ASTM D1498-93

(Practice)Standard Practice for Oxidation-Reduction Potential of Water

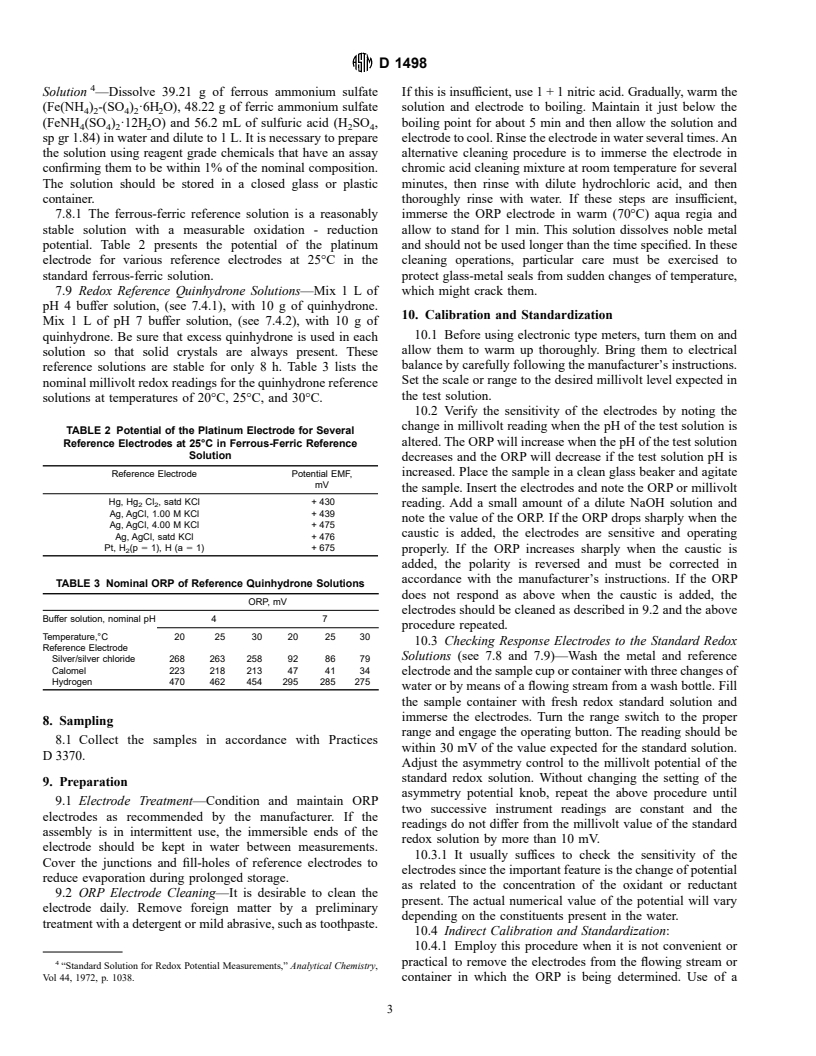

Standard Practice for Oxidation-Reduction Potential of Water

SCOPE

1.1 This practice covers the apparatus and procedure for the electrometric measurement of oxidation-reduction potential (ORP) in water. It does not deal with the manner in which the solutions are prepared, the theoretical interpretation of the oxidation-reduction potential, or the establishment of a standard oxidation-reduction potential for any given system. The practice described has been designed for the routine and process measurement of oxidation-reduction potential.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or

withdrawn. Contact ASTM International (www.astm.org) for the latest information.

Designation: D 1498 – 93

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Practice for

1

Oxidation-Reduction Potential of Water

This standard is issued under the fixed designation D 1498; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

n 5 number of electrons involved in process

reaction, and

1.1 This practice covers the apparatus and procedure for the

A and A 5 activities of the reactants in the process.

ox red

electrometric measurement of oxidation-reduction potential

3.2 For definitions of other items used in this practice, refer

(ORP) in water. It does not deal with the manner in which the

to Terminology D 1129.

solutions are prepared, the theoretical interpretation of the

oxidation-reduction potential, or the establishment of a stan-

4. Summary of Practices

dard oxidation-reduction potential for any given system. The

4.1 This is a practice designed to measure the ORP which is

practice described has been designed for the routine and

defined as the electromotive force between a noble metal

process measurement of oxidation-reduction potential.

electrode and a reference electrode when immersed in a

1.2 This standard does not purport to address all of the

solution. The practice describes the electronic equipment

safety problems, if any, associated with its use. It is the

available to make the measurement and describes how to

responsibility of the user of this standard to establish appro-

determine the sensitivity of the electrodes as well as the

priate safety and health practices and determine the applica-

calibration of equipment to solutions having a known potential.

bility of regulatory limitations prior to use.

The ORP electrodes are inert and measure the ratio of the

activities of the oxidized to the reduced species in the process

2. Referenced Documents

reactions.

2.1 ASTM Standards:

2

5. Interferences

D 1129 Terminology Relating to Water

2

D 1193 Specification for Reagent Water

5.1 The ORP electrodes reliably measured ORP in nearly all

D 3370 Practices for Sampling Water from Closed Con-

aqueous solutions and in general are not subject to solution

2

duits

interference from color, turbidity, colloidal matter, and

suspended matter.

3. Terminology

5.2 The ORP of an aqueous solution is sensitive to change

in temperature of the solution, but temperature correction is

3.1 Definitions of Terms Specific to This Standard:

rarely done due to its minimal effect and complex reactions.

3.1.1 oxidation-reduction potential—the electromotive

Temperature corrections are usually applied only when it is

force, Em, developed between a noble metal electrode and a

desired to relate the ORP to the activity of an ion in the

standard reference electrode. This oxidation-reduction poten-

solutions.

tial (ORP) is related to the solution composition by:

5.3 The ORP of an aqueous solution is almost always

RT

o

sensitive to pH variations even to reactions that do not appear

E 5 E 1 2.3 log A / A

m ox red

nF

to involve hydrogen or hydroxyl ions. The ORP generally tends

to increase with an increase in hydrogen ions and to decrease

where:

with an increase in hydroxyl ions during such reactions.

E 5 ORP,

m

o

5.4 Reproducible oxidation-reduction potentials cannot be

E 5 constant that depends on the choice of

obtained for chemical systems that are not reversible. Most

reference electrodes.

natural and ground waters do not contain reversible systems, or

F 5 Faraday constant,

R 5 gas constant, may contain systems that are shifted by the presence of air. The

T 5 absolute temperature, °C + 273.15,

measurement of end point potential in oxidation-reduction

titration is sometimes of this type.

5.5 If the metallic portion of the ORP electrode is sponge-

1

This practice is under the jurisdiction of ASTM Committee D-19 on Water and like, materials absorbed from solutions may not be washed

is the direct responsibility of Subcommittee D19.11 on Water for Power Generation

away, even by repeated rinsings. In such cases, the electrode

and Process Use.

may exhibit a memory effect, particularly if it is desired to

Current edition approved Sept. 15, 1993. Published December 1993. Originally

2

detect a relatively low concentration of a particular species

published as D 1498 – 57 T. Last previous edition D 1498 – 76 (1981)e .

2

Annual Book of ASTM Standards, Vol 11.01. immediately after a measurement has been made in a relatively

1

---------------------- Page: 1 ----------------------

D 1498

concentrated solution. A bright

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.