ASTM F2767-09

(Specification)Standard Specification for Electrofusion Type Polyamide-12 Fittings for Outside Diameter Controlled Polyamide-12 Pipe and Tubing for Gas Distribution

Standard Specification for Electrofusion Type Polyamide-12 Fittings for Outside Diameter Controlled Polyamide-12 Pipe and Tubing for Gas Distribution

SCOPE

1.1 This specification covers polyamide- 12 electrofusion fittings for use with outside diameter-controlled polyamide- 12 pipe, covered by Specification D 2513. Requirements for materials, workmanship, and testing performance are included. Where applicable in this specification “pipe” shall mean “pipe” or “tubing.”

1.2 Polyamide 12 electrofusion fittings are intended for use in polyamide 12 systems only. As per the manufacturer’s recommendations, no cross fusion between PA12, PA11 and PE is permitted.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 The following safety hazards caveat pertains only to the test method portion, Section 9, of this specification:This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2767 −09 AnAmerican National Standard

Standard Specification for

Electrofusion Type Polyamide-12 Fittings for Outside

Diameter Controlled Polyamide-12 Pipe and Tubing for Gas

Distribution

This standard is issued under the fixed designation F2767; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D2122 Test Method for Determining Dimensions of Ther-

moplastic Pipe and Fittings

1.1 This specification covers polyamide- 12 electrofusion

D2513 Specification for Polyethylene (PE) Gas Pressure

fittings for use with outside diameter-controlled polyamide- 12

Pipe, Tubing, and Fittings

pipe, covered by Specification D2513. Requirements for

D4066 Classification System for Nylon Injection and Extru-

materials, workmanship, and testing performance are included.

sion Materials (PA)

Where applicable in this specification “pipe” shall mean “pipe”

D6779 Classification System for and Basis of Specification

or “tubing.”

for Polyamide Molding and Extrusion Materials (PA)

1.2 Polyamide 12 electrofusion fittings are intended for use

F412 Terminology Relating to Plastic Piping Systems

in polyamide 12 systems only. As per the manufacturer’s

F905 Practice for Qualification of Polyethylene Saddle-

recommendations, no cross fusion between PA12, PA11 and PE

Fused Joints

is permitted.

3. Terminology

1.3 The values stated in inch-pound units are to be regarded

as standard. The values given in parentheses are mathematical 3.1 Definitions are in accordance with Terminology F412,

conversions to SI units that are provided for information only and abbreviations are in accordance with Terminology D1600,

and are not considered standard. unless otherwise specified.

1.4 The following safety hazards caveat pertains only to the

3.2 Definitions of Terms Specific to This Standard:

test method portion, Section 9, of this specification:This 3.2.1 electrofusion—a heat fusion joining process where the

standard does not purport to address all of the safety concerns,

heat source is an integral part of the fitting, such that when

if any, associated with its use. It is the responsibility of the user

electric current is applied, heat is produced that melts and joins

of this standard to establish appropriate safety and health

the plastics.

practices and determine the applicability of regulatory limita-

3.2.2 fusion interface—surface in the heat fusion process

tions prior to use.

where the plastic materials of the products being joined bond

together.

2. Referenced Documents

3.2.3 fusion zone length—total length of the melted material

2.1 ASTM Standards:

in the fitting cross-section under evaluation.

D638 Test Method for Tensile Properties of Plastics

D1598 Test Method for Time-to-Failure of Plastic Pipe

4. Materials and Manufacture

Under Constant Internal Pressure

4.1 This specification covers fittings made from polyamide

D1599 Test Method for Resistance to Short-Time Hydraulic

12 (PA12) meeting the requirements for Group 4, Class 2, and

Pressure of Plastic Pipe, Tubing, and Fittings

Grade 3, (PA423 16) as prescribed in Specification D6779 and

D1600 Terminology for Abbreviated Terms Relating to Plas-

D4066.

tics

4.2 Rework Material—Clean rework polyamide- 12 mate-

rial of the same resin, free of any wire or contaminants

This specification is under the jurisdiction of ASTM Committee F17 on Plastic

generated from the fitting manufacturer’s own production, may

Piping Systems and is the direct responsibility of Subcommittee F17.60 on Gas.

be used by the same manufacturer, as long as the fittings

Current edition approved April 1, 2009. Published May 2009. DOI: 10.1520/

produced conform to the requirements of this specification.

F2767-09.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4.3 Heating Mechanism—The heat mechanism shall be of

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

materials not detrimental to the performance of the fitting or

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. the pipe to which it is intended to be joined.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2767−09

5. Performance Requirements D2513, such that the joints will satisfy the performance

requirements in Section 5. (See Test Method D2122.)

5.1 The following requirements are for electrofusion joints

6.2 Because of the varying designs for electrofusion fittings,

that have been joined using the manufacturer’s recommended

the actual spread of dimensions may be quite different from

joining procedures. These requirements must be met by each

manufacturer to manufacturer. A table of dimensions and

electrofusion joint design, on each size and type of pipe

tolerances encompassing these differences would be meaning-

material for which the manufacturer recommends use of their

less and without value and, therefore, is omitted from this

fitting. Any revisions to the electrofusion joint design or

specification.

processing by the manufacturer after the initial testing requires

retesting to ensure these requirements can still be met. Fittings

6.3 The manufacturer shall furnish to the user the electrical

intended for use in the distribution of natural gas or liquid

resistance, critical dimensions, and tolerances of his fittings.

petroleum gas shall also meet the requirements of Specification

This information must include at least the following dimen-

D2513.

sions and tolerances:

5.1.1 It is not required that each configuration of a fitting be

6.3.1 Coupling inside diameter,

tested to meet all of these qualifications (that is, 2 in. main 6.3.2 Temperature joining limits, and

saddle joint with multiple outlet configurations offered) as long

6.3.3 Operating pressure of the fitting.

as the electrofusion joint design is not altered in the configu-

NOTE 2—There are other items that fall beyond the scope of this

ration differences.

specification which would be of interest to the user for proper application

of the fittings and is recommended as additional information to be

NOTE 1—It is permissible when accomplishing these tests, to do so on

furnished. A few of these are: (1) maximum pipe out of round allowed at

the highest and lowest dimension ratio of the same pipe material. If in

joint area; (2) minimum/maximum pipe SDR capability of the fitting, and

those tests all performance requirements are met, all dimension ratios

(3) for saddles intended for use on a live main, the maximum allowable

between those tested may be considered as having met the requirements.

line pressure when making the joint.

These tests do not have to cover the full range of dimension ratios

available, only the dimension ratio range on which the manufacturer

7. Workmanship, Finish and Appearance

recommends his fitting be used.

7.1 The manufacture of these fittings shall be in accordance

5.2 Pressure Requirements:

with good commercial practice so as to produce fittings

5.2.1 Minimum Hydraulic Burst Pressure—The minimum

meeting the requirements of this specification.

hydraulic burst pressure of the test specimen shall not be less

7.2 The fittings shall be homogeneous throughout, except

than that required to produce 3900psi (26.9MPa) fiber stress in

where a heating coil or electrical connectors are incorporated,

the pipe being used in the test when tested in accordance with

and free of cracks, holes, foreign inclusions, or injurious

9.1. The test equipment, procedures, and failures definitions

defects such as gouges, dents, cuts, etc. The fittings shall be as

shall be as specified in Test Method D1599.

uniform as commercially practicable in opacity, density, and

5.2.2 Sustained Pressure—The fitting and fused joint shall

other physical properties. Any heating coils, connecting cables,

not fail when tested in accordance with 9.2.

connectors, and related electrical power source shall be de-

signed to prevent electrical shock to the user.

5.3 Tensile Strength Requirements (Coupling Type Joints

Only)—The fitting or the pipe to fitting joint made on pipe shall

8. Specimen Preparation

not fail when tested in accordance with 9.3. Specimens shall be

8.1 Conditioning:

subjected to a tensile stress that causes the pipe to yield or

8.1.1 Unless otherwise specified, condition the specimens

causes the pipe to break outside the joint area. Tensile tests

(pipe and fittings) prior to joining at the minimum pipe

must be made on specimens as joined, not on straps cut from

temperature allowable for fusion as recommended by the

the specimen. Yielding must be measured only in the pipe,

manufacturer, for not less than 16 h and make the fusion joint

independent of the fitting or joint.

at that temperature for those tests where conditioning is

5.4 Impact Resistance (Saddle Type Joints Only)—The joint

required.

made on the specimen shall not fail when impacted with a force

8.1.2 Unless otherwise specified, condition the specimens

sufficient to break the body or other portion of the specimen.

(pipe and fittings) prior to joining at the maximum pipe

Tests of 500 ft-lb or higher impact with no failures noted shall

temperature allowable for fusion as recommended by the

be considered as a “pass” impact test. The device for testing

manufacturer, for not less than 16 h and make the fusion joint

and the methods shall be as defined in Practice F905.

at that temperature for those tests where conditioning is

required.

5.5 Joint Integrity Tests—(Couplings and Saddle Type

Joints)—The joint made on the specimen shall meet the

8.2 Test Conditions—Conduct the tests at the Standard

requirements in 9.4 and 9.5 of this specification, when tested in

Laboratory Temperature of 23.6 6 2°C (73.4 6 3.6°F) unless

accordance with 9.4.

otherwise specified.

8.3 Preparation of Specimens for Testing:

6. Dimensions, Mass, and Permissible Variations

8.3.1 Prepare test specimens so that the minimum length of

6.1 Dimension and tolerances of electrofusion fittings must unreinforced pipe on one side of any fitting is equal to three

be such that heat fusion is possible to outside diameter (OD) times the diameter of the pipe, but in no case less than 12 in.

controlled PA-12 pipes such as those listed in Specifications (304 mm). It is permissible to test multiple fittings together

F2767−09

provided they are separated by a minimum distance equal to failures occur, reduce the pressure of the test and repeat until

three times the diameter of the pipe, but in no case less than 12 170-h results or pipe brittle failures are achieved.

in. (304 mm).

9.2.3 Failure of the fitting or joint shall constitute specimen

8.3.2 Fuse all fitting outlets with the appropriate size pipe

failure.

in accordance with the manufacturer’s recommended proce-

9.2.4 Failure of one of the four specimens tested is cause for

dures.

retest of four additional specimens, joined at the failed-

8.3.3 All saddle fusion joint specimens conditioned as in

specimens-joining temperature. Failure of any of these four

8.1.2 and destined for quick burst testing as in 9.1 and

additional specimens shall constitute a failure of the test.

sustained pressure testing as in 9.2, are to be joined with the

9.3 Tensile Strength Test:

pipe at no less than maximum allowable operating pressure of

the pipe system or fitting, whichever is lowest, when being 9.3.1 Select four fittings at random and prepare specimens

prepared for those tests. The pipe should be left under pressure in accordance with Section 8. If the limits of tensile machine

for a time period not less than recommended by the manufac- will not allow 25 % elongation with pipe specimens of

three-pipe diameters on pipe sizes above 4 in. (102 mm) IPS

turer for cooling in the field prior to disturbing the joint. Saddle

joint specimens destined for mechanical/destructive type tests than the minimum free pipe length can of 20 in. (304 mm).

such as impact as in 5.4 or crush tests as in 9.4, or specimens From the four specimens, condition two specimens each in

conditioned for cold temperature joining as in 8.1.1, may be accordance with 8.1.1 and 8.1.2.

made on unpressured pipe specimens.

9.3.2 Test the specimens using the apparatus of Test Method

D638. Test at a pull rate of 0.20 in. (5.0 mm) per min, 625 %.

9. Test Methods

9.3.3 Failure of the fitting or joint as defined in 5.3, shall

9.1 Minimum Hydraulic Burst Pressure Test: constitute specimen failure. Failure of one of the four speci-

9.1.1 Select four fittings at random and prepare specimens mens tested is cause for retest of four additional specimens,

in accordance with Section 8. From the four specimens,

joined at the failed specimens joining temperature. Failure of

condition two specimens each in accordance with 8.1.1 and any of these four additional specimens shall constitute a failure

8.1.2. of the test.

9.1.2 Test the specimens in accordance with Test Method

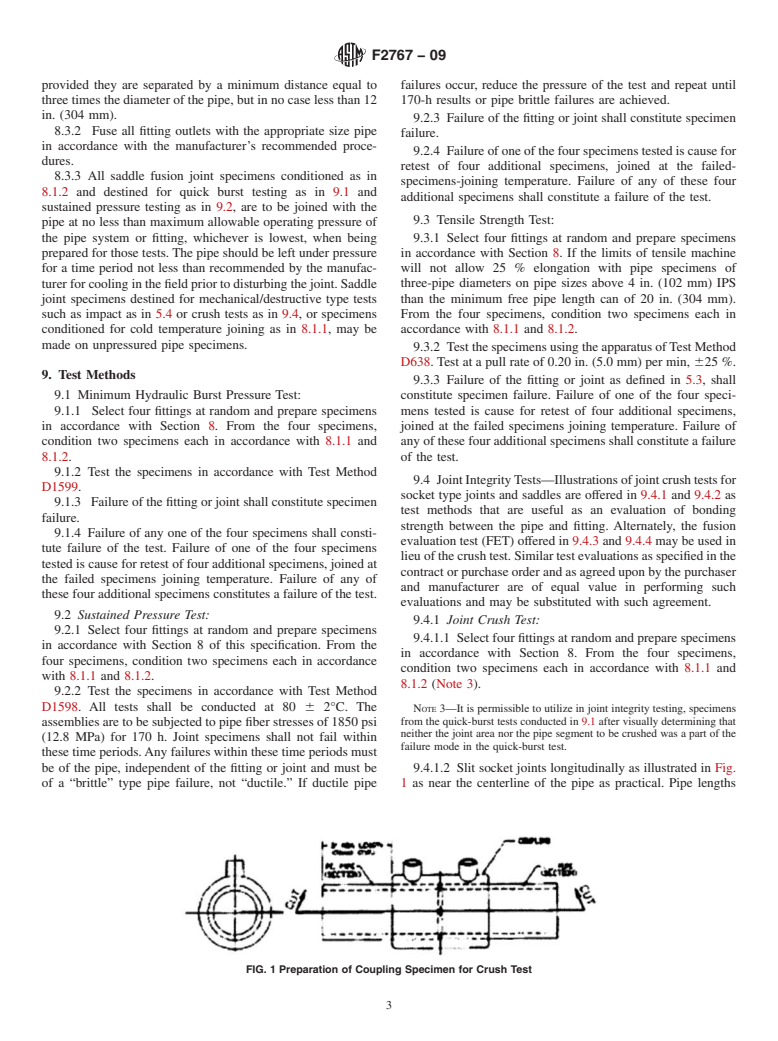

9.4 Joint Integrity Tests—Illustrations of joint crush tests for

D1599.

socket type joints and saddles are offered in 9.4.1 and 9.4.2 as

9.1.3 Failure of the fitting or joint shall constitute specimen

test methods that are useful as an evaluation of bonding

failure.

strength between the pipe and fitting. Alternately, the fusion

9.1.4 Failure of any one of the four specimens shall consti-

evaluation test (FET) offered in 9.4.3 and 9.4.4 may be used in

tute failure of the test. Failure of one of the four specimens

lieu of the crush test. Similar test evaluations as specified in the

tested is cause for retest of four additional specimens, joined at

contract or purchase order and as agreed upon by the purchaser

the failed specimens joining temperature. Failure of any of

and manufacturer are of equal value in performing such

these four additional specimens constitutes a failure of the test.

evaluations and may be substituted with such agreement.

9.2 Sustained Pressure Test:

9.4.1 Joint Crush Test:

9.2.1 Select four fittings at random and prepare specimens

9.4.1.1 Select four fittings at random and prepare specimens

in accordance with Section 8 of this specification. From the

in accordance with Section 8. From the four specimens,

four specimens, condition two specimens each in accordance

condition two specimens each in accordance with 8.1.1 and

with 8.1.1 and 8.1.2.

8.1.2 (Note 3).

9.2.2 Test the specimens in accordance with Test Method

D1598. All tests shall be conducted at 80 6 2°C. The

NOTE 3—It is permissible to utilize in joint integrity testing, specimens

assemblies are to be subjected to pipe fiber stresses of 1850 psi from the quick-burst tests co

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.