ASTM D7127-05

(Test Method)Standard Test Method for Measurement of Surface Roughness of Abrasive Blast Cleaned Metal Surfaces Using a Portable Stylus Instrument

Standard Test Method for Measurement of Surface Roughness of Abrasive Blast Cleaned Metal Surfaces Using a Portable Stylus Instrument

SIGNIFICANCE AND USE

This method may be useful in assuring conformance of a prepared surface to profile requirements specified by the manufacturer of a protective coating.

This method includes determination of the peak density (number of profile peaks in a specified distance). Some workers in the field believe that optimizing peak height and peak density can improve coating adhesion.

This method allows specifiers to objectively define surface texture after abrasive blast cleaning rather than using subjective terms such as “angular pattern” or “dense and uniform pattern.”

SCOPE

1.1 This test method describes a shop or field procedure for determination of four roughness characteristics of surfaces prepared for painting by abrasive blasting. The procedure uses a portable skidded or non-skidded stylus profile tracing instrument. The three measured characteristics are: Rt, Rmax, and Pc.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 In general, this method should be limited to the measurement of surface roughness where Rmax is in the range 10 to 150 m (0.4 to 6 mil) and where the Peak Count, Pc, is less than 180 peaks/cm (450 peaks/in.).

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7127 − 05

StandardTest Method for

Measurement of Surface Roughness of Abrasive Blast

Cleaned Metal Surfaces Using a Portable Stylus Instrument

This standard is issued under the fixed designation D7127; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope surface roughness and instrument parameters below are con-

tained in the referenced standards.

1.1 This test method describes a shop or field procedure for

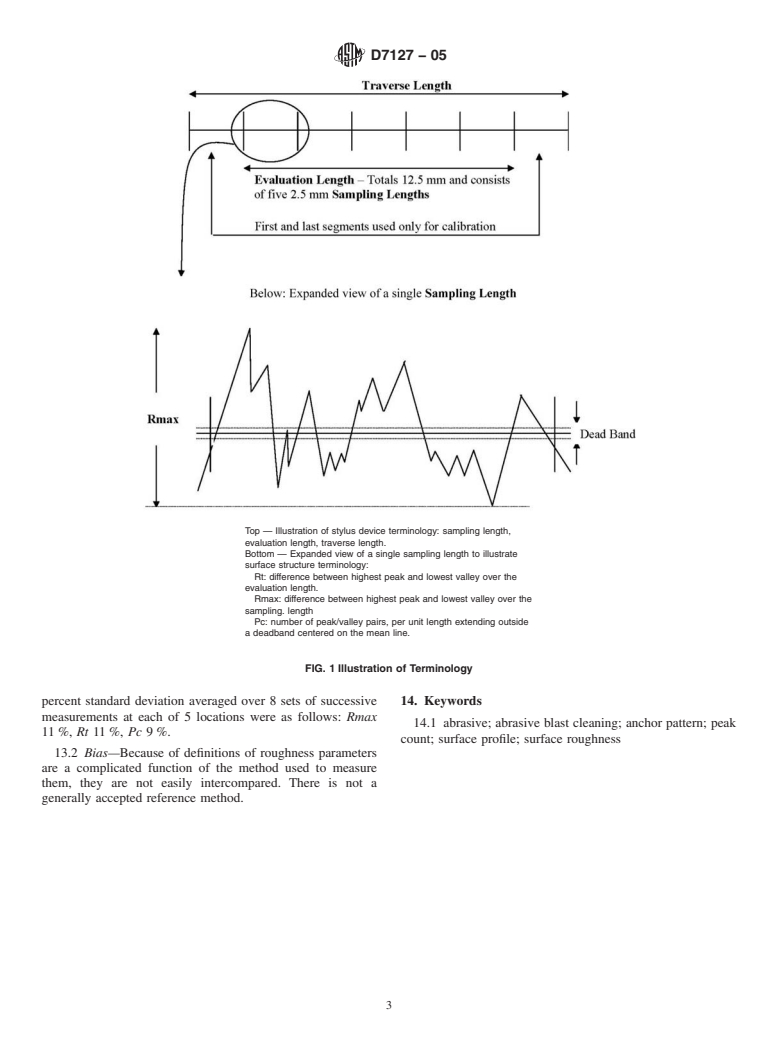

3.1.1 deadband, n—that distance above and below the mean

determination of four roughness characteristics of surfaces

line that a continuous trace line must cross in both directions

prepared for painting by abrasive blasting. The procedure uses

(up and down) to count as a single peak.

a portable skidded or non-skidded stylus profile tracing instru-

3.1.1.1 Discussion—Use of a deadband diminishes the ef-

ment. The three measured characteristics are: Rt, Rmax, and

fect of small, spurious peaks due to noise.

Pc.

3.1.2 evaluation length, n—a sequence of five consecutive

1.2 The values stated in SI units are to be regarded as the

sampling lengths.

standard. The values given in parentheses are for information

3.1.3 Pc, n—the number of peak/valley pairs, per unit of

only.

length, extending outside a “deadband” centered on the mean

1.3 In general, this method should be limited to the mea-

line.

surement of surface roughness where Rmax is in the range 10

3.1.4 Rmax, n—the largest peak to valley measurement is

to 150 µm (0.4 to 6 mil) and where the Peak Count, Pc, is less

determined from the five sampling lengths, and the largest of

than 180 peaks/cm (450 peaks/in.).

these five values is Rmax.

1.4 This standard does not purport to address all of the

3.1.5 Rt, n—the distance between the highest peak and the

safety concerns, if any, associated with its use. It is the

lowest valley within any given evaluation length.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

3.1.6 sampling length, n—thenominalintervalwithinwhich

bility of regulatory limitations prior to use.

a single value of a surface parameter is determined.

3.1.7 surface preparation, n—the cleaning and profiling of a

2. Referenced Documents

metallic surface using an abrasive blast media or mechanical

2.1 ASME Standard:

means to prepare that surface for coating.

ASME B46.1-2002 Surface Texture, Surface Roughness

3.1.8 surface profile, n—for purposes of the standard, the

Waviness and Lay

positive and negative vertical deviations (peaks and valleys)

2.2 ISO Standards:

are measured from a mean line approximately the center of the

ISO 4287: 1997 Geometrical Product Specifications

profile being evaluated.

(GPS)—Surface Texture: Profile Method—Terms,

3.1.9 surface roughness, n—the combined characteristics of

Definitions, and Surface Parameters

surface profile (height) and peak count (linear density) for a

surface.

3. Terminology

3.1.10 traversing length, n—seven sampling lengths com-

3.1 Definitions—The following definitions are provided as

prising the evaluation length and the pre-travel and post-travel

an aid to users of this document. Formal definitions of the

segments.

4. Summary of Test Method

This test method is under the jurisdiction of ASTM Committee D01 on Paint

and Related Coatings, Materials, andApplications and is the direct responsibility of

4.1 This test method describes the proper use of a portable

Subcommittee D01.46 on Industrial Protective Painting.

stylus surface roughness measuring device to evaluate specific

Current edition approved Dec. 1, 2005. Published January 2006. DOI: 10.1520/

D7127-05.

surface parameters and evaluate their suitability for the appli-

Available from American Society of Mechanical Engineers (ASME), ASME

cation of the selected coating to the surface being prepared by

International Headquarters, Three Park Ave., New York, NY 10016-5990.

abrasive blasting, or other mechanical means, prior to applica-

Available from International Organization for Standardization (ISO), 1 rue de

Varembé, Case postale 56, CH-1211, Geneva 20, Switzerland. tion.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7127 − 05

4.2 The method describes considerations relevant to setup 8. Preparation of the Sample

of stylus instruments for acquisition of required surface rough-

8.1 Select a 15 by 15 cm (6 by 6 in.) area of the surface to

ness parameters.

be tested that is visibly free from obvious defects such as

scratches, deep marks, or other construction or corrosion

5. Significance and Use

defects.

5.1 This method may be useful in assuring conformance of

8.2 Using a stiff nylon bristle brush, remove any dust or

a prepared surface to profile requirements specified by the

abrasive particles from the surface in the selected sample

manufacturer of a protective coating.

evaluation area. If not removed, such dust and micronic

5.2 This method includes determination of the peak density

metallic particles may cause damage to the stylus and errone-

(number of profile peaks in a specified distance). Some

ous readings.

workers in the field believe that optimizing peak height and

peak density can improve coating adhesion.

9. Calibration and Standardization

5.3 This method allows specifiers to objectively define 9.1 Precisionreproductionsofstandardsurfaceprofilessuch

surface texture after abrasive blast cleaning rather than using

as those used by the manufacturer of the equipment, or

subjective terms such as “angular pattern” or “dense and described in their operational literature, may be used as

uniform pattern.”

calibration standards for the apparatus.

6. Apparatus

10. Procedure

6.1 The apparatus consists of a portable skidded or non-

10.1 Obtain an initial trace m

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.