ASTM D8380-21

(Test Method)Standard Test Method for Dry Abrasion Resistance of Hydrophobic and Omniphobic Coatings

Standard Test Method for Dry Abrasion Resistance of Hydrophobic and Omniphobic Coatings

SIGNIFICANCE AND USE

5.1 The test method is to be used to determine the abrasion resistance or mechanical durability of thin omniphobic or thin hydrophobic coatings. These coatings are often used to enhance the surface’s value by promoting fingerprint resistance, water removal, stain resistance, and easy-clean properties. A comparison of the contact angle and the depreciation of that contact angle due to exposure to mechanical abrasion determines the coating’s ability to remain effective after exposure to environmental abrasion.

5.1.1 The test method is used to appraise the removal of thin films when gravimetric measurements will not yield a detectable change in film mass due to the small amount of material comprising these films, which are on the order of nanometers thick.

5.1.2 Only fully cured specimens are evaluated unless otherwise specified and agreed upon by the interested parties.

5.2 Different coating materials may be evaluated for relative durability by evaluating abrasion cycles versus water contact angle using this method.

5.3 Different curing or conditioning methods may be evaluated by preparing test specimens with the same coating and then evaluating abrasion resistance using this method.

SCOPE

1.1 This test method describes a procedure for evaluating dry abrasion resistance of a thin hydrophobic or omniphobic coating, or both. The coating is typically less than 100 nm thick and is applied to a planar, glass substrate by application methods including, but not limited to, physical vapor deposition (PVD), dip, or spray.

1.2 Units—The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard with the exception of angular measurement which are reported in degrees.

Note 1: This test method measures a static contact angle and is not equivalent to Test Method C813 which measures an advancing contact angle.

Note 2: Test Method D4060 is not applicable to hydrophobic and omniphobic coatings because the molecular monolayer does not generally result in a detectable weight change to the specimen after subjecting it to abrasion.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D8380 − 21

Standard Test Method for

Dry Abrasion Resistance of Hydrophobic and Omniphobic

1

Coatings

This standard is issued under the fixed designation D8380; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D16TerminologyforPaint,RelatedCoatings,Materials,and

Applications

1.1 This test method describes a procedure for evaluating

D1193Specification for Reagent Water

dry abrasion resistance of a thin hydrophobic or omniphobic

D4060Test Method for Abrasion Resistance of Organic

coating,orboth.Thecoatingistypicallylessthan100nmthick

Coatings by the Taber Abraser

and is applied to a planar, glass substrate by application

D5946Test Method for Corona-Treated Polymer Films Us-

methods including, but not limited to, physical vapor deposi-

ing Water Contact Angle Measurements

tion (PVD), dip, or spray.

D7490TestMethodforMeasurementoftheSurfaceTension

1.2 Units—The values stated in SI units are to be regarded

of Solid Coatings, Substrates and Pigments using Contact

asstandard.Nootherunitsofmeasurementareincludedinthis

Angle Measurements

standard with the exception of angular measurement which are

E177Practice for Use of the Terms Precision and Bias in

reported in degrees.

ASTM Test Methods

E691Practice for Conducting an Interlaboratory Study to

NOTE 1—This test method measures a static contact angle and is not

equivalent to Test Method C813 which measures an advancing contact Determine the Precision of a Test Method

angle.

NOTE 2—Test Method D4060 is not applicable to hydrophobic and 3. Terminology

omniphobiccoatingsbecausethemolecularmonolayerdoesnotgenerally

3.1 Definitions—Definitions used in this test method are in

result in a detectable weight change to the specimen after subjecting it to

accordance withTerminology D16, unless otherwise specified.

abrasion.

1.3 This standard does not purport to address all of the 3.2 Definitions of Terms Specific to This Standard:

safety concerns, if any, associated with its use. It is the 3.2.1 abrasion cycle, n—in abrasion testing, one or more

responsibility of the user of this standard to establish appro- movements of the abradant across a material surface, or the

priate safety, health, and environmental practices and deter- materialsurfaceacrosstheabradant,thatpermitsareturntoits

mine the applicability of regulatory limitations prior to use.

starting position; for this test method, one abrasion cycle is a

1.4 This international standard was developed in accor- complete back and forth motion.

dance with internationally recognized principles on standard-

3.2.2 static contact angle, Ө (degrees), n—the angle be-

ization established in the Decision on Principles for the

tween the substrate surface and the tangent line drawn to the

Development of International Standards, Guides and Recom-

droplet surface at the three-phase point, when a liquid drop is

mendations issued by the World Trade Organization Technical

resting on a plane solid surface (see Fig. 1).

Barriers to Trade (TBT) Committee.

4. Summary of Test Method

2. Referenced Documents

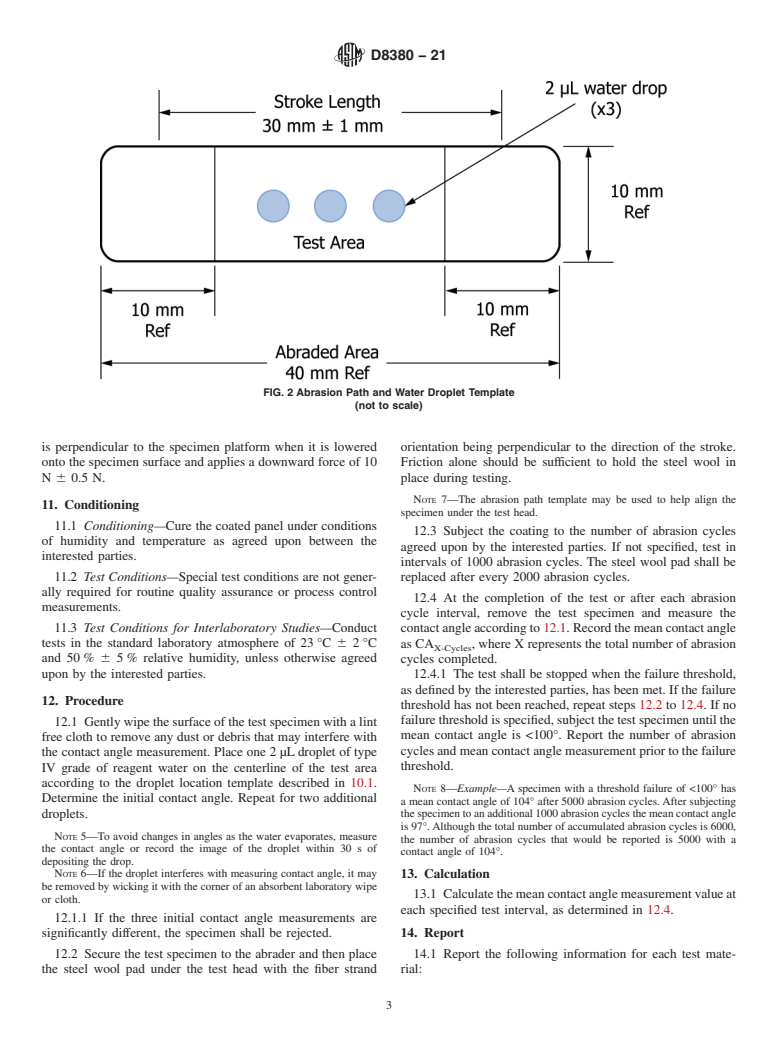

4.1 The coating is applied in a uniform thickness to planar

2

2.1 ASTM Standards:

glass panels and, after curing, the surface is abraded using a

C813TestMethodforHydrophobicContaminationonGlass

reciprocating rubbing action under controlled conditions of

by Contact Angle Measurement

pressure and abrasive action. Droplets of type IV grade of

reagent water are placed on the surface of the specimen, and

1 the contact angle values are measured and then averaged. The

This test method is under the jurisdiction of ASTM Committee D01 on Paint

and Related Coatings, Materials, andApplications and is the direct responsibility of

test specimen is subjected to abrasion in the same location,

Subcommittee D01.23 on Physical Properties of Applied Paint Films.

until the failure threshold has been reached. Abrasion resis-

Current edition approved Jan. 1, 2021. Published February 2021. DOI: 10.1520/

tance is assessed by measuring the water contact angle within

D8380-21.

2

theabradedareaofthetestspecimenandreportingthenumber

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

of abrasion cycles.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. NOTE 3—Aglass substrate was selected because the abradant will wear

Copyright © ASTM International, 100 Barr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.