ASTM C1165-17

(Test Method)Standard Test Method for Determining Plutonium by Controlled-Potential Coulometry in H2SO4 at a Platinum Working Electrode

Standard Test Method for Determining Plutonium by Controlled-Potential Coulometry in H<inf>2</inf>SO<inf>4</inf> at a Platinum Working Electrode

SIGNIFICANCE AND USE

5.1 This test method is to be used to ascertain whether or not materials meet specifications for plutonium content or plutonium assay, or both.

5.2 A chemical calibration of the coulometer is necessary for accurate results.

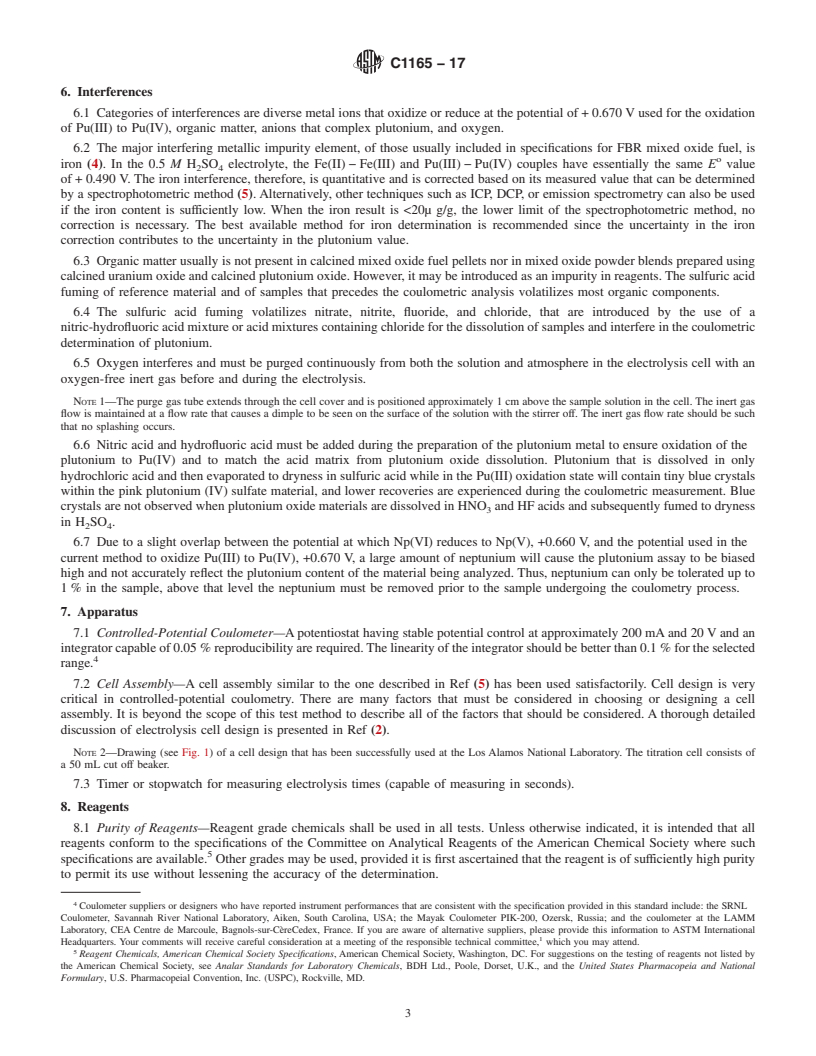

FIG. 1 Example of a Cell Design Used at Los Alamos National Laboratory (LANL)

5.3 Fitness for Purpose of Safeguards and Nuclear Safety Application—Methods intended for use in safeguards and nuclear safety applications shall meet the requirements specified by Guide C1068 for use in such applications.

SCOPE

1.1 This test method covers the determination of milligram quantities of plutonium in unirradiated uranium-plutonium mixed oxide having a U/Pu ratio range of 0.1 to 10. This test method is also applicable to plutonium metal, plutonium oxide, uranium-plutonium mixed carbide, various plutonium compounds including fluoride and chloride salts, and plutonium solutions.

1.2 The recommended amount of plutonium for each aliquant in the coulometric analysis is 5 to 10 mg. Precision worsens for lower amounts of plutonium, and elapsed time of electrolysis becomes impractical for higher amounts of plutonium.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section 9.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1165 − 17

Standard Test Method for

Determining Plutonium by Controlled-Potential Coulometry

1

in H SO at a Platinum Working Electrode

2 4

This standard is issued under the fixed designation C1165; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope C757Specification for Nuclear-Grade Plutonium Dioxide

Powder for Light Water Reactors

1.1 This test method covers the determination of milligram

C758Test Methods for Chemical, Mass Spectrometric,

quantities of plutonium in unirradiated uranium-plutonium

Spectrochemical,Nuclear,andRadiochemicalAnalysisof

mixed oxide having a U/Pu ratio range of 0.1 to 10. This test

Nuclear-Grade Plutonium Metal

methodisalsoapplicabletoplutoniummetal,plutoniumoxide,

C759Test Methods for Chemical, Mass Spectrometric,

uranium-plutonium mixed carbide, various plutonium com-

Spectrochemical,Nuclear,andRadiochemicalAnalysisof

pounds including fluoride and chloride salts, and plutonium

Nuclear-Grade Plutonium Nitrate Solutions

solutions.

C833Specification for Sintered (Uranium-Plutonium) Diox-

1.2 The recommended amount of plutonium for each ali-

ide Pellets for Light Water Reactors

quant in the coulometric analysis is 5 to 10 mg. Precision

C859Terminology Relating to Nuclear Materials

worsens for lower amounts of plutonium, and elapsed time of

C1009Guide for Establishing and Maintaining a Quality

electrolysis becomes impractical for higher amounts of pluto-

AssuranceProgramforAnalyticalLaboratoriesWithinthe

nium.

Nuclear Industry

1.3 The values stated in SI units are to be regarded as C1068Guide for Qualification of Measurement Methods by

a Laboratory Within the Nuclear Industry

standard. No other units of measurement are included in this

standard. C1108Test Method for Plutonium by Controlled-Potential

Coulometry

1.4 This standard does not purport to address all of the

C1128Guide for Preparation of Working Reference Materi-

safety concerns, if any, associated with its use. It is the

als for Use in Analysis of Nuclear Fuel Cycle Materials

responsibility of the user of this standard to establish appro-

C1156Guide for Establishing Calibration for a Measure-

priate safety, health, and environmental practices and deter-

ment Method Used toAnalyze Nuclear Fuel Cycle Mate-

mine the applicability of regulatory limitations prior to use.

rials

Specific precautionary statements are given in Section 9.

C1168PracticeforPreparationandDissolutionofPlutonium

1.5 This international standard was developed in accor-

Materials for Analysis

dance with internationally recognized principles on standard-

C1210Guide for Establishing a Measurement System Qual-

ization established in the Decision on Principles for the

ity Control Program for Analytical Chemistry Laborato-

Development of International Standards, Guides and Recom-

ries Within the Nuclear Industry

mendations issued by the World Trade Organization Technical

C1297Guide for Qualification of Laboratory Analysts for

Barriers to Trade (TBT) Committee.

the Analysis of Nuclear Fuel Cycle Materials

2. Referenced Documents

3. Terminology

2

2.1 ASTM Standards:

3.1 Except as otherwise defined herein, definitions of terms

are as given in Terminology C859.

1

ThistestmethodisunderthejurisdictionofASTMCommitteeC26onNuclear

4. Summary of Test Method

Fuel Cycle and is the direct responsibility of Subcommittee C26.05 on Methods of

Test.

4.1 In controlled-potential coulometry, the analyte reacts at

Current edition approved Nov. 1, 2017. Published November 2017. Originally

an electrode having a maintained potential that precludes

approved in 1990. Last previous edition approved in 2012 as C1165–12. DOI:

10.1520/C1165-17.

reactionsofasmanyimpuritycomponentsasisfeasible.Inthe

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

electrolysis, current decreases exponentially as the reaction

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

proceeds until a selected background current is reached. The

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. quantity of analyte reacted is calculable by Faraday’s law.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1165 − 17

Detailed discussions of the theory and applications of this

3

technique are presented in Refs (1) and (2).

4.2 Plutonium and many impurity element ions are initially

reduced in a 0.5 M H SO electrolyte at a platinum working

2 4

electrode (3) maintained at+0.310 V versus a saturat

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C1165 − 12 C1165 − 17

Standard Test Method for

Determining Plutonium by Controlled-Potential Coulometry

1

in H SO at a Platinum Working Electrode

2 4

This standard is issued under the fixed designation C1165; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of milligram quantities of plutonium in unirradiated uranium-plutonium mixed

oxide having a U/Pu ratio range of 0.1 to 10. This test method is also applicable to plutonium metal, plutonium oxide,

uranium-plutonium mixed carbide, various plutonium compounds including fluoride and chloride salts, and plutonium solutions.

1.2 The recommended amount of plutonium for each aliquant in the coulometric analysis is 5 to 10 mg. Precision worsens for

lower amounts of plutonium, and elapsed time of electrolysis becomes impractical for higher amounts of plutonium.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section 89.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

C757 Specification for Nuclear-Grade Plutonium Dioxide Powder for Light Water Reactors

C758 Test Methods for Chemical, Mass Spectrometric, Spectrochemical, Nuclear, and Radiochemical Analysis of Nuclear-

Grade Plutonium Metal

C759 Test Methods for Chemical, Mass Spectrometric, Spectrochemical, Nuclear, and Radiochemical Analysis of Nuclear-

Grade Plutonium Nitrate Solutions

C833 Specification for Sintered (Uranium-Plutonium) Dioxide Pellets for Light Water Reactors

C859 Terminology Relating to Nuclear Materials

C1009 Guide for Establishing and Maintaining a Quality Assurance Program for Analytical Laboratories Within the Nuclear

Industry

C1068 Guide for Qualification of Measurement Methods by a Laboratory Within the Nuclear Industry

C1108 Test Method for Plutonium by Controlled-Potential Coulometry

C1128 Guide for Preparation of Working Reference Materials for Use in Analysis of Nuclear Fuel Cycle Materials

C1156 Guide for Establishing Calibration for a Measurement Method Used to Analyze Nuclear Fuel Cycle Materials

C1168 Practice for Preparation and Dissolution of Plutonium Materials for Analysis

C1210 Guide for Establishing a Measurement System Quality Control Program for Analytical Chemistry Laboratories Within

the Nuclear Industry

C1297 Guide for Qualification of Laboratory Analysts for the Analysis of Nuclear Fuel Cycle Materials

3. Terminology

3.1 Except as otherwise defined herein, definitions of terms are as given in Terminology C859.

1

This test method is under the jurisdiction of ASTM Committee C26 on Nuclear Fuel Cycle and is the direct responsibility of Subcommittee C26.05 on Methods of Test.

Current edition approved June 1, 2012Nov. 1, 2017. Published June 2012November 2017. Originally approved in 1990. Last previous edition approved in 20052012 as

C1165 – 90 (2005).C1165 – 12. DOI: 10.1520/C1165-12.10.1520/C1165-17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1165 − 17

4. Summary of Test Method

4.1 In controlled-potential coulometry, the analyte reacts at an electrode having a maintained potential that precludes reactions

of as many impurity components as is feasible. In the electrolysis, current decreases exponentially as the r

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.