ASTM F1267-18

(Specification)Standard Specification for Metal, Expanded, Steel

Standard Specification for Metal, Expanded, Steel

ABSTRACT

This specification covers expanded metal. Expanded metal shall be of the following types, classes, grades such as type I-expanded, type II-expanded and flattened, class I-uncoated, class2-hot-dip zinc uncoated, class 3-corrosion resisting steel, grade A and grade B. Expanded metal shall be made from commercial steel, carbon steel sheets or from stainless steel sheets. Expanded metal shall be manufactured with the corresponding thickness, design size, opening size and strand size. Each single strand test specimen shall be visually inspected, and that surface of the strand observed to have the most nearly uniform coating shall be the tension surface when the strand is subject to bending. The coating thickness shall be measured microscopically at a suitable magnification. The minimum and maximum coating thicknesses shall be measured on each of the four exposed surfaces, but not at the corners.

SCOPE

1.1 This specification covers expanded metal.

1.1.1 Expanded metal covered by this specification is intended for a variety of applications.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only and may be approximate.

1.3 The following precautionary caveat pertains only to the test methods portion, Section 11, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F1267 − 18

Standard Specification for

1

Metal, Expanded, Steel

This standard is issued under the fixed designation F1267; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* Stainless Steel Sheet, Strip, Plate, and Flat Bar

A700 Guide for Packaging, Marking, and Loading Methods

1.1 This specification covers expanded metal.

for Steel Products for Shipment

1.1.1 Expanded metal covered by this specification is in-

A1008/A1008M Specification for Steel, Sheet, Cold-Rolled,

tended for a variety of applications.

Carbon, Structural, High-Strength Low-Alloy, High-

1.2 The values stated in inch-pound units are to be regarded

Strength Low-Alloy with Improved Formability, Solution

as the standard. The values given in parentheses are for

Hardened, and Bake Hardenable

information only and may be approximate.

A1011/A1011M Specification for Steel, Sheet and Strip,

1.3 The following precautionary caveat pertains only to the Hot-Rolled, Carbon, Structural, High-Strength Low-

test methods portion, Section 11, of this specification. This

Alloy, High-Strength Low-Alloy with Improved

standard does not purport to address all of the safety concerns, Formability, and Ultra-High Strength

3

if any, associated with its use. It is the responsibility of the user

2.2 SAE Standard:

of this standard to establish appropriate safety, health, and

SAE J 1086 Numbering Metals and Alloys (Stabilized Oc-

environmental practices and determine the applicability of

tober 2012)

regulatory limitations prior to use.

4

2.3 Military Standards:

1.4 This international standard was developed in accor-

MIL-C-16173 Corrosion Preventive Compound, Solvent

dance with internationally recognized principles on standard-

Cutback, Cold-Application

ization established in the Decision on Principles for the

MIL-STD-105 Sampling Procedures and Tables for Inspec-

Development of International Standards, Guides and Recom-

tion by Attributes

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

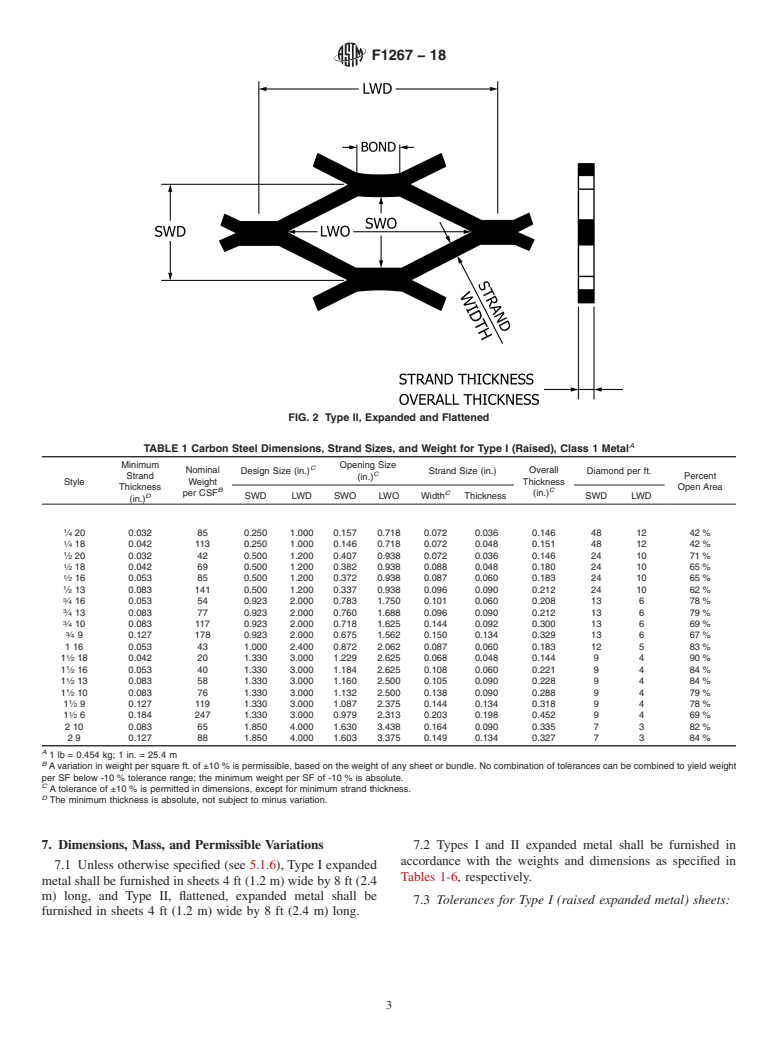

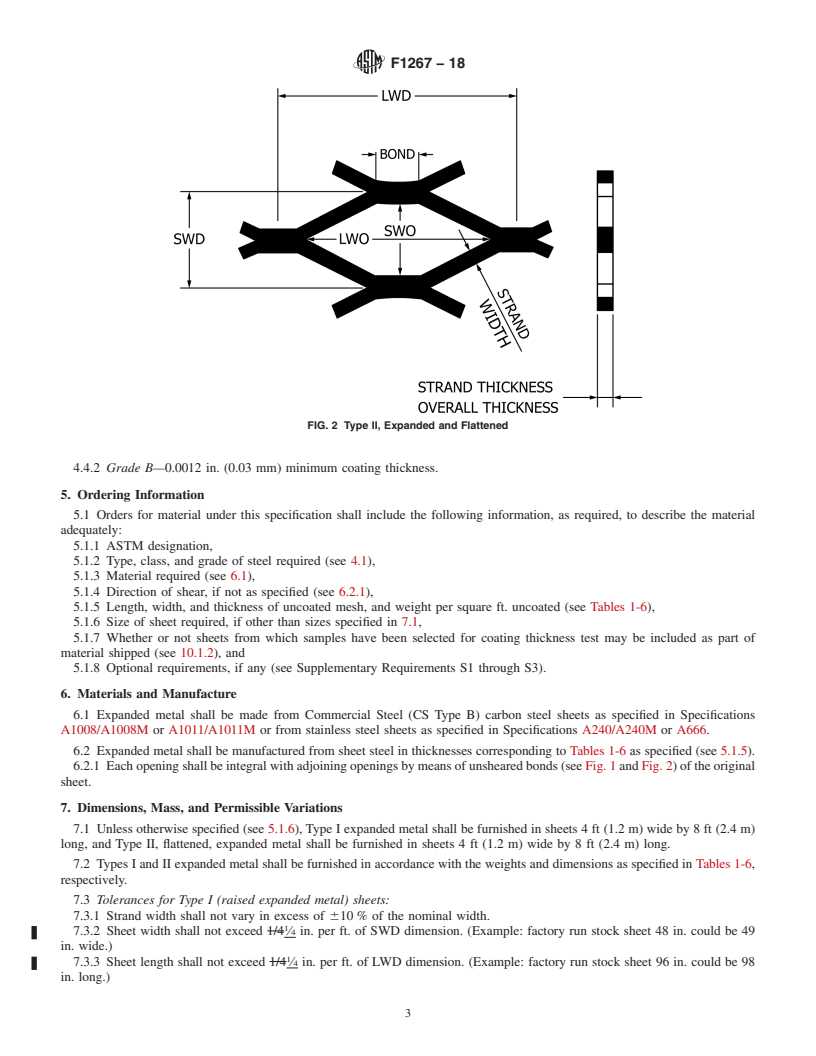

3. Terminology

3.1 Expanded Metal Terminology:

2. Referenced Documents

2 3.1.1 bond, n—the solid intersection of two strands.

2.1 ASTM Standards:

3.1.2 camber, n—the bow of a side or edge from end to end

A123/A123M Specification for Zinc (Hot-Dip Galvanized)

from a straight line.

Coatings on Iron and Steel Products

A240/A240M Specification for Chromium and Chromium-

3.1.3 diamonds, n—open area of metal after expanding.

Nickel Stainless Steel Plate, Sheet, and Strip for Pressure

Most expanded metal open area or patterns are uniform

Vessels and for General Applications

diamond shaped, but may also be hexagonal, louvered,

A653/A653M Specification for Steel Sheet, Zinc-Coated

asymmetric, square, or other shapes, or combinations thereof.

(Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed)

3.1.4 edge configuration, n—refers to the edge condition of

by the Hot-Dip Process

a sheet may they be closed diamonds (bonded), or open

A666 Specification for Annealed or Cold-Worked Austenitic

diamonds (random) produced by shearing.

3.1.5 expanded metal, n—a rigid sheet of metal that is

1

simultaneously been slit and stretched creating an open dia-

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel and Related Alloysand is the direct responsibility of Subcommittee mond pattern.

A01.19 on Steel Sheet and Strip.

Current edition approved March 1, 2018. Published April 2018. Originally

approved in 1989. Last previous edition approved in 2015 as F1267 – 15. DOI:

3

10.1520/F1267-18. Available from Society of Automotive Engineers (SAE), 400 Commonwealth

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Dr., Warrendale, PA 15096-0001, http://www.sae.org.

4

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from Manufacturers Standardization Society of the Valve and Fittings

Standards volume information, refer to the standard’s Document Summary page on Industry (MSS), 127 Park St., NE, Vienna, VA 22180-4602, http://www.mss-

the ASTM website. hq.com.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F1267 − 18

3.1.6 flattened, v (F)—expanded metal that has been cold- 4.3.1 Class 1—Uncoated.

rolled after expansion. 4.3.2 Class 2—Hot-dip zinc-coated (galvanized or gal-

van

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F1267 − 15 F1267 − 18

Standard Specification for

1

Metal, Expanded, Steel

This standard is issued under the fixed designation F1267; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 This specification covers expanded metal.

1.1.1 Expanded metal covered by this specification is intended for a variety of applications.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information

only and may be approximate.

1.3 The following precautionary caveat pertains only to the test methods portion, Section 11, of this specification. This standard

does not purport to address all of the safety problems concerns, if any, associated with its use. It is the responsibility of the user

of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the applicability

of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

A123/A123M Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products

A240/A240M Specification for Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip for Pressure Vessels and

for General Applications

A653/A653M Specification for Steel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by the

Hot-Dip Process

A666 Specification for Annealed or Cold-Worked Austenitic Stainless Steel Sheet, Strip, Plate, and Flat Bar

A700 Guide for Packaging, Marking, and Loading Methods for Steel Products for Shipment

A1008/A1008M Specification for Steel, Sheet, Cold-Rolled, Carbon, Structural, High-Strength Low-Alloy, High-Strength

Low-Alloy with Improved Formability, Solution Hardened, and Bake Hardenable

A1011/A1011M Specification for Steel, Sheet and Strip, Hot-Rolled, Carbon, Structural, High-Strength Low-Alloy, High-

Strength Low-Alloy with Improved Formability, and Ultra-High Strength

3

2.2 SAE Standard:

SAE J 1086 Numbering Metals and Alloys in the Unified Numbering System(Stabilized October 2012)

4

2.3 Military Standards:

MIL-C-16173 Corrosion Preventive Compound, Solvent Cutback, Cold-Application

MIL-STD-105 Sampling Procedures and Tables for Inspection by Attributes

3. Terminology

3.1 Expanded Metal Terminology:

3.1.1 bond, n—the solid intersection of two strands.

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloysand is the direct responsibility of Subcommittee A01.19

on Steel Sheet and Strip.

Current edition approved Nov. 1, 2015March 1, 2018. Published December 2015April 2018. Originally approved in 1989. Last previous edition approved in 20122015

as F1267 – 12.F1267 – 15. DOI: 10.1520/F1267-15.10.1520/F1267-18.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from Society of Automotive Engineers (SAE), 400 Commonwealth Dr., Warrendale, PA 15096-0001, http://www.sae.org.

4

Available from Manufacturers Standardization Society of the Valve and Fittings Industry (MSS), 127 Park St., NE, Vienna, VA 22180-4602, http://www.mss-hq.com.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F1267 − 18

3.1.2 camber, n—the bow of a side or edge from end to end from a straight line.

3.1.3 diamonds, n—open area of metal after expanding. Most expanded metal open area or patterns are uniform diamond

shaped, but may also be hexagonal, louvered, asymmetric, square, or other shapes, or combinations thereof.

3.1.4 edge configuration, n—refers to the edge condition of a sheet may they

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.