ASTM A517/A517M-06

(Specification)Standard Specification for Pressure Vessel Plates, Alloy Steel, High-Strength, Quenched and Tempered

Standard Specification for Pressure Vessel Plates, Alloy Steel, High-Strength, Quenched and Tempered

ABSTRACT

This specification covers standard requirements for high-strength quenched and tempered alloy steel plates intended for use in fusion welded boilers and other pressure vessels. The steel shall be killed and shall conform to the fine austenitic grain size requirement. Heat and product analyses shall be conducted wherein the material shall conform to the required chemical composition for carbon, manganese, phosphorus, sulfur, silicon, nickel, chromium, molybdenum, boron, vanadium, titanium, zirconium, copper, and columbium. Tensile properties of the steel plate shall meet the specified values for tensile strength, yield strength, and elongation. The material shall undergo mechanical tests such as tension test and transverse Charpy V-notch impact test.

SCOPE

1.1 This specification covers high-strength quenched and tempered alloy steel plates intended for use in fusion welded boilers and other pressure vessels.

1.2 This specification includes a number of grades as manufactured by different producers, but all having the same mechanical properties and general characteristics.

1.3 The maximum thickness of plates furnished under this specification shall be as follows:Grade Thickness A, B 1.25 in. [32 mm] H, S2 in. [50 mm] P 4 in. [100 mm] F 2.50 in. [65 mm] E, Q 6 in. [150 mm]

1.4 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system is to be used independently of the other without combining values in any way.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A517/A517M – 06

Standard Specification for

Pressure Vessel Plates, Alloy Steel, High-Strength,

1

Quenched and Tempered

This standard is issued under the fixed designationA517/A517M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* A577/A577M Specification for UltrasonicAngle-Beam Ex-

2 amination of Steel Plates

1.1 This specification covers high-strength quenched and

A578/A578M Specification for Straight-Beam Ultrasonic

tempered alloy steel plates intended for use in fusion welded

Examination of Rolled Steel Plates for Special Applica-

boilers and other pressure vessels.

tions

1.2 This specification includes a number of grades as

manufactured by different producers, but all having the same

3. General Requirements and Ordering Information

mechanical properties and general characteristics.

3.1 Plates furnished to this material specification shall

1.3 The maximum thickness of plates furnished under this

conform to Specification A20/A20M. These requirements out-

specification shall be as follows:

line the testing and retesting methods and procedures, permis-

Grade Thickness

sible variations in dimensions, and mass, quality and repair of

A, B 1.25 in. [32 mm]

H, S 2 in. [50 mm]

defects, marking, loading, etc.

P 4 in. [100 mm]

3.2 Specification A20/A20M also establishes the rules for

F 2.50 in. [65 mm]

the ordering information which should be complied with when

E, Q 6 in. [150 mm]

purchasing material to this specification.

1.4 The values stated in either inch-pound units or SI units

3.3 In addition to the basic requirements of this specifica-

are to be regarded separately as standard. Within the text, the

tion, certain supplementary requirements are available when

SI units are shown in brackets. The values stated in each

additional control, testing, or examination is required to meet

system are not exact equivalents; therefore, each system is to

end use requirements. These include:

beusedindependentlyoftheotherwithoutcombiningvaluesin

3.3.1 Vacuum treatment,

any way.

3.3.2 Additional or special tension testing,

3.3.3 Impact testing, and

2. Referenced Documents

3.3.4 Nondestructive examination.

3

2.1 ASTM Standards:

3.4 The purchaser is referred to the listed supplementary

A20/A20M Specification for General Requirements for

requirements in this specification and to the detailed require-

Steel Plates for Pressure Vessels

ments in Specification A20/A20M.

A435/A435M Specification for Straight-Beam Ultrasonic

3.5 If the requirements of this specification are in conflict

Examination of Steel Plates

with the requirements of SpecificationA20/A20M, the require-

ments of this specification shall prevail.

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

4. Manufacture

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

A01.11 on Steel Plates for Boilers and Pressure Vessels.

4.1 Steelmaking Practice—The steel shall be killed and

Current edition approved May 1, 2006. Published May 2006. Originally

shall conform to the fine austenitic grain size requirement of

approved in 1964. Last previous edition approved in 2004 as A517/A517M – 93

´1

Specification A20/A20M.

(2004) . DOI: 10.1520/A0517_A0517M-06.

2

For ASME Boiler and Pressure Vessel Code applications, see related Specifi-

5. Heat Treatment

cation SA-517/SA-517M in Section II of that Code.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.1 Exceptasallowedbysection5.2,theplatesshallbeheat

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

treated by heating to not less than 1650°F [900°C], quenching

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. in water or oil and tempering at not less than 1150°F [620°C].

*ASummary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A517/A517M – 06

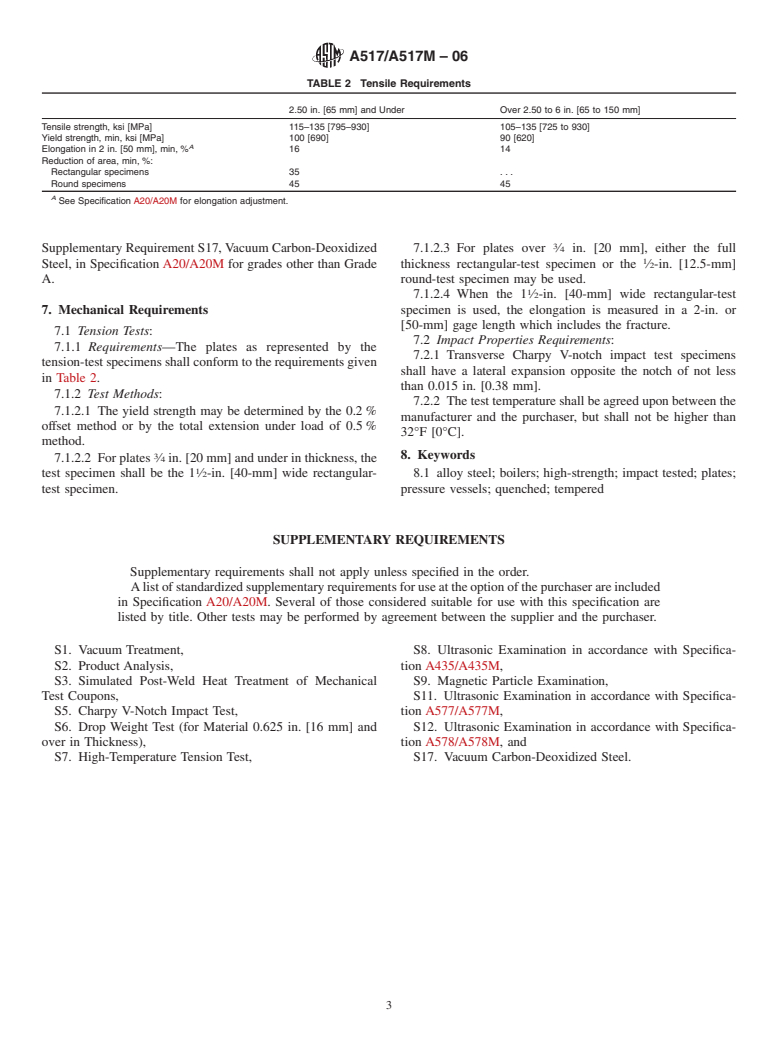

TABLE 1 Chemical Requirements

Elements Composition, %

Grade Grade Grade Grade Grade Grade Grade Grade

A B E F H P Q S

Carbon:

Heat analysis 0.15 0.15 0.12 0.10 0.12 0.12 0.14 0.10

–0.21 –0.21 –0.20 –0.20 –0.21 –0.21 –0.21 –0.20

Product analysis 0.13 0.13 0.10 0.08 0.10 0.10 0.12 0.10

–0.23 –0.23 –0.22 –0.22 –0.23 –0.23 –0.23 –0.22

Manganese:

Heat analysis 0.80 0.70 0.40 0.60 0.95 0.45 0.95 1.10

–1.10 –1.00 –0.70 –1.00 –1.30 –0.70 –1.30 –1.50

Product analysis 0.74 0.64

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.