ASTM D7342-07

(Test Method)Standard Test Method for Shear Stability of Lubricating Grease in Presence of Water (Water Stability Test)

Standard Test Method for Shear Stability of Lubricating Grease in Presence of Water (Water Stability Test)

SIGNIFICANCE AND USE

It is known that contamination by water can affect the shear stability of some greases in service. Both test procedures specified in this method are widely used to determine the wet shear stability of greases in service. Many grease specifications require these procedures as a wet shear stability test. No accurate correlation is established between the test results and wet shear stability of grease in actual service.

SCOPE

1.1 This test method covers two procedures for determining the shear stability of lubricating grease in the presence of water (wet shear stability) by a full scale grease worker or a roll stability test apparatus. Both procedures can be used to determine the relative wet shear stability of greases, but the results between procedures are not directly comparable. This test method is also known as the water stability test.

1.2 The values stated in SI units are to be regarded as the standard; The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7342 − 07

StandardTest Method for

Shear Stability of Lubricating Grease in Presence of Water

(Water Stability Test)

This standard is issued under the fixed designation D7342; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope synonymously with penetration. Generally, consistency refers

to the worked penetration of a grease. D217

1.1 This test method covers two procedures for determining

the shear stability of lubricating grease in the presence of water

3.1.2 lubricating grease, n—semi-fluid to solid product of a

(wet shear stability) by a full scale grease worker or a roll

dispersion of a thickener in a liquid lubricant.

stability test apparatus. Both procedures can be used to

3.1.2.1 Discussion—The dispersion of the thickener forms a

determine the relative wet shear stability of greases, but the

two-phase system and immobilizes the liquid lubricant by

results between procedures are not directly comparable. This

surface tension and other physical forces. Other ingredients are

test method is also known as the water stability test.

commonly included to impart special properties. D217

1.2 The values stated in SI units are to be regarded as

3.1.3 penetration, n—of lubricating grease, depth that the

standard. No other units of measurement are included in this

standard cone, when released to fall under its own weight for

standard.

5 s, enters the sample. D217

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the 3.1.4 thickener, n—in lubricating grease, substance com-

responsibility of the user of this standard to establish appro-

posed of finely divided particles dispersed in a liquid lubricant

priate safety and health practices and determine the applica-

to form the product’s structure.

bility of regulatory limitations prior to use.

3.1.4.1 Discussion—The thickener can be fibers (such as

various metallic soaps) or plates or spheres (such as certain

2. Referenced Documents

non-soap thickener) which are insoluble or, at most, only very

2.1 ASTM Standards:

slightly soluble in liquid lubricant. The general requirements

D217 Test Methods for Cone Penetration of Lubricating

are that the solid particles to be relatively stable, gel-like

Grease

structure with the liquid lubricant. D217

D1403 Test Methods for Cone Penetration of Lubricating

3.1.5 wet shear stability, n—of lubricating grease,changein

Grease Using One-Quarter and One-Half Scale Cone

consistency of a mixture of sample and small amount of water

Equipment

after a specified amount of working in a grease worker or a roll

D1831 Test Method for Roll Stability of Lubricating Grease

stability test apparatus.

D1193 Specification for Reagent Water

3.1.6 worked penetration, n—of lubricating grease, the

3. Terminology

penetration at 25°C, without delay, of a sample after 60 double

3.1 Definitions:

strokes in a standard grease worker. D217

3.1.1 consistency, n—of lubricating grease, degree of resis-

3.1.7 working, n—of lubricating grease, subjection of a

tance to movement under stress.

sample to the shearing action of the standard grease worker.

3.1.1.1 Discussion—Theterm consistencyisusedsomewhat

D217

4. Summary of Test Method

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

4.1 Agrease sample mixed with a small amount of water is

D02.G0.07 on Research Techniques.

subjected to low shear at 20 to 35°C for a specified time or

Current edition approved May 1, 2007. Published May 2007. DOI: 10.1520/

D7342-07.

strokes in a standard grease worker (Procedure A) or a roll

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

stability apparatus (Procedure B). The difference between the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

cone penetration before working and the cone penetration after

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. is used as a measure of the wet shear stability of the grease.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

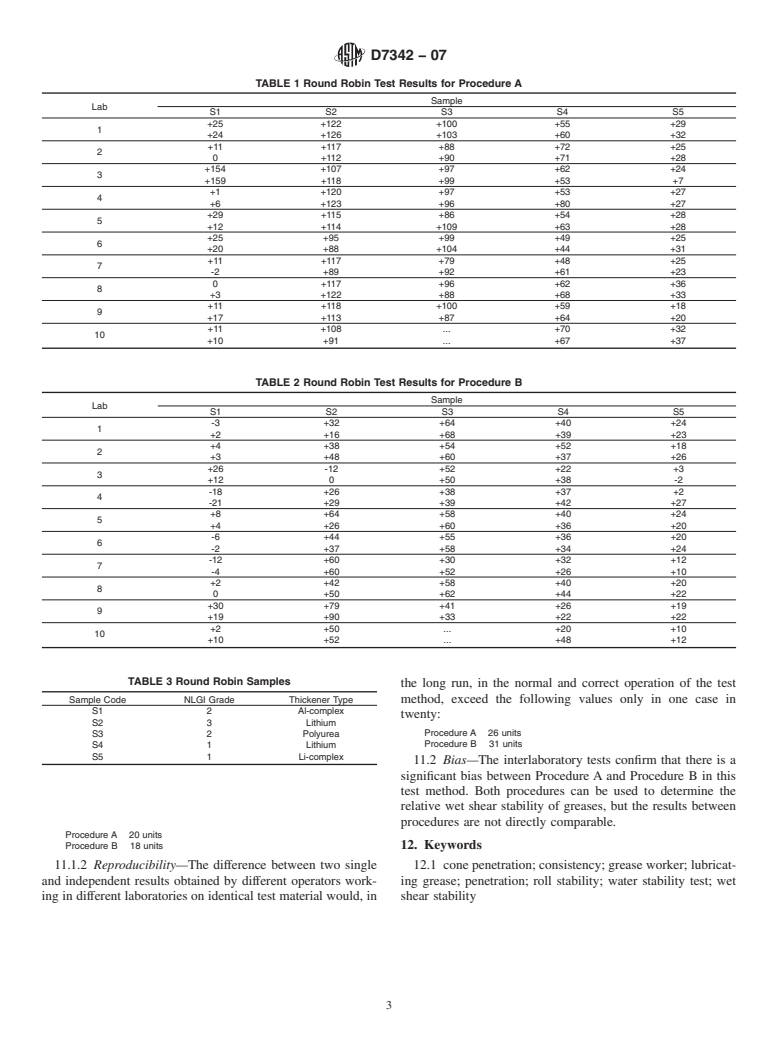

D7342 − 07

5. Significance and Use 8.4 Immediately after the grease sample reaches 25 6

0.5°C, rework the sample an additional 60 double strokes.

5.1 It is known that contamination by water can affect the

Determine the worked penetration.

shear stability of some greases in service. Both test procedures

specified in this method are widely used to determine the wet

Procedure B—Wet Shell Roll Test

shear stability of greases in service. Many grease specifications

8.5 Determine the worked penetration of the grease to be

require these procedures as a wet shear stability test. No

tested in accordance with Test Methods D1403.

accurate correlation is established between the test results and

wet shear stability of grease in actual service. 8.6 Transfer 63.0 6 0.2 g of unworked grease to test

cylinder. Distribute the grease uniformly on the inside wall of

6. Apparatus the cylinder with a spatula.

6.1 Motorized Grease Worker, as specified in Test Methods 8.7 Place the weighed roll in the cylinder.

D217.

8.8 Add 7.0 6 0.2 g distilled water to the cylinder, and

6.2 Roll Stability Test Apparatus, as specified in Test tighten the cap.

Method D1831.

8.9 Mount the cylinder in position, start the machine, and

6.3 Penetrometer, as specified in Test Methods D217. record the time and room temperature which should be limited

to 20 to 35°C. If the cylinder is enclosed within a cabinet, the

6.4 One-Quarter or One-Half Scale Cone and Shaft with

temperature around cylinder shall be maintained at 20 to 35°C.

Worker, as described in Test Methods D1403.

8.10 After rolling the cylinder for 2 h 6 5 min, remove the

6.5 Electric Kitchen-type mixer, Low speed of 500 rpm.

grease from the cylinder promptly and proceed with the

6.6 Suitable Mixing Bowl.

requirements of worked penetration in Test Methods D1403.

Record the worked penetratio

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.