3.2 Definitions of Terms Specific to This Standard:

3.2.1 deaerated (de-aired) water—water in which the

of this standard to consider significant digits used in analysis

methods for engineering design. amount of dissolved gas (air) has been reduced.

3.2.2 flow rate—the quantity of water flowing through the

1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the test specimen in a given period of time, when subjected to a

certain constant head differential.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- 3.2.3 soaking—placement of a specimen in water for the

purpose of removing gas contained in the pore space, through

bility of regulatory limitations prior to use.

bouyancy, and replacement with water to cause saturation of

the specimen. This method of saturation does not effectively

ThistestmethodisunderthejurisdictionofASTMCommitteeD18onSoiland

Rock and is the direct responsibility of Subcommittee D18.04 on Hydrologic

Properties of Soil and Rock.

Current edition approved Feb. 1, 2006. Published March 2006. Originally For referenced ASTM standards, visit the ASTM website, www.astm.org, or

approved in 1992. Last previous edition approved in 2000 as D4511–00. DOI: contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

10.1520/D4511-00R06. Standards volume information, refer to the standard’s Document Summary page on

Forfurtherinformation,see“MethodsforMeasurementofSaturatedHydraulic the ASTM website.

Conductivity,” Peat Testing Manual, Technical Memorandum No. 125, NRC National Research Council of Canada, Publications Section, Building R–88,

Canada, pp. 80–84. Ottawa, Canada K1A 0R6. Out of print.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D4511–00 (2006)

remove all the gas contained in the specimen and does not 6.1.4 Direct proportionality of flow velocity with hydraulic

prevent the continuous slow formation of gas from decompo- gradients below certain values, after which flow becomes

sition under anaerobic conditions. turbulent.

6.2 All other types of flow involving partial saturation of

4. Significance and Use

void space, turbulent flow, and unsteady state of flow are

4.1 Values of hydraulic conductivity determined by this test

transient in character and yield variable and time-dependent

method may be useful in making rough preliminary estimates

valuesofhydraulicconductivity;therefore,theyrequirespecial

oftheinitialratesofdrainageandcompressionofpeatdeposits

test conditions and procedures.

when the only effective stress increase on the deposit is that

resultingfromamoderate,gradualloweringofthewatertable.

7. Apparatus

4.2 Even under light, sustained loads, peat will undergo

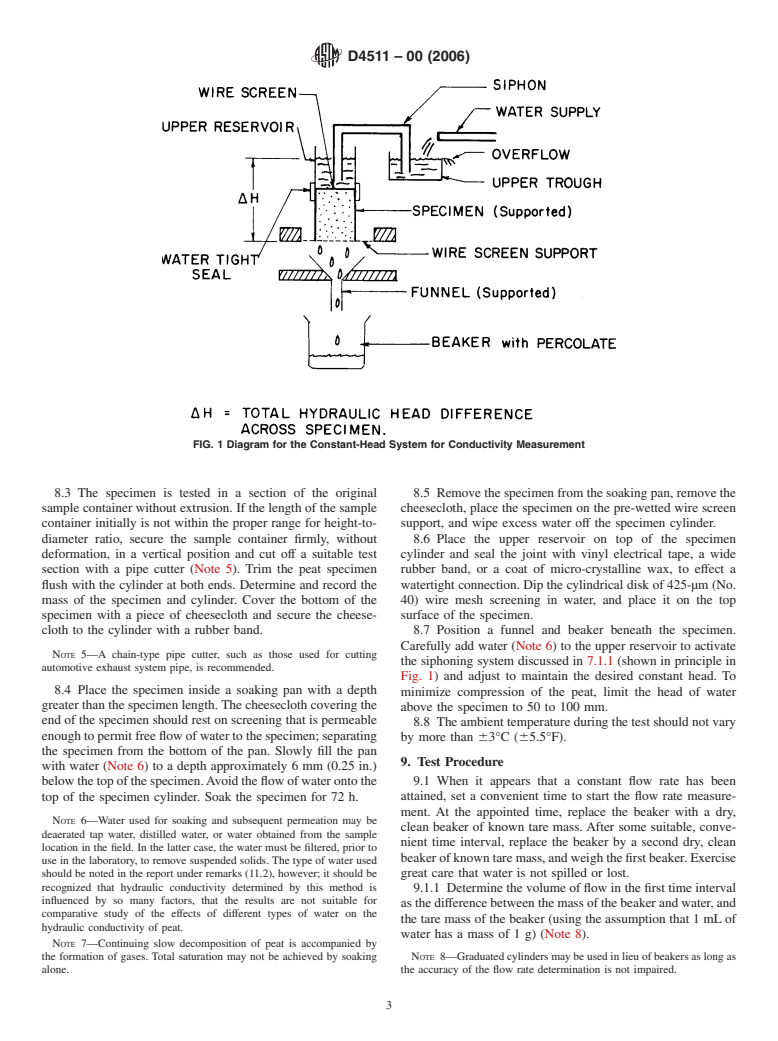

7.1 Flow Device—TheflowdeviceshallbeasshowninFig.

dramatic volume changes that influence (decrease) the hydrau-

1, fitted with the following components:

lic conductivity of the deposit by several orders of magnitude.

7.1.1 Constant-Head Filter Tank, as shown in Fig. 1 ofTest

This test method does not offer provisions for the determina-

Method D2434, to supply water and to remove most of the air

tionoftherelationshipbetweenhydraulicconductivityandthe

from the water. The tank shall be fitted with a suitable siphon.

voidratioscorrespondingtoincreasingstresslevels.Therefore,

NOTE 2—Alternatively, deaerated water may be used, supplied from a

thistestmethodisnotsuitableforapplicationsinvolvinggrade

self-siphoning burette with attached inverted flask (minimum 750-mL

increases, such as embankment construction or placement of

capacity), filled with deaerated water, and closed with a rubber stopper

access berms alongside drainage ditches.

holding a tube, 150 cm (6 in.) long with the end cut diagonally.

4.3 Undisturbed specimens from apparently homogeneous

7.1.2 Upper Reservoir, of the same diameter as the sam-

peat deposits at the same location often exhibit significantly

pling cylinder and approximately 150 cm (6 in.) high.

different hydraulic conductivity properties due to variations in

7.1.3 Wire-Screen Support, fabricated from a ring clamp,

material composition and sampling procedure.

with an inside diameter greater than the specimen cylinder and

NOTE 1—The quality of the result produced by this standard is

covered with 425-µm (No. 40) wire mesh screening.

dependent on the competence of the personnel performing it, and the

7.1.4 Circular Disk, cut from 425-µm (No. 40) wire mesh

suitability of the equipment and facilities used. Agencies that meet the

screening, with a diameter 1 mmm smaller than that of the

criteria of Practice D3740 are generally considered capable of competent

specimen.

and objective testing/sampling/inspection/etc. Users of this standard are

7.1.5 Funnel, with a head diameter at least 10% larger than

cautioned that compliance with Practice D3740 does not in itself ensure

reliable results. Reliable results depend on many factors; Practice D3740 that of the specimen cylinder.

provides a means of evaluating some of those factors.

7.1.6 Two 400-mL Beakers.

7.2 Balance—Abalanceorscaleconformingtotherequire-

5. Interferences

ments of Specification D4753, readable (with no estimate) to

5.1 Due to the generally fibrous texture and extremely high

0.1% of the test mass, or better.

compressibilityofpeat,presentsamplingtechnologiesmaynot

7.3 Miscellaneous Apparatus and Materials, such as ther-

be able to obtain samples truly representative of the in situ

mometers, timer reading to nearest second, soaking pan, pipe

conditions. Disturbance caused by sampling and specimen

cutters, trimming knife, cheese cloth, rubber bands, vinyl

preparation as well as heterogeneity existing in situ may cause

electrical tape, and micro-crystalline wax.

the hydraulic conductivity determined using this method to be

significantly different than the in situ hydraulic conductivity.

8. Specimen Preparation and Set Up

5.2 There are no provisions in this test method for verifica-

8.1 Specimens shall have a minimum diameter of 73 mm

tion of compliance with the fundamental test conditions listed

(2.87 in.). The height-to-diameter ratio shall be between 1 and

in 6.1.1 and 6.1.2. The assumption is made that these condi-

2.

tions are satisfied if the flow rate, with time, is a linear

8.2 Prepare specimens from tube samples secured in accor-

relationship.

dance with Practice D1587, or other acceptable undisturbed

5.3 Theresultofthetestmaybeinfluencedbyflowthrough

sampling procedure, yielding cylindrical samples obtained in

open passages between the specimen and the rigid wall of the

tight-fitting, rigid-metal core holders (Note 3). Preserve and

specimencontainer.Ifsuchaconditionissuspectedorvisually

transport the specimens in accordance with the practice for

verified, notice thereof should be made in the test report.

Group D samples in Practices D4220 (Note 4).

6. Fundamental Test Conditions

NOTE 3—Samples of fibrous peat from shallow depths can be secured

6.1 The following ideal test conditions are prerequisite for with the least amount of disturbance using a rotary type sampling device

equipped with a thin cutting edge, serrated with saw-teeth.

laminar flow of water through porous media under constant-

NOTE 4—The integrity of a sample contained in a sampler liner or core

head conditions:

holderisbestpreservedifthesampleendsaretrimmedflushwiththeends

6.1.1 Continuity of flow with no volume change during a

of the liner and capped using tight-fitting, rigid-metal end caps, securely

test,

taped in place and dipped in micro-crystalline wax.

6.1.2 Flow with the void space saturated with water and no

air bubbles in the voids,

6.1.3 Flow in the steady state with no changes in hydraulic

S

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.