ASTM A600-92a(2024)

(Specification)Standard Specification for Tool Steel High Speed

Standard Specification for Tool Steel High Speed

ABSTRACT

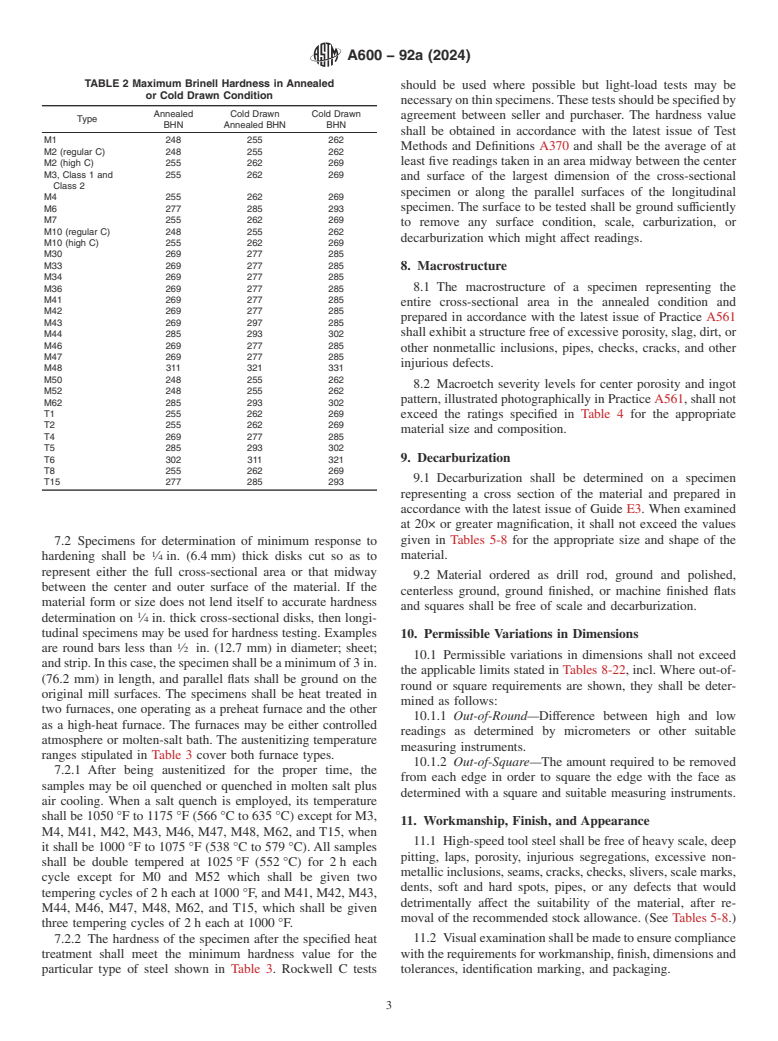

This specification covers seven tungsten-type (types T1, T2, T4, T5, T6, T8, and T15) and nineteen molybdenum-type high-speed steels (types M1, M2, M3, M4, M6, M7, M10, M30, M33, M34, M36, M41, M42, M43, M44, M46, M47, M48, and M62) in the form of annealed, hot-rolled bars, forgings, plate, sheet, or strip, and annealed, cold-finished bars or forgings used primarily in the fabrication of tools. Two intermediate high speed tool steels designated as M50 and M52 are also covered. Unless otherwise specified, material shall be made by an electric melting process. A chemical analysis of each heat of steel shall be made to determine the percentage of the elements specified (including carbon, manganese, phosphorus, sulfur, silicon, chromium, vanadium, tungsten, molybdenum, and cobalt) and these values shall conform to the requirements as to the prescribed chemical composition. Requirements for: (1) heat treatment such as austenitizing, quenching, and tempering, (2) hardness testing (3) macrostructure and macroetch standard for porosity and ingot pattern, and (4) decarburization determination are detailed. The maximum Brinell hardness and minimum Rockwell C hardness for the tool steels are given.

SCOPE

1.1 This specification covers tungsten-type and molybdenum-type high-speed steels available as annealed, hot-rolled bars, forgings, plate, sheet, or strip, and annealed, cold-finished bars or forgings used primarily in the fabrication of tools.

1.2 Seven types of tungsten high-speed tool steels designated T1, T2, etc., seventeen types of molybdenum high-speed tool steels designated M1, M2, etc., and two intermediate high-speed steels designated as M50 and M52 are covered. Selection will depend upon design, service conditions, and mechanical properties.

1.3 The term “high-speed steel” is described and its minimum requirements are covered in the Annex.

1.4 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: A600 − 92a (Reapproved 2024)

Standard Specification for

1

Tool Steel High Speed

This standard is issued under the fixed designation A600; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope A561 Practice for Macroetch Testing of Tool Steel Bars

A700 Guide for Packaging, Marking, and Loading Methods

1.1 This specification covers tungsten-type and

for Steel Products for Shipment

molybdenum-type high-speed steels available as annealed,

E3 Guide for Preparation of Metallographic Specimens

hot-rolled bars, forgings, plate, sheet, or strip, and annealed,

E30 Test Methods for Chemical Analysis of Steel, Cast Iron,

cold-finished bars or forgings used primarily in the fabrication

3

Open-Hearth Iron, and Wrought Iron (Withdrawn 1995)

of tools.

E45 Test Methods for Determining the Inclusion Content of

1.2 Seven types of tungsten high-speed tool steels desig-

Steel

nated T1, T2, etc., seventeen types of molybdenum high-speed

E59 Practice for Sampling Steel and Iron for Determination

3

tool steels designated M1, M2, etc., and two intermediate

of Chemical Composition (Withdrawn 1996)

high-speed steels designated as M50 and M52 are covered.

2.2 Military Standard:

Selection will depend upon design, service conditions, and

MIL-STD-163 Steel Mill Products, Preparation for Ship-

mechanical properties.

4

ment and Storage

1.3 The term “high-speed steel” is described and its mini-

2.3 Federal Standards:

mum requirements are covered in the Annex.

4

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

1.4 The values stated in inch-pound units are to be regarded

Fed. Std. No. 183 Continuous Identification Marking of Iron

4

as standard. The values given in parentheses are mathematical

and Steel Products

conversions to SI units that are provided for information only

and are not considered standard.

3. Classification

1.5 This international standard was developed in accor-

3.1 Material in accordance with this specification is classi-

dance with internationally recognized principles on standard-

fied by chemical composition. Types correspond to respective

ization established in the Decision on Principles for the

AISI designations.

Development of International Standards, Guides and Recom-

3.1.1 Types T1, T2, T4, T5, T6, T8, and T15 are character-

mendations issued by the World Trade Organization Technical

ized by a controlled high tungsten content along with other

Barriers to Trade (TBT) Committee.

alloying elements.

3.1.2 Types M1, M2, M3, M4, M6, M7, M10, M30, M33,

2. Referenced Documents

M34, M36, M41, M42, M43, M44, M46, M47, M48, and M62

2

2.1 ASTM Standards:

are characterized by a controlled high molybdenum content

A370 Test Methods and Definitions for Mechanical Testing

along with other alloying elements.

of Steel Products

3.1.3 Types M2, M3, and M10 are further classified accord-

A388/A388M Practice for Ultrasonic Examination of Steel

ing to carbon range. Type M3 is further classified according to

Forgings

vanadium range.

3.1.4 Types M50 and M52 are considered intermediate

high-speed steels in view of their lower total alloy content than

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

the standard types. These leaner alloy grades normally are

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

limited to less severe service conditions.

A01.29 on Tool Steels.

Current edition approved March 1, 2024. Published March 2024. Originally

approved in 1969. Last previous edition approved in 2016 as A600 – 92a (2016).

DOI: 10.1520/A0600-92AR24.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or The last approved version of this historical standard is referenced on

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM www.astm.org.

4

Standards volume information, refer to the standard’s Document Summary page on Available from DLA Document Services, Building 4/D, 700 Robbins Avenue,

the ASTM website. Philadelphia, PA 19111-5094, http://quicksearch.dla.mil.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A600 − 92a (2024)

4. Ordering Information 6. Chemical Composition

4.1 Orders for material under this specification shall include

6.1 An analysis of each

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.