ASTM F1760-01(2005)e1

(Specification)Standard Specification for Coextruded Poly(Vinyl Chloride) (PVC) Non-Pressure Plastic Pipe Having Reprocessed-Recycled Content

Standard Specification for Coextruded Poly(Vinyl Chloride) (PVC) Non-Pressure Plastic Pipe Having Reprocessed-Recycled Content

ABSTRACT

This specification has been published in response to the special circumstance of regulatory requirements regarding federal procurement guidelines for plastic pipe having recycled content. This specification covers coextruded Poly(Vinyl Chloride) (PVC) plastic pipe with a center layer and concentric inner and outer solid layers. The pipe is produced using a multi-layer coextrusion die. The inner and outer layers are made of virgin PVC compound and the center layer has reprocessed-recycled PVC content. The pipe is for nonpressure use in three series: Sewer-Drain series; IPS Schedule 40 series; and IPS Pipe Stiffness (PS) series. Quality control test requirement: nondestructive testing; impact resistance; bond integrity; flattening integrity; pipe stiffness; joint integrity, solvent-cement joints; and joint integrity, elastomeric-gasket joints shall be performed to conform with the specified requirements.

SCOPE

1.1 This specification has been published in response to the special circumstance of regulatory requirements regarding federal procurement guidelines for plastic pipe having recycled content.

1.2 This specification covers coextruded Poly(Vinyl Chloride) (PVC) plastic pipe with a center layer and concentric inner and outer solid layers. The pipe is produced using a multi-layer coextrusion die. The inner and outer layers are made of virgin PVC compound and the center layer has reprocessed-recycled PVC content. The pipe is for non-pressure use in three series:

1.2.1 Sewer-Drain series with a sewer-pipe outside diameter and a pipe stiffness of 46 psi (320 kPa),

1.2.2 IPS Schedule 40 series, and

1.2.3 IPS Pipe Stiffness (PS) series with pipe stiffnesses of 100 psi (690 kPa) and 120 psi (830 kPa).

1.3 Pipe that is outside-diameter controlled does not necessarily have an inside diameter suitable for use as a fitting socket.

1.4 All series may be perforated.

1.5 The values stated in inch-pound units are to be regarded as the standard. The SI values are provided for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

´1

Designation: F1760 – 01 (Reapproved 2005)

Standard Specification for

Coextruded Poly(Vinyl Chloride) (PVC) Non-Pressure Plastic

Pipe Having Reprocessed-Recycled Content

This standard is issued under the fixed designation F1760; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—Sections 5 and 12 were editorially updated in November 2005.

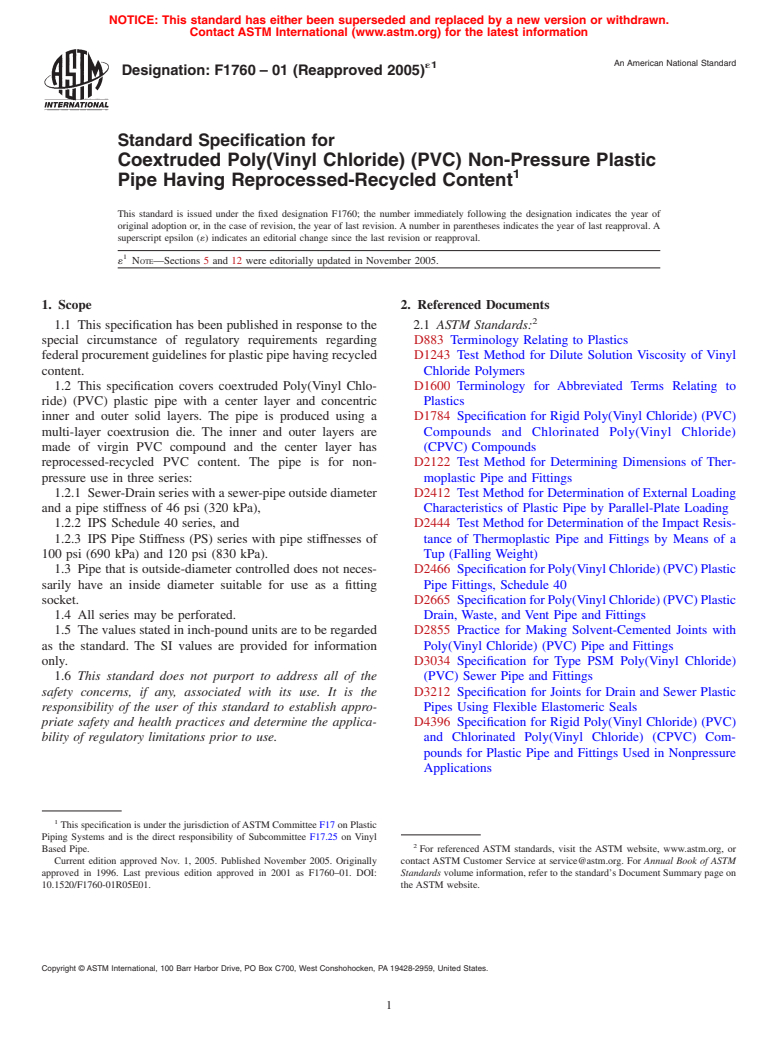

1. Scope 2. Referenced Documents

1.1 This specification has been published in response to the 2.1 ASTM Standards:

special circumstance of regulatory requirements regarding D883 Terminology Relating to Plastics

federalprocurementguidelinesforplasticpipehavingrecycled D1243 Test Method for Dilute Solution Viscosity of Vinyl

content. Chloride Polymers

1.2 This specification covers coextruded Poly(Vinyl Chlo- D1600 Terminology for Abbreviated Terms Relating to

ride) (PVC) plastic pipe with a center layer and concentric Plastics

inner and outer solid layers. The pipe is produced using a D1784 Specification for Rigid Poly(Vinyl Chloride) (PVC)

multi-layer coextrusion die. The inner and outer layers are Compounds and Chlorinated Poly(Vinyl Chloride)

made of virgin PVC compound and the center layer has (CPVC) Compounds

reprocessed-recycled PVC content. The pipe is for non- D2122 Test Method for Determining Dimensions of Ther-

pressure use in three series: moplastic Pipe and Fittings

1.2.1 Sewer-Drainserieswithasewer-pipeoutsidediameter D2412 Test Method for Determination of External Loading

and a pipe stiffness of 46 psi (320 kPa), Characteristics of Plastic Pipe by Parallel-Plate Loading

1.2.2 IPS Schedule 40 series, and D2444 Test Method for Determination of the Impact Resis-

1.2.3 IPS Pipe Stiffness (PS) series with pipe stiffnesses of tance of Thermoplastic Pipe and Fittings by Means of a

100 psi (690 kPa) and 120 psi (830 kPa). Tup (Falling Weight)

1.3 Pipe that is outside-diameter controlled does not neces- D2466 SpecificationforPoly(VinylChloride)(PVC)Plastic

sarily have an inside diameter suitable for use as a fitting Pipe Fittings, Schedule 40

socket. D2665 SpecificationforPoly(VinylChloride)(PVC)Plastic

1.4 All series may be perforated. Drain, Waste, and Vent Pipe and Fittings

1.5 The values stated in inch-pound units are to be regarded D2855 Practice for Making Solvent-Cemented Joints with

as the standard. The SI values are provided for information Poly(Vinyl Chloride) (PVC) Pipe and Fittings

only. D3034 Specification for Type PSM Poly(Vinyl Chloride)

1.6 This standard does not purport to address all of the (PVC) Sewer Pipe and Fittings

safety concerns, if any, associated with its use. It is the D3212 Specification for Joints for Drain and Sewer Plastic

responsibility of the user of this standard to establish appro- Pipes Using Flexible Elastomeric Seals

priate safety and health practices and determine the applica- D4396 Specification for Rigid Poly(Vinyl Chloride) (PVC)

bility of regulatory limitations prior to use. and Chlorinated Poly(Vinyl Chloride) (CPVC) Com-

pounds for Plastic Pipe and Fittings Used in Nonpressure

Applications

This specification is under the jurisdiction ofASTM Committee F17 on Plastic

Piping Systems and is the direct responsibility of Subcommittee F17.25 on Vinyl

Based Pipe. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Nov. 1, 2005. Published November 2005. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1996. Last previous edition approved in 2001 as F1760–01. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/F1760-01R05E01. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

´1

F1760 – 01 (2005)

F412 Terminology Relating to Plastic Piping Systems 4.1.1 Sewer-Drain Series—Produced with a sewer pipe OD

F477 SpecificationforElastomericSeals(Gaskets)forJoin- and a pipe stiffness of 46 psi (320 kPa). Sewer-drain pipe is

ing Plastic Pipe intended for use outside of buildings as sewer, sewer connec-

F512 Specification for Smooth-Wall Poly(Vinyl Chloride) tions, underground drain, and storm drain. Wall thicknesses

(PVC) Conduit and Fittings for Underground Installation shallbeproducedsothatminimumpipestiffnessesaremet,but

F1336 Specification for Poly(Vinyl Chloride) (PVC) Gas- shall not be thinner than the minimum wall thickness require-

keted Sewer Fittings ments in Table 1 and Table 2.

F1365 Test Method for Water Infiltration Resistance of

NOTE 1—Base inside diameters will be slightly smaller than those

Plastic Underground Conduit Joints Which Use Flexible

calculated for SDR 35 sewer-drain series pipe when wall thicknesses are

Elastomeric Seals

increased to ensure minimum 46 pipe stiffness.

2.2 Plastic Pipe Institute Technical Report:

4.1.2 IPS Diameter Family—Produced in a Schedule 40

PPI-TR-7 Recommended Method for Calculation of Nomi-

series and a Pipe Stiffness (PS) series.

nal Weight of Plastic Pipe

4.1.2.1 IPS Schedule 40 Series—Produced to Schedule 40

wall thicknesses in accordance with Table 3 and Table 4.

3. Terminology

Schedule 40 pipe is intended for use as underground drain,

3.1 Definitions—Definitions are in accordance with Termi-

DWV (drain, waste, and vent), sewer connections, and other

nologies D883, D1600, and F412, unless otherwise indicated.

non-pressure uses.

3.1.1 coextrusion—a process whereby two or more plastic

4.1.2.2 IPS Pipe Stiffness Series—Produced to pipe stiffness

material streams are forced through one or more shaping

of 100 psi (690 kPa) or 120 psi (830 kPa). Intended uses

orifices and become one continuously formed piece.

include underground communications and electrical distribu-

3.2 Definitions of Terms Specific to This Standard:

tion. Wall thicknesses shall be produced so that minimum pipe

3.2.1 center-layer compound—general description for “in-

stiffnesses are met, but shall not be thinner than the minimum

ternal recycled material” (3.2.5), “external recycled material”

wall thickness requirements in Table 5 and Table 6.

(3.2.4), and “post-consumer recycled material” (3.2.6). These

NOTE 2—The IPS Pipe Stiffness (PS) series having pipe stiffnesses of

materials can be used straight or blended with virgin materials

100psi(690kPa)and120psi(830kPa)isdesignedfordirectburial(DB).

to make a compound, in accordance with this specification.

Encasement in concrete is not necessary.

3.2.2 certificate of composition—a certificate describing

4.1.3 Before installing pipe for industrial waste disposal

certain properties of an external recycled material or a post-

use, the approval of the code official having jurisdiction should

consumer recycled material.

be obtained, as conditions not commonly found in normal use

3.2.2.1 Discussion—Examples include polymer, molecular

may be encountered.

weight, percentage of inorganic material, contamination type

and level, tensile strength, modulus of elasticity, and izod

5. Material

impact.

3.2.3 composition disclosure—a document describing the

5.1 Center-layer Compounds—Center-layer compounds

formulation of an external recycled material.

(internal recycled, external recycled, and post-consumer re-

3.2.4 external recycled material—industrial rework gener-

cycled materials) shall be characterized as being PVC-

ated by a different company from the company manufacturing

polymer-based. Other PVC-compatible additives (such as lu-

to this specification. Composition is known by the industrial

bricants, stabilizers, non-polyvinyl-chloride resin modifiers,

source of the material.

pigments, and inorganic fillers) may be present in these

3.2.5 internal recycled material—rework generated by the

materials. The three plastic material types may be used in the

same company’s production that is manufacturing to this

percentages specified in 5.1.1, 5.1.2, and 5.1.3, provided that

specification. Composition of the material is known by the

the pipe produced meets all of the requirements of this

company manufacturing to this specification.

specification.

3.2.6 post-consumer recycled material—finished goods that

5.1.1 Internal Recycled Material—May comprise up to

have been purchased by the public, then returned to industry

100 % of the center layer.This material shall not be used in the

and reprocessed into raw materials. Identity of finished goods

inner or outer layers.

is known by the reprocessing company.

3.2.7 thermoplastic coextruded pipe—pipe consisting of

two or more concentric thermoplastic layers formed through

TABLE 1 Requirements for Sewer-Drain Pipe

the process of coextrusion.

Impact

Nominal Average, Tolerance on Minimum Wall

Resistance,

A

Size, in. OD, in. Average, in. Thickness, in.

ft-lb

4. Classification

4 4.215 60.009 0.120 150

4.1 The pipes are produced in two diameter families:

6 6.275 60.011 0.180 210

sewer-drain and IPS.

8 8.400 60.012 0.240 210

10 10.500 60.015 0.300 220

12 12.500 60.018 0.360 220

15 15.300 60.023 0.437 220

A

Available from Plastic Pipe Institute, 1275 K Street NW, Suite 400, Washing-

Themaximumwallthicknessshallnotbegreaterthan1.25timestheminimum

ton, DC 20005. wall thickness.

´1

F1760 – 01 (2005)

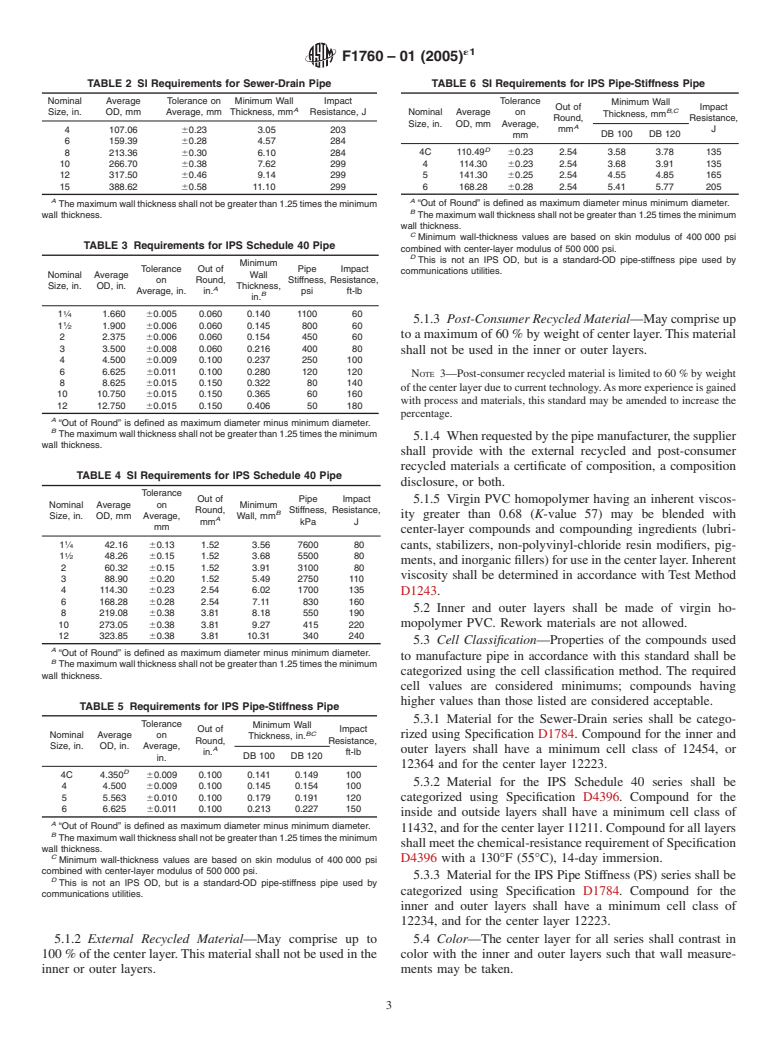

TABLE 2 SI Requirements for Sewer-Drain Pipe TABLE 6 SI Requirements for IPS Pipe-Stiffness Pipe

Nominal Average Tolerance on Minimum Wall Impact Tolerance

Minimum Wall

Out of Impact

A

B,C

Size, in. OD, mm Average, mm Thickness, mm Resistance, J Nominal Average on

Thickness, mm

Round, Resistance,

Size, in. OD, mm Average,

A

4 107.06 60.23 3.05 203 mm J

DB 100 DB 120

mm

6 159.39 60.28 4.57 284

D

8 213.36 60.30 6.10 284 4C 110.49 60.23 2.54 3.58 3.78 135

10 266.70 60.38 7.62 299 4 114.30 60.23 2.54 3.68 3.91 135

5 141.30 60.25 2.54 4.55 4.85 165

12 317.50 60.46 9.14 299

15 388.62 60.58 11.10 299 6 168.28 60.28 2.54 5.41 5.77 205

A A

Themaximumwallthicknessshallnotbegreaterthan1.25timestheminimum “Out of Round” is defined as maximum diameter minus minimum diameter.

B

wall thickness. Themaximumwallthicknessshallnotbegreaterthan1.25timestheminimum

wall thickness.

C

Minimum wall-thickness values are based on skin modulus of 400 000 psi

TABLE 3 Requirements for IPS Schedule 40 Pipe

combined with center-layer modulus of 500 000 psi.

D

This is not an IPS OD, but is a standard-OD pipe-stiffness pipe used by

Minimum

Tolerance Out of Pipe Impact

communications utilities.

Nominal Average Wall

on Round, Stiffness, Resistance,

Size, in. OD, in. Thickness,

A

Average, in. in. psi ft-lb

B

in.

1 ⁄4 1.660 60.005 0.060 0.140 1100 60

5.1.3 Post-Consumer Recycled Material—Maycompriseup

1 ⁄2 1.900 60.006 0.060 0.145 800 60

to a maximum of 60 % by weight of center layer.This material

2 2.375 60.006 0.060 0.154 450 60

3 3.500 60.008 0.060 0.216 400 80

shall not be used in the inner or outer layers.

4 4.500 60.009 0.100 0.237 250 100

6 6.625 60.011 0.100 0.280 120 120

NOTE 3—Post-consumer recycled material is limited to 60 % by weight

8 8.625 60.015 0.150 0.322 80 140

ofthecenterlayerduetocurrenttechnology.Asmoreexperienceisgained

10 10.750 60.015 0.150 0.365 60 160

with process and materials, this standard may be amended to increase the

12 12.750 60.015 0.150 0.406 50 180

percentage.

A

“Out of Round” is defined as maximum diameter minus minimum diameter.

B

Themaximumwallthicknessshallnotbegreaterthan1.25timestheminimum

5.1.4 Whenrequestedbythepipemanufacturer,thesupplier

wall thickness.

shall provide with the external recycled and post-consumer

recycled materials a certificate of composition, a composition

TABLE 4 SI Requirements for IPS Schedule 40 Pipe

disclosure, or both.

Tolerance

Out of Pipe Impact 5.1.5 Virgin PVC homopolymer having an inherent viscos-

Nominal Average on Minimum

Round, Stiffness, Resistance,

B

Size, in. OD, mm Average, Wall, mm ity greater than 0.68 (K-value 57) may be blended with

A

mm kPa J

mm

center-layer compounds and compounding ingredients (lubri-

1 ⁄4 42.16 60.13 1.52 3.56 7600 80

cants, stabilizers, non-polyvinyl-chloride resin modifiers, pig-

1 ⁄2 48.26 60.15 1.52 3.68 5500 80

ments,andinorganicfillers)foruseinthecenterlayer.Inherent

2 60.32 60.15 1.52 3.91 3100 80

viscosity shall be determined in accordance with Test Method

3 88.90 60.20 1.52 5.49 2750 110

4 114.30 60.23 2.54 6.02 1700 135

D1243.

6 168.28 60.28 2.54 7.11 830 160

5.2 Inner and outer layers shall be made of virgin ho-

8 219.08 60.38 3.81 8.18 550 190

mopolymer PVC. Rework materials are not allowed.

10 273.05 60.38 3.81 9.27 415 220

12 323.85 60.38 3.81 10.31 340 240

5.3 Cell Classification—Properties of the compounds used

A

“Out of Round” is defined as maximum diameter minus minimum diameter.

to manufacture pipe in accordance with this standard shall be

B

Themaximumwallthicknessshallnotbegreaterthan1.25timestheminimum

categorized using the cell classification method. The required

wall thickness.

cell values are considered minimums; compounds having

higher values than those listed are considered acceptable.

TABLE 5 Requirements for IPS Pipe-Stiffness Pipe

5.3.1 Material for the Sewer-Drain series shall be catego-

Tolerance

Minimum Wall

Out of Impact

BC

rized using Specification D1784. Compound for the inner and

Nominal Average on

Thickness, in.

Round, Resistance,

Size, in. OD, in. Average,

A

outer layers shall have a minimum cell class of 12454, or

in. ft-lb

DB 100 DB 120

in.

12364 and for the center layer 12223.

D

4C 4.350 60.009 0.100 0.141 0.149 100

5.3.2 Material for the IPS Schedule 40 series shall be

4 4.500 60.009 0.100 0.145 0.154 100

5 5.563 60.010 0.100 0.179 0.191 120 categorized using Specification D4396. Compound for the

6 6.625 60.011 0.100 0.213 0.227 150

inside and outside layers shall have a minimum cell class of

A

“Out of Round” is defined as maximum diameter minus minimum diameter.

11432, and for the center layer 11211. Compound for all layers

B

Themaximumwallthicknessshallnotbegreaterthan1.25timestheminimum

shallmeetthechemical-resistancerequirementofSpecification

wall thickness.

C

D4396 with a 130°F (55°C), 14-day immersion.

Minimum wall-thickness values are based on skin modulus of 400 000 psi

combined with center-layer modulus of 500 000 psi.

5.3.3 Material for the IPS Pipe Stiffness (PS) series shall be

D

This is not an IPS OD, but is a standard-OD pipe-stiffness pipe used by

categorized using Specification D1784. Compound for the

communications utilities.

inner and outer layers shall have a minimum cell class of

12234, and for the center layer 12223.

5.1.2 External Recycled Material—May comprise up to 5.4 Color—The center layer fo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.