ASTM B467-88(2003)

(Specification)Standard Specification for Welded Copper-Nickel Pipe

Standard Specification for Welded Copper-Nickel Pipe

ABSTRACT

This specification covers welded copper-nickel alloy pipes produced from Copper Alloy UNS Nos. C70600 and C71500 for general engineering applications. Pipes may be produced in any one of the following tempers: as-welded from annealed sheets, strips, or plates (WM50); as-welded from cold-worked sheets, strips, or plates (WM00, WM01, WM02, and so forth); welded and annealed (WO50); welded, light cold drawn (WR00) or hard cold drawn (WR04), and stress relieved; or fully finished as annealed, light drawn (WH00) or hard drawn (WH04), and stress relieved. Products shall be sampled and prepared, then tested accordingly to examine their conformance to dimensional (outside diameter, specific and stock lengths, wall thickness, squareness of cut, and roundness), mechanical (tensile and yield strengths, and elongation), and chemical composition requirements. Specimens shall also undergo nondestructive tests such as radiographic examination, eddy-current test, and hydrostatic test.

SCOPE

1.1 This specification covers welded copper-nickel alloy pipe for general engineering purposes. The following alloys are covered:Copper AlloyUNS No.Previously UsedDesignationNominal Composition, %CopperNickelC706007069010C715007157030

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B467 – 88 (Reapproved 2003)

Standard Specification for

Welded Copper-Nickel Pipe

This standard is issued under the fixed designation B467; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Unified Numbering System (UNS)

2.3 Other Documents:

1.1 This specification covers welded copper-nickel alloy

American Welding Society Specification A5.6

pipeforgeneralengineeringpurposes.Thefollowingalloysare

2 American Welding Society Specification A5.7

covered:

Copper Alloy Previously Used Nominal Composition, %

3. Terminology

UNS No. Designation

Copper Nickel

3.1 Definitions:

C70600 706 90 10

3.1.1 welded pipe—product made from sheet, strip, or plate

C71500 715 70 30

with a seam made by welding.

1.2 The values stated in inch-pound units are to be regarded

3.1.2 flash or bead—weld metal that protrudes beyond the

as the standard. The values given in parentheses are for

normal wall, both inside and outside.

information only.

3.1.3 scarfing—the removing of flash or bead by a cutting

operation.

2. Referenced Documents

3.2 Definitions of Terms Specific to This Standard:

2.1 The following documents of the issue in effect on date

3.2.1 capable of—asusedinthisspecification,thetestisnot

of material purchase form a part of this specification to the

mandatory under the terms of this specification unless defi-

extent referenced herein:

nitely specified in the purchase order; however, should subse-

2.2 ASTM Standards:

quent testing by the purchaser establish that the material does

B153 Test Method for Expansion (Pin Test) of Copper and

not meet these requirements, the material may be rejected.

Copper-Alloy Pipe and Tubing

B601 Classification for Temper Designations for Copper 4. Ordering Information

and Copper Alloys—Wrought and Cast

4.1 Orders for material under this specification shall include

E8 Test Methods for Tension Testing of Metallic Materials

the following information:

E29 Practice for Using Significant Digits in Test Data to

4.1.1 Copper Alloy UNS No. (Section 1 and Table 1),

Determine Conformance with Specifications

4.1.2 Temper (Section 9),

E75 Test Methods for ChemicalAnalysis of Copper-Nickel

4.1.3 Radiographic examination (Section 11),

and Copper-Nickel-Zinc Alloys

4.1.4 Dimensions: diameter and wall thickness (see 12.3,

E243 Practice for Electromagnetic (Eddy-Current) Exami-

section 12.4, and section 12.5),

nation of Copper and Copper-Alloy Tubes

4.1.5 Lengths: whether specific or stock (see section 12.6),

E255 Practice for Sampling Copper and Copper Alloys for

4.1.6 Quantity of each size,

the Determination of Chemical Composition

4.1.7 If the product is to be subsequently welded (see Table

E527 Practice for Numbering Metals and Alloys in the

1 and Footnote D), and

4.1.8 Packing and marking (Section 20).

5. Types of Welded Pipe

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper

and CopperAlloys and is the direct responsibility of Subcommittee B05.04 on Pipe

5.1 As-Welded—Pipe that has been welded with no further

and Tube.

workperformedotherthanstraighteningorcuttingtolength,or

Current edition approved Oct. 1, 2003. Published November 2003. Originally

approved in 1986. Last previous edition approved in 1997 as B467 – 88 (1997). both.

DOI: 10.1520/B0467-88R03.

5.2 Welded and Annealed—Welded pipe that has been

The UNS system for copper and copper alloys (see Practice E527) is a simple

annealed to produce a uniform grain size appropriate to the

expansion of the former standard designation system accomplished by the addition

specified annealed temper.

of a prefix “C” and a suffix “00.” The suffix can be used to accommodate

composition variations of the base alloy.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contactASTM Customer Service at service@astm.org. ForAnnual Book ofASTM

Standards volume information, refer to the standard’s Document Summary page on Available from The American Welding Society (AWS), 550 NW LeJeune Rd.,

the ASTM website. Miami, FL 33126.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B467 – 88 (2003)

TABLE 1 Chemical Requirements

Composition, %

Copper Alloy

Manganese, Sulfur, Phosphorus, Other Named

A B C D D

UNS No Copper Nickel Lead, max Iron Zinc, max

max max max Elements

D

C70600 remainder 9.0–11.0 0.05 1.0–1.8 1.0 1.0 0.02 0.02

D

C71500 remainder 29.0–33.0 0.05 0.40–1.0 1.0 1.0 0.02 0.02

A

New designation established in accordance with Practice E527.

B

Silver counting as copper.

C

Cobalt counting as nickel.

D

When the product is for subsequent welding applications and so specified by the purchaser, zinc shall be 0.50 % max, lead 0.02 % max, and carbon 0.05 % max.

TABLE 2 Mechanical Requirements of As-Welded and Fully

5.3 Welded and Cold Drawn—Welded pipe with internal

Finished Pipe When Furnished in the Annealed Temper (WO61)

flash removed by scarfing, and subsequently cold drawn to

Yield

conform to the specified temper.

Copper Tensile Strength at Elongation

5.4 Fully Finished—Welded pipe with internal and external

Alloy Outside Diameter, Strength, 0.5 % Ex- in2in.

A

UNS in. (mm) min, ksi tension Under (50.8 mm),

flash removed by scarfing and the pipe or tube subsequently

B

No. (MPa ) Load, min, min, %

cold drawn over a mandrel and annealed as necessary to A B

ksi (MPa )

conform to the specified temper.

C70600 up to 4 ⁄2 (114), incl 40 (275) 15 (105) 25.0

over 4 ⁄2 (114) 38 (260) 13 (90) 25.0

6. Chemical Composition 1

C71500 up to 4 ⁄2 (114), incl 50 (345) 20 (140) 30.0

over 4 ⁄2 (114) 45 (310) 15 (105) 30.0

6.1 Thematerialshallconformtothechemicalrequirements

A

ksi = 1000 psi.

specified in Table 1.

B

See Appendix X2.

6.2 These specification limits do not preclude the presence

of other elements. Limits for unnamed elements may be

TABLE 3 Mechanical Requirements of Welded and Cold-Drawn

established by agreement between manufacturer or supplier

and Fully Finished Pipe in Drawn Tempers

and purchaser.

Yield

6.2.1 For copper alloys in which copper is specified as the

Strength at Elonga-

Tensile

Copper 0.5 % Ex- tion in

remainder, copper may be taken as the difference between the

Outside Diameter, Strength,

Alloy tension Un- 2in.

A

sum of all the elements analyzed and 100 %. in. (mm) min, ksi

UNS No. der Load, (50.8 mm),

B

(MPa )

A

6.2.1.1 When all the elements in Table 1 are analyzed, their

min, ksi min, %

B

(MPa )

sum shall be 99.5 % minimum.

C71500 up to 2 (50.8), incl, for 72 (495) 50 (345) 12.0

wall thicknesses up to

7. Flash

0.048 (1.21 mm), incl.

for wall thicknesses over 72 (495) 50 (345) 15.0

7.1 If the pipe is made by the high-frequency welding

0.048 in. (1.21 mm)

process, the external flash shall always be removed. The

A

ksi = 1000 psi.

internal flash shall be treated as one of the following:

B

See Appendix X2.

7.1.1 IFI—Internal flash to remain in the “as-welded”

condition,

TABLE 4 Mechanical Requirements of As-Welded Pipe

7.1.2 IFR—Internal flash to be removed by scarfing, or

Yield Strength

Tensile

7.1.3 IFD—Internal flash to be displaced.

Copper at 0.5 % Ex-

Outside Diam- Strength,

7.2 Unless otherwise specified, the IFI condition will be

Alloy UNS Condition tension Under

eter, in. (mm) min, ksi

No. Load, min, ksi

furnished.

(MPa)

(MPa)

C70600 welded from annealed up to 4 ⁄2 (114), 45 (310) 30 (205)

8. Filler Material

strip incl

welded from cold- up to 4 ⁄2 (114), 54 (375) 45 (310)

8.1 Filler material, if used in the welding process, shall

rolled strip incl

conform to classification ECuNi ofAWS SpecificationA5.6 or

RCuNi of AWS Specification A5.7.

9. Temper 9.1.5 Fully finished as annealed (WO61) light drawn (Cop-

per Alloy UNS No. C70600 only), or hard drawn, stress

9.1 The pipe shall be supplied in any one of the following

relieved (WH00, WH04).

tempers as specified and shall meet the mechanical require-

ments of Table 2, Table 3, and Table 4:

10. Dimensions and Permissible Variations

9.1.1 As welded from annealed sheet, strip, or plate

10.1 For purposes of determining conformance with the

(WM50),

dimensional requirements prescribed in this specification, any

9.1.2 As welded from cold-worked sheet, strip, or plate

measured value outside the specified limiting values for any

(WM00, WM01, WM02, etc.).

dimension may be cause for rejection.

9.1.3 Welded and annealed (WO50),

9.1.4 Welded and cold drawn in either light drawn (Copper

NOTE 1—Blank spaces in the tolerance tables indicate that the material

Alloy UNS No. C70600 only) or hard drawn, stress relieved

is not generally available or that no tolerance has been established (see

(WR00), (WR04), or Appendix X1).

B467 – 88 (2003)

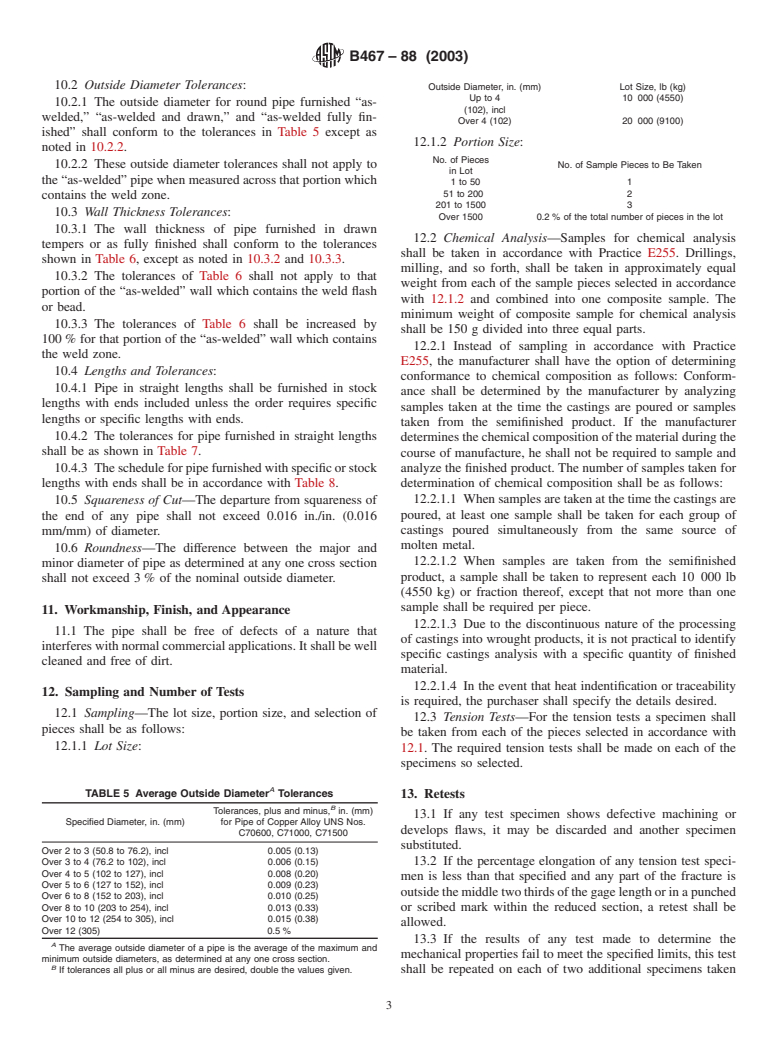

10.2 Outside Diameter Tolerances:

Outside Diameter, in. (mm) Lot Size, lb (kg)

Up to 4 10 000 (4550)

10.2.1 The outside diameter for round pipe furnished “as-

(102), incl

welded,” “as-welded and drawn,” and “as-welded fully fin-

Over 4 (102) 20 000 (9100)

ished” shall conform to the tolerances in Table 5 except as

12.1.2 Portion Size:

noted in 10.2.2.

No. of Pieces

10.2.2 These outside diameter tolerances shall not apply to No. of Sample Pieces to Be Taken

in Lot

the “as-welded” pipe when measured across that portion which

1to50 1

51 to 200 2

contains the weld zone.

201 to 1500 3

10.3 Wall Thickness Tolerances:

Over 1500 0.2 % of the total number of pieces in the lot

10.3.1 The wall thickness of pipe furnished in drawn

12.2 Chemical Analysis—Samples for chemical analysis

tempers or as fully finished shall conform to the tolerances

shall be taken in accordance with Practice E255. Drillings,

shown in Table 6, except as noted in 10.3.2 and 10.3.3.

milling, and so forth, shall be taken in approximately equal

10.3.2 The tolerances of Table 6 shall not apply to that

weight from each of the sample pieces selected in accordance

portion of the “as-welded” wall which contains the weld flash

with 12.1.2 and combined into one composite sample. The

or bead.

minimum weight of composite sample for chemical analysis

10.3.3 The tolerances of Table 6 shall be increased by

shall be 150 g divided into three equal parts.

100 % for that portion of the “as-welded” wall which contains

12.2.1 Instead of sampling in accordance with Practice

the weld zone.

E255, the manufacturer shall have the option of determining

10.4 Lengths and Tolerances:

conformance to chemical composition as follows: Conform-

10.4.1 Pipe in straight lengths shall be furnished in stock

ance shall be determined by the manufacturer by analyzing

lengths with ends included unless the order requires specific

samples taken at the time the castings are poured or samples

lengths or specific lengths with ends.

taken from the semifinished product. If the manufacturer

10.4.2 The tolerances for pipe furnished in straight lengths

determinesthechemicalcompositionofthematerialduringthe

shall be as shown in Table 7.

course of manufacture, he shall not be required to sample and

10.4.3 Thescheduleforpipefurnishedwithspecificorstock analyze the finished product. The number of samples taken for

lengths with ends shall be in accordance with Table 8. determination of chemical composition shall be as follows:

12.2.1.1 Whensamplesaretakenatthetimethecastingsare

10.5 Squareness of Cut—The departure from squareness of

poured, at least one sample shall be taken for each group of

the end of any pipe shall not exceed 0.016 in./in. (0.016

castings poured simultaneously from the same source of

mm/mm) of diameter.

molten metal.

10.6 Roundness—The difference between the major and

12.2.1.2 When samples are taken from the semifinished

minor diameter of pipe as determined at any one cross section

product, a sample shall be taken to represent each 10 000 lb

shall not exceed 3 % of the nominal outside diameter.

(4550 kg) or fraction thereof, except that not more than one

sample shall be required per piece.

11. Workmanship, Finish, and Appearance

12.2.1.3 Due to the discontinuous nature of the processing

11.1 The pipe shall be free of defects of a nature that

of castings into wrought products, it is not practical to identify

interfereswithnormalcommercialapplications.Itshallbewell

specific castings analysis with a specific quantity of finished

cleaned and free of dirt.

material.

12.2.1.4 In the event that heat indentification or traceability

12. Sampling and Number of Tests

is required, the purchaser shall specify the details desired.

12.1 Sampling—The lot size, portion size, and selection of

12.3 Tension Tests—For the tension tests a specimen shall

pieces shall be as follows:

be taken from each of the pieces selected in accordance with

12.1.1 Lot Size:

12.1. The required tension tests shall be made on each of the

specimens so selected.

A

TABLE 5 Average Outside Diameter Tolerances

13. Retests

B

Tolerances, plus and minus, in. (mm)

13.1 If any test specimen shows defective machining or

Specified Diameter, in. (mm) for Pipe of Copper Alloy UNS Nos.

develops flaws, it may be discarded and another specimen

C70600, C71000, C71500

substituted.

Over 2 to 3 (50.8 to 76.2), incl 0.005 (0.13)

Over 3 to 4 (76.2 to 102), incl 0.006 (0.15) 13.2 If the percentage elongation of any tension test speci-

Over 4 to 5 (102 to 127), incl 0.008 (0.20)

men is less than that specified and any part of the fracture is

Over 5 to 6 (127 to 152), incl 0.009 (0.23)

outsidethemiddletwothirdsofthegagelengthorinapunched

Over 6 to 8 (152 to 203), incl 0.010 (0.25)

Over 8 to 10 (203 to 254), incl 0.013 (0.33) or scribed mark within the reduced section, a retest shall be

Over 10 to 12 (254 to 305), incl 0.015 (0.38)

allowed.

Over 12 (305) 0.5 %

13.3 If the results of any test made to determine the

A

The average outside diameter of a pipe is the average of the maximum and

mechanical properties fail to meet the specified limits, this test

minimum outside diameters, as determined at any one cross section.

B

If tolerances all plus or all minus are desired, double the values given. shall be repeated on each of two additional specimens taken

B467 – 88 (2003)

TABLE 6 Wall Thickness Tolerances, in. (mm)

NOTE 1—Maximum Deviation at Any Point: The following tolerances are plus and minus; if tolerances all plus or all minus are desired, double the

values given.

Outside Diameter, in. (mm)

1 1 1 1 1 1 1 1

Up to 2 ⁄2 (63.5), Over 2 ⁄2 to 4 ⁄2 Over 4 ⁄2 to 6 ⁄2 Over 6 ⁄2 to9(165 Over 9 to 11 ⁄2 Over 11 ⁄2

incl (63.5 to 114), incl (114 to 165), incl to 230), incl (230 to 292), incl (292)

To 0.017 (0.43), incl 0.0013 . . . . .

(0.0033)

Over 0.017 to 0.021 (0.43 to 0.53),

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.