ASTM D2844-94

(Test Method)Standard Test Method for Resistance R-Value and Expansion Pressure of Compacted Soils

Standard Test Method for Resistance R-Value and Expansion Pressure of Compacted Soils

SCOPE

1.1 This test method covers the procedure for testing both treated and untreated laboratory compacted soils or aggregates with the stabilometer and expansion pressure devices to obtain results indicative of performance when placed in the base, subbase, or subgrade of a road subjected to traffic.

1.2 The values stated in inch-pound units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 2844 – 94

Standard Test Method for

Resistance R-Value and Expansion Pressure of Compacted

Soils

This standard is issued under the fixed designation D 2844; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the procedure for testing both

treated and untreated laboratory compacted soils or aggregates

with the stabilometer and expansion pressure devices to obtain

results indicative of performance when placed in the base,

subbase, or subgrade of a road subjected to traffic.

1.2 The values stated in inch-pound units are to be regarded

as the standard.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

C 670 Practice for Preparing Precision and Bias Statements

for Test Methods for Construction Materials

E 4 Practices for Force Verification of Testing Machines

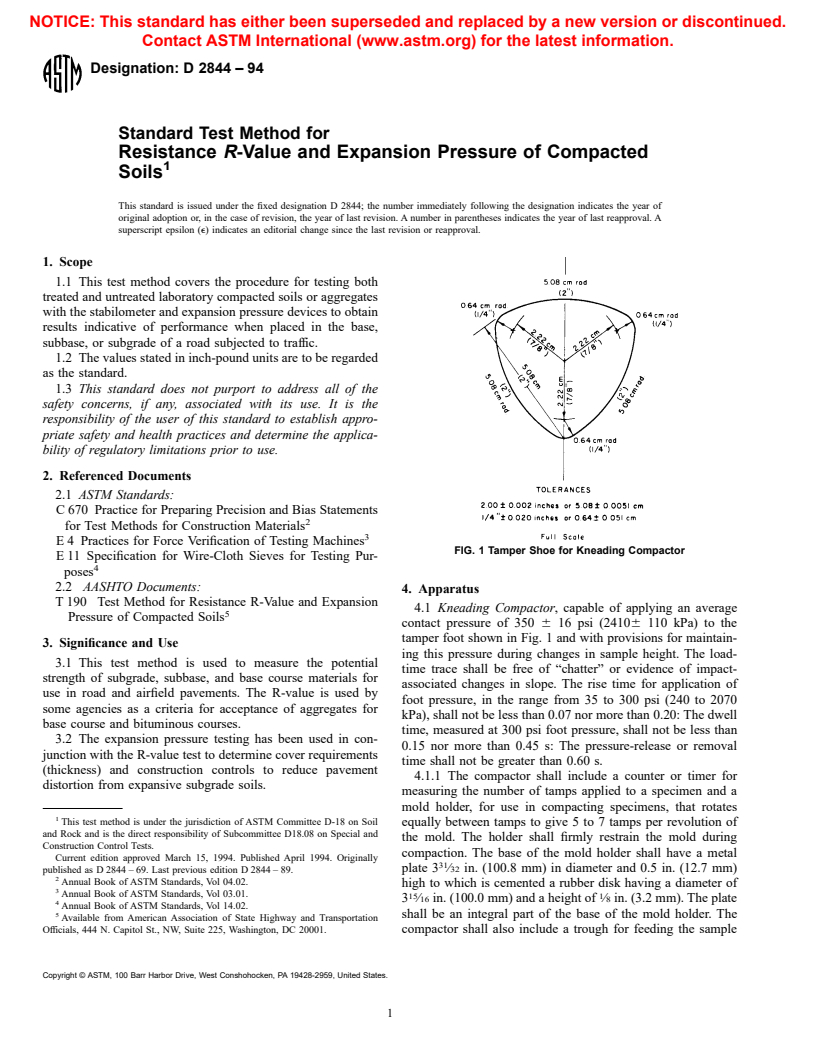

FIG. 1 Tamper Shoe for Kneading Compactor

E 11 Specification for Wire-Cloth Sieves for Testing Pur-

poses

2.2 AASHTO Documents:

4. Apparatus

T 190 Test Method for Resistance R-Value and Expansion

4.1 Kneading Compactor, capable of applying an average

Pressure of Compacted Soils

contact pressure of 350 6 16 psi (24106 110 kPa) to the

tamper foot shown in Fig. 1 and with provisions for maintain-

3. Significance and Use

ing this pressure during changes in sample height. The load-

3.1 This test method is used to measure the potential

time trace shall be free of “chatter” or evidence of impact-

strength of subgrade, subbase, and base course materials for

associated changes in slope. The rise time for application of

use in road and airfield pavements. The R-value is used by

foot pressure, in the range from 35 to 300 psi (240 to 2070

some agencies as a criteria for acceptance of aggregates for

kPa), shall not be less than 0.07 nor more than 0.20: The dwell

base course and bituminous courses.

time, measured at 300 psi foot pressure, shall not be less than

3.2 The expansion pressure testing has been used in con-

0.15 nor more than 0.45 s: The pressure-release or removal

junction with the R-value test to determine cover requirements

time shall not be greater than 0.60 s.

(thickness) and construction controls to reduce pavement

4.1.1 The compactor shall include a counter or timer for

distortion from expansive subgrade soils.

measuring the number of tamps applied to a specimen and a

mold holder, for use in compacting specimens, that rotates

This test method is under the jurisdiction of ASTM Committee D-18 on Soil equally between tamps to give 5 to 7 tamps per revolution of

and Rock and is the direct responsibility of Subcommittee D18.08 on Special and

the mold. The holder shall firmly restrain the mold during

Construction Control Tests.

compaction. The base of the mold holder shall have a metal

Current edition approved March 15, 1994. Published April 1994. Originally

plate 3 ⁄32 in. (100.8 mm) in diameter and 0.5 in. (12.7 mm)

published as D 2844 – 69. Last previous edition D 2844 – 89.

Annual Book of ASTM Standards, Vol 04.02.

high to which is cemented a rubber disk having a diameter of

Annual Book of ASTM Standards, Vol 03.01.

15 1

3 ⁄16 in. (100.0 mm) and a height of ⁄8 in. (3.2 mm). The plate

Annual Book of ASTM Standards, Vol 14.02.

shall be an integral part of the base of the mold holder. The

Available from American Association of State Highway and Transportation

Officials, 444 N. Capitol St., NW, Suite 225, Washington, DC 20001. compactor shall also include a trough for feeding the sample

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 2844

into the mold in 20 increments (Fig. 2). Troughs with a mm) thick, creped surface, medium-fast filtering speed, me-

FIG. 2 Compactor with Sample Feed Trough

3 2

semicircular cross section of 6 in. (39 cm ) in area and 20 in. dium retention.

(50.8 cm) long have proven satisfactory. 4.10 Expansion-Pressure Device, with accessories as shown

4.2 Compression Testing Machine, with a minimum capac- in Fig. 6. There should be at least three of these devices for

ity of 10 000 lbf (45 kN) and satisfying the requirements of each sample to be tested within a day’s time.

Practices E 4.

4.11 Deflection Gage, with divisions of 0.0001 in. (0.002

4.3 Mold,4 6 0.002 in. (101.6 6 0.05 mm) inside diameter mm) and an allen wrench as shown in Fig. 6.

by 5 6 0.008 in. (127 6 0.20 mm) high. (See Fig. 3 for surface

4.12 Stabilometer, with accessories, as shown in Fig. 7 and

roughness.) Fig. 8.

15 1

4.4 Rubber Disks,3 ⁄16 in. (100 mm) in diameter by ⁄8 in.

4.13 Standard Metal Specimen, 4 in. (101.60 mm) in outside

(3 mm) thick and having a durometer hardness of 60 6 15.

diameter by 6 in. (152.2 mm) high as shown in Fig. 8.

4.5 Metal Follower, solid-walled, metal specimen follower

4.14 Balance, 5000-g capacity, accurate to 1 g.

3.95 6 0.005 in. (100.33 6 0.13 mm) in outside diameter by

4.15 Sieves, 1 in. (25.0 mm), ⁄4 in. (19.0 mm) and No. 4

5 in. (127 mm) long.

(4.75 mm) conforming to the requirements of Specification

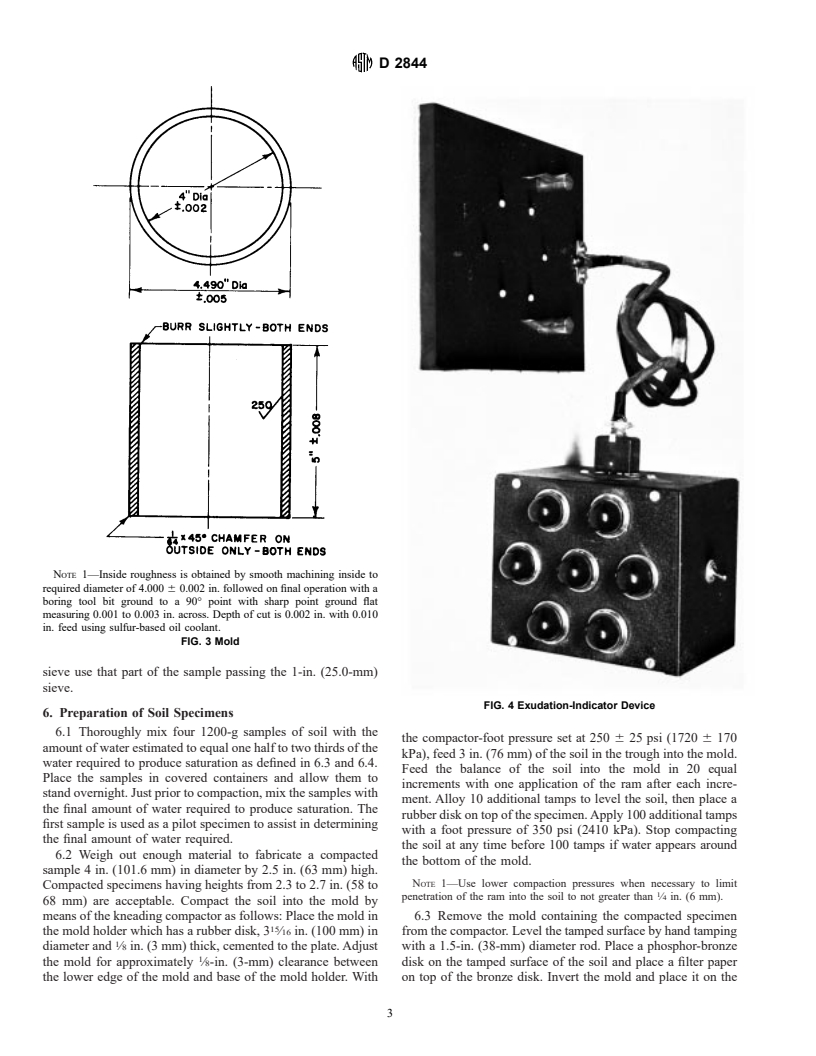

4.6 Exudation Device, as shown in Fig. 4.

E11.

4.7 Phosphor Bronze Disk, as shown in Fig. 5.

4.16 Miscellaneous Equipment, including mixing pans,

4.8 Filter Paper, 100 mm in diameter and 0.006 in. (1.5

spoons, spatulas, and gallon cans with close-fitting lids.

mm) thick, smooth surface, medium filtering speed, medium

retention.

5. Soil Preparation

4.9 Filter Paper, 110 mm in diameter and 0.006 in. (1.5

5.1 Remove any coatings from coarse aggregate and break

clay lumps to pass the No. 4 (4.75-mm) sieve.

5.2 Adjust the soil graduation when some of the material is

Copies of detailed drawings of the apparatus shown in Figs. 4 (1 drawing), 6 (4

retained on the ⁄4-in. (19.0-mm) sieve. When 75 % or more

drawings), 7 and 8 (7 drawings) are available at a nominal cost from the ASTM

passes the ⁄4-in. sieve, use that part of the sample passing

Headquarters. Request Adjunct No. ADJD284401, ADJD284402, and

ADJD284403, respectively. the ⁄4-in. sieve. If less than 75 % of the sample passes the 1-in.

D 2844

NOTE 1—Inside roughness is obtained by smooth machining inside to

required diameter of 4.000 6 0.002 in. followed on final operation with a

boring tool bit ground to a 90° point with sharp point ground flat

measuring 0.001 to 0.003 in. across. Depth of cut is 0.002 in. with 0.010

in. feed using sulfur-based oil coolant.

FIG. 3 Mold

sieve use that part of the sample passing the 1-in. (25.0-mm)

sieve.

FIG. 4 Exudation-Indicator Device

6. Preparation of Soil Specimens

6.1 Thoroughly mix four 1200-g samples of soil with the

the compactor-foot pressure set at 250 6 25 psi (1720 6 170

amount of water estimated to equal one half to two thirds of the

kPa), feed 3 in. (76 mm) of the soil in the trough into the mold.

water required to produce saturation as defined in 6.3 and 6.4.

Feed the balance of the soil into the mold in 20 equal

Place the samples in covered containers and allow them to

increments with one application of the ram after each incre-

stand overnight. Just prior to compaction, mix the samples with

ment. Alloy 10 additional tamps to level the soil, then place a

the final amount of water required to produce saturation. The

rubber disk on top of the specimen. Apply 100 additional tamps

first sample is used as a pilot specimen to assist in determining

with a foot pressure of 350 psi (2410 kPa). Stop compacting

the final amount of water required.

the soil at any time before 100 tamps if water appears around

6.2 Weigh out enough material to fabricate a compacted

the bottom of the mold.

sample 4 in. (101.6 mm) in diameter by 2.5 in. (63 mm) high.

NOTE 1—Use lower compaction pressures when necessary to limit

Compacted specimens having heights from 2.3 to 2.7 in. (58 to

penetration of the ram into the soil to not greater than ⁄4 in. (6 mm).

68 mm) are acceptable. Compact the soil into the mold by

means of the kneading compactor as follows: Place the mold in 6.3 Remove the mold containing the compacted specimen

the mold holder which has a rubber disk, 3 ⁄16 in. (100 mm) in from the compactor. Level the tamped surface by hand tamping

diameter and ⁄8 in. (3 mm) thick, cemented to the plate. Adjust with a 1.5-in. (38-mm) diameter rod. Place a phosphor-bronze

the mold for approximately ⁄8-in. (3-mm) clearance between disk on the tamped surface of the soil and place a filter paper

the lower edge of the mold and base of the mold holder. With on top of the bronze disk. Invert the mold and place it on the

D 2844

7.3 If the deflection gage does not check the above readings,

loosen the top frame bar and adjust the position of the shims,

between the frame and the spring steel bar, until the required

readings are obtained.

NOTE 3—Some models of the expansion-pressure apparat

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.