ASTM E2352-04(2010)

(Practice)Standard Practice for Aerospace Cleanrooms and Associated Controlled Environments-Cleanroom Operations

Standard Practice for Aerospace Cleanrooms and Associated Controlled Environments-Cleanroom Operations

ABSTRACT

This practice specifies the basic requirements, procedures, and practices for operating aerospace cleanrooms and controlled environments and the precautions associated with the facility and equipment used. This practice covers the requirements for operational systems, appropriate cleanroom clothing, authorized work personnel, stationary equipments, materials and mobile equipments, proper cleanroom operations, correct cleaning methods, and critical surfaces.

SCOPE

1.1 This practice specifies basic requirements, procedures, and practices for operating aerospace cleanrooms and controlled environments and precautions associated with the facility and equipment used.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E2352 − 04 (Reapproved 2010)

Standard Practice for

Aerospace Cleanrooms and Associated Controlled

Environments—Cleanroom Operations

This standard is issued under the fixed designation E2352; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E1731 Test Method for Gravimetric Determination of Non-

volatile Residue from Cleanroom Gloves

1.1 This practice specifies basic requirements, procedures,

E2042 Practice for Cleaning and Maintaining Controlled

and practices for operating aerospace cleanrooms and con-

Areas and Clean Rooms

trolled environments and precautions associated with the

E2088 Practice for Selecting, Preparing, Exposing, andAna-

facility and equipment used.

lyzing Witness Surfaces for Measuring Particle Deposi-

1.2 This standard does not purport to address all of the

tion in Cleanrooms and Associated Controlled Environ-

safety concerns, if any, associated with its use. It is the

ments

responsibility of the user of this standard to establish appro-

E2217 Practice for Design and Construction of Aerospace

priate safety and health practices and determine the applica-

Cleanrooms and Contamination Controlled Areas

bility of regulatory limitations prior to use.

F25 Test Method for Sizing and CountingAirborne Particu-

late Contamination in Cleanrooms and Other Dust-

2. Referenced Documents

Controlled Areas

2.1 ASTM Standards:

F50 Practice for Continuous Sizing and Counting of Air-

D737 Test Method for Air Permeability of Textile Fabrics

borne Particles in Dust-Controlled Areas and Clean

E595 Test Method for Total Mass Loss and Collected Vola-

Rooms Using Instruments Capable of Detecting Single

tile Condensable Materials from Outgassing in a Vacuum

Sub-Micrometre and Larger Particles

Environment

F51 Test Method for Sizing and Counting Particulate Con-

E1216 Practice for Sampling for Particulate Contamination

taminant In and On Clean Room Garments

by Tape Lift

F318 Practice for Sampling Airborne Particulate Contami-

E1234 Practice for Handling, Transporting, and Installing

nation in Cleanrooms for Handling Aerospace Fluids

Nonvolatile Residue (NVR) Sample Plates Used in Envi-

2.2 Government Standards:

ronmentally Controlled Areas for Spacecraft

Federal Standard 209E Airborne Particulate Cleanliness

E1235 Test Method for Gravimetric Determination of Non-

Classes in Cleanroom and Clean Zones (cancelled Nov.

volatile Residue (NVR) in Environmentally Controlled

29, 2001)

Areas for Spacecraft

NASA-STD-6001, Test #7 Flammability, Odor, Offgassing

E1549 Specification for ESD Controlled Garments Required

and Compatibility Requirements and Test Procedures for

in Cleanrooms and Controlled Environments for Space-

Materials in Environments That Support Combustion

craft for Non-Hazardous and Hazardous Operations

2.3 Other Technical Society Standards:

E1559 Test Method for Contamination Outgassing Charac-

IEST-RP-CC003 Garments Required in Cleanrooms and

teristics of Spacecraft Materials

Controlled Environments

E1560 Test Method for Gravimetric Determination of Non-

IEST-RP-CC004 Evaluating Wiping Materials Used in

volatile Residue From Cleanroom Wipers

Cleanrooms and Other Controlled Environments

IEST-RP-CC005 Cleanroom Gloves and Finger Cots

IEST-RP-CC018 Cleanroom Housekeeping—Operating and

This practice is under the jurisdiction of ASTM Committee E21 on Space

Monitoring Procedures

Simulation andApplications of Space Technology and is the direct responsibility of

Subcommittee E21.05 on Contamination.

Current edition approved April 1, 2010. Published May 2010. Originally

approved in 2004. Last previous edition approved in 2004 as E2352 – 04. DOI:

10.1520/E2352-04R10. AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments,

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from Institute of Environmental Sciences and Technology (IEST),

Standards volume information, refer to the standard’s Document Summary page on Arlington Place One, 2340 S.Arlington Heights Rd., Suite 100,Arlington Heights,

the ASTM website. IL 60005-4516, http://www.iest.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E2352 − 04 (2010)

IEST-RP-CC020 Substrates and Forms for Documentation 3.1.1 airlock—intermediate room or area that is normally

in Cleanrooms ventilated and used to minimize the transfer of airborne

IEST-RP-CC022 Electrostatic Charge in Cleanrooms and contamination from one area to another. The airlock is main-

Other Controlled Environments tained at a lower air pressure than the cleanroom and a higher

IEST-RP-CC026 Cleanroom Operations pressure than the outside area.

IEST-RP-CC027 Personnel Practices and Procedures in

3.1.2 changing room—room where people using a clean-

Cleanrooms and Controlled Environments

room may change into or out of cleanroom clothing.

IEST-RP-CC0016 Recommended Practice for the Rate of

4 3.1.3 cross-over bench—bench that is used as an aid to

Deposition of Nonvolatile Residue in Cleanrooms

changingofcleanroomclothingandwhichprovidesabarrierto

JIS B9923 Methods for Sizing and Counting Particle Con-

5 the tracking of floor contamination.

taminants in and on Clean Room Garments

3.1.4 fiber—particlehavinganaspect(length-to-width)ratio

JIS B9926 Test Methods for Dust Generation from Moving

Mechanisms of 10 or more.

JACA Number 14C Guidance for Operation of Clean

3.1.5 non-unidirectional airflow—air distribution where the

Rooms

supply air entering the room mixes with the internal air by

2.4 International Standards:

means of induction.

ISO 14644-1 Cleanrooms and Associated Controlled

3.1.5.1 Discussion—This type of air distribution results in

Environments—Part 1: Classification of Air Cleanliness

dilution of the particle concentration.

ISO 14644-2 Cleanrooms and Associated Controlled

3.1.6 operational—condition where the installation is func-

Environments—Part 2: Specifications for Testing and

tioning in the specified manner, with the personnel present and

Monitoring to Prove Continued Compliance with ISO

7 working in the manner agreed upon.

14644-1

ISO 14644-3 Cleanrooms and Associated Controlled 3.1.7 operator—person working in the cleanroom perform-

Environments—Part 3: Metrology and Test Methods ing production work or carrying out process procedures.

ISO 14644-4 Cleanrooms and Associated Controlled

3.1.8 particle—small piece of matter with defined physical

Environments—Part 4: Design, Construction, and Start-

boundaries.

up

3.1.9 personnel—persons entering the cleanroom for any

ISO/AWI 14644-6 Cleanrooms and Associated Controlled

7 purpose, but typically operators.

Environments—Part 6: Terms and Definitions

ISO 14644-7 Cleanrooms and Controlled Environments— 3.1.10 stationary equipment—large equipment that cannot

be easily moved.

Part 7: Separative Devices

ISO 7730 Moderate Thermal Environments—Determination

3.1.11 unidirectional airflow—air flow which has a singular

of the PMV and PPD Indices and Specification of the

direction of flow and may or may not contain uniform

Conditions for Thermal Comfort

velocities of air flow along parallel lines. Formerly known as

ISO 9237 Textiles—Determination of Permeability of Fab-

laminar airflow.

rics to Air

ISO 11092 Textiles—Physiological Effects—Measurement

4. Requirements

of Thermal and Water-Vapour Resistance Under Steady-

4.1 Operational Systems:

State Conditions (Sweating Guarded-Hotplate Test)

4.1.1 General—The air cleanliness class required shall be

EN 1149-1 (1994) Protective Clothing—Electrostatic

determined before the facility is certified or used initially.

Properties—Part 1 Surface Resistivity (Test Methods and

Operations may be performed in a controlled area if the

Requirements)

products are not sensitive to contamination, or if they will be

CEI IIEC 1025:1990 Fault Tree Analysis (FTA)

cleanedadequatelyduringlatersteps.Normallyoperationswill

CEI IIEC 812:1985 Analysis Techniques for System

be performed in a cleanroom of at least class 8 or cleaner per

Reliability—Procedure for Failure Mode and Effective

ISO 14644-1 (class 100 000 or cleaner per FED-STD-209E).

Analysis (FMEA)

4.1.2 A set of risk factors, appropriate for the use of the

3. Terminology

specificcleanroom,shallidentifytheareaswherethereisarisk

ofcontaminationtotheprocess.Impropercontrolofthecritical

3.1 Definitions:

elements of an operational cleanroom can pose a risk to the

5 cleanliness of the cleanroom and the quality of the product. A

AvailablefromJapanIndustrialStandards(JIS),1-3-1Kasumigaseki,Chiyoda-

ku, Tokyo, 100-8901, Japan.

risk assessment must be done and plans formulated to remedy

Available from Japan Air Cleaning Association (JACA), Tomoe-Ya Building

out-of-control situations. A method for monitoring these risks

No. 2-14, 1-Chome, Uchi-Kanda, Chiyoda-ku, Tokyo, 101, Japan.

shall be instituted so that action can be taken when conditions

Available from International Organization for Standardization (ISO), 1, ch. de

are outside of specifications. The following list identifies some

la Voie-Creuse, Case postale 56, CH-1211, Geneva 20, Switzerland, http://

www.iso.ch.

of the risks that may prove important. Cleanroom parameters

Available from European Committee for Standardization (CEN), 36 rue de

including heating, ventilation and air conditioning, pressure

Stassart, B-1050, Brussels, Belgium, http://www.cenorm.be.

differential, temperature, humidity, air change rates, and filters,

International Electrotechnical Commission, Case postale 131, 1211 Geneva 20,

Switzerland. are discussed in ISO 14644-2, ISO 14644-3, and ISO 14644-4.

E2352 − 04 (2010)

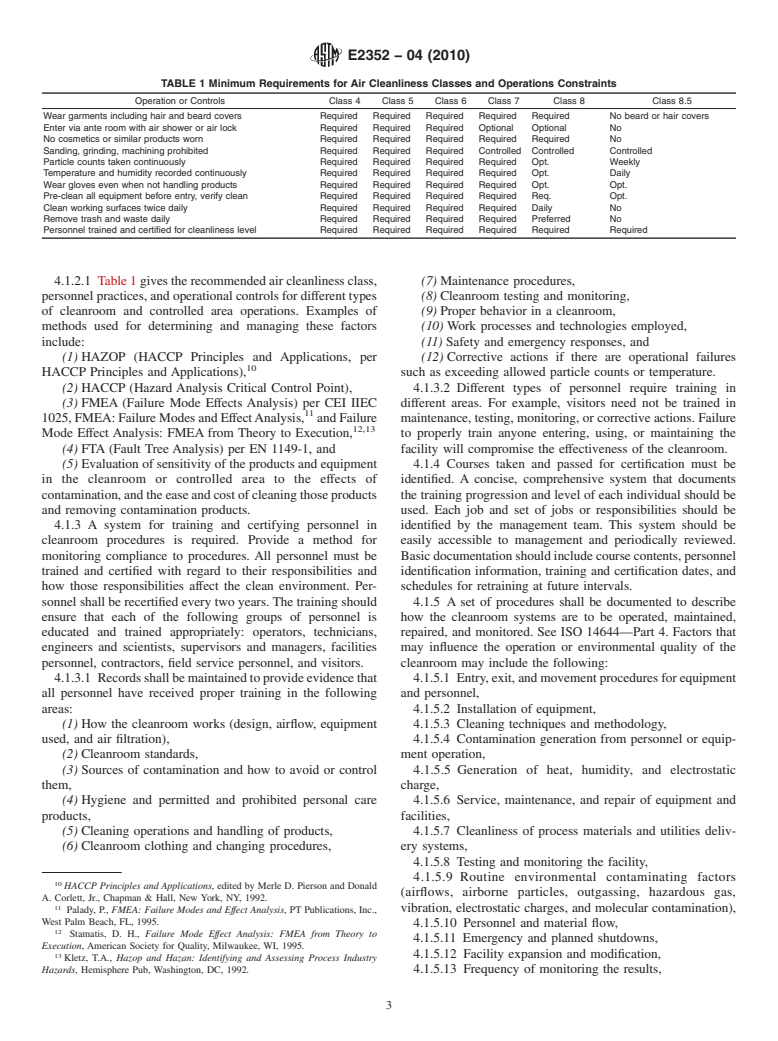

TABLE 1 Minimum Requirements for Air Cleanliness Classes and Operations Constraints

Operation or Controls Class 4 Class 5 Class 6 Class 7 Class 8 Class 8.5

Wear garments including hair and beard covers Required Required Required Required Required No beard or hair covers

Enter via ante room with air shower or air lock Required Required Required Optional Optional No

No cosmetics or similar products worn Required Required Required Required Required No

Sanding, grinding, machining prohibited Required Required Required Controlled Controlled Controlled

Particle counts taken continuously Required Required Required Required Opt. Weekly

Temperature and humidity recorded continuously Required Required Required Required Opt. Daily

Wear gloves even when not handling products Required Required Required Required Opt. Opt.

Pre-clean all equipment before entry, verify clean Required Required Required Required Req. Opt.

Clean working surfaces twice daily Required Required Required Required Daily No

Remove trash and waste daily Required Required Required Required Preferred No

Personnel trained and certified for cleanliness level Required Required Required Required Required Required

4.1.2.1 Table1givestherecommendedaircleanlinessclass, (7) Maintenance procedures,

personnelpractices,andoperationalcontrolsfordifferenttypes (8) Cleanroom testing and monitoring,

of cleanroom and controlled area operations. Examples of (9) Proper behavior in a cleanroom,

methods used for determining and managing these factors (10) Work processes and technologies employed,

include: (11) Safety and emergency responses, and

(1) HAZOP (HACCP Principles and Applications, per (12) Corrective actions if there are operational failures

HACCP Principles and Applications), such as exceeding allowed particle counts or temperature.

(2) HACCP (Hazard Analysis Critical Control Point), 4.1.3.2 Different types of personnel require training in

(3) FMEA (Failure Mode Effects Analysis) per CEI IIEC different areas. For example, visitors need not be trained in

1025,FMEA:FailureModesandEffectAnalysis, andFailure maintenance, testing, monitoring, or corrective actions. Failure

12,13

Mode Effect Analysis: FMEA from Theory to Execution, to properly train anyone entering, using, or maintaining the

(4) FTA (Fault Tree Analysis) per EN 1149-1, and facility will compromise the effectiveness of the cleanroom.

(5) Evaluation of sensitivity of the products and equipment 4.1.4 Courses taken and passed for certification must be

in the cleanroom or controlled area to the effects of identified. A concise, comprehensive system that documents

contamination,andtheeaseandcostofcleaningthoseproducts the training progression and level of each individual should be

and removing contamination products. used. Each job and set of jobs or responsibilities should be

4.1.3 A system for training and certifying personnel in identified by the management team. This system should be

cleanroom procedures is required. Provide a method for easily accessible to management and periodically reviewed.

monitoring compliance to procedures. All personnel must be Basicdocumentationshouldincludecoursecontents,personnel

trained and certified with regard to their responsibilities and identification information, training and certification dates, and

how those responsibilities affect the clean environment. Per- schedules for retraining at future intervals.

sonnel shall be recertified every two years.The training should 4.1.5 A set of procedures shall be documented to describe

ensure that each of the following groups of personnel is how the cleanroom systems are to be operated, maintained,

educated and trained appropriately: operators, technicians, repaired, and monitored. See ISO 14644—Part 4. Factors that

engineers and scientists, supervisors and managers, facilities may influence the operation or environmental quality of the

personnel, contractors, field service personnel, and visitors. cleanroom may include the following:

4.1.3.1 Recordsshallbemaintainedtoprovideevidencethat 4.1.5.1 Entry,exit,andmovementproceduresforequipment

all personnel have received proper training in the following and personnel,

areas: 4.1.5.2 Installation of equipment,

(1) How the cleanroom works (design, airflow, equipment 4.1.5.3 Cleaning techniques and methodology,

used, and air filtration), 4.1.5.4 Contamination generation from personnel or equip-

(2) Cleanroom standards, ment operation,

(3) Sources of contamination and how to avoid or control 4.1.5.5 Generation of heat, humidity, and electrostatic

them, charge,

(4) Hygiene and permitted and prohibited personal care 4.1.5.6 Service, maintenance, and repair of equipment and

products, facilities,

(5) Cleaning op

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.