ASTM C719-13

(Test Method)Standard Test Method for Adhesion and Cohesion of Elastomeric Joint Sealants Under Cyclic Movement (Hockman Cycle)

Standard Test Method for Adhesion and Cohesion of Elastomeric Joint Sealants Under Cyclic Movement (Hockman Cycle)

SIGNIFICANCE AND USE

5.1 The failure of a building sealant in an active joint is usually manifested by cohesive failure in the sealant or adhesive failure between the sealant and the substrate, or both. The method described in this test method relates only to the performance of the sealant when properly installed with recommended primers, and does not evaluate sealant failures caused by improper joint design, excessive joint movement, improper application practices, and other factors known to cause sealant failure in buildings and building areas.

SCOPE

1.1 This test method is an accelerated laboratory procedure for evaluating the performance of a building sealant in a test configuration that is subjected to water immersion, cyclic movement, and temperature change.3

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C719 − 13

StandardTest Method for

Adhesion and Cohesion of Elastomeric Joint Sealants

1,2

Under Cyclic Movement (Hockman Cycle)

This standard is issued under the fixed designation C719; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 4. Summary of Test Method

1.1 This test method is an accelerated laboratory procedure 4.1 This test method consists of subjecting standard joint

for evaluating the performance of a building sealant in a test specimens to a series of treatments as follows: (a) immersion

configuration that is subjected to water immersion, cyclic inwaterforsevendays;(b)exposureinanovenforsevendays

3

movement, and temperature change. while under compression; (c) automatic compression and

extension cycling at room temperature at a specified rate and

1.2 The values stated in inch-pound units are to be regarded

amount of joint movement; and (d) alternate compression and

as standard. The values given in parentheses are mathematical

extension of the joint at high and low temperatures,

conversions to SI units that are provided for information only

respectively, under specified conditions described herein.

and are not considered standard.

4.2 The effects of the test shall be evaluated by visual

1.3 This standard does not purport to address all of the

inspection for cohesive and adhesive failures, sealant

safety concerns, if any, associated with its use. It is the

deformation, and bubble formation within the sealant.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

4.3 This test method is applicable to any joint movement.

bility of regulatory limitations prior to use.

The most common test movements are 612.5 and 625% as

used in the examples.

2. Referenced Documents

5. Significance and Use

4

2.1 ASTM Standards:

5.1 The failure of a building sealant in an active joint is

C33Specification for Concrete Aggregates

usually manifested by cohesive failure in the sealant or

C109/C109MTest Method for Compressive Strength of

adhesive failure between the sealant and the substrate, or both.

Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube

The method described in this test method relates only to the

Specimens)

performance of the sealant when properly installed with

C150Specification for Portland Cement

recommended primers, and does not evaluate sealant failures

C717Terminology of Building Seals and Sealants

caused by improper joint design, excessive joint movement,

3. Terminology improper application practices, and other factors known to

cause sealant failure in buildings and building areas.

3.1 Definitions—For definitions of terms used in this test

method, refer to Terminology C717.

6. Apparatus

5

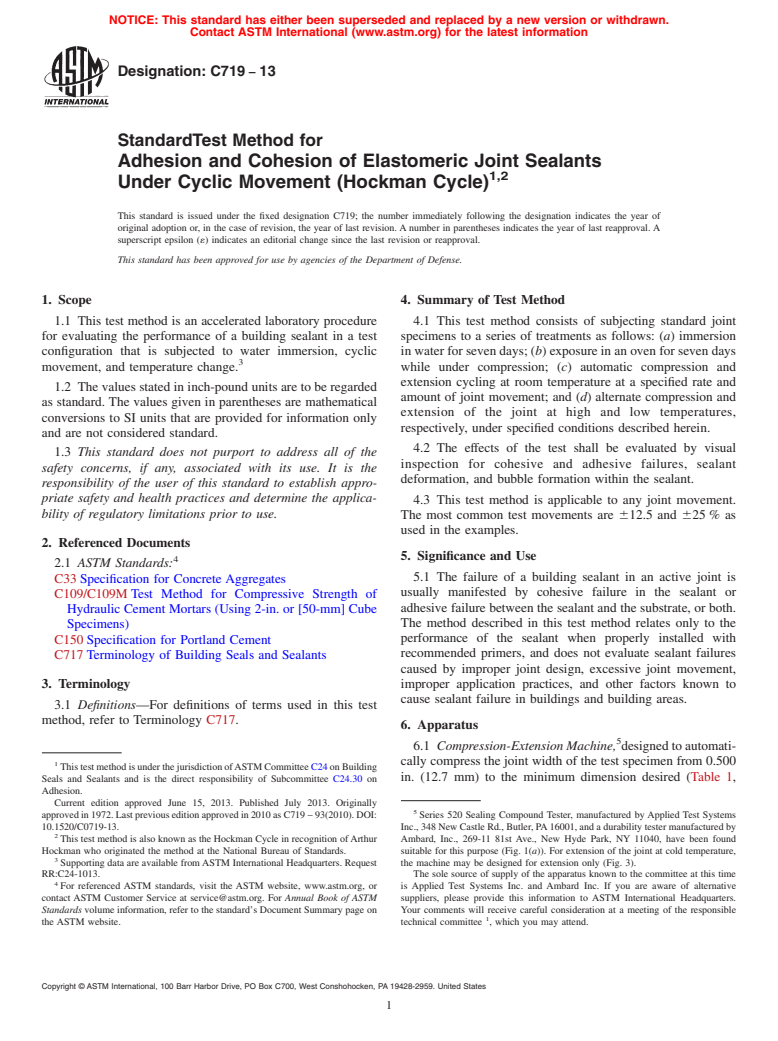

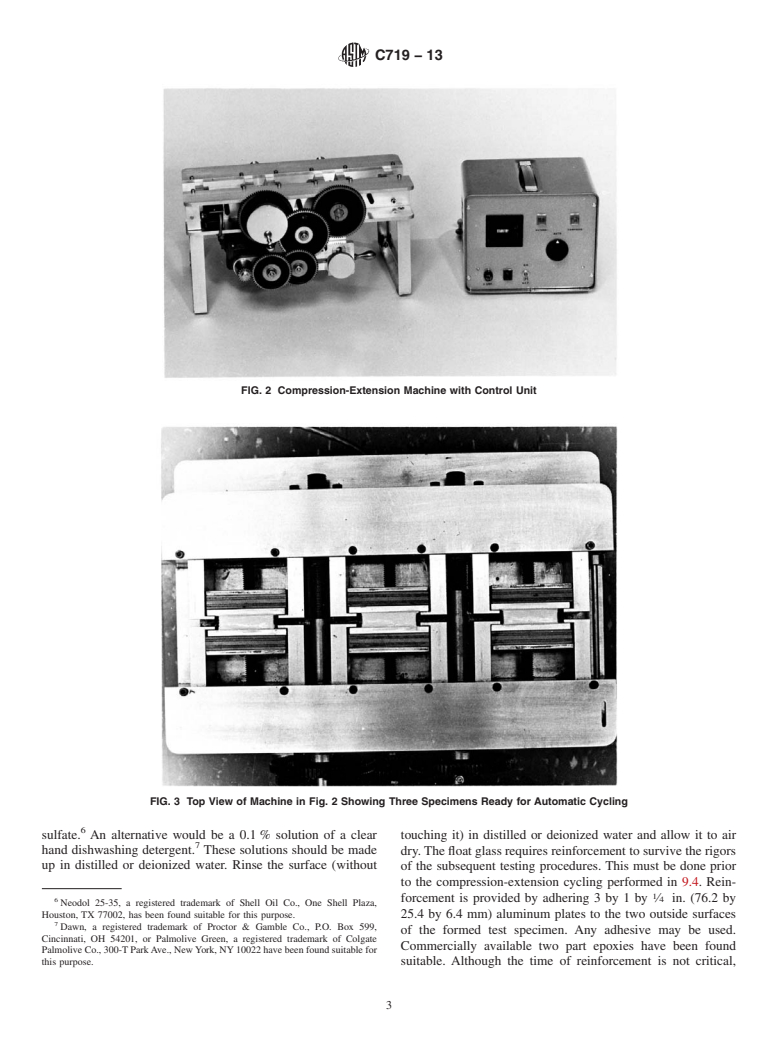

6.1 Compression-Extension Machine, designedtoautomati-

cally compress the joint width of the test specimen from 0.500

1

ThistestmethodisunderthejurisdictionofASTMCommitteeC24onBuilding

Seals and Sealants and is the direct responsibility of Subcommittee C24.30 on in. (12.7 mm) to the minimum dimension desired (Table 1,

Adhesion.

Current edition approved June 15, 2013. Published July 2013. Originally

5

approvedin1972.Lastpreviouseditionapprovedin2010asC719–93(2010).DOI: Series 520 Sealing Compound Tester, manufactured by Applied Test Systems

10.1520/C0719-13. Inc.,348NewCastleRd.,Butler,PA16001,andadurabilitytestermanufacturedby

2

This test method is also known as the Hockman Cycle in recognition ofArthur Ambard, Inc., 269-11 81st Ave., New Hyde Park, NY 11040, have been found

Hockman who originated the method at the National Bureau of Standards. suitable for this purpose (Fig. 1(a)). For extension of the joint at cold temperature,

3

Supporting data are available fromASTM International Headquarters. Request the machine may be designed for extension only (Fig. 3).

RR:C24-1013. The sole source of supply of the apparatus known to the committee at this time

4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or is Applied Test Systems Inc. and Ambard Inc. If you are aware of alternative

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM suppliers, please provide this information to ASTM International Headquarters.

Standards volume information, refer to the standard’s Document Summary page on Your comments will receive careful consideration at a meeting of the responsible

1

the ASTM website. technical committee , which you may attend.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Con

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C719 − 93 (Reapproved 2010) C719 − 13

Standard Test Method for

Adhesion and Cohesion of Elastomeric Joint Sealants

1,2

Under Cyclic Movement (Hockman Cycle)

This standard is issued under the fixed designation C719; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 This test method is an accelerated laboratory procedure for evaluating the performance of a building sealant in a test

3

configuration that is subjected to water immersion, cyclic movement, and temperature change.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

4

2.1 ASTM Standards:

C33 Specification for Concrete Aggregates

C109/C109M Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens)

C150 Specification for Portland Cement

C717 Terminology of Building Seals and Sealants

3. Terminology

3.1 Definitions—For definitions of terms used in this test method, refer to Terminology C717.

4. Summary of Test Method

4.1 This test method consists of subjecting standard joint specimens to a series of treatments as follows: (a) immersion in water

for seven days; (b) exposure in an oven for seven days while under compression; (c) automatic compression and extension cycling

at room temperature at a specified rate and amount of joint movement; and (d) alternate compression and extension of the joint

at high and low temperatures, respectively, under specified conditions described herein.

4.2 The effects of the test shall be evaluated by visual inspection for cohesive and adhesive failures, sealant deformation, and

bubble formation within the sealant.

4.3 This test method is applicable to any joint movement. The most common test movements are 612.5 and 625 % as used

in the examples.

5. Significance and Use

5.1 The failure of a building sealant in an active joint is usually manifested by cohesive failure in the sealant or adhesive failure

between the sealant and the substrate, or both. The method described in this test method relates only to the performance of the

1

This test method is under the jurisdiction of ASTM Committee C24 on Building Seals and Sealants and is the direct responsibility of Subcommittee C24.30 on Adhesion.

Current edition approved June 15, 2010June 15, 2013. Published August 2010July 2013. Originally approved in 1972. Last previous edition approved in 20052010 as

C719 – 93(2005).(2010). DOI: 10.1520/C0719-93R10.10.1520/C0719-13.

2

This test method is also known as the Hockman Cycle in recognition of Arthur Hockman who originated the method at the National Bureau of Standards.

3

Supporting data are available from ASTM International Headquarters. Request RR:C24-1013.

4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C719 − 13

sealant when properly installed with recommended primers, and does not evaluate sealant failures caused by improper joint design,

excessive joint movement, improper application practices, and other factors known to cause sealant failure in buildings and

building areas.

6. Apparatus

5

1

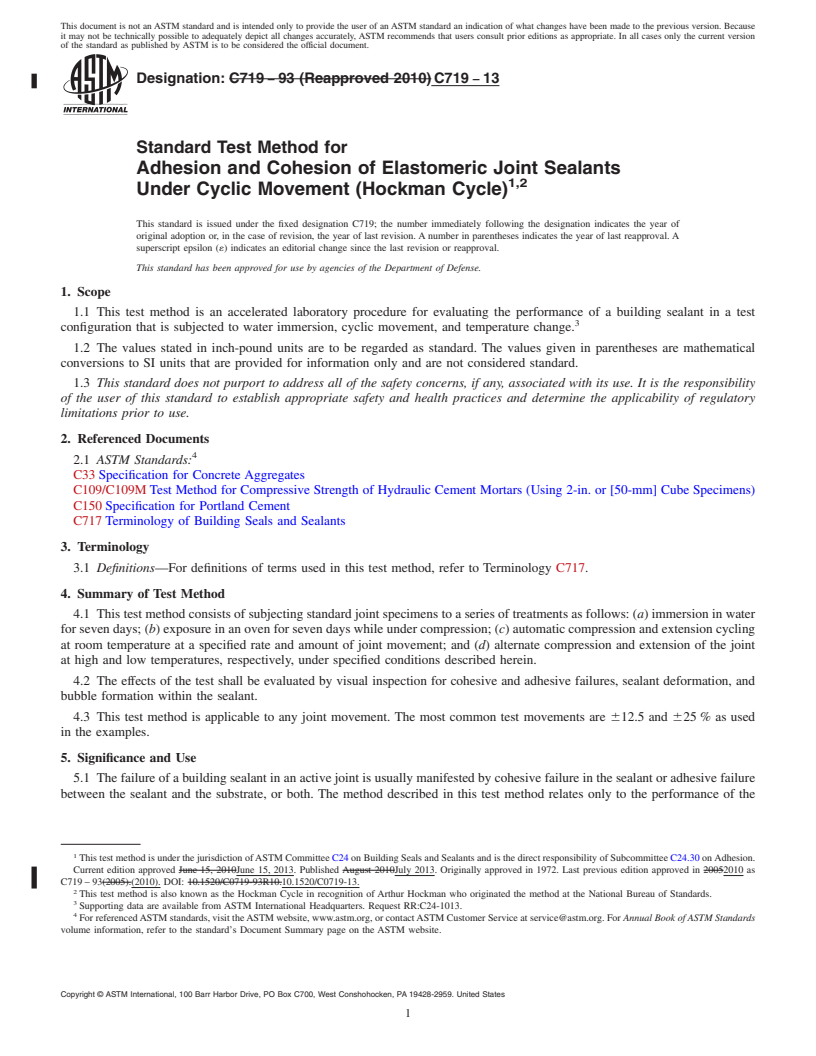

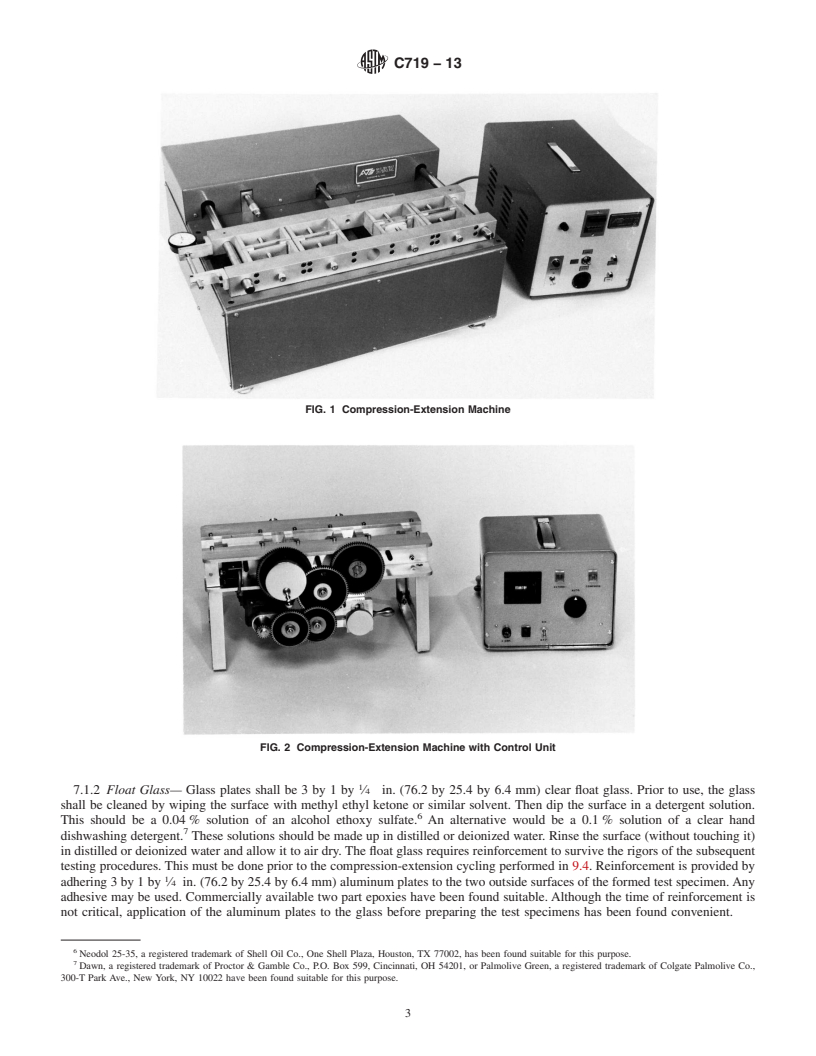

6.1 Compression-Extension Machine, designed to automatically compress the joint width of the test specimen from ⁄20.500 in.

1

(12.7 mm) to the minimum dimension desired (Table 1, Column C) and extend the specimen from ⁄20.500 in. to the maximum

1

extension desired (Table 1, Column E) at a constant rate of ⁄8 in./h (3.2 mm/h). The machine shall be equipped with grips of

sufficient

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.