ASTM B640-00(2006)

(Specification)Standard Specification for Welded Copper Tube for Air Conditioning and Refrigeration Service

Standard Specification for Welded Copper Tube for Air Conditioning and Refrigeration Service

SCOPE

1.1 This specification establishes the requirements for welded copper tube for air conditioning and refrigeration service for use in connections, repairs, and alterations. The tube shall be made from one of the following coppers:

1.2 Copper UNS No. C12200 shall be furnished, unless otherwise specified. The copper tube shall be supplied in annealed coils or drawn temper straight lengths.

1.3 UnitsThe values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units which are provided for information only and are not considered standard.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 640 – 00 (Reapproved 2006)

Standard Specification for

Welded Copper Tube for Air Conditioning and Refrigeration

Service

This standard is issued under the fixed designation B640; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* B153 Test Method for Expansion (Pin Test) of Copper and

Copper-Alloy Pipe and Tubing

1.1 This specification establishes the requirements for

B170 SpecificationforOxygen-FreeElectrolyticCopper—

welded copper tube for air conditioning and refrigeration

Refinery Shapes

serviceforuseinconnections,repairs,andalterations.Thetube

B224 Classification of Coppers

shall be made from one of the following coppers:

B577 Test Methods for Detection of Cuprous Oxide (Hy-

Copper UNS Previously Used Type of Copper

A

drogen Embrittlement Susceptibility) in Copper

No. Designation

B601 Classification for Temper Designations for Copper

C10100 OFE oxygen-free electronic

and Copper Alloys—Wrought and Cast

C10200 OF oxygen-free without-residual oxidants

B846 Terminology for Copper and Copper Alloys

C12000 DLP phosphorized, low-residual phosphorus

C12200 DHP phosphorized, high-residual phosphorus

E3 Guide for Preparation of Metallographic Specimens

E8 Test Methods for Tension Testing of Metallic Materials

A

Designation listed in Classification B 224.

E8M Test Methods for Tension Testing of Metallic Mate-

1.2 Copper UNS No. C12200 shall be furnished, unless

rials [Metric]

otherwise specified. The copper tube shall be supplied in

E29 Practice for Using Significant Digits in Test Data to

annealed coils or drawn temper straight lengths.

Determine Conformance with Specifications

1.3 Units—The values stated in inch-pound units are to be

E53 Test Method for Determination of Copper in Unal-

regarded as standard. The values given in parentheses are

loyed Copper by Gravimetry

mathematical conversions to SI units which are provided for

E62 Test Methods for Chemical Analysis of Copper and

information only and are not considered standard.

Copper Alloys (Photometric Methods)

1.4 This standard does not purport to address all of the

E112 Test Methods for Determining Average Grain Size

safety concerns, if any, associated with its use. It is the

E243 Practice for Electromagnetic (Eddy-Current) Exami-

responsibility of the user of this standard to establish appro-

nation of Copper and Copper-Alloy Tubes

priate safety and health practices and determine the applica-

E255 Practice for Sampling Copper and CopperAlloys for

bility of regulatory limitations prior to use.

the Determination of Chemical Composition

2. Referenced Documents

3. Terminology

2.1 ASTM Standards:

3.1 For definitions of terms related to copper and copper

alloys, refer to Terminology B846.

3.2 Definitions of Terms Specific to This Standard:

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper

and CopperAlloys and is the direct responsibility of Subcommittee B05.04 on Pipe

3.2.1 coil, n—a length of the product wound into a series of

and Tube.

connected turns. The unqualified term “coiled” as applied to

Current edition approved March 15, 2006. Published April 2006. Originally

tube usually refers to a bunched coil.

approved in 1978. Last previous edition approved in B640–00.

3.2.1.1 bunched, adj—a coil in which the turns are bunched

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

and held together such that the cross section of the bunched

Standards volume information, refer to the standard’s Document Summary page on

turns is approximately circular.

the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B 640 – 00 (2006)

3.2.1.2 level or traverse wound, adj—a coil in which the 5.2.3.2 Weldedtubethathasbeenmechanicallyworkedinto

turns are wound into layers parallel to the axis of the coil such asmoothtubewithouttheneedforinternalorexternalscarfing,

that successive turns in a given layer are next to one another. or other metal removal and subsequently cold drawn over a

3.2.2 flash, n—the metal that protrudes at the weld, both on mandrel and annealed as necessary to conform to the specified

the inside and outside of a tube, as a result of the pressure size and temper.

applied when a forge-type seam is produced. The two types of 5.2.4 CoiledlengthsspecifiedasO60,soft-annealedtemper,

flash are internal flash and external flash. shall be bright annealed after coiling, then dehydrated, and

3.2.3 tube, air-conditioning, n—a welded copper tube con- capped, plugged, crimped, or otherwise closed at both ends so

forming to a standard series of sizes and to specified internal astomaintaintheinternalcleannessofthetubingundernormal

cleanness requirements, normally furnished in drawn temper conditions of handling and storage.

straight lengths, with the ends capped or sealed. 5.2.5 Straight lengths specified as H58, hard-drawn temper,

3.2.4 tube, refrigeration-service, n—a welded copper tube shall be cleaned and capped, plugged, or otherwise closed at

conforming to a standard series of sizes and to special internal both ends so as to maintain the internal cleanness of the tubing

cleannessanddehydrationrequirements,normallyfurnishedin under normal conditions of handling and storage.

soft temper coils, with ends capped or sealed.

6. Chemical Composition

4. Ordering Information

6.1 The product shall conform to the chemical composi-

4.1 Orders for product under this specification shall include tional requirements in Table 1 for the Copper UNS No.

the following information: designation specified in the ordering information.

4.1.1 ASTM designation and year of issue, 6.2 These composition limits do not preclude the presence

4.1.2 Copper UNS No. designation, of other elements. Limits may be established and analysis

4.1.3 Temper (Section 7), required for unnamed elements by agreement between the

4.1.4 Dimensions: diameter, wall thickness, length, and so manufacturer or supplier and the purchaser.

forth (Section 11),

7. Temper

4.1.5 Howfurnished(coiledlengthsorstraightlengths),and

4.1.6 Quantity: total weight or number of pieces or coils of 7.1 The standard tempers for products described in this

specification are given in Table 2.

each copper, size, and temper.

4.2 The following options are available and should be 7.1.1 Drawn general purpose H58.

7.1.2 Annealed temper O60.

specified at the time of placing the order when required:

4.2.1 Hydrogen embrittlement susceptibility (9.3), 7.2 Tempers are defined in Classification B601. Other

special anneal tempers may be supplied as agreed upon

4.2.2 Electromagnetic (eddy-current) test on coiled lengths

between the manufacturer or supplier and the purchaser.

(10.1),

4.2.3 Expansion test (9.1),

8. Mechanical Property Requirements

4.2.4 Cleanness test (10.2),

8.1 Tensile Strength Requirements:

4.2.5 Flattening test (9.4),

8.1.1 Product furnished under this specification shall con-

4.2.6 Reverse bend test (9.5),

form to the tensile requirements prescribed in Table 2 when

4.2.7 Certification (Section 21),

tested in accordance with Test MethodsE8 andE8M.

4.2.8 Test report (Section 18), and

8.1.1.1 Acceptance or rejection based upon mechanical

4.2.9 When product is purchased for agencies of the U.S.

properties shall depend only on tensile strength.

Government (10.3).

9. Performance Requirements

5. Materials and Manufacture

9.1 Expansion Test:

5.1 Material—Thematerialofmanufactureshallbesheetor

9.1.1 When specified in the contract or purchase order,

strip of copper of such quality and soundness as to be suitable

product test specimens from tube furnished in the O60 an-

for processing into welded tube to meet the properties pre-

nealed temper shall be expanded in accordance with Test

scribed herein.

5.2 Manufacture:

TABLE 1 Chemical Requirements

5.2.1 The product shall be manufactured by forming the

material into a tubular shape on a suitable forming mill and Composition, %

Copper or

welded using an automatic process.

Phosphorus Total Other

A

Copper Alloy

Copper, Lead,

Iron Zinc Elements,

5.2.2 The product shall be cold worked to the finished size UNS No.

min Max

Max

and wall thickness and subsequently annealed, when required,

B

C10100 99.99 . . . . . . . . . 0.0003 max . . .

to meet the temper properties specified.

C

C10200 99.95 . . . . .

5.2.3 The product shall conform to “fully finished tube” as

C12000 99.90 . . . . . . . . . 0.004–0.012 . . .

C12200 99.9 . . . . . . . . . 0.015–0.040 . . .

required in 5.2.3.1 and 5.2.3.2:

A

5.2.3.1 Welded tube with internal and external flash re- Silver counting as copper.

B

This value is exclusive of silver and shall be determined as the difference

movedbyscarfing,andthetubesubsequentlycolddrawn,over

between the sum of results for all impurity elements listed in Table 1 of Specifica-

a mandrel and annealed as necessary to conform to the

tion B 170 for Grade 1 and 100 %.

C

specified temper. Oxygen in C10200 shall be 10 ppm max.

B 640 – 00 (2006)

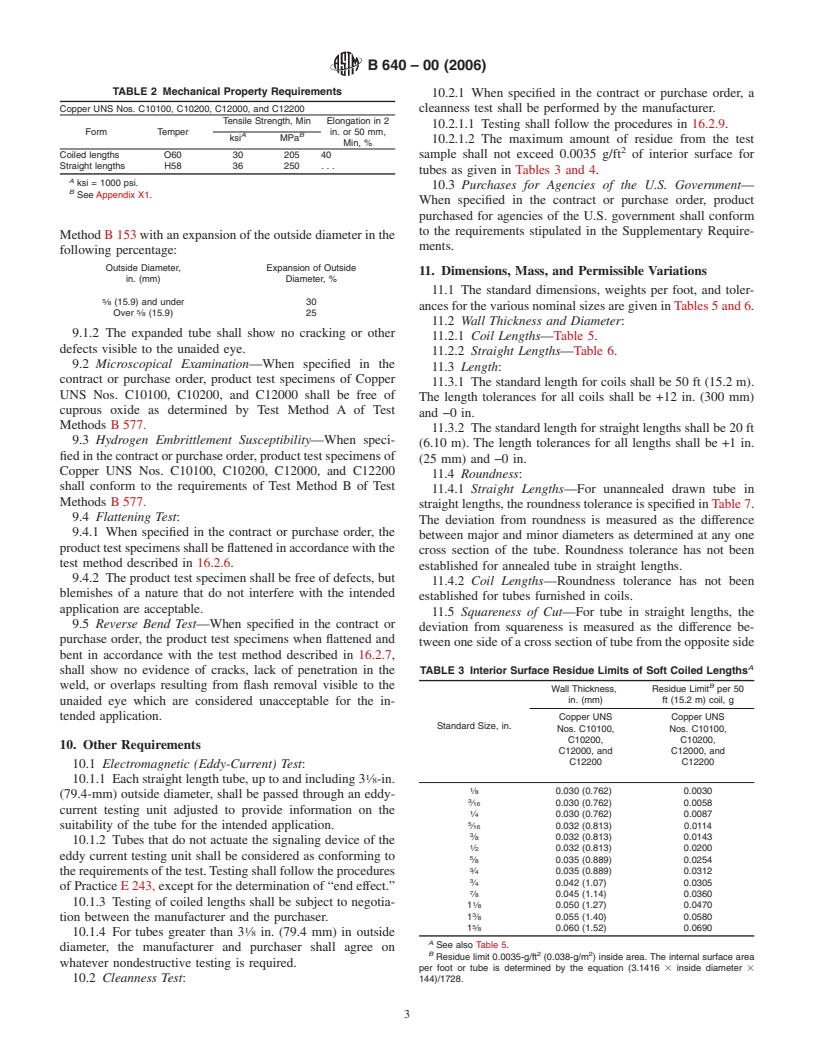

TABLE 2 Mechanical Property Requirements

10.2.1 When specified in the contract or purchase order, a

Copper UNS Nos. C10100, C10200, C12000, and C12200 cleanness test shall be performed by the manufacturer.

Tensile Strength, Min Elongation in 2

10.2.1.1 Testing shall follow the procedures in 16.2.9.

Form Temper in.or50mm,

A B

ksi MPa

10.2.1.2 The maximum amount of residue from the test

Min, %

Coiled lengths O60 30 205 40 sample shall not exceed 0.0035 g/ft of interior surface for

Straight lengths H58 36 250 . . .

tubes as given in Tables 3 and 4.

A

ksi = 1000 psi.

10.3 Purchases for Agencies of the U.S. Government—

B

See Appendix X1.

When specified in the contract or purchase order, product

purchased for agencies of the U.S. government shall conform

to the requirements stipulated in the Supplementary Require-

MethodB153withanexpansionoftheoutsidediameterinthe

ments.

following percentage:

Outside Diameter, Expansion of Outside

11. Dimensions, Mass, and Permissible Variations

in. (mm) Diameter, %

11.1 The standard dimensions, weights per foot, and toler-

⁄8 (15.9) and under 30

ancesforthevariousnominalsizesaregiveninTables5and6.

Over ⁄8 (15.9) 25

11.2 Wall Thickness and Diameter:

9.1.2 The expanded tube shall show no cracking or other

11.2.1 Coil Lengths—Table 5.

defects visible to the unaided eye.

11.2.2 Straight Lengths—Table 6.

9.2 Microscopical Examination—When specified in the

11.3 Length:

contract or purchase order, product test specimens of Copper

11.3.1 The standard length for coils shall be 50 ft (15.2 m).

UNS Nos. C10100, C10200, and C12000 shall be free of

The length tolerances for all coils shall be +12 in. (300 mm)

cuprous oxide as determined by Test Method A of Test

and −0 in.

Methods B577.

11.3.2 The standard length for straight lengths shall be 20 ft

9.3 Hydrogen Embrittlement Susceptibility—When speci-

(6.10 m). The length tolerances for all lengths shall be +1 in.

fiedinthecontractorpurchaseorder,producttestspecimensof

(25 mm) and −0 in.

Copper UNS Nos. C10100, C10200, C12000, and C12200

11.4 Roundness:

shall conform to the requirements of Test Method B of Test

11.4.1 Straight Lengths—For unannealed drawn tube in

Methods B577.

straightlengths,theroundnesstoleranceisspecifiedinTable7.

9.4 Flattening Test:

The deviation from roundness is measured as the difference

9.4.1 When specified in the contract or purchase order, the

between major and minor diameters as determined at any one

producttestspecimensshallbeflattenedinaccordancewiththe

cross section of the tube. Roundness tolerance has not been

test method described in 16.2.6.

established for annealed tube in straight lengths.

9.4.2 The product test specimen shall be free of defects, but

11.4.2 Coil Lengths—Roundness tolerance has not been

blemishes of a nature that do not interfere with the intended

established for tubes furnished in coils.

application are acceptable.

11.5 Squareness of Cut—For tube in straight lengths, the

9.5 Reverse Bend Test—When specified in the contract or

deviation from squareness is measured as the difference be-

purchase order, the product test specimens when flattened and

tweenonesideofacrosssectionoftubefromtheoppositeside

bent in accordance with the test method described in 16.2.7,

A

shall show no evidence of cracks, lack of penetration in the TABLE 3 Interior Surface Residue Limits of Soft Coiled Lengths

B

weld, or overlaps resulting from flash removal visible to the

Wall Thickness, Residue Limit per 50

in. (mm) ft (15.2 m) coil, g

unaided eye which are considered unacceptable for the in-

tended application.

Copper UNS Copper UNS

Standard Size, in.

Nos. C10100, Nos. C10100,

C10200, C10200,

10. Other Requirements

C12000, and C12000, and

C12200 C12200

10.1 Electromagnetic (Eddy-Current) Test:

10.1.1 Eachstraightlengthtube,uptoandincluding3 ⁄8-in.

⁄8 0.030 (0.762) 0.0030

(79.4-mm) outside diameter, shall be passed through an eddy-

⁄16 0.030 (0.762) 0.0058

current testing unit adjusted to provide information on the 1

⁄4 0.030 (0.762) 0.0087

suitability of the tube for the intended application. ⁄16 0.032 (0.813) 0.0114

⁄8 0.032 (0.813) 0.0143

10.1.2 Tubes that do not actuate the signaling device of the

⁄2 0.032 (0.813) 0.0200

eddy current testing unit shall be considered as conforming to

⁄8 0.035 (0.889) 0.0254

⁄4 0.035 (0.889) 0.0312

therequirementsofthetest.Testingshallfollowtheprocedures

⁄4 0.042 (1.07) 0.0305

of Practice E243, except for the determination of “end effect.”

⁄8 0.045 (1.14) 0.0360

10.1.3 Testing of coiled lengths shall be subject to negotia- 1

1 ⁄8 0.050 (1.27) 0.0470

1 ⁄8 0.055 (1.40) 0.0580

tion between the manufacturer and the purchaser.

1 ⁄8 0.060 (1.52) 0.0690

10.1.4 For tubes greater than 3 ⁄8 in. (79.4 mm) in outside

A

See also Table 5.

diameter, the manufacturer and purchaser shall agree on

B 2 2

Residue limit 0.0035-g/ft (0.038-g/m ) inside area. The internal surface area

whatever nondestructive testing is required.

per foot or tube is determined by the equation (3.1416 3 inside diameter 3

10.2 Cleanness Test: 144)/1728.

B 640 – 00 (2006)

A

TABLE 4 Interior Surface Residue Limits of Straight Lengths

13.2.1 Samples for chemical analysis shall be taken in

B

Wall Thickness, in. Residue Limit per 20 accordance with Practice E255. Dril

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.