ASTM F836M-02(2010)

(Specification)Standard Specification for Style 1 Stainless Steel Metric Nuts

Standard Specification for Style 1 Stainless Steel Metric Nuts

ABSTRACT

This specification covers the chemical and mechanical requirements for style 1 stainless steel metric nuts. Groups and property classes of austenitic, ferritic, martensitic, and precipitation hardening stainless steel alloys are covered. Materials shall be cold-formed, hot-formed, or machined form, and shall conform to chemical, mechanical, dimensional and surface finish properties. Stainless steel shall also conform to heat treatment requirements depending on material grade. The material shall be capable of passing chemical, mechanical, and corrosion resistance tests in accordance to the specification. Product marking and packaging shall conform to the requirements of the specification.

SCOPE

1.1 This specification covers the chemical and mechanical requirements for stainless steel metric nuts with nominal thread diameters M1.6 through M36 and intended for use in engineering applications requiring general corrosion resistance.

1.2 Eight groups of stainless steel alloys are covered, including three austenitic (Grades A1, A2, and A4), one ferritic (Grade F1), three martensitic (Grades C1, C3, and C4), and one precipitation hardening (Grade P1).

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F836M −02(Reapproved 2010)

Standard Specification for

Style 1 Stainless Steel Metric Nuts (Metric)

This standard is issued under the fixed designation F836M; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 1.7 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this

1.1 This specification covers the chemical and mechanical

standard.

requirementsforstainlesssteelmetricnutswithnominalthread

diametersM1.6throughM36andintendedforuseinengineer-

2. Referenced Documents

ing applications requiring general corrosion resistance.

2.1 ASTM Standards:

1.2 Eight groups of stainless steel alloys are covered,

A262Practices for Detecting Susceptibility to Intergranular

includingthreeaustenitic(GradesA1,A2,andA4),oneferritic

Attack in Austenitic Stainless Steels

(GradeF1),threemartensitic(GradesC1,C3,andC4),andone

A342/A342MTest Methods for Permeability of Weakly

precipitation hardening (Grade P1).

Magnetic Materials

1.3 Seventeen property classes are covered, including nine

A380Practice for Cleaning, Descaling, and Passivation of

austenitic, one ferritic, six martensitic, and one precipitation

Stainless Steel Parts, Equipment, and Systems

hardening.The property classes with the permissible alloys for

A493Specification for Stainless Steel Wire and Wire Rods

each are listed in Table 1.

for Cold Heading and Cold Forging

1.4 This specification is based in concept and content on

A555/A555MSpecification for General Requirements for

ISO 3506. The chemical and mechanical requirements speci-

Stainless Steel Wire and Wire Rods

fied for all property classes, except as given in 1.4.1, are

A564/A564M Specification for Hot-Rolled and Cold-

essentially identical with classes of the same designation in

Finished Age-Hardening Stainless Steel Bars and Shapes

ISO 3506.

A582/A582MSpecification for Free-Machining Stainless

1.4.1 This specification includes 13 of the 16 property

Steel Bars

classes covered in ISO 3506.Additionally, it includes property

A751Test Methods, Practices, and Terminology for Chemi-

classes A1-70, A2–70, A4–70, A1–80, A2–80, and A4–80 for

cal Analysis of Steel Products

products with nominal thread diameters larger than M20; and

D3951Practice for Commercial Packaging

four non-ISO property classes, C1-110, C4-110, C3-120, and

E29Practice for Using Significant Digits in Test Data to

P1-90.

Determine Conformance with Specifications

F606MTest Methods for Determining the Mechanical Prop-

1.5 Supplementary requirements of an optional nature are

erties of Externally and Internally Threaded Fasteners,

provided, applicable only when agreed upon between the

Washers, and Rivets (Metric)

manufacturer and the purchaser at the time of the inquiry and

F738M Specification for Stainless Steel Metric Bolts,

order.

Screws, and Studs

1.6 Suitable bolts, hex cap screws, and studs for use with

F1470Practice for Fastener Sampling for Specified Me-

nuts included in this specification are covered by Specification

chanical Properties and Performance Inspection

F738M. Unless otherwise specified, all bolts, hex cap screws,

2.2 ISO Standard:

and studs used with these nuts shall conform to the require-

ISO3506 Corrosion-Resistant Stainless Steel Fasteners

ments of Specification F738M and shall be of the same alloy

group.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

This specification is under the jurisdiction of ASTM Committee F16 on contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Fastenersand is the direct responsibility of Subcommittee F16.04 on Nonferrous Standards volume information, refer to the standard’s Document Summary page on

Fasteners. the ASTM website.

Current edition approved Oct. 1, 2010. Published January 2011. Originally Available from American Society of Mechanical Engineers (ASME), ASME

approved in 1983. Last previous edition approved in 2002 as F536–02. DOI: International Headquarters, Three Park Ave., New York, NY 10016-5990, http://

10.1520/F0836M-02R10. www.asme.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F836M−02 (2010)

TABLE 1 Property Classes of Stainless Steel Nuts

4.1.1 Quantity (number of pieces of each item);

Property Class Permissible Alloys

4.1.2 Name of item (specific type and style, and references

A

A1-50 304, 304L, 305

to dimensional standard when appropriate);

A1-70 384, 18–9LW, 302HQ

4.1.3 Size (nominal diameter, thread pitch);

A1-80

4.1.4 Property class;

A2-50

4.1.5 Supplementary requirements, if any (S1 through S3).

A2-70 321, 347

4.1.6 Orders for nuts under this specification may include

A2-80

the following optional requirements:

A4-50

4.1.6.1 Forming (5.1);

A4-70 316, 316L

A4-80

4.1.6.2 Alloy condition (5.2);

B 4.1.6.3 Alloy selection (7.2.1 and S2);

F1-45 430

4.1.6.4 Test report (15.2);

C1-70 410

4.1.6.5 Additional testing (11.3);

C1-110

4.1.6.6 Corrosion resistance testing (11.2);

C3-80 431

4.1.6.7 Inspection (13.1);

C3-120

4.1.6.8 Heat number (11.1.1);

C4-70 416, 416Se

4.1.6.9 Certification (15.1);

C4-110

4.1.6.10 Proof load testing (9.2).

P1-90 630

4.1.7 ASTM specification and date of issue. When date of

A

When approved by the purchaser, Alloys 303, 303Se, or XM1 may be furnished.

issueisnotspecified,nutsshallbefurnishedtothelatestissue.

B

When approved by the purchaser, Alloy 430F may be furnished.

NOTE 2—Example: 10000 pieces, hex nut, ASME B18.2.4.1M, M6 ×

1, Class A2-70, furnish test report, ASTM F836M–XX.

15000 pieces, Hex Flange Nuts, ASME B18.2.4.4M, M8 × 1.25,

2.3 ASME Standards:

class A4-50, Supplementary Requirement S3, ASTM F836–XX.

ASME B1.13MMetric Screw Threads—M Profile

ASME B18.2.4.1M Metric Hex Nuts, Style 1

5. Materials and Manufacture

NOTE 1—The following ASTM standards are noted for information

5.1 Forming—Unless otherwise specified, nuts shall be

only as suitable sources of material for the manufacture of nuts to this

cold-formed, hot-formed, or machined, at the option of the

specification: Specifications A493, A564/A564M, and A582/A582M.

manufacturer.

3. Classification

5.2 Condition—Nuts shall be furnished in the condition

3.1 The designation of each property class is comprised of

specified for the property class in Table 2. If other conditions

three parts, a letter followed by a single digit, followed by

are required, the condition and resultant mechanical properties

either two or three digits (see Table 1).

shall be as agreed upon between the manufacturer and the

3.1.1 The letter indicates the general composition type of

purchaser.

stainless steel:

5.3 Surface Finish—Unless otherwise specified, nuts shall

3.1.1.1 A for austenitic steels,

be cleaned and descaled in accordance with Practice A380.

3.1.1.2 F for ferritic steels,

3.1.1.3 C for martensitic steels, and

6. Heat Treatment

3.1.1.4 P for precipitation-hardening steel.

3.1.2 The first digit (1, 2, 3, or 4) indicates the alloy group. 6.1 Austenitic Alloys, Grades A1, A2, and A4:

The permissible alloys within each group are given in Table 1.

6.1.1 When Condition A is specified, the nuts shall be

3.1.3 The last two or three digits (50, 70, 110, etc.) indicate

machined from annealed or solution annealed stock, thus

10%ofthespecifiednutproofloadstressofthepropertyclass.

retaining the properties of the original material, or hot formed

3.1.4 For example, ClassA1-50 is an austenitic steel of any

and solution annealed.

one of six permitted alloys, and the manufactured nut has a

6.1.2 When Condition AF is specified, the nuts, following

proof load stress of 500 MPa.

manufacture, shall be annealed by heating to 1040 6 30°C, at

which time the chromium carbide will go into solution. The

nuts shall be held for a sufficient time and then cooled at a rate

sufficient to prevent precipitation of the carbide and to provide

the properties specified in Table 2.

6.1.3 When Condition CW is specified, the austenitic alloy

shallbeannealedasspecifiedin6.1.1,andthencold-workedto

develop the properties specified in Table 2.

6.1.4 When Condition SH is specified, nuts shall be ma-

4. Ordering Information

chined from strain hardened stock.

4.1 Orders for nuts under this specification shall include the

following : 6.2 Ferritic Alloys, Grade F1:

F836M−02 (2010)

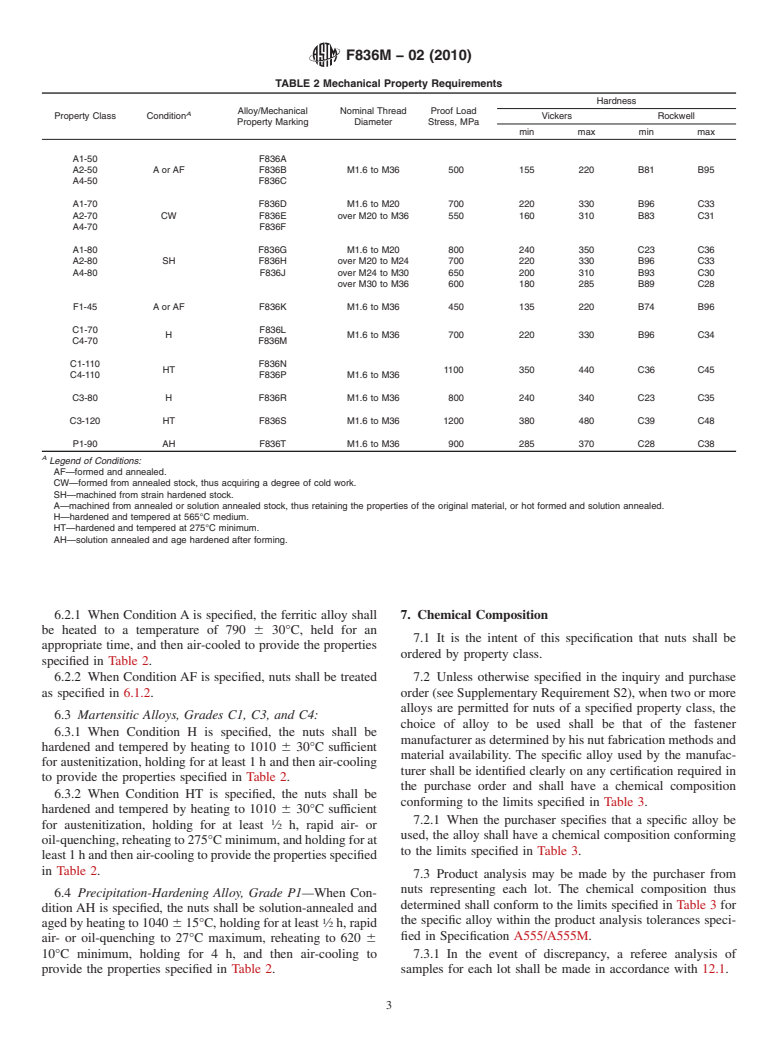

TABLE 2 Mechanical Property Requirements

Hardness

Alloy/Mechanical Nominal Thread Proof Load

A

Property Class Condition Vickers Rockwell

Property Marking Diameter Stress, MPa

min max min max

A1-50 F836A

A2-50 A or AF F836B M1.6 to M36 500 155 220 B81 B95

A4-50 F836C

A1-70 F836D M1.6 to M20 700 220 330 B96 C33

A2-70 CW F836E over M20 to M36 550 160 310 B83 C31

A4-70 F836F

A1-80 F836G M1.6 to M20 800 240 350 C23 C36

A2-80 SH F836H over M20 to M24 700 220 330 B96 C33

A4-80 F836J over M24 to M30 650 200 310 B93 C30

over M30 to M36 600 180 285 B89 C28

F1-45 A or AF F836K M1.6 to M36 450 135 220 B74 B96

C1-70 F836L

H M1.6 to M36 700 220 330 B96 C34

C4-70 F836M

C1-110 F836N

HT 1100 350 440 C36 C45

C4-110 F836P M1.6 to M36

C3-80 H F836R M1.6 to M36 800 240 340 C23 C35

C3-120 HT F836S M1.6 to M36 1200 380 480 C39 C48

P1-90 AH F836T M1.6 to M36 900 285 370 C28 C38

A

Legend of Conditions:

AF—formed and annealed.

CW—formed from annealed stock, thus acquiring a degree of cold work.

SH—machined from strain hardened stock.

A—machined from annealed or solution annealed stock, thus retaining the properties of the original material, or hot formed and solution annealed.

H—hardened and tempered at 565°C medium.

HT—hardened and tempered at 275°C minimum.

AH—solution annealed and age hardened after forming.

6.2.1 When ConditionAis specified, the ferritic alloy shall 7. Chemical Composition

be heated to a temperature of 790 6 30°C, held for an

7.1 It is the intent of this specification that nuts shall be

appropriate time, and then air-cooled to provide the properties

ordered by property class.

specified in Table 2.

6.2.2 When ConditionAF is specified, nuts shall be treated 7.2 Unless otherwise specified in the inquiry and purchase

as specified in 6.1.2. order(seeSupplementaryRequirementS2),whentwoormore

alloys are permitted for nuts of a specified property class, the

6.3 Martensitic Alloys, Grades C1, C3, and C4:

choice of alloy to be used shall be that of the fastener

6.3.1 When Condition H is specified, the nuts shall be

manufacturerasdeterminedbyhisnutfabricationmethodsand

hardened and tempered by heating to 1010 6 30°C sufficient

material availability. The specific alloy used by the manufac-

for austenitization, holding for at least 1 h and then air-cooling

turer shall be identified clearly on any certification required in

to provide the properties specified in Table 2.

the purchase order and shall have a chemical composition

6.3.2 When Condition HT is specified, the nuts shall be

conforming to the limits specified in Table 3.

hardened and tempered by heating to 1010 6 30°C sufficient

7.2.1 When the purchaser specifies that a specific alloy be

for austenitization, holding for at least ⁄2 h, rapid air- or

used, the alloy shall have a chemical composition conforming

oil-quenching,reheatingto275°Cminimum,andholdingforat

to the limits specified in Table 3.

least1handthenair-coolingtoprovidethepropertiesspecified

in Table 2.

7.3 Product analysis may be made by the purchaser from

nuts representing each lot. The chemical composition thus

6.4 Precipitation-Hardening Alloy, Grade P1—When Con-

determined shall conform to the limits specified in Table 3 for

ditionAH is specified, the nuts shall be solution-annealed and

1 the specific alloy within the product analysis tolerances speci-

agedbyheatingto1040 615°C,holdingforatleast ⁄2h,rapid

fied in Specification A555/A555M.

air- or oil-quenching to 27°C maximum, reheating to 620 6

10°C minimum, holding for 4 h, and then air-cooling to 7.3.1 In the event of discrepancy, a referee analysis of

provide the properties specified in Table 2. samples for each lot shall be made in accordance with 12.1.

F836M−02 (2010)

TABLE 3 Chemical Requirements

Composition, % maximum except as shown

UNS

Alloy

Alloy Desig-

Car- Manga- Phospho- Molyb-

Group

Sulfur Silicon Chromium Nickel Copper Others

nation

bon nese rus denum

Austenitic Alloys

A

A1 303 S30300 0.15 2.00 0.20 0.15 min 1.00 17.0 to 19.0 8.0 to 10.0 0.60 max

A1 303Se S30323 0.15 2.00 0.20 0.060 1.00 17.0 to 19.0 8.0 to 10.0 Se 0.15 min

A1 304 S30400 0.08 2.00 0.045 0.030 1.00 18.0 to 20.0 8.0 to 10.5 1.00

A1 304L S30403 0.03 2.00 0.045 0.030 1.00 18.0 to 20.0 8.0 to 12.0 1.00

A1 305 S30500 0.12 2.00 0.045 0.030 1.00 17.0 to 19.0 10.5 to 13.0 1.00

A1 384 S38400 0.08 2.00 0.045 0.030 1.00 15.0 to 17.0 17.0 to 19.0

A

A1 XM1 S20300 0.08 5.0 to 6.5 0.040 0.18 to 1.00 16.0 to 18.0 5.0 to 6.5 1.75 to 0.50 max

0.35 2.25

A1 18–9LW S30430 0.10 2.00 0.045 0.030 1.00 17.0 to 19.0 8.0 to 10.0 3.0 to 4.0

A1 302HQ S30433 0.03 2.00 0.045 0.030 1.00 17.0 to 19.0 8.0 to 10.0 3.0 to 4.0

A4 316 S31600 0.08 2.00 0.045 0.030 1.00 16.0 to 18.0 10.0 to 14.0 2.00–3.00

A4 316L S31603 0.03 2.00 0.045 0.030 1.00 16.0 to 18.0 10.0 to 14.0 2.00–3.00

A4 321 S32100 0.08 2.00 0.045 0.030 1.00 17.0 to 19.0 9.0 to 12.0 Ti 5 × C

min

A2 347 S34700 0.08 2.00 0.045 0.030 1.00 17.0 to 19.0 9.0 to 13.0 Cb + Ta

10×Cmin

Ferritic Alloys

F1 430 S43000 0.12 1.00 0.040 0.030 1.00 16.0 to 18.0

A

F1 430F S43020 0.12 1.25 0.060 0.15 min 1.00 16.0 to 18.0 0.60 max

Martensitic Alloys

C1 410 S41000 0.15 1.00 0.040 0.030 1.00 11.5 to 13.5

A

C4 416 S41600 0.15 1.25 0.060 0.15 min 1.00 12.0 to 14.0 0.60 max Se 0.15 min

416Se

C4 S41623 0.15 1.25 0.060 0.060 1.00 12.0 to 14.0

C3 431 S43100 0.20 1.00 0.040 0.030 1.00 15.0 to 17.0 1.25 to 2.50

Precipitation Hardening Alloy

P1 630 S17400 0.07 1.00 0.040 0.030 1.00 15.0 to 17.5 3.0 to 5.0 3.0 to 5.0 Cb + Ta

0.15–0.45

A

At manufacturer’s option, determined only when intentionally added.

8. Corrosion Resistance 9.2 Unless proof load testing is specified in the inquiry and

purchase order, nuts of all classes in nominal thread diameters

8.1 Carbide Precipitation:

M4andsmaller,andnutsofallclasseswithproofloadsgreater

8.1.1 Rod, bar, and wire in the austeniticAlloy GroupsA1,

than 530 kN, as specified in Table 4, shall be furnished on the

A2, andA4, except the free-machining grades, 303 and 303Se,

basisofhavingahardnessnotlessthantheminimumhardness

used to make nuts in accordance with this specification, shall

specified in Table 2.

becapableofpassi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.