ASTM D5176-08(2015)

(Test Method)Standard Test Method for Total Chemically Bound Nitrogen in Water by Pyrolysis and Chemiluminescence Detection

Standard Test Method for Total Chemically Bound Nitrogen in Water by Pyrolysis and Chemiluminescence Detection

SIGNIFICANCE AND USE

5.1 This test method is useful for the determination of total chemically bound nitrogen in wastewaters and other waters.

SCOPE

1.1 This test method covers the determination of the total nitrogen content of water in concentrations from 0.5 to 1000 mg/L. Higher nitrogen concentrations may be determined by making the proper dilutions.

1.2 This test method does not determine molecular nitrogen (N2).

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5176 − 08 (Reapproved 2015)

Standard Test Method for

Total Chemically Bound Nitrogen in Water by Pyrolysis and

Chemiluminescence Detection

This standard is issued under the fixed designation D5176; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Summary of Test Method

4.1 The sample of water is introduced into a stream of

1.1 This test method covers the determination of the total

nitrogen content of water in concentrations from 0.5 to 1000 oxygen or inert/oxygen mix flowing through a quartz pyrolysis

tube. Oxidative pyrolysis converts chemically bound nitrogen

mg/L. Higher nitrogen concentrations may be determined by

making the proper dilutions. to nitric oxide (NO). The gas stream is dried and the NO is

contacted with ozone (O ) producing metastable nitrogen

1.2 This test method does not determine molecular nitrogen

dioxide (NO *). As the NO * decays, light is emitted and

2 2

(N ).

detected by a photomultiplier tube. The resulting signal is a

1.3 The values stated in SI units are to be regarded as

measure of the total chemically bound nitrogen in the sample.

standard. No other units of measurement are included in this

standard.

5. Significance and Use

1.4 This standard does not purport to address all of the

5.1 This test method is useful for the determination of total

safety concerns, if any, associated with its use. It is the

chemically bound nitrogen in wastewaters and other waters.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- 6. Apparatus

bility of regulatory limitations prior to use.

6.1 Pyrolysis Furnace—An electric tube furnace capable of

achieving a temperature of 1100°C. The furnace may be single

2. Referenced Documents

or multizoned and may have common or separate and inde-

2.1 ASTM Standards: pendent temperature controls.

D1129 Terminology Relating to Water

6.2 Pyrolysis Tube—The pyrolysis tube must be fabricated

D1193 Specification for Reagent Water

from quartz and should be designed to ensure complete

D2777 Practice for Determination of Precision and Bias of

pyrolysis of a wide variety of samples.

Applicable Test Methods of Committee D19 on Water

6.3 Chemiluminescence Detector—Thedetectorshallhavea

photomultiplier tube capable of sensing the light emission of

3. Terminology

the decaying NO *. The detector shall have digital display,

3.1 Definitions:

onboard ozone generator and analog output for data system or

3.1.1 For definitions of terms used in this standard, refer to

strip chart recorder.

Terminology D1129.

6.4 Recorder (optional)—The recorder shall be able to

3.2 Definitions of Terms Specific to This Standard:

accept a 1 V full scale signal and to provide a chart speed of 1

3.2.1 total chemically bound nitrogen, n—all inorganic and

cm/min.

organicnitrogeninthesample,exceptmolecularnitrogen(N ).

6.5 Microlitre Syringe—Any standard series of microlitre

syringes with stainless steel needles is acceptable. See manu-

facturer’s instructions for appropriate syringe sizes.

This test method is under the jurisdiction of ASTM Committee D19 on Water

6.6 Syringe Drive Mechanism—The syringe drive shall be

andisthedirectresponsibilityofSubcommitteeD19.06onMethodsforAnalysisfor

Organic Substances in Water.

capable of driving the sample from a microlitre syringe at a

Current edition approved June 15, 2015. Published June 2015. Originally

controlled, reproducible rate.

approved in 1991. Last previous edition approved in 2008 as D5176 – 08. DOI:

10.1520/D5176-08R15.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM The apparatus described in 6.1 – 6.7 is manufactured by Antek Instruments,

Standards volume information, refer to the standard’s Document Summary page on Inc., Houston, TX and Dohrmann Division of Rosemount Analytical Inc., Santa

the ASTM website. Clara, CA, and was used in the validation study of this test method.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5176 − 08 (2015)

6.7 Sample Boat—Samples with high concentrations of injected, withdraw the syringe needle. Retract the plunger so

suspended matter or dissolved nonvolatile compounds may that the sample meniscus is again at the 1 µLpoint and note the

tendtoplugthesyringeneedleuponinjectionintothepyrolysis plunger position. The true amount injected is the difference

tube. In this case a sample boat of quartz or platinum, with or between the two plunger positions.

without quartz wool, should be used, in conjunction with the

NOTE 1—If water samples contain high concentrations of suspended

appropriate pyrolysis tube. The pyrolysis tube shall allow the

matter or dissolved nonvolatile compounds, the syringe needle may tend

introduction of the sample into the boat by microlitre syringe

to plug or the precision and bias of the test method may be degraded. In

such a case, the sample boat system should be used (see 6.7).

without interrupting the gas flow system.

9.4 Boat Injection—Fill the microlitre syringe to the mark

7. Reagents and Materials

and inject the sample directly into the boat while holding the

7.1 Purity of Reagents—Reagent grade chemicals shall be

needle in contact with the side of the boat or with the quartz

used.Unlessotherwiseindicated,itisintendedthatallreagents

wool.

shall conform to the specifications of the Committee on

9.5 Determine each calibration standard and the zero blank

Analytical Reagents of the American Chemical Society.

three times and record the net response from the average of

Other grades may be used, provided it is first determined that

each set of standard responses.

the reagent is of sufficiently high purity to permit its use

9.6 By injecting the same volumetric amount of sample for

without lessening the accuracy of the determination.

each determination, the only variables will be total nitrogen

7.2 Purity of Water—Unless otherwise indicated, references

concentrationanddetectorresponse(digitaldisplay).Construct

to water shall be understood to mean reagent water that meets

a curve plotting milligrams of N per litre versus detector

the purity specifications of Type I or Type II water, presented

response. Check the complete calibration curve at least once

in Specification D1193.

per week; check one or two standards daily.

7.3 Inert Gas, Argon (minimum purit

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D5176 − 08 D5176 − 08 (Reapproved 2015)

Standard Test Method for

Total Chemically Bound Nitrogen in Water by Pyrolysis and

Chemiluminescence Detection

This standard is issued under the fixed designation D5176; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of the total nitrogen content of water in concentrations from 0.5 to 1000 mg/L.

Higher nitrogen concentrations may be determined by making the proper dilutions.

1.2 This test method does not determine molecular nitrogen (N ).

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D1129 Terminology Relating to Water

D1193 Specification for Reagent Water

D2777 Practice for Determination of Precision and Bias of Applicable Test Methods of Committee D19 on Water

3. Terminology

3.1 Definitions—Definitions: For definitions of terms used in this test method, refer to Terminology D1129.

3.1.1 For definitions of terms used in this standard, refer to Terminology D1129.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 total chemically bound nitrogen—nitrogen, n—all inorganic and organic nitrogen in the sample, except molecular nitrogen

(N ).

4. Summary of Test Method

4.1 The sample of water is introduced into a stream of oxygen or inert/oxygen mix flowing through a quartz pyrolysis tube.

Oxidative pyrolysis converts chemically bound nitrogen to nitric oxide (NO). The gas stream is dried and the NO is contacted with

ozone (O ) producing metastable nitrogen dioxide (NO *). As the NO * decays, light is emitted and detected by a photomultiplier

3 2 2

tube. The resulting signal is a measure of the total chemically bound nitrogen in the sample.

5. Significance and Use

5.1 This test method is useful for the determination of total chemically bound nitrogen in wastewaters and other waters.

6. Apparatus

6.1 Pyrolysis Furnace—An electric tube furnace capable of achieving a temperature of 1100°C. The furnace may be single or

multizoned and may have common or separate and independent temperature controls.

This test method is under the jurisdiction of ASTM Committee D19 on Water and is the direct responsibility of Subcommittee D19.06 on Methods for Analysis for

Organic Substances in Water.

Current edition approved May 1, 2008June 15, 2015. Published June 2008June 2015. Originally approved in 1991. Last previous edition approved in 20032008 as

D5176 – 91 (2003).D5176 – 08. DOI: 10.1520/D5176-08.10.1520/D5176-08R15.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

The apparatus described in 6.1 – 6.7 is manufactured by Antek Instruments, Inc., Houston, TX and Dohrmann Division of Rosemount Analytical Inc., Santa Clara, CA,

and was used in the validation study of this test method.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

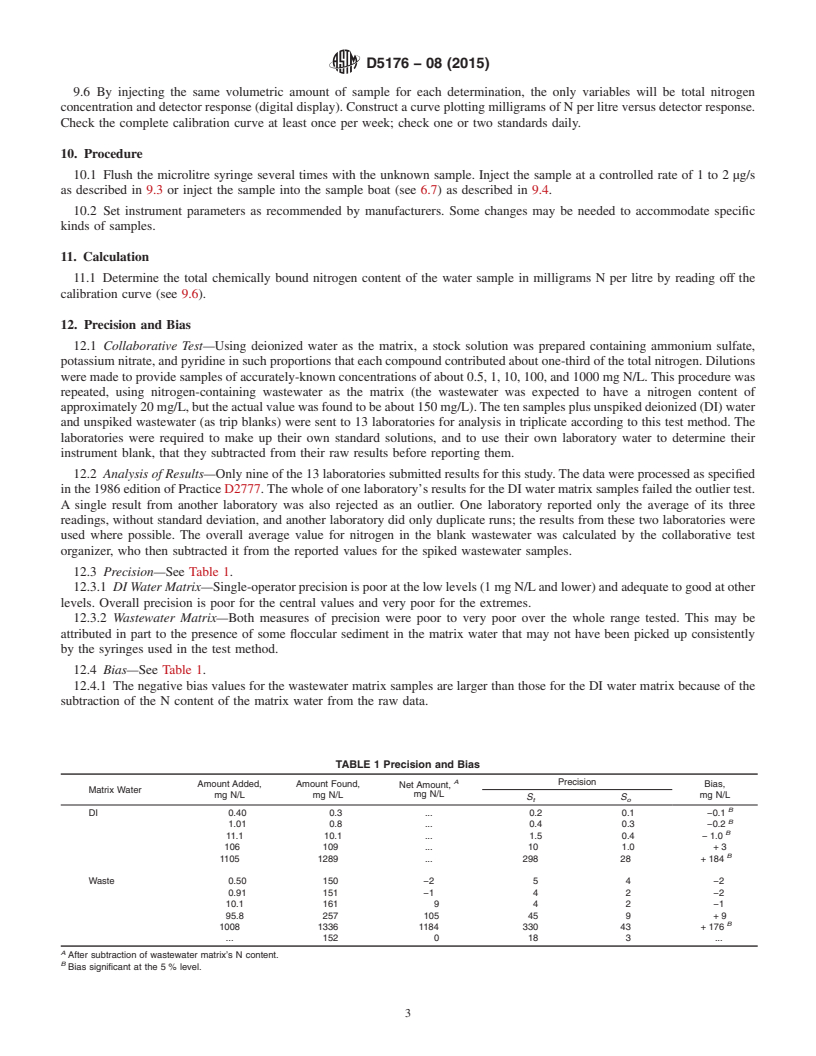

D5176 − 08 (2015)

6.2 Pyrolysis Tube—The pyrolysis tube must be fabricated from quartz and should be designed to ensure complete pyrolysis of

a wide variety of samples.

6.3 Chemiluminescence Detector —Detector—The detector shall have a photomultiplier tube capable of sensing the light

emission of the decaying NO *. The detector shall have digital display, onboard ozone generator and analog output for data system

or strip chart recorder.

6.4 Recorder (optional)—The recorder shall be able to accept a 1 V full scale signal and to provide a chart speed of 1 cm/min.

6.5 Microlitre Syringe—Any standard series of microlitre syringes with stainless steel needles is acceptable. See manufacturer’s

instructions for appropriate syringe sizes.

6.6 Syringe Drive Mechanism—The syringe drive shall be capable of driving the sample from a microlitre syringe at a

controlled, reproducible rate.

6.7 Sample Boat—Samples with high concentrations of suspended matter or dissolved nonvolatile compounds may tend to plug

the syringe needle upon injection into the pyrolysis tube. In this case a sample boat of quartz or platinum, with or without quartz

wool, should be used, in conjunction with the appropriate pyrolysis tube. The pyrolysis tube shall allow the introduction of the

sample into the boat by microlitre syringe without interrupting the gas flow system.

7. Reagents and Materials

7.1 Purity of Reagents—Reagent grade chemicals shall be used. Unless otherwise indicated, it is intended that all reagents shall

conform to the specifications of the Committee on Analytical Reagents of the American Chemical Society. Other grades may be

used, provided it is first determined that the reagent is of sufficiently high purity to permit its use without lessening the accuracy

of the determination.

7.2 Purity of Water—Unless otherwise indicated, references to water shall be understood to mean reagent water that meets the

purity specifications of Type I or Type II water, presented in Specification D1193.

7.3 Inert Gas, Argon (minimum purity 99.99 %).

7.4 Oxygen (minimum purity 99.6 %).

7.5 Stock Solution, Pyridine (10 000 mg N/L)—Prepare by accurately weighing 5.647 g of pyridine into a 100 mL volumetric

flask and dilute to 100 mL with water.

7.6 Pyridine Solutions, Standard (1000, 500, 100, 50, 10, 5, 1, and 0.5 mg N/L)—Dilute ten volumes of the stock solution (see

6.5) with 90 volumes of water to prepare a 1000 mg N/L standard. Similarly, by serial dilution with water, prepare 500, 100, 50,

10, 5, 1, and 0.5 mg N/L standards.

8. Preparation of Apparatus

8.1 Assemble apparatus according to manufacturer’s instructions.

9. Calibration and Standardization

9.1 Use the water that was used to prepare the standards as a zero blank standard.

9.2 A sample size of 5 to 10 μL is sufficient to cover the concentration range of this test method. The volume of the sample shall

be accurately determined.

9.3 Syringe Injection—Fill the syringe to the 5 μL mark and retract the plunger so that the liquid meniscus is at the 1 μL mark.

Note

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.