ASTM B363-23

(Specification)Standard Specification for Seamless and Welded Unalloyed Titanium and Titanium Alloy Welding Fittings

Standard Specification for Seamless and Welded Unalloyed Titanium and Titanium Alloy Welding Fittings

ABSTRACT

This specification covers fittings intended for general corrosion-resisting and elevated-temperature services, factory made from unalloyed titanium and titanium alloys. The titanium for welding fittings may consist of billets, bars, plates, seamless or welded pipe or tube that conforms to all the requirements for manufacturing process, testing, chemical composition, and mechanical properties. Forging, forming, or shaping operations may be performed by hammering, pressing, piercing, extruding, upsetting, rolling, bending, fusion welding, or by a combination of two or more of these operations. The titanium shall conform to the requirements as to prescribed chemical composition. Product analysis tolerances of aluminum, carbon, chromium, hydrogen, iron, molybdenum, nickel, niobium, nitrogen, oxygen, palladium, ruthenium, silicon, vanadium, zirconium, and some residuals shall be specified. The titanium shall conform to the requirements as to tensile properties prescribed in the specifications.

SCOPE

1.1 This specification2 covers fittings intended for general corrosion-resisting and elevated-temperature services, factory made from unalloyed titanium and titanium alloys. The term welding fittings applies to parts such as 45° and 90° elbows, 180° returns, caps, tees, reducers, lap-joint stub ends, and other types.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: B363 − 23

Standard Specification for

Seamless and Welded Unalloyed Titanium and Titanium

1

Alloy Welding Fittings

This standard is issued under the fixed designation B363; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* B381 Specification for Titanium and Titanium Alloy Forg-

2 ings

1.1 This specification covers fittings intended for general

B600 Guide for Descaling and Cleaning Titanium and Tita-

corrosion-resisting and elevated-temperature services, factory

nium Alloy Surfaces

made from unalloyed titanium and titanium alloys. The term

B861 Specification for Titanium and Titanium Alloy Seam-

welding fittings applies to parts such as 45° and 90° elbows,

less Pipe

180° returns, caps, tees, reducers, lap-joint stub ends, and other

B862 Specification for Titanium and Titanium Alloy Welded

types.

Pipe

1.2 This standard does not purport to address all of the

4,5

2.2 ANSI Standards:

safety concerns, if any, associated with its use. It is the

ASME/ANSI B16.5 Pipe Flanges and Flanged Fittings

responsibility of the user of this standard to establish appro-

ASME/ANSI B16.9 Factory-Made Wrought Steel Butt-

priate safety, health, and environmental practices and deter-

Welding Fittings

mine the applicability of regulatory limitations prior to use.

ASME/ANSI B16.11 Forged Fittings, Socket Welding and

1.3 This international standard was developed in accor-

Threaded

dance with internationally recognized principles on standard-

ASME/ANSI B36.19 Stainless Steel Pipe

ization established in the Decision on Principles for the

2.3 Manufacturers’ Standardization Society of the Valve and

Development of International Standards, Guides and Recom-

6

Fittings Industry Standards:

mendations issued by the World Trade Organization Technical

MSS SP-25 Standard Marking System for Valves, Fittings,

Barriers to Trade (TBT) Committee.

Flanges and Unions

MSS SP-43 Standard Practice for Wrought and Fabricated

2. Referenced Documents

Butt-Welded Fittings for Low Pressure, Corrosion Resis-

3

2.1 ASTM Standards:

tant Applications

B265 Specification for Titanium and Titanium Alloy Strip,

MSS SP-97 Standard Integrally Reinforced Forged Branch

Sheet, and Plate

Outlet Fittings — Socket Welding, Threaded, and Butt-

B338 Specification for Seamless and Welded Titanium and

Welding Ends

Titanium Alloy Tubes for Condensers and Heat Exchang-

MSS SP-119 Standard Factory-Made Wrought Belled End

ers

Socket-Welding Fittings for Socket Welding

B348 Specification for Titanium and Titanium Alloy Bars

7

2.4 ASME Standard:

and Billets

ASME Boiler and Pressure Vessel Code Sections VIII

B367 Specification for Titanium and Titanium Alloy Cast-

Division 1 Pressure Vessels and Section IX

ings

1 4

This specification is under the jurisdiction of ASTM Committee B10 on Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

Reactive and Refractory Metals and Alloys and is the direct responsibility of 4th Floor, New York, NY 10036, http://www.ansi.org.

5

Subcommittee B10.01 on Titanium. Specifications in the order are for “dimensions only” with no requirements for

Current edition approved Nov. 1, 2023. Published November 2023. Originally strength or pressure rating to be inferred. (that is, Class XXXX is not intended to

approved in 1961. Last previous edition approved in 2019 as B363 – 19. DOI: designate a strength or pressure rating requirement for titanium; only to define a

10.1520/B0363-23. dimension for that category.)

2 6

For ASME Boiler and Pressure Vessel Code applications, see related Specifi- Available from Manufacturers Standardization Society of the Valve and Fittings

cation SB-363 in Section II of that Code. Industry (MSS), 127 Park St., NE, Vienna, VA 22180-4602, http://www.mss-

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or hq.com.

7

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from American Society of Mechanical Engineers (ASME), ASME

Standards volume information, refer to the standard’s Document Summary page on International Headquarters, Two Park Ave., New York, NY 10016-5990, http://

the ASTM website. www.asme.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

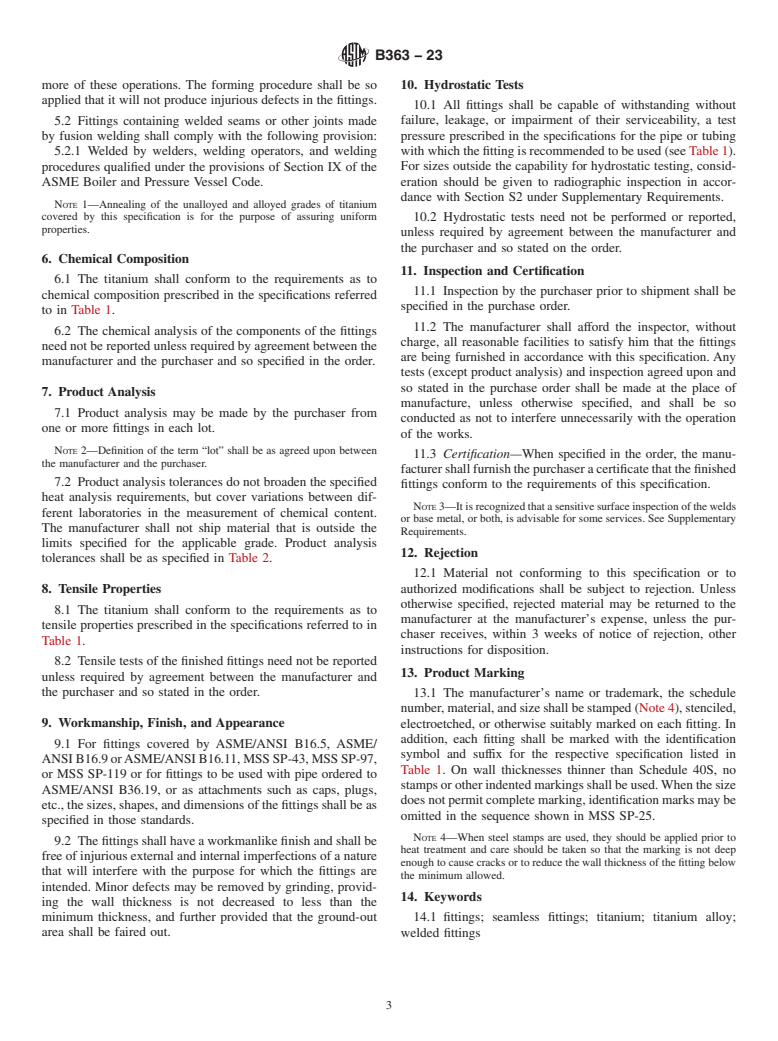

------------------

...

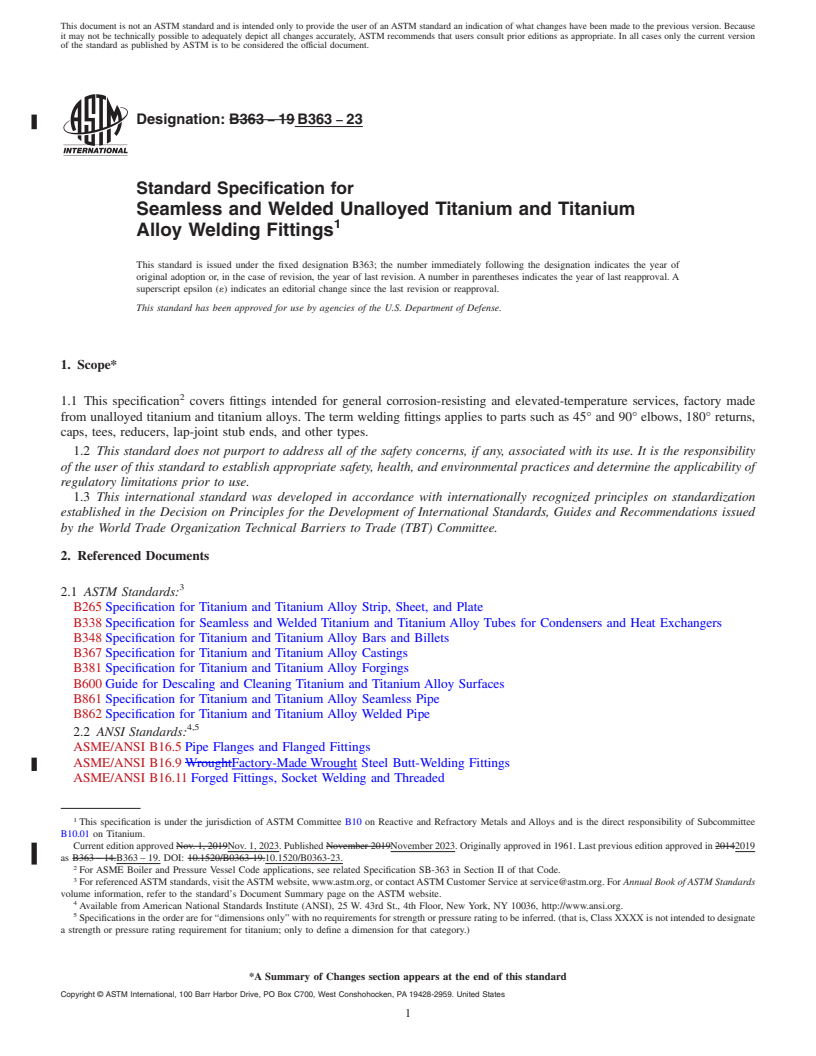

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B363 − 19 B363 − 23

Standard Specification for

Seamless and Welded Unalloyed Titanium and Titanium

1

Alloy Welding Fittings

This standard is issued under the fixed designation B363; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

2

1.1 This specification covers fittings intended for general corrosion-resisting and elevated-temperature services, factory made

from unalloyed titanium and titanium alloys. The term welding fittings applies to parts such as 45° and 90° elbows, 180° returns,

caps, tees, reducers, lap-joint stub ends, and other types.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

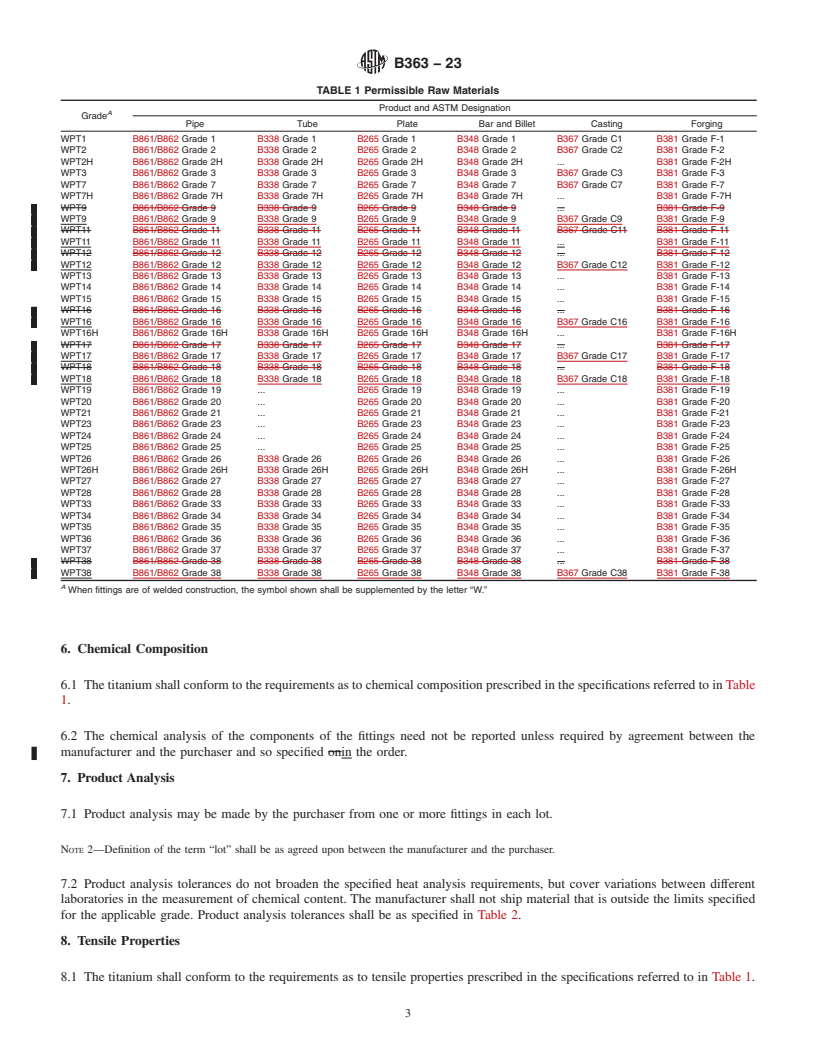

2. Referenced Documents

3

2.1 ASTM Standards:

B265 Specification for Titanium and Titanium Alloy Strip, Sheet, and Plate

B338 Specification for Seamless and Welded Titanium and Titanium Alloy Tubes for Condensers and Heat Exchangers

B348 Specification for Titanium and Titanium Alloy Bars and Billets

B367 Specification for Titanium and Titanium Alloy Castings

B381 Specification for Titanium and Titanium Alloy Forgings

B600 Guide for Descaling and Cleaning Titanium and Titanium Alloy Surfaces

B861 Specification for Titanium and Titanium Alloy Seamless Pipe

B862 Specification for Titanium and Titanium Alloy Welded Pipe

4,5

2.2 ANSI Standards:

ASME/ANSI B16.5 Pipe Flanges and Flanged Fittings

ASME/ANSI B16.9 WroughtFactory-Made Wrought Steel Butt-Welding Fittings

ASME/ANSI B16.11 Forged Fittings, Socket Welding and Threaded

1

This specification is under the jurisdiction of ASTM Committee B10 on Reactive and Refractory Metals and Alloys and is the direct responsibility of Subcommittee

B10.01 on Titanium.

Current edition approved Nov. 1, 2019Nov. 1, 2023. Published November 2019November 2023. Originally approved in 1961. Last previous edition approved in 20142019

as B363 – 14.B363 – 19. DOI: 10.1520/B0363-19.10.1520/B0363-23.

2

For ASME Boiler and Pressure Vessel Code applications, see related Specification SB-363 in Section II of that Code.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

4

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

5

Specifications in the order are for “dimensions only” with no requirements for strength or pressure rating to be inferred. (that is, Class XXXX is not intended to designate

a strength or pressure rating requirement for titanium; only to define a dimension for that category.)

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B363 − 23

ASME/ANSI B36.19 Stainless Steel Pipe

6

2.3 Manufacturers’ Standardization Society of the Valve and Fittings Industry Standards:

MSS SP-25 Standard Marking System for Valves, Fittings, Flanges and Unions

MSS SP-43 Standard Practice for Light Weight Stainless Steel Butt-Welding FittingsWrought and Fabricated Butt-Welded

Fittings for Low Pressure, Corrosion Resistant Applications

MSS SP-97 Standard Integrally Reinforced Forged Branch Outlet Fittings — Socket Welding, Threaded, and Butt-Welding Ends

MSS SP-119 Standard Factory-Made Wrought Belled End Socket-Welding Fittings for Socket Welding

7

2.4 ASME Standard:

ASME Boiler and Pressure Vessel Code Sections VIII Division 1 Pressure Vessels and Section IX

3. Ordering Information

3.1 Orders for material to this s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.