ASTM F2262-04

(Specification)Standard Specification for Crosslinked Polyethylene/Aluminum/Crosslinked Polyethylene Tubing OD Controlled SDR9

Standard Specification for Crosslinked Polyethylene/Aluminum/Crosslinked Polyethylene Tubing OD Controlled SDR9

SCOPE

1.1 This specification covers establishes requirements for coextruded crosslinked polyethylene multi-layer pressure tubing with a continuously welded aluminum tube construction between inner and outer layers of plastic. The inner and outer crosslinked polyethylene layers are bonded to the aluminum by a melt adhesive. The tubing is outside diameter controlled and made in one standard dimension ratio, SDR9 and is intended to be used for hot and cold water conveyance in applications up to 180F (82.2C). Included in this specification is a system of nomenclature for crosslinked polyethylene-aluminum-crosslinked polyethylene (PEX-AL-PEX) tubes, and the requirements and test methods for materials, dimensions of component layers and the finished tubing, layer adhesion test, weld strength, short-term burst pressure, long-term sustained pressure and marking requirements. The tubing covered by this specification is intended for use in potable water distribution systems for residential and commercial applications, water service, hydronic radiant heating (HRH), radiant panel heating, baseboard, and snow melt systems.

1.2 This specification covers only plastic-metal-plastic multi-layer tubes incorporating a continuous welded aluminum tube. Tubing consisting of metallic layers not welded together is outside the scope of this specification.

1.3 Units—The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are mathematical conversions to SI units which are provided for information only and are not considered standard.

1.4 Specifications for connectors for use with pipe meeting the requirements of this specification are given in .

1.5 The following precautionary caveat pertains only to the test method portion, Section 9, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: F 2262 – 04

Standard Specification for

Crosslinked Polyethylene/Aluminum/Crosslinked

1

Polyethylene Tubing OD Controlled SDR9

This standard is issued under the fixed designation F 2262; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

1.1 This specification covers establishes requirements for 2.1 ASTM Standards:

coextruded crosslinked polyethylene multi-layer pressure tub- D 618 Practice for Conditioning Plastics and Electrical

ing with a continuously welded aluminum tube construction Insulating Materials for Testing

between inner and outer layers of plastic. The inner and outer D 883 Terminology Relating to Plastics

crosslinkedpolyethylenelayersarebondedtothealuminumby D 1598 Test Method for Time-To-Failure of Plastic Pipe

a melt adhesive. The tubing is outside diameter controlled and Under Constant Internal Pressure

made in one standard dimension ratio, SDR9 and is intended to D 1599 Test Method for Short-Time, Hydraulic Failure

be used for hot and cold water conveyance in applications up Pressure of Plastic Pipe, Tubing, and Fittings

to 180°F (82.2°C). Included in this specification is a system of D 1600 Terminology for Abbreviated Terms Relating to

nomenclature for crosslinked polyethylene-aluminum- Plastics

crosslinked polyethylene (PEX-AL-PEX) tubes, and the re- D 2122 Test Method for Determining Dimensions of Ther-

quirements and test methods for materials, dimensions of moplastic Pipe and Fittings

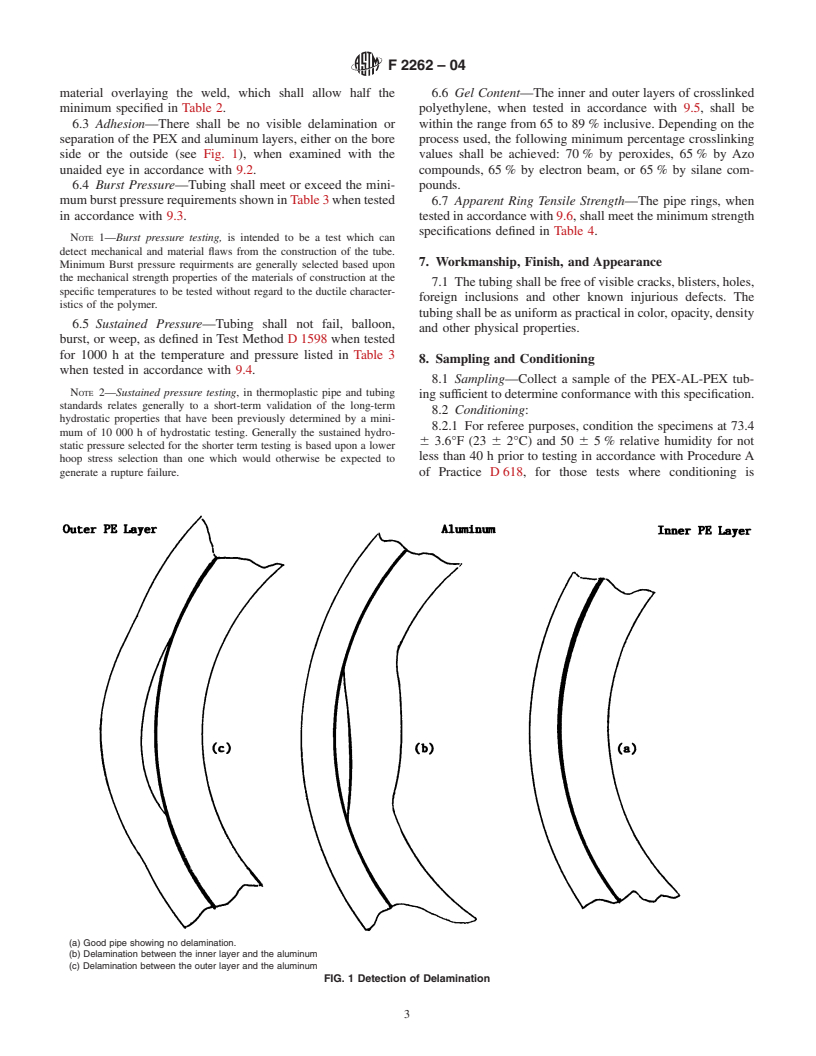

component layers and the finished tubing, layer adhesion test, D 2765 Test Methods for Determination of Gel Content and

weld strength, short-term burst pressure, long-term sustained Swell Ratio of Crosslinked Ethylene Plastics

pressure and marking requirements.The tubing covered by this D 3350 Specification for Polyethylene Plastics Pipe and

specification is intended for use in potable water distribution Fittings Materials

systems for residential and commercial applications, water F 412 Terminology Relating to Plastic Piping Systems

service, hydronic radiant heating (HRH), radiant panel heating, 2.2 NSF International Standards:

baseboard, and snow melt systems. NSF/ANSI 14 for Plastic Piping Components and Related

3

1.2 This specification covers only plastic-metal-plastic Materials

multi-layer tubes incorporating a continuous welded aluminum NSF/ANSI 61 for Drinking Water System Components-

3

tube. Tubing consisting of metallic layers not welded together Health Effects

is outside the scope of this specification. 2.3 Federal Standard:

4

1.3 Units—The values stated in inch-pound units are to be Fed. Std. No. 123 Marking for Shipments (CivilAgencies)

regarded as the standard. The values given in parentheses are 2.4 Military Standard:

4

mathematical conversions to SI units which are provided for MIL-STD-129 Marking for Shipment and Storage

information only and are not considered standard. 2.5 Uniform Classification and Committee Standard:

5

1.4 Specifications for connectors for use with pipe meeting Uniform Freight Classification

the requirements of this specification are given in Annex A1. 2.6 National Motor Freight Traffıc Association Standard:

6

1.5 The following precautionary caveat pertains only to the National Motor Freight Classification

test method portion, Section 9, of this specification. This

standard does not purport to address all of the safety concerns,

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

if any, associated with its use. It is the responsibility of the user

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

of this standard to establish appropriate safety and health

Standards volume information, refer to the standard’s Document Summary page on

practices and determine the applicability of regulatory require-

the ASTM website.

3

ments prior to use.

Available from the NSF International, 789 Dixboro Rd.,AnnArbor, MI 48105.

4

AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

1 5

This specification is under the jurisdiction ofASTM Committee F17 on Plastic Available from the Uniform Classification Committee, Suite 1106, 222 South

Piping Systems and is the direct responsibility of Subcommittee F17.11 on Riverside Plaza, Chicago, IL 60606.

6

Composites. Available from the National Motor Freight Traffic Association, Inc., National

Current edition approved Dec. 1, 2004. Published December 2004. Originally Motor Freight Classification, American Tracking Associations, Inc., Traffic Dept.,

approved in 2003. Las

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.