ASTM D1932-13

(Test Method)Standard Test Method for Thermal Endurance of Flexible Electrical Insulating Varnishes

Standard Test Method for Thermal Endurance of Flexible Electrical Insulating Varnishes

SIGNIFICANCE AND USE

5.1 A major factor affecting the long term performance of insulating materials is thermal degradation. It is possible that factors, such as moisture and vibration, will cause failures after the material has been weakened by thermal degradation.

5.2 An electrical insulating varnish is effective in protecting electrical equipment only as long as it retains its physical and electrical integrity.

5.3 The thermal degradation of the varnish results in weight loss, porosity, crazing, and generally a reduction in flexibility. Degradation of the varnish can be detected by a decrease in dielectric strength, which is therefore used as the failure criterion for this test method.

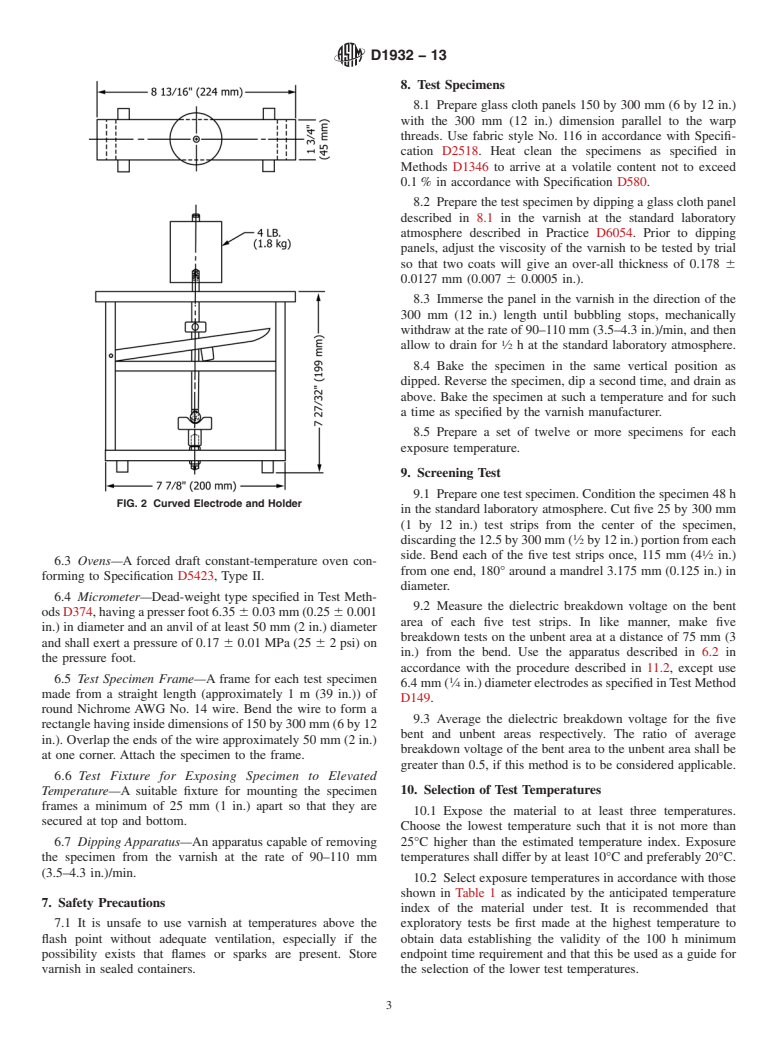

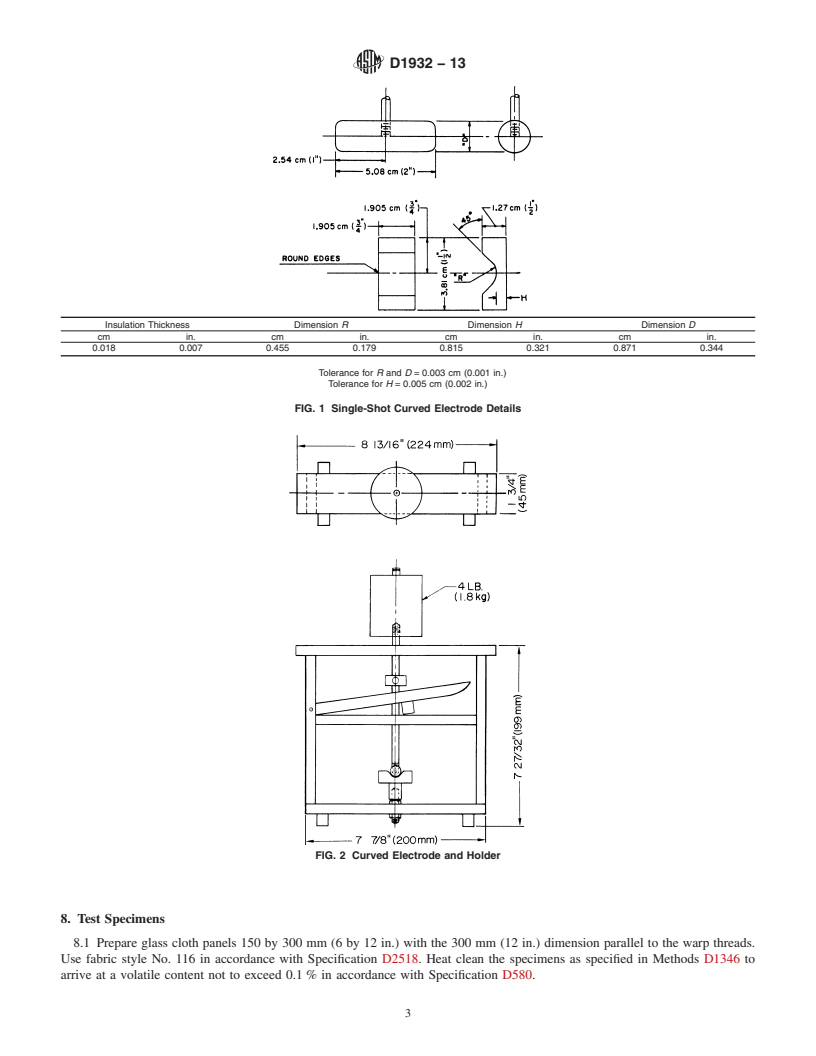

5.4 Electrical insulating varnishes undergo flexing in service due to vibration and thermal expansion. For this reason, this functional test includes flexing and elongation of the insulation. The electrodes used in this test method are designed to elongate the outer surface of the specimen 2 % with respect to the neutral axis of the base fiber while being tested for dielectric breakdown.

SCOPE

1.1 This test method covers the determination of the relative thermal endurance of flexible electrical insulating varnishes by determining the time necessary at elevated temperatures to decrease the dielectric breakdown of the varnish to an arbitrarily selected value when applied to a standard glass fiber fabric.

1.2 This test method does not apply to varnishes that lose a high percentage of their dielectric breakdown voltage when flexed before elevated temperature exposure as prescribed in the screening test (Section 9). Examples of such varnishes are those used for high speed armatures and laminated structures. Also, this test method is not applicable to varnishes which distort sufficiently during thermal elevated temperature exposure so that they cannot be tested using the curved electrode assembly.

1.3 Thermal endurance is expressed in terms of a temperature index.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.Note 1—There is no equivalent IEC or ISO standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Section 7.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D1932 − 13

Standard Test Method for

Thermal Endurance of Flexible Electrical Insulating

1

Varnishes

This standard is issued under the fixed designation D1932; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* 2. Referenced Documents

2

1.1 Thistestmethodcoversthedeterminationoftherelative 2.1 ASTM Standards:

thermal endurance of flexible electrical insulating varnishes by D149 Test Method for Dielectric Breakdown Voltage and

determining the time necessary at elevated temperatures to DielectricStrengthofSolidElectricalInsulatingMaterials

decrease the dielectric breakdown of the varnish to an arbi- at Commercial Power Frequencies

trarily selected value when applied to a standard glass fiber D374 Test Methods for Thickness of Solid Electrical Insu-

3

fabric. lation (Withdrawn 2013)

D580 Specification for Greige Woven Glass Tapes and

1.2 This test method does not apply to varnishes that lose a

Webbings

high percentage of their dielectric breakdown voltage when

D1346 Test Method for Testing Electrical Insulating Var-

flexed before elevated temperature exposure as prescribed in

3

nishes for 180 C and Above (Withdrawn 1986)

the screening test (Section 9). Examples of such varnishes are

D1711 Terminology Relating to Electrical Insulation

those used for high speed armatures and laminated structures.

D2518 Specification for Woven Glass Fabrics for Electrical

Also, this test method is not applicable to varnishes which

3

Insulation (Withdrawn 2013)

distort sufficiently during thermal elevated temperature expo-

D5423 Specification for Forced-Convection Laboratory Ov-

sure so that they cannot be tested using the curved electrode

ens for Evaluation of Electrical Insulation

assembly.

D6054 Practice for Conditioning Electrical Insulating Mate-

3

1.3 Thermal endurance is expressed in terms of a tempera-

rials for Testing (Withdrawn 2012)

4

ture index.

2.2 IEEE Publications:

1.4 The values stated in SI units are to be regarded as IEEE No. 101A Guide for the Statistical Analysis of Ther-

standard. No other units of measurement are included in this mal Life Test Data (including Appendix A)

standard. 2.3 IEC Publications:

IEC 60216 Guide for the Determination of Thermal Endur-

NOTE 1—There is no equivalent IEC or ISO standard.

5

ance Properties of Electrical Insulating Materials (Part 1)

1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

3. Terminology

responsibility of the user of this standard to establish appro-

3.1 Definitions:

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. For specific hazard

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

statements, see Section 7.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

1

This test method is under the jurisdiction of ASTM Committee D09 on the ASTM website.

3

Electrical and Electronic Insulating Materials and is the direct responsibility of The last approved version of this historical standard is referenced on

Subcommittee D09.01 on Electrical Insulating Varnishes, Powders and Encapsulat- www.astm.org.

4

ing Compounds. Available from the Institute of Electrical and Electronics Engineers, 1828 LSt.,

Current edition approved April 1, 2013. Published April 2013. Originally NW, Suite 1202, Washington, DC 20036–5104.

5

approved in 1967. Last previous edition approved in 2009 as D1932 – 04 (2009). Available from American National Standards Institute, 25 West 43rd St., 4th

DOI: 10.1520/D1932-13. Floor, New York, NY 10036.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D1932 − 13

3.1.1 temperature index (TI), n—a number which permits (300 V/mil) of original thickness unless lower endpoint values

comparison of the temperature/time characteristics of an elec- are agreed upon or indicated in the applicable material speci-

trical insulating material, or a simple combination of materials, fications.

based on the temperature in degrees Celsius which is obtained

by extrapolating the Arrhenius plot of endpoint time versus

5. Significance and Use

temperature to a specified time, usually 20 000 h.

5.1 A major factor affecting the long term performanc

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D1932 − 04 (Reapproved 2009) D1932 − 13 An American National Standard

Standard Test Method for

Thermal Endurance of Flexible Electrical Insulating

1

Varnishes

This standard is issued under the fixed designation D1932; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope Scope*

1.1 This test method covers the determination of the relative thermal endurance of flexible electrical insulating varnishes by

determining the time necessary at elevated temperatures to decrease the dielectric breakdown of the varnish to an arbitrarily

selected value when applied to a standard glass fiber fabric.

1.2 This test method does not apply to varnishes that lose a high percentage of their dielectric breakdown voltage when flexed

before elevated temperature exposure as prescribed in the screening test (Section 9). Examples of such varnishes are those used

for high speed armatures and laminated structures. Also, this test method is not applicable to varnishes which distort sufficiently

during thermal elevated temperature exposure so that they cannot be tested using the curved electrode assembly.

1.3 Thermal endurance is expressed in terms of a temperature index.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

NOTE 1—There is no equivalent IEC or ISO standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For specific hazard statements, see Section 7.

2. Referenced Documents

2

2.1 ASTM Standards:

D149 Test Method for Dielectric Breakdown Voltage and Dielectric Strength of Solid Electrical Insulating Materials at

Commercial Power Frequencies

3

D374 Test Methods for Thickness of Solid Electrical Insulation (Withdrawn 2013)

D580 Specification for Greige Woven Glass Tapes and Webbings

3

D1346 Test Method for Testing Electrical Insulating Varnishes for 180 C and Above (Withdrawn 1986)

D1711 Terminology Relating to Electrical Insulation

3

D2518 Specification for Woven Glass Fabrics for Electrical Insulation (Withdrawn 2013)

D5423 Specification for Forced-Convection Laboratory Ovens for Evaluation of Electrical Insulation

3

D6054 Practice for Conditioning Electrical Insulating Materials for Testing (Withdrawn 2012)

4

2.2 IEEE Publications:

IEEE No. 101A Guide for the Statistical Analysis of Thermal Life Test Data (including Appendix A)

2.3 IEC Publications:

5

IEC 60216 Guide for the Determination of Thermal Endurance Properties of Electrical Insulating Materials (Part 1)

1

This test method is under the jurisdiction of ASTM Committee D09 on Electrical and Electronic Insulating Materials and is the direct responsibility of Subcommittee

D09.01 on Electrical Insulating Varnishes, Powders and Encapsulating Compounds.

Current edition approved Oct. 1, 2009April 1, 2013. Published February 2010April 2013. Originally approved in 1967. Last previous edition approved in 20042009 as

D1932 – 04.D1932 – 04 (2009). DOI: 10.1520/D1932-04R09.10.1520/D1932-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

4

Available from the Institute of Electrical and Electronics Engineers, 1828 L St., NW, Suite 1202, Washington, DC 20036–5104.

5

Available from American National Standards Institute, 25 West 43rd St., 4th Floor, New York, NY 10036.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D1932 − 13

3. Terminology

3.1 Definitions:

3.1.1 temperature index (TI), n—a number which permits comparison of the temperature/time characteristics of an electrical

insulating material, or a simple combination of materia

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.