ASTM D6-95(2000)e1

(Test Method)Standard Test Method for Loss on Heating of Oil and Asphaltic Compounds

Standard Test Method for Loss on Heating of Oil and Asphaltic Compounds

SCOPE

1.1 This test method covers the determination of the loss in mass (exclusive of water) of oil and asphaltic compounds when heated as hereinafter prescribed.

1.2 The values in inch-pound units are to be regarded as standard. The values in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability and regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

American Association State

e1

Designation:D6–95 (Reapproved 2000) Highway and Transportation Officials Standard

AASHTO No.: T47

Standard Test Method for

Loss on Heating of Oil and Asphaltic Compounds

This standard is issued under the fixed designation D 6; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

e NOTE—Editorially switched from English dominant to SI dominant.

1. Scope 5. Apparatus

1.1 This test method covers the determination of the loss in 5.1 Oven—The oven shall be electrically heated and shall

mass(exclusiveofwater)ofoilandasphalticcompoundswhen conform to the performance requirements of Specification

heated as hereinafter prescribed. E 145Type I, Grade B, for operating temperatures up to 180°C

1.2 The values in SI units are to be regarded as standard. (365°F).DuringthetestsforcompliancetoSpecificationE 145

The values in parentheses are for information only. requirements, the oven shelf, properly placed shall be in place

1.3 This standard does not purport to address all of the and rotating. In addition, it shall also comply with the

safety concerns, if any, associated with its use. It is the following requirements:

responsibility of the user of this standard to establish appro- 5.1.1 Construction (Note 1)—The oven shall be rectangular

priate safety and health practices and determine the applica- with minimum interior dimensions of 330 mm (13 in.) in each

bility and regulatory limitations prior to use. direction. The oven shall have in front a tightly fitting hinged

door, which shall provide a clear opening substantially the

2. Referenced Documents

same as the interior height and width of the oven. The door

2.1 ASTM Standards: may contain a window with dimensions of at least 100 by 100

D 5 Test Method for Penetration of Bituminous Materials

mm (4 by 4 in.), and with two sheets of glass separated by an

E 1 Specification for ASTM Thermometers air space, through which a vertical thermometer located as

E 145 Specification for Gravity-Convection and Forced-

specified in Section 8, may be read without opening the door;

Ventilation Ovens or the oven may be provided with an inner glass door, through

which the thermometer may be observed on opening the outer

3. Summary of Test Method

door momentarily. The oven shall be adequately ventilated by

3.1 Fifty grams of material, spread out in a dish 55 mm in

convection currents of air and for this purpose shall be

diameter, is heated in moving air for 5 h at 163°C (325°F) and

provided with openings for the entrance of air and for the exit

the percent loss of mass determined along with a comparison,

of heated air and vapors. Openings may be of any size and

before and after, of any other desired characteristics. This test

arrangement provided the requirements of Specification E 145,

method provides only a relative measurement of the volatility

Type I, Grade B, are met.

of a material under test conditions.

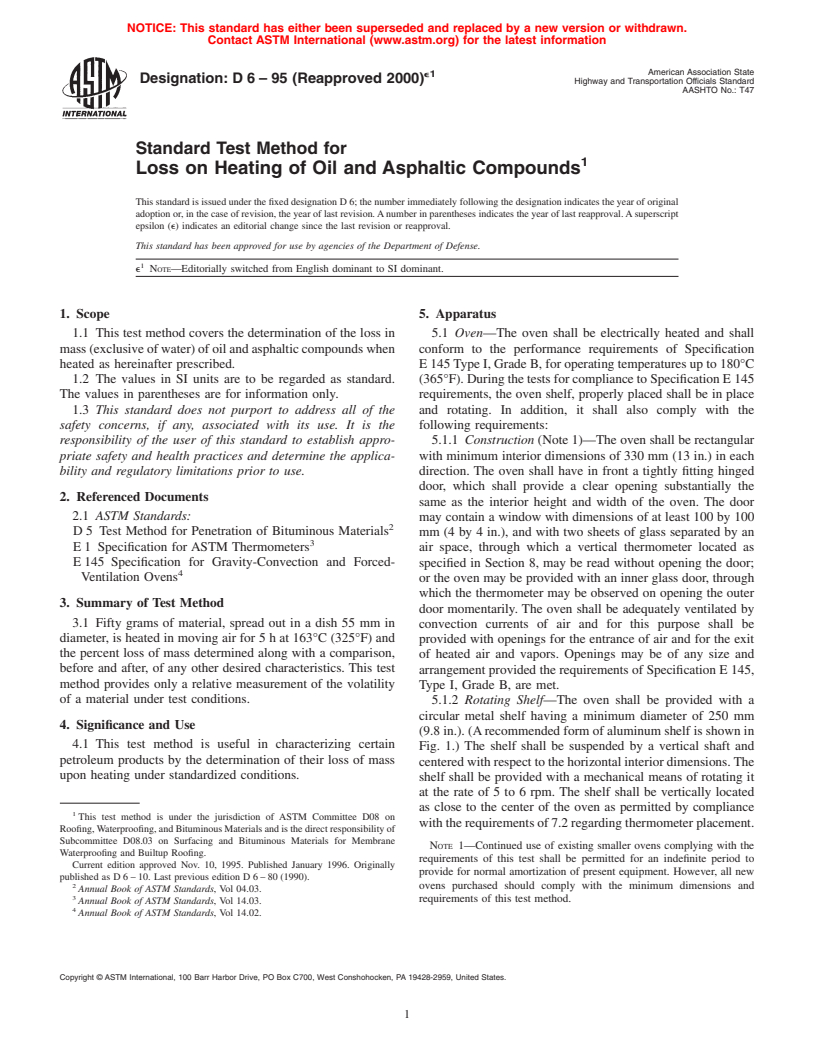

5.1.2 Rotating Shelf—The oven shall be provided with a

circular metal shelf having a minimum diameter of 250 mm

4. Significance and Use

(9.8 in.). (Arecommended form of aluminum shelf is shown in

4.1 This test method is useful in characterizing certain

Fig. 1.) The shelf shall be suspended by a vertical shaft and

petroleum products by the determination of their loss of mass

centeredwithrespecttothehorizontalinteriordimensions.The

upon heating under standardized conditions.

shelf shall be provided with a mechanical means of rotating it

at the rate of 5 to 6 rpm. The shelf shall be vertically located

as close to the center of the oven as permitted by compliance

This test method is under the jurisdiction of ASTM Committee D08 on

withtherequirementsof7.2regardingthermometerplacement.

Roofing,Waterproofing, and Bituminous Materials and is the direct responsibility of

Subcommittee D08.03 on Surfacing and Bituminous Materials for Membrane

NOTE 1—Continued use of existing smaller ovens complying with the

Waterproofing and Builtup Roofing.

requirements of this test shall be permitted for an indefinite period to

Current edition approved Nov. 10, 1995. Published January 1996. Originally

provide for normal amortization of present equipment. However, all new

published as D 6 – 10. Last previous editionD6–80 (1990).

ovens purchased should comply with the minimum dimensions and

Annual Book of ASTM Standards, Vol 04.03.

requirements of this test method.

Annual Book of ASTM Standards, Vol 14.03.

Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6

Metric Equivalents

1 9 1 5 23 15 1 3 15 1 15 7

in. ⁄16 ⁄64 ⁄4 ⁄16 ⁄64 ⁄32 ⁄2 ⁄4 1 ⁄32 1 ⁄2 2 ⁄16 4 ⁄8

mm 1.6 3.6 6.4 7.9 9.1 11.9 12.7 19.0 37.3 38.1 74.6 123.8

FIG. 1 Aluminum Shelf

5.2 Thermometer—An ASTM Loss on Heat Thermometer requirements of 5.3, and weigh to the nearest 0.01 g. If the

graduated in Celsius degrees, having a range from 155 to material has been heated to facilitate transfer, cool the sample

170°C and

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.