ASTM D2862-16

(Test Method)Standard Test Method for Particle Size Distribution of Granular Activated Carbon

Standard Test Method for Particle Size Distribution of Granular Activated Carbon

SIGNIFICANCE AND USE

4.1 It is necessary to know the distribution of particle sizes of granular activated carbon in order to provide proper contact of gases or liquid in a packed bed of the material. Changes in particle size distribution can affect the pressure drop across the bed and the rate of adsorption in a bed of a given size.

4.2 Mean particle diameter is a property of activated carbons that influences pressure drop.

4.3 Effective size and uniformity coefficient are two properties of activated carbons often of interest in municipal water treatment applications where control of particle size is of interest.

SCOPE

1.1 This test method covers the determination of the particle size distribution of granular activated carbon. For the purposes of this test, granular activated carbon is defined as a minimum of 90 % of the sample weight being retained on a 180-μm Standard sieve. A U.S. mesh 80 sieve is equivalent to a 180–μm Standard sieve.

Note 1: For extruded carbons, as the length/diameter ratio of the particles increases, the validity of the test results might be affected.

1.2 The data obtained may also be used to calculate mean particle diameter (MPD), effective size, and uniformity coefficient.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3.1 Exception—All mass measurements are in SI units only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D2862 − 16

Standard Test Method for

1

Particle Size Distribution of Granular Activated Carbon

This standard is issued under the fixed designation D2862; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope E177 Practice for Use of the Terms Precision and Bias in

ASTM Test Methods

1.1 This test method covers the determination of the particle

E300 Practice for Sampling Industrial Chemicals

size distribution of granular activated carbon. For the purposes

E691 Practice for Conducting an Interlaboratory Study to

of this test, granular activated carbon is defined as a minimum

Determine the Precision of a Test Method

of 90 % of the sample weight being retained on a 180-µm

Standardsieve.AU.S.mesh80sieveisequivalenttoa180–µm

3. Summary of Test Method

Standard sieve.

3.1 A known weight of granular activated carbon is placed

NOTE 1—For extruded carbons, as the length/diameter ratio of the

on the top sieve of a stacked set of U.S. Standard sieves and

particles increases, the validity of the test results might be affected.

shaken under standard conditions for a specific time period,

1.2 The data obtained may also be used to calculate mean

after which the weight percent of the total retained on each

particle diameter (MPD), effective size, and uniformity coef-

sieve and bottom pan is determined.

ficient.

4. Significance and Use

1.3 The values stated in inch-pound units are to be regarded

as standard. The values given in parentheses are mathematical 4.1 It is necessary to know the distribution of particle sizes

conversions to SI units that are provided for information only of granular activated carbon in order to provide proper contact

and are not considered standard. of gases or liquid in a packed bed of the material. Changes in

1.3.1 Exception—All mass measurements are in SI units particle size distribution can affect the pressure drop across the

only. bed and the rate of adsorption in a bed of a given size.

1.4 This standard does not purport to address all of the

4.2 Mean particle diameter is a property of activated car-

safety concerns, if any, associated with its use. It is the

bons that influences pressure drop.

responsibility of the user of this standard to establish appro-

4.3 Effective size and uniformity coefficient are two prop-

priate safety and health practices and determine the applica-

erties of activated carbons often of interest in municipal water

bility of regulatory limitations prior to use.

treatment applications where control of particle size is of

interest.

2. Referenced Documents

2

5. Apparatus

2.1 ASTM Standards:

3

D2652 Terminology Relating to Activated Carbon

5.1 Mechanical Sieve Shaker —This is a mechanically op-

D2854 Test Method for Apparent Density of Activated

erated sieve shaker that imparts a uniform rotating and tapping

Carbon

motion to a stack of 8-in. (203-mm or equivalent) sieves as

E11 Specification for Woven Wire Test Sieve Cloth and Test

described in 5.2. The sieve shaker should be adjusted to

Sieves

accommodate the desired number of sieves, receiver pan, and

sieve cover. The bottom stops should be adjusted to give a

1

clearance of approximately ⁄16 in. (1.5 mm) between the upper

1

This test method is under the jurisdiction of ASTM Committee D28 on

carrying plate stops and the sieve cover plate, so that the sieves

Activated Carbon and is the direct responsibility of Subcommittee D28.04 on Gas

will be free to rotate. The sieve shaker shall be powered with

Phase Evaluation Tests.

1

⁄4-hp(186-W)electricmotorproducing1725to1750rpm.The

CurrenteditionapprovedJune1,2016.PublishedJuly2016.Originallyapproved

in 1970. Last previous edition approved in 2010 as D2862 – 10. DOI: 10.1520/

D2862-16.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or TheTyler Ro-Tap Model RX-19-1 has been used in developing this test. Newer

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM models may not produce the same separations (Model RX-19-2 is equivalent to

Standards volume information, refer to the standard’s Document Summary page on Model RX-19-1). This model is available from Fisher Scientific, Pittsburgh, PA

the ASTM website. 15238.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D2862 − 16

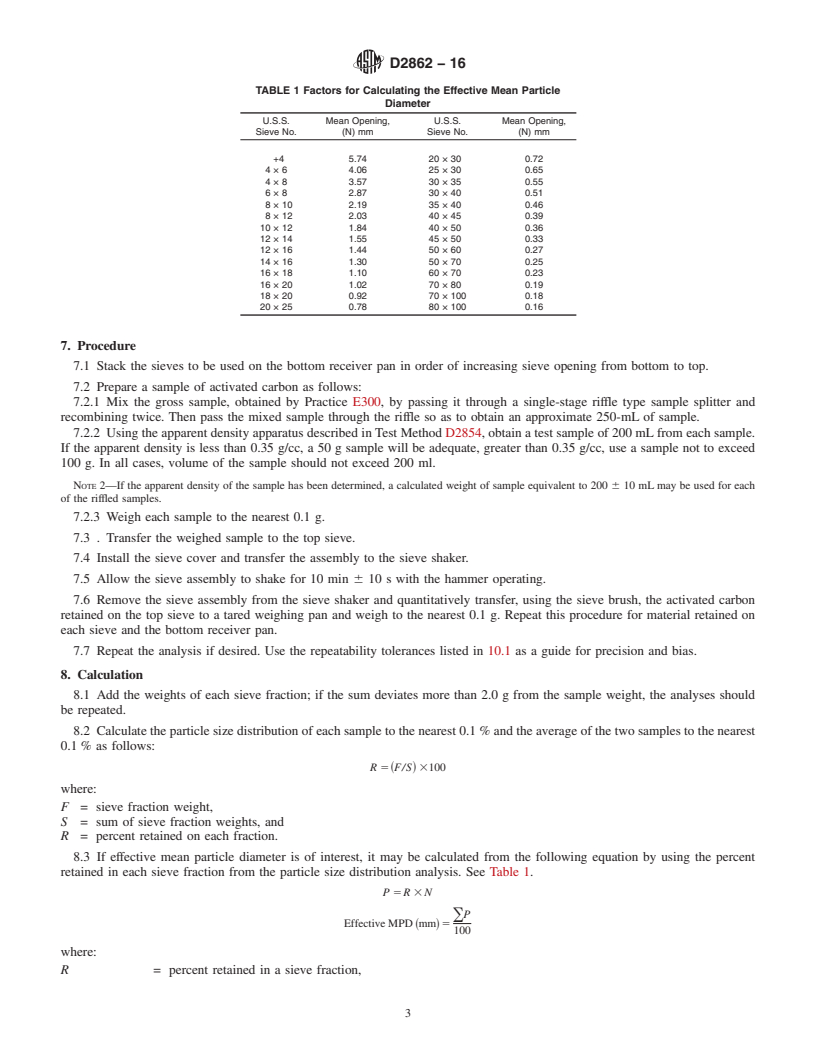

FIG. 1 Cumulative Particle Size Distribution Curve

sieve shaker should produce 140 to 160 raps per minute with 6. Sampling

the striker ar

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D2862 − 10 D2862 − 16

Standard Test Method for

1

Particle Size Distribution of Granular Activated Carbon

This standard is issued under the fixed designation D2862; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 This test method covers the determination of the particle size distribution of granular activated carbon. For the purposes of

this test, granular activated carbon is defined as a minimum of 90 % of the sample weight being retained on a 180-μm Standard

sieve. A U.S. mesh 80 sieve is equivalent to a 180–μm Standard sieve.

NOTE 1—For extruded carbons, as the length/diameter ratio of the particles increases, the validity of the test results might be affected.

1.2 The data obtained may also be used to calculate mean particle diameter (MPD), effective size, and uniformity coefficient.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3.1 Exception—All mass measurements are in SI units only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D2652 Terminology Relating to Activated Carbon

D2854 Test Method for Apparent Density of Activated Carbon

E11 Specification for Woven Wire Test Sieve Cloth and Test Sieves

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E300 Practice for Sampling Industrial Chemicals

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Summary of Test Method

3.1 A known weight of granular activated carbon is placed on the top sieve of a stacked set of U.S. Standard sieves and shaken

under standard conditions for a specific time period, after which the weight percent of the total retained on each sieve and bottom

pan is determined.

4. Significance and Use

4.1 It is necessary to know the distribution of particle sizes of granular activated carbon in order to provide proper contact of

gases or liquid in a packed bed of the material. Changes in particle size distribution can affect the pressure drop across the bed

and the rate of adsorption in a bed of a given size.

4.2 Mean particle diameter is a property of activated carbons that influences pressure drop.

4.3 Effective size and uniformity coefficient are two properties of activated carbons often of interest in municipal water

treatment applications where control of particle size is of interest.

1

This test method is under the jurisdiction of ASTM Committee D28 on Activated Carbon and is the direct responsibility of Subcommittee D28.04 on Gas Phase

Evaluation Tests.

Current edition approved April 1, 2010June 1, 2016. Published July 2010July 2016. Originally approved in 1970. Last previous edition approved in 20092010 as

ε1

D2862 – 97D2862 – 10. (2009) . DOI: 10.1520/D2862-10.10.1520/D2862-16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D2862 − 16

FIG. 1 Cumulative Particle Size Distribution Curve

5. Apparatus

3

5.1 Mechanical Sieve Shaker —This is a mechanically operated sieve shaker that imparts a uniform rotating and tapping motion

to a stack of 8-in. (203-mm or equivalent) sieves as described in 5.2. The sieve shaker should be adjusted to accommodate the

desired number of sieves, receiver pan, and sieve cover. The bottom stops should be adjusted to give a clearance of approximately

1

⁄16 in. (1.5 mm) between the upper carrying plate stops and the sieve cover plate, so that the sieves will be free to rotate. The sieve

1

shaker shall be powered with ⁄4-hp (186-W

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.