ASTM C1851-18(2023)

(Practice)Standard Practice for Determining the Extent of Cracking in a Sealant using the Difference between the Compressive and Tensile Modulus

Standard Practice for Determining the Extent of Cracking in a Sealant using the Difference between the Compressive and Tensile Modulus

SIGNIFICANCE AND USE

5.1 The intent of this practice is to quantitatively determine the amount of cracking of a sealant relative to an unexposed or uncracked sample. Some samples of sealant have been observed to exhibit some degree of cracking some period after installation. The degree of cracking is assessed visually in a qualitative manner that takes into account the area of the cracks at the exposed surface of the sealant, but does not take into account the depth or profile of the cracks. The degree of cracking in the sealant has been used as an indication of performance change.

SCOPE

1.1 This practice covers a procedure for quantitatively determining the extent of cracking in a sealant sample by evaluating the difference between the measured compressive and tensile modulus of a sealant relative to an unexposed or uncracked version of the same sealant. The cracks will reduce the area of the sealant in the tensile modulus, but in the compressive modulus measurement they will not change the area over which the modulus is determined.

1.2 The values in SI units are to be regarded as standard. The values in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C1851 − 18 (Reapproved 2023)

Standard Practice for

Determining the Extent of Cracking in a Sealant using the

Difference between the Compressive and Tensile Modulus

This standard is issued under the fixed designation C1851; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This practice covers a procedure for quantitatively 3.1 Definitions:

determining the extent of cracking in a sealant sample by 3.1.1 For definitions of terms used in this practice, refer to

evaluating the difference between the measured compressive Terminologies E631 and C717.

and tensile modulus of a sealant relative to an unexposed or

4. Summary of Practice

uncracked version of the same sealant. The cracks will reduce

4.1 This practice consists of measuring the modulus of the

the area of the sealant in the tensile modulus, but in the

sealant usingTest Method C1735 in both tension and compres-

compressive modulus measurement they will not change the

sion. Once these values have been determined the formula

area over which the modulus is determined.

presented in this practice will be used to determine the degree

1.2 The values in SI units are to be regarded as standard.

ofcrackinginthesealantrelativetoanunexposedoruncracked

The values in parentheses are for information only.

sample of the same sealant.

1.3 This standard does not purport to address all of the

4.2 The motivation for this practice is to quantitatively

safety concerns, if any, associated with its use. It is the

determine the extent of cracking in the sealant. This measure-

responsibility of the user of this standard to establish appro-

ment is currently determined with a qualitative measure of

priate safety, health, and environmental practices and deter-

cracking determined by visual inspection. The degree of

mine the applicability of regulatory limitations prior to use.

cracking has been used as a measure of performance for

1.4 This international standard was developed in accor-

sealant.

dance with internationally recognized principles on standard-

4.3 This practice will enable determination of the percent of

ization established in the Decision on Principles for the

cracking of a sealant relative to an unexpected or uncracked

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical vesion of the same sealant.

Barriers to Trade (TBT) Committee.

5. Significance and Use

5.1 The intent of this practice is to quantitatively determine

2. Referenced Documents

2 the amount of cracking of a sealant relative to an unexposed or

2.1 ASTM Standards:

uncracked sample. Some samples of sealant have been ob-

C717 Terminology of Building Seals and Sealants

served to exhibit some degree of cracking some period after

C719 Test Method for Adhesion and Cohesion of Elasto-

installation. The degree of cracking is assessed visually in a

meric Joint Sealants Under Cyclic Movement (Hockman

qualitativemannerthattakesintoaccounttheareaofthecracks

Cycle)

at the exposed surface of the sealant, but does not take into

C1735 Test Method for Measuring the Time Dependent

account the depth or profile of the cracks. The degree of

Modulus of Sealants Using Stress Relaxation

cracking in the sealant has been used as an indication of

E631 Terminology of Building Constructions

performance change.

6. Procedure

This practice is under the jurisdiction of ASTM Committee C24 on Building

Seals and Sealants and is the direct responsibility of Subcommittee C24.20 on 6.1 The modulus of the sealant is determined in compres-

General Test Methods.

sion and separately in tension usingTest Method C1735.These

Current edition approved Jan. 1, 2023. Published January 2023. Originally

values are determined from a new sample (the unexposed

approved in 2018. Last previous edition approved in 2018 as C1851 – 18. DOI:

reference without any cracking), and the sample of interest.

10.1520/C1851-18R23.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

6.2 From the four modulus measurements obtained from

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Test Method C1735, determine the value of the modulus at

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 100 s for each of these four conditions:

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1851 − 18 (2023)

6.2.1 New Sample (the unexposed reference without any eter measures the change in modulus that is not due to crack

cracking), compression (E ), formation. The details of the derivation of these two expres-

100,bo,C

6.2.2 New Sample (the unexposed reference without any sions (Eq 1 and Eq 2) are detailed in Appendix X1.

cracking), Tension (E ), Additionally, a worked example is presented in Appendix X2.

100,bo,T

6.2.3 Test Sample, Compression, (E ),

100,C

6.2.4 Test sample, Tension (E ). 7. Report

100,T

6.3 Insert the four values determined in 6.2 into the follow- 7.1 Report the following information:

ing two empirically derived relationships: 7.1.1 Identification of the sealant measured, including type,

source, manufacturer code number, curing conditions

E 5 d·E $1 2 a f 2 ~1 2 a !f % (1)

100,T 100,bo,T 2 2

employed,

E 5 d·E ~1 2 a f! (2)

100,C 100,bo,C 1

7.1.2 Identification of the substrates,

6.4 In these expressions, the experimentally determined

7.1.3 Name and description of primers that were used, if

values should be used, a = 0.118 and a = 0.562. With these

any,

1 2

expressions and the values determined in 6.3, there are two

7.1.4 Number of specimens tested,

equations and two unknowns.

7.1.5 Description of the sealant appearance.

7.1.6 The value calculated for f. This can be reported as the

6.5 Solve for the two remaining undermined values f and d.

calculated 0-1 value or if multiplied by 100 as % cracked.

Theunknown frepresentsthefractionofcracksandhasavalue

7.1.7 The value calculated for modulus change not attrib-

between 0 and 1. Since Eq 1 is quadratic, f will have two

uted to cracking, d.

values. Only the positive value should be used. The d param-

8. Keywords

The derivation of these relationships are shown in Appendix X1 and Appendix

X2 of this practice. 8.1 compression; cracks; modulus; sealant; tension

APPENDIXES

X1. ANALYSIS OF A CRACKED SEALANT

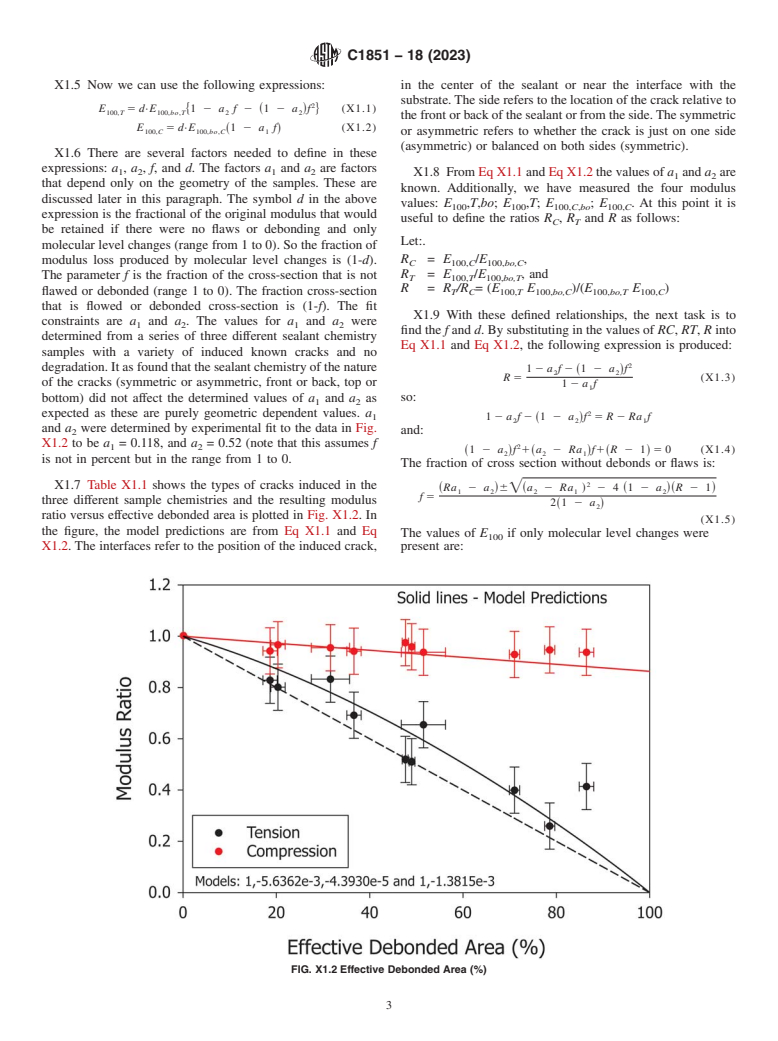

X1.1 A Test Method C719 sealant sample is characterized X1.2 The black circles in this plot are the pre-exposure

using Test Method C1735. This standard yields a modulus results from the Test Method C1735 tensions tests. The

versus time curve for the sealant. This performed in both compression baseline results would look very similar.

tension and compression. See Fig. X1.1.

X1.3 The sample experiences some type of exposure. The

sample is removed from the exposure and once again Test

MethodC1735isperformedintwotests,compressionmodulus

and tensile modulus. In Fig. X1.1, a series of Test Method

C1735 tensile modulus results after different exposures are

plotted.At this point it is important to note that the curve shape

is the same but the exposure has caused the modulus to be

lower.

X1.4 Instead of keeping the entire time dependence, the

changes to the entire curve can be represented by a single time

point. An arbitrary choice of 100 s after the stress relaxation

component of the Test Method C1735 test is chosen to be far

enough away from the complications associated with imposed

strain and not too long to start to see extensive relaxation of the

sealant affecting the sealant. The modulus value recorded at

100 s is represented by: E . So now we have four values for

the 100 s modulus determined by the four Test Method C1735

tests:

X1.4.1 Theinitial(baselinemodulus)intension: E , T, bo.

X1.4.2 The value in tension after some exposure b: E , T.

X1.4.3 The initial (baseline modulus) in compression: E ,

C, bo.

X1.4.4 The value in compression after some exposure b:

FIG. X1.1 Modulus versus Time Curve E , C.

C1851 − 18 (2023)

X1.5 Now we can use the following expressions: in the center of the sealant or near the interface with the

substrate.The side refers to the location of the crack relative to

E 5 d·E $1 2 a f 2 ~1 2 a !f % (X1.1)

100,T 100,bo,T 2 2

the front or back of the sealant or from the side.The symmetric

E 5 d·E 1 2 a f (X1.2)

~ !

100,C

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.