ASTM D6898-03(2010)

(Test Method)Standard Test Method for Evaluating Diesel Fuel Lubricity by an Injection Pump Rig

Standard Test Method for Evaluating Diesel Fuel Lubricity by an Injection Pump Rig

SIGNIFICANCE AND USE

Diesel fuel injection equipment has some reliance on lubricating properties of the diesel fuel. Shortened life of engine components, such as diesel fuel injection pumps and injectors, has sometimes been ascribed to lack of lubricity in a diesel fuel.

Pump Lubricity Value (PLV) test results generally rank fuel effects on diesel injection system pump component distress due to wear in the same order as Bosch, Lucas, Stanadyne, and Cummins in-house rig tests. In these fuel/hardware tests, boundary lubrication is believed to be a factor in the operation of the component.

The PLV is sensitive to contamination of the fluids and test materials and the temperature of the test. Lubricity evaluations are also sensitive to trace contaminants acquired during test fuel sampling and storage.

Test Methods D6078 and D6079 are two methods for evaluating diesel fuel lubricity. No absolute correlation has been developed between these two test methods, or between either of these methods and the PLV.

The PLV may be used to evaluate the relative effectiveness of a fluid for preventing wear under the prescribed test conditions.

This test method is designed to evaluate boundary lubrication properties. While viscosity effects on lubricity are not totally eliminated, they are minimized.

This test can indicate whether or not an additive will improve the lubricity of a poor lubricity fuel.

SCOPE

1.1 This test method covers evaluating the lubricity of diesel fuels using a pump rig test and Stanadyne Model DB4427-4782 pumps.

Note 1—Other pumps may be used if a correlation between pump performance factors and fuel lubricity has been developed.

1.2 This test method is applicable to any fuel used in diesel engines, including those which may contain a lubricity enhancing additive.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific warning statements are given in Section 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6898 − 03(Reapproved 2010)

Standard Test Method for

Evaluating Diesel Fuel Lubricity by an Injection Pump Rig

This standard is issued under the fixed designation D6898; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

All diesel fuel injection equipment relies, to some extent, on diesel fuel as a lubricant. Shortened

lifeofdieselfuelinjectionpumpsandinjectorsfromwearcausedbyexcessivefrictionhassometimes

been ascribed to lack of lubricity in the fuel. This test assesses the lubricity of a fuel by operation of

the fuel in a typical fuel injection system comprised of injection pump, high pressure pipes, and

injectors on a pump test rig bench. The test models an actual commercial application of such

equipment. The pump performance is evaluated on a test bench meeting SAE J1668 requirements.

1. Scope D362SpecificationforIndustrialGradeToluene(Withdrawn

1989)

1.1 Thistestmethodcoversevaluatingthelubricityofdiesel

D4057Practice for Manual Sampling of Petroleum and

fuels using a pump rig test and Stanadyne Model DB4427-

Petroleum Products

4782 pumps.

D4177Practice for Automatic Sampling of Petroleum and

NOTE 1—Other pumps may be used if a correlation between pump

Petroleum Products

performance factors and fuel lubricity has been developed.

D4306Practice for Aviation Fuel Sample Containers for

1.2 This test method is applicable to any fuel used in diesel

Tests Affected by Trace Contamination

engines,includingthosewhichmaycontainalubricityenhanc-

D6078TestMethodforEvaluatingLubricityofDieselFuels

ing additive.

by the Scuffing Load Ball-on-Cylinder Lubricity Evalua-

tor (SLBOCLE)

1.3 The values stated in SI units are to be regarded as

D6079TestMethodforEvaluatingLubricityofDieselFuels

standard. No other units of measurement are included in this

by the High-Frequency Reciprocating Rig (HFRR)

standard.

2.2 SAE Standards:

1.4 This standard does not purport to address all of the

SAE J967Calibration Fluid for Diesel Injection Equipment

safety concerns, if any, associated with its use. It is the

SAE J968/1Diesel Injection Pump Testing—Part 1: Cali-

responsibility of the user of this standard to establish appro-

brating Nozzles and Holder Assemblies

priate safety and health practices and determine the applica-

SAE J1418Fuel Injection Pumps—High Pressure Pipes

bility of regulatory limitations prior to use. Specific warning

(Tubing) for Testing

statements are given in Section 7.

SAE J1668Diesel Engines—Fuel Injection Pump Testing

2. Referenced Documents

3. Terminology

2.1 ASTM Standards:

3.1 Definitions of Terms Specific to This Standard:

D329Specification for Acetone

3.1.1 boundary lubrication, n—a condition in which the

friction and wear between two surfaces in relative motion are

determined by the properties of the surfaces and the properties

This test method is under the jurisdiction of ASTM Committee D02 on

of the contacting fluid, other than bulk viscosity.

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

3.1.1.1 Discussion—Metal to metal contact occurs and the

Subcommittee D02.E0 on Burner, Diesel, Non-Aviation Gas Turbine, and Marine

chemistry of the system is involved. Physically adsorbed or

Fuels.

Current edition approved Oct. 1, 2010. Published November 2010. Originally

approved in 2003. Last previous edition approved in 2003 as D6898–03. DOI:

10.1520/D6898-03R10.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or The last approved version of this historical standard is referenced on

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM www.astm.org.

Standards volume information, refer to the standard’s Document Summary page on Available from Society of Automotive Engineers (SAE), 400 Commonwealth

the ASTM website. Dr., Warrendale, PA 15096-0001.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

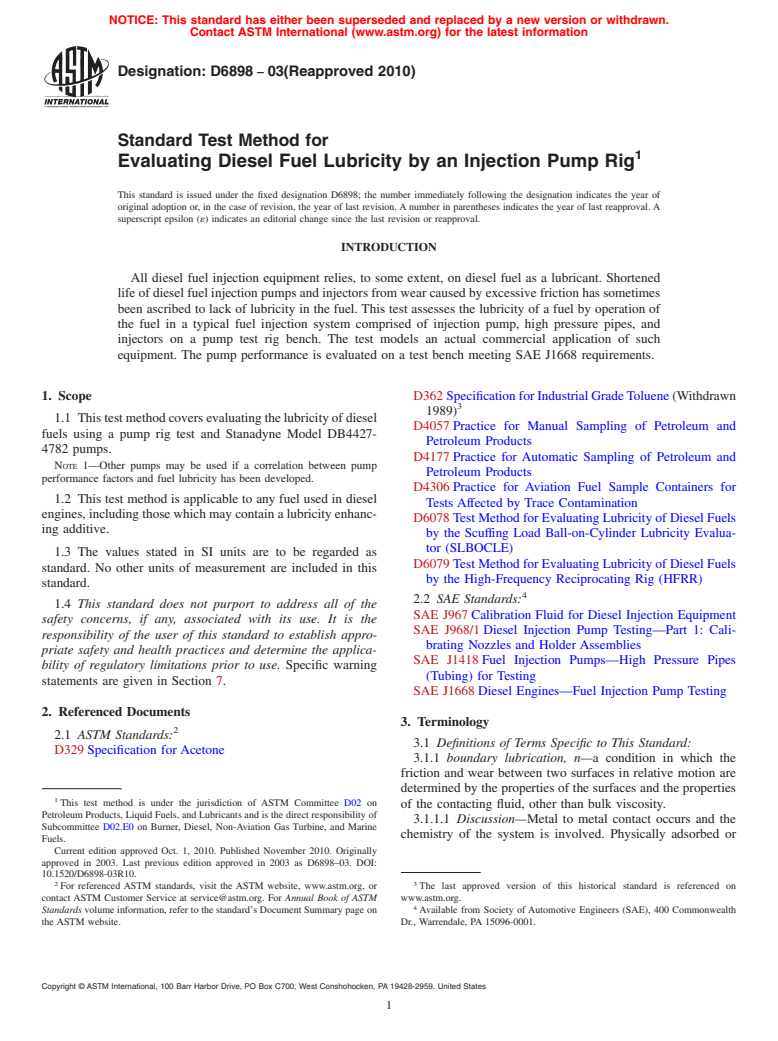

D6898 − 03 (2010)

Trademark of STANADYNE Diesel Systems

FIG. 1 Schematic of Stanadyne Model DB4427-4782 Pump

chemically reacted soft films (usually very thin) support 5. Significance and Use

contact loads. Consequently, some wear is inevitable.

5.1 Diesel fuel injection equipment has some reliance on

3.1.2 lubricity, n—a qualitative term describing the ability

lubricating properties of the diesel fuel. Shortened life of

of a fluid to affect friction between, and wear to, surfaces in

engine components, such as diesel fuel injection pumps and

relative motion under load.

injectors, has sometimes been ascribed to lack of lubricity in a

3.1.2.1 Discussion—In this test method, the lubricity of a

diesel fuel.

fluid is evaluated by comparing critical pump component

5.2 Pump Lubricity Value (PLV) test results generally rank

dimensions, fuel flow rate and transfer pump pressures before

fuel effects on diesel injection system pump component dis-

and after testing under defined and controlled conditions. A

tress due to wear in the same order as Bosch, Lucas,

computed value known as pump lubricity value (PLV) results.

Stanadyne, and Cummins in-house rig tests. In these fuel/

3.1.3 roller-to-roller (R-R), n—a linear measurement of

hardware tests, boundary lubrication is believed to be a factor

opposing pumping plungers in an injection pump when pres-

in the operation of the component.

surized to force the plungers outward against the adjustable

5.3 The PLV is sensitive to contamination of the fluids and

stop mechanism.

test materials and the temperature of the test. Lubricity

3.1.4 transfer pump (TP), n—a vane type low pressure

evaluations are also sensitive to trace contaminants acquired

supply pump internal to an injection pump.

during test fuel sampling and storage.

5.4 Test Methods D6078 and D6079 are two methods for

4. Summary of Test Method

evaluating diesel fuel lubricity. No absolute correlation has

4.1 Prior to the start of the 500 h test, the roller-to-roller

been developed between these two test methods, or between

(R-R) dimension and transfer pump (TP) blade thickness are

either of these methods and the PLV.

measured on two new or rebuilt pumps. The fuel flow

3 5.5 The PLV may be used to evaluate the relative effective-

(mm /stroke) and TP pressure (kPa) of each pump are mea-

ness of a fluid for preventing wear under the prescribed test

sured at 100 rpm increments from 1000 to 2200 rpm.

conditions.

4.2 The pumps are mounted on the test bench and a

5.6 This test method is designed to evaluate boundary

thorough flushing process is performed. The test fuel(s) are

lubrication properties. While viscosity effects on lubricity are

stored in epoxy-lined containers (55 U.S. gal drums are

not totally eliminated, they are minimized.

suitable) which are plumbed to the test bench.

5.7 This test can indicate whether or not an additive will

4.3 The pumps are operated at 1100 rpm for 500 h at the

improve the lubricity of a poor lubricity fuel.

specified test conditions.

4.4 The pumps are removed from the test bench and the

pre-test measurements are repeated.

Nikanjam, M., Crosby, T., Henderson, P., Gray, C., Meyer, K., and Davenport,

4.5 The pre- and post- test data are used to compute the

N., “ISO Diesel Fuel Lubricity Round Robin Program,” SAE Paper 952372, Oct.

pump lubricity value (PLV). 16-19, 1995.

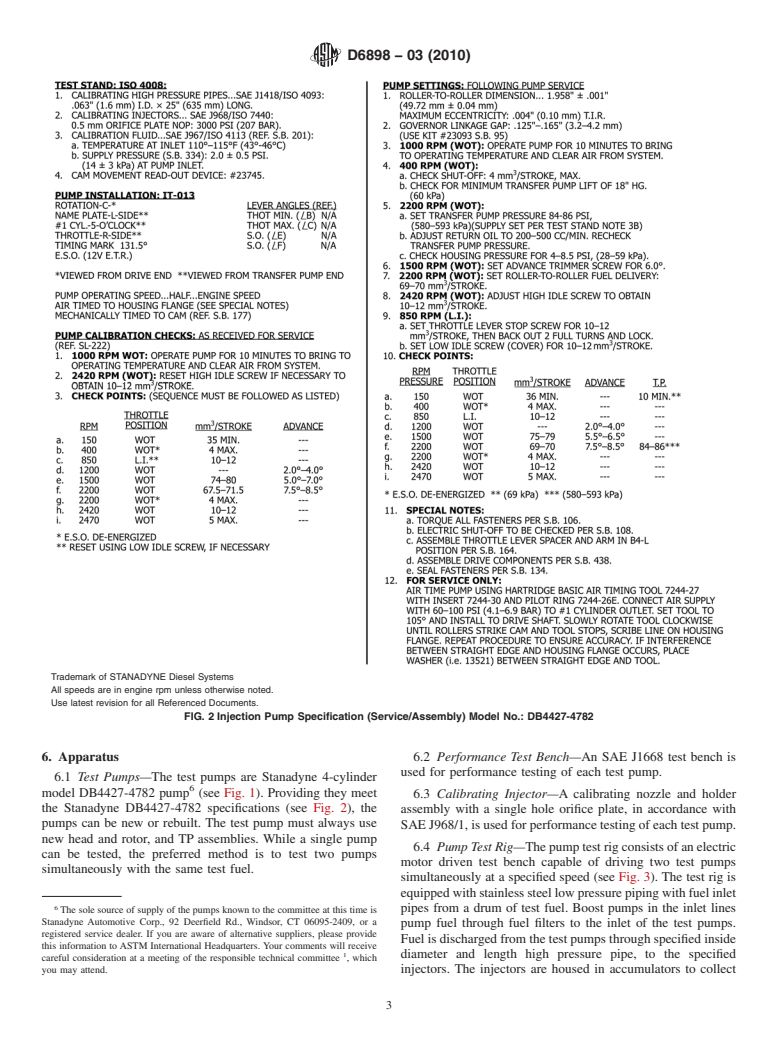

D6898 − 03 (2010)

Trademark of STANADYNE Diesel Systems

All speeds are in engine rpm unless otherwise noted.

Use latest revision for all Referenced Documents.

FIG. 2 Injection Pump Specification (Service/Assembly) Model No.: DB4427-4782

6. Apparatus 6.2 Performance Test Bench—An SAE J1668 test bench is

used for performance testing of each test pump.

6.1 Test Pumps—The test pumps are Stanadyne 4-cylinder

model DB4427-4782 pump (see Fig. 1). Providing they meet

6.3 Calibrating Injector—A calibrating nozzle and holder

the Stanadyne DB4427-4782 specifications (see Fig. 2), the

assembly with a single hole orifice plate, in accordance with

pumps can be new or rebuilt. The test pump must always use

SAEJ968/1,isusedforperformancetestingofeachtestpump.

new head and rotor, and TP assemblies. While a single pump

6.4 Pump Test Rig—Thepumptestrigconsistsofanelectric

can be tested, the preferred method is to test two pumps

motor driven test bench capable of driving two test pumps

simultaneously with the same test fuel.

simultaneously at a specified speed (see Fig. 3). The test rig is

equippedwithstainlesssteellowpressurepipingwithfuelinlet

pipes from a drum of test fuel. Boost pumps in the inlet lines

The sole source of supply of the pumps known to the committee at this time is

Stanadyne Automotive Corp., 92 Deerfield Rd., Windsor, CT 06095-2409, or a

pump fuel through fuel filters to the inlet of the test pumps.

registered service dealer. If you are aware of alternative suppliers, please provide

Fuelisdischargedfromthetestpumpsthroughspecifiedinside

this information toASTM International Headquarters. Your comments will receive

diameter and length high pressure pipe, to the specified

careful consideration at a meeting of the responsible technical committee , which

you may attend. injectors. The injectors are housed in accumulators to collect

D6898 − 03 (2010)

6.14 Point Micrometer, 0 to 25.4 mm with a resolution of

0.001 mm and an accuracy of 0.003 mm to measure the

thickness of the TP blades.

6.15 R-R Setting Fixture, a special tool available from

Stanadyne.

6.16 Electronic Control Unit, any commercially available

unit capable of operating the test rig.

6.17 Tachometers, used to measure the rpm of the test

pumps.

6.18 Thermocouples, used to measure air temperature, and

fuel temperatures in the drum, after the boost pump, after the

DB4427-4782 pumps, and in the fuel return lines.

6.19 Pressure Transducers, used to measure the pressure

after the boost pump and after the DB4427-4782 pumps.

6.20 Flow Meters,usedtomeasurethefuelflowthroughthe

DB4427-4782 pumps.

NOTE 1—The system shown in this figure is a six–cylinder (six

injectors) pump, while the test pump (see 6.1) is a four–cylinder

6.21 Level Sensor, used to monitor the level of fuel in the

application.

drum.

FIG. 3 Test Rig Portable Bench

6.22 Hydrocarbon Gas Detector, used to monitor for poten-

tially explosive vapors in the room.

the discharged fuel and return it to the drum. Thus the fuel

6.23 Flushing Adapters, necessary fittings and adapters to

systemisclosedandthefuelcontinuouslyrecirculates.Thetest

bypassthefuelfilter,connectthefuelpumpinletdirectlytothe

rig is operated in a room with an ambient temperature of 24 6

HPpipes, and connect the HPpipes to the accumulator. These

3°C.

adapters are used to flush the test rig between fuel tests.

6.5 Electric Motor, an adjustable speed motor capable of

producing speeds to 1500 rpm and a torque of 122 N-m.

7. Reagents and Materials

6.6 Low Pressure Piping, 9.5 mm inside diameter stainless

7.1 Acetone, conforming to Specification D329.

steel tubing of whatever length is needed for the application.

(Warning—Extremely flammable. Vapors may cause flash

6.7 Boost Pumps, pumps which operate at 14 to 34 kPa and

fire.)

pump 76 to 114 L/h.

7.2 Calibration Fluid, a fluid formulated from refined and

6.8 Fuel Filters, Stanadyne model 100 or John Deere RF

deodorized fuel stocks, meeting SAE J967 specifications, used

624118.

for pump performance testing.

6.9 Filter Head/Fuel Handler,Stanadyne33260 forattach-

7.3 Compressed Air, containing less than 0.1 ppmv hydro-

ment of fuel filters.

carbons and 50 ppmv water. (Warning—Compressed gas

6.10 High Pressure Pipes—HP pipes in accordance with under high pressure. Use with extreme caution in the presence

SAEJ1418are1.6 60.025mminsidediameter×640 65mm of combustible material.)

longwithanominaloutsidediameterof6mmandaminimum

7.4 Flushing Fluid, 75/25 mixture of toluene and acetone

central line bend radius of 16 mm for both the performance

used to flush the pump test rig between fuel tests.

testing and the test rig testing testing.

7.5 Toluene, conforming to Specification D362.

NOTE 2—SAE J1418 specifies the length of this tubing as 600 65mm

but 640 mm is required in these applications. (Warning—Flammable. Harmful if inhaled.)

6.11 Test Rig Injectors—ThetestriginjectorsareStanadyne

8. Sampling and Sample Containers

p/n 27336 (see Fig. 4). These injectors are known as engine

injectors as compared to calibrating injectors.

8.1 Unless otherwise specified, take samples by the proce-

dure described in Practice D4057 or Practice D4177.

6.12 Accumulator, a stainless steel box, into which the

injectors are screwed, that has a line to return the injected fuel

8.2 Because of the sensitivity of lubricity measurements to

back to the drum (see Fig. 5).

trace materials, sample containers shall be only fully epoxy-

linedmetaldrums,cleanedandrinsedthoroughlyatleastthree

6.13 Micrometer,25.4to50.8mmwitharesolutionof0.001

mm and an accuracy of 0.003 mm to measure the R-R timeswiththeproducttobesampledbeforeuse,asspecifiedin

Practice D4306.

dimension.

8.3 New sample containers are preferred, but if not

available, Practice D4306 gives guidance on suitable cleaning

Available from Stanadyne Automotive Corp., 92 Deerfield Rd., Windsor, CT

06095-2409, or a registered service dealer. procedures.

D6898 − 03 (2010)

FIG. 4 Injector Specification

D6898 − 03 (2010)

FIG. 5 Accumulator for Test Rig Injectors

FIG. 6 Measurement of R-R Dimension

9. Preparation of Apparatus, Pumps, and Engine

Injectors

9.1 Disassembleatestpumpinaccordancewiththeinstruc-

tions in Stanadyne Publication 99689 to permit measurement

of the R-R dimension and the TP blade thickness.

9.2 SecureR-Rsettingfixture19969inviseandinsertrotor

assembly (see Fig. 6). Connect dry, clean, filtered compressed

air source regulated to 4.5 to 11.3 kPa to force the plungers

outwarduntiltheshoescontacttheleafsprings.Usingthe25.4

to 50.8 micrometer, measure the distance between the outer

surfaces of each pair of opposed rollers to the nearest 0.002

mm. The R-R dimension must be 49.73 6 0.04 mm. The leaf

spring adjusting screws can be turned clockwise to increase or

counterclockwise to decrease the dimension. The two dimen-

sionsmustbewithin0.08mmofeachotherandtheaverageof

the two dimensions must be within 0.04 mm of 49.73 mm.

9.2.1 Example—One pair of rollers measures 49.76 mm

while the other measures 49.68 mm. The two dimensions are

within 0.08 mm of eac

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.