ASTM D4-86(1998)

(Test Method)Standard Test Method for Bitumen Content

Standard Test Method for Bitumen Content

SCOPE

1.1 This test method covers the determination of bitumen content in materials containing at least 25% bitumen. Bitumen content may usually be expeditiously and accurately determined by Procedure No. 1, Section 7. However, some bituminous materials containing finely divided mineral matter may clog the filter or the mineral residue may not be easily retained, in which cases Procedure No. 2, Section 8, shall be followed.

1.2 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability and regulatory limitations prior to use. For specific precautionary information, see Section 4.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D4–86 (Reapproved 1998)

Standard Test Method for

Bitumen Content

This standard is issued under the fixed designation D 4; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense. Although this test method was withdrawn by the

Society in June 1966 at the request of Committee D-4, the Committee on Standards has approved its reinstatement under the jurisdiction

of Committee D-8 on the basis that Procedure No. 2 still applies to their interest. Procedure No. 1 has been replaced by Method D 2042,

Test for Solubility of Asphalt Materials in Trichloroethylene.

1. Scope 3.3 Beakers—One 30-mL beaker, Griffin low-form, and one

150-mL beaker, Griffin low-form.

1.1 This test method covers the determination of bitumen

3.4 Carbon Disulfide, cp.

content in materials containing at least 25 % bitumen. Bitumen

content may usually be expeditiously and accurately deter-

NOTE 1—For filled asphaltic materials, trichloroethylene may be di-

mined by Procedure No. 1, Section 7. However, some bitumi- rectly substituted for carbon disulfide if desired. However, carbon disul-

fide shall be used in referee testing.

nous materials containing finely divided mineral matter may

clog the filter or the mineral residue may not be easily retained,

3.5 Filtering Flask, with crucible adapter.

in which cases Procedure No. 2, Section 8, shall be followed.

3.6 Drying Oven.

1.2 This standard does not purport to address all of the

3.7 Bunsen Burner or Muffle Furnace.

safety concerns, if any, associated with its use. It is the

3.8 Suction Pump.

responsibility of the user of this standard to establish appro-

3.9 Analytical Balance.

priate safety and health practices and determine the applica-

3.10 Desiccator.

bility and regulatory limitations prior to use. For specific

3.11 Evaporating Dish.

precautionary information, see Section 4.

3.12 Watch Glasses.

2. Referenced Documents

4. Safety Precautions

2.1 ASTM Standards:

4.1 Carbon disulfide is extremely flammable. The vapor will

D 370 Test Method for Dehydration of Oil-Type Preserva-

often ignite spontaneously on contact with a hot surface such as

tives

a hot plate, oven, or radiator. When using this solvent, be sure

E 177 Practice for Use of the Terms Precision and Bias in

that the filtration is conducted under a hood and well away

ASTM Test Methods

from flame or other sources of heat. Before placing crucibles or

other containers in the oven, all traces of carbon disulfide

3. Apparatus, Reagents, and Materials

should be removed (as indicated by the disappearance of all

3.1 Filtering Crucible, porcelain, high-form, 25 to 40-mL

odor). Otherwise, the vapors will ignite. Carbon disulfide is

capacity, with fine-porosity bottom, 7-μm maximum porosity.

also very irritating to the skin and direct contact should be

5 6

3.2 Celite Analytical Filter Aid (CAFA), dried to constant

avoided.

mass at 105°C and stored in a tightly stoppered container.

5. Preparation of Sample

1 5.1 The sample shall be representative, and if it contains

This test method is under the jurisdiction of ASTM Committee D08 on

Roofing, Waterproofing, and Bituminous Materialsand is the direct responsibility of more than 2 % of water it shall be dehydrated in accordance

Subcommittee D08.03 on Surfacing and Bituminous Materials for Membrane

with Test Method D 370. If the material is hard and brittle, it

Waterproofing and Builtup Roofing.

may be ground and dried at a temperature below the tempera-

Current edition approved May 30, 1986. Published July 1986. Originally

ture of volatilization of the material.

published as D4–11. Last previous edition D4–80 (1985).

Annual Book of ASTM Standards, Vol 04.09.

Annual Book of ASTM Standards, Vol 14.02. 6. Crucible Preparation

Selas grade 01, size FC 30 or FC 40, or equivalent. Available from various

6.1 If the crucible, after thorough cleaning (see 6.2), has

laboratory supply houses such as Fisher Scientific. An alternative is Royal Berlin

been used for less than six determinations, clean it as follows:

2A2 (size equivalent to FC 40) from Fish Schurman Corp., 70 Portman Road, New

Rochelle, NY 10802.

Remove the CAFA mat completely, wash the crucible with

Trademark of Manville Corp.

distilled water, dry, and ignite in a muffle furnace for1hat

Use Celite 211 Analytical Filter Aid from Fisher Scientific, Pittsburgh, PA, or

about 800°C. Cool the crucible slowly by placing it in a drying

Celite 505 from Manville Corp., Denver, CO.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

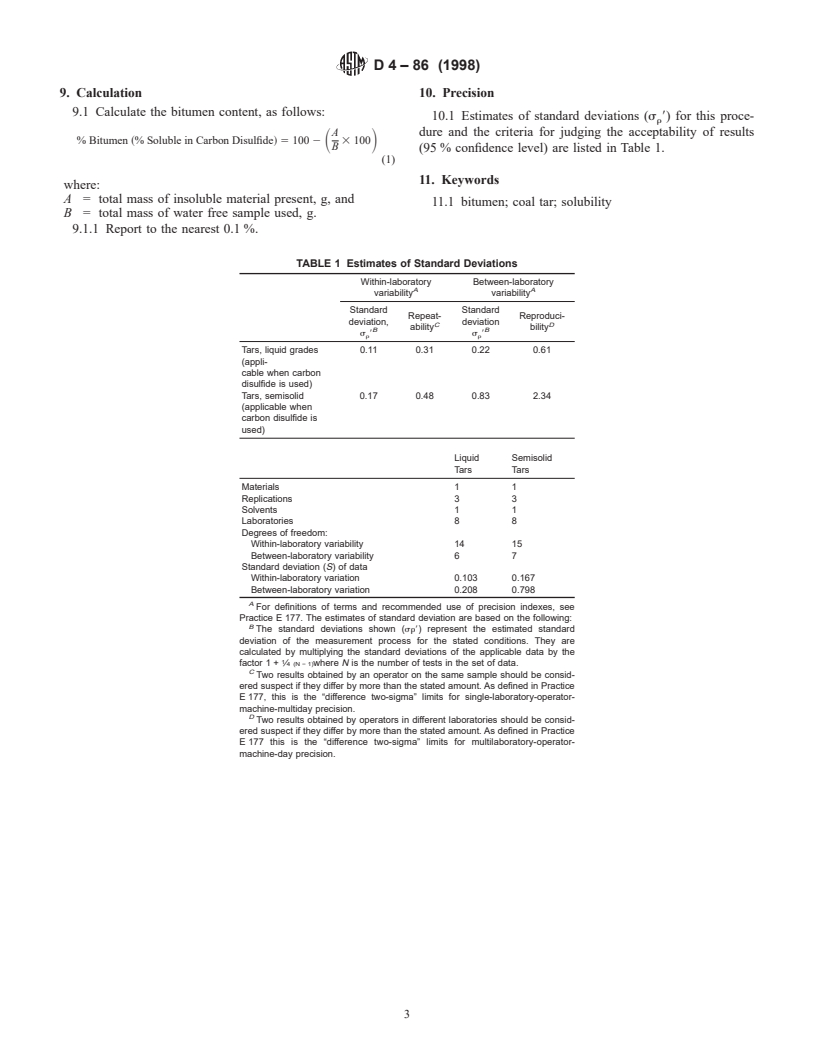

D4–86 (1998)

oven for 1 h after removal from the furnace to prevent cracking 8. Procedure No. 2

and place it in a desiccator while still warm.

8.1 Weigh approximately2gofthe sample into a tared

6.2 After the crucible has been used for six determinations,

50-mL beaker. Add to the beaker about 0.5 g, weighed to the

remove any residual ash from pores in the filtering area by

nearest 0.001 g, of freshly dried CAFA. Cover with about 25

boiling in 1 + 1 hydrochloric acid. Then boil the crucible in

mL of carbon disulfide and stir the filter aid into the liquid. Let

distilled water, thoroughly back wash with distilled water, dry,

stand, covered with a watch glass, at least 1 h, stirring

and ignite as in 6.1.

occasionally in order to dissolve the sample completely.

7. Procedure No. 1

8.2 Transfer 0.45 to 0.55 g of dry CAFA to a clean, dry,

7.1 Weigh approximately2gofthe sample (size sample to

filtering crucible. Distribute the Celite evenly over the bottom.

obtain 0.1 to 0.3 g of insoluble matter) into a tared 150-mL

Immediately weigh and record the mass of crucible plus Celite.

beaker and add 100 mL of carbon disulfide to the beaker in

8.3 Immediately before starting the filtering process, stir the

small portions, with continuous agitation, until all lumps

filter aid into the liquid. Wet the CAFA mat in the crucible with

disappear and nothing adheres to the beaker. Cover the beaker

carbon disulfide. Pour the solution from the beaker onto the

with a watch glass and set it aside for 15 min.

pad, filling the crucible to the top. Apply light suction and, as

7.2 Transfer 0.45 to 0.55 g of dry CAFA to a clean, dry,

the liquid filters through, pour the remaining contents of the

filtering crucible. Distribute the Celite evenly over the bottom.

50-mL beaker into the crucible. Wash the beaker with a small

Immediately weigh and record the weight of crucible plus

amount of carbon disulfide and transfer all sediment from the

Celite.

beaker to the mat. Do not allow the CAFA mat to dry out until

7.3 Decant the carbon disulfide solution carefully through

filtration is complete. Wash with carbon disulfide until the

the CAFA mat (previously wetted with carbon disulfide) in the

filtrate is substantially colorless, then apply strong suction to

prepared crucible, with or without light suction as may be

remove the remaining carbon disulfide. Rem

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.