ASTM F1309-98(2007)

(Practice)Standard Practice for Installation Procedures for Fitting Chocks to Marine Machinery Foundations

Standard Practice for Installation Procedures for Fitting Chocks to Marine Machinery Foundations

SIGNIFICANCE AND USE

p>This practice provides the three principal methods of fitting chocks to marine machinery foundations to ensure that the machinery is free of vibration and perfectly aligned after installation.

The three principal methods of installing chocks described herein are as follows:

Type A—Epoxy-based resin, nonshrinking Chockfast Orange PR 610 TCF by Philadelphia Resin Corp., or equal, and

Type B—Two-piece wedge chocks.

Type C—Solid, one-piece fitted chocks.

SCOPE

1.1 This practice covers the acceptable methods of fitting chocks to marine machinery foundations.

1.2 The values stated in SI units shall be regarded as standard. The values in parentheses are for information only.

1.3 This standard does not purport to address the safety concerns associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F1309 − 98(Reapproved 2007) An American National Standard

Standard Practice for

Installation Procedures for Fitting Chocks to Marine

Machinery Foundations

This standard is issued under the fixed designation F1309; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Significance and Use

1.1 This practice covers the acceptable methods of fitting

3.1 This practice provides the three principal methods of

chocks to marine machinery foundations.

fitting chocks to marine machinery foundations to ensure that

the machinery is free of vibration and perfectly aligned after

1.2 The values stated in SI units shall be regarded as

installation.

standard. The values in parentheses are for information only.

3.1.1 The three principal methods of installing chocks

1.3 This standard does not purport to address the safety

described herein are as follows:

concerns associated with its use. It is the responsibility of the

3.1.1.1 Type A—Epoxy-based resin, nonshrinking Chock-

user of this standard to establish appropriate safety and health

fastOrangePR610TCFbyPhiladelphiaResinCorp.,orequal,

practices and determine the applicability of regulatory limita-

and

tions prior to use.

3.1.1.2 Type B—Two-piece wedge chocks.

2. Referenced Documents 3.1.1.3 Type C—Solid, one-piece fitted chocks.

2.1 ASTM Standards:

4. Procedure

A370 Test Methods and Definitions for Mechanical Testing

of Steel Products

4.1 General Requirements for Types A, B, and C Chocking

D638 Test Method for Tensile Properties of Plastics

Systems:

D648 Test Method for Deflection Temperature of Plastics

4.1.1 Machining:

Under Flexural Load in the Edgewise Position

4.1.1.1 Type A chocks, machinery bedplates, foundation

D695 Test Method for Compressive Properties of Rigid

plates, and bolts do not require finish machining if the chocks

Plastics

are not designed to be removed. Unless specified otherwise,

2.2 Other Documents:

Types B and C chock, bolts/studs, machinery bedplate, foun-

American Bureau of Shipping Rules for Building and

dation plates, and fitted holes need to be finished machined and

Classing Steel Vessels

fitted.

American Welding Society Publication, AWS D1.1 Struc-

4.1.1.2 Surfaces in way of the chock areas on the machinery

tural Welding Code

bedplate and the foundation plate may be machined before

installation or while the ship is not waterborne, or both.

This practice is under the jurisdiction of ASTM Committee F25 on Ships and 4.1.1.3 Unless otherwise specified, all finished surfaces

Marine Technology and is the direct responsibility of Subcommittee F25.03 on

shall be finished to a maximum of 0.003–mm roughness height

Outfitting and Deck Machinery.

average (RHA).

Current edition approved Dec. 1, 2007. Published January 2008. Originally

4.1.1.4 Finished areas on the machinery bedplate and the

approved in 1990. Last previous edition approved in 2003 as F1309 - 98(2003).

DOI: 10.1520/F1309-98R07.

foundation plate in way of the chocks shall be sufficiently

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

greater in size than the chock to prevent interference from the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

unfinished area with the chock during installation.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

4.1.1.5 Spotface hole edge radius shall be such that there

Available from American Bureau of Shipping (ABS), ABS Plaza, 16855

will not be any interference between it and the bolt head-to-

Northchase Dr., Houston, TX 77060, http://www.eagle.org.

4 shank radius. The spotface area shall be sufficiently greater in

Available from American Welding Society (AWS), 550 NW LeJeune Rd.,

area than that of the bolt head or nut so as not to cause any

Miami, FL 33126, http://www.aws.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1309 − 98 (2007)

interference when tightening or with the tooling used. The 4.2.1 Provision for Future Machinery Removal—To prevent

spotface surfaces shall be perpendicular to the finished fitted adhesion of chocks to adjoining surfaces and facilitate future

hole centerline. removal of machinery, spray an aerosol release agent on all

contact surfaces. This precaution allows these chocks to be

4.1.2 Installation:

removed in a similar manner to steel chocks.

4.1.2.1 The ship must be waterborne and fairly well com-

4.2.2 Applicable Techniques:

pleted before final alignment is accomplished. Ship shall be

trimmed as close to the even keel position as practicable. The

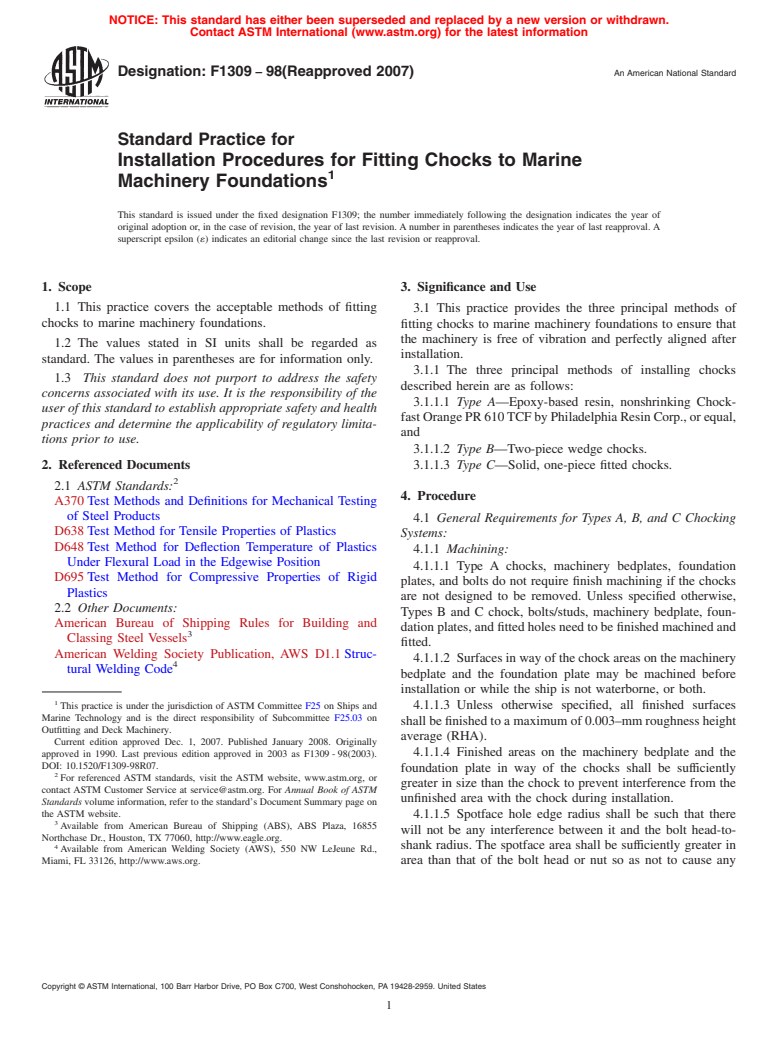

4.2.2.1 Position dams to retain the compound during pour-

same trim position shall be maintained throughout the align- ing and curing without distortion. Damming materials may be

ment procedure. No heavyweight shall be moved, loaded, or

expanded plastic, foam rubber stripping and sheet metal, or

unloaded during alignment; ramps for Ro-Ros shall not be light gage flat bar. (See Fig. 1.)

lowered or hoisted.

4.2.2.2 Follow resin manufacturer’s instructions including

4.1.2.2 Final machining of the fitted or bearing areas of the the relative design parameters on loading, temperature, allow-

machinery bedplate to chock to foundation plate and the

able thickness, additional design, installation, bolt tension, and

mating areas of the fitted portion of the bolt/stud shank and to

inspection.

the hole wall shall be a minimum of 85 % uniformly distrib-

4.2.3 Foundation Bolts—Install hold-down bolts before

uted around the mating area.Alight coat of Prussian blue shall

pouring of resin. Tension (torque) bolts only after resin

be used to check the contact areas.

manufacturer’s recommended cure time.

4.1.2.3 Machineryshallbealignedusingasufficientnumber

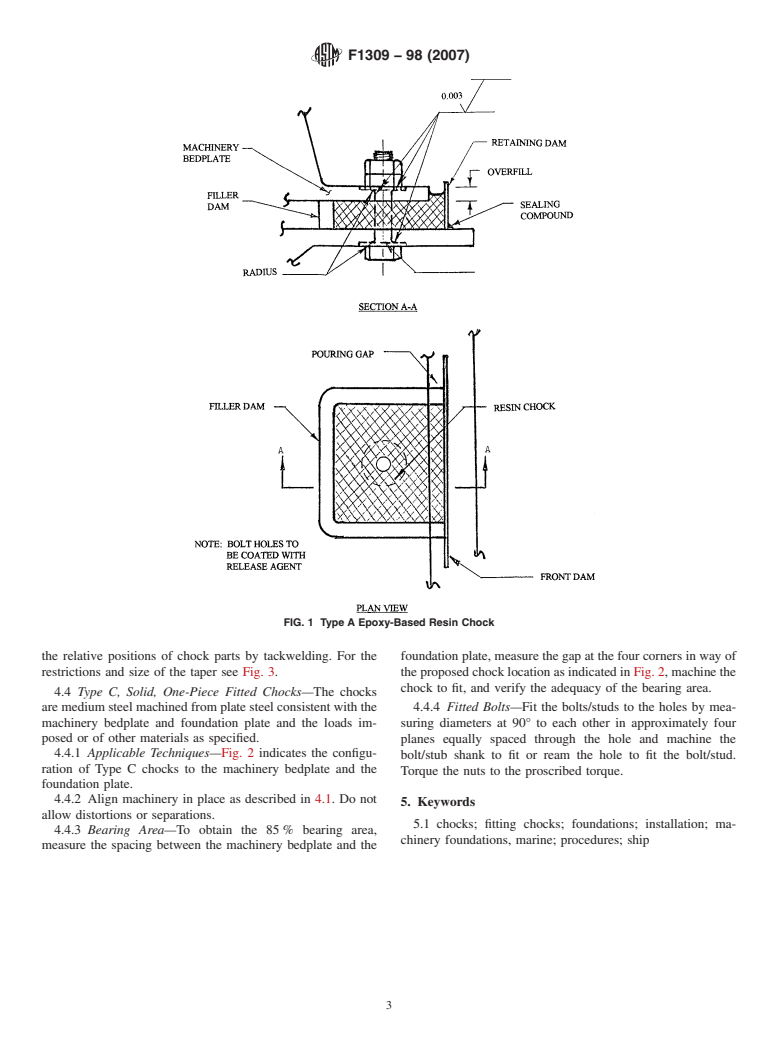

4.3 Type B, Two-Piece Wedge Chock—The two-piece

of jackscrews, shims, and wedges to accommodate adequate

wedges are drop-forged, medium steel or machined from steel

up-down, port-starboard, and fore-aft movement without dis-

plate of equal strength or of other materials as specified.

torting the machinery bedplate or foundation plate and, once

4.3.1 Applicable Techniques—Fig. 2 indicates the configu-

aligned, be able to hold that alignment firmly during the final

ration of Type C chocks to the machinery bedplate and the

chock installation and bolt-fitting phase.

foundation plate.

4.1.2.4 A sufficient number of fitted bolts and chocks shall

4.3.1.1 The taper on the sloped faces of each half of the

be installed to maintain the alignment and prevent any relative

chock must not exceed a rise of one over a run o

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.