ASTM E1441-00(2005)

(Guide)Standard Guide for Computed Tomography (CT) Imaging

Standard Guide for Computed Tomography (CT) Imaging

SCOPE

1.1 Computed tomography (CT) is a radiographic method that provides an ideal examination technique whenever the primary goal is to locate and size planar and volumetric detail in three dimensions. Because of the relatively good penetrability of X-rays, as well as the sensitivity of absorption cross sections to atomic chemistry, CT permits the nondestructive physical and, to a limited extent, chemical characterization of the internal structure of materials. Also, since the method is X-ray based, it applies equally well to metallic and non-metallic specimens, solid and fibrous materials, and smooth and irregularly surfaced objects. When used in conjunction with other nondestructive evaluation (NDE) methods, such as ultrasound, CT data can provide evaluations of material integrity that cannot currently be provided nondestructively by any other means.

1.2 This guide is intended to satisfy two general needs for users of industrial CT equipment: (1) the need for a tutorial guide addressing the general principles of X-ray CT as they apply to industrial imaging; and (2) the need for a consistent set of CT performance parameter definitions, including how these performance parameters relate to CT system specifications. Potential users and buyers, as well as experienced CT inspectors, will find this guide a useful source of information for determining the suitability of CT for particular examination problems, for predicting CT system performance in new situations, and for developing and prescribing new scan procedures.

1.3 This guide does not specify test objects and test procedures for comparing the relative performance of different CT systems; nor does it treat CT inspection techniques, such as the best selection of scan parameters, the preferred implementation of scan procedures, the analysis of image data to extract densitometric information, or the establishment of accept/reject criteria for a new object.

1.4 Standard practices and methods are not within the purview of this guide. The reader is advised, however, that examination practices are generally part and application specific, and industrial CT usage is new enough that in many instances a consensus has not yet emerged. The situation is complicated further by the fact that CT system hardware and performance capabilities are still undergoing significant evolution and improvement. Consequently, an attempt to address generic examination procedures is eschewed in favor of providing a thorough treatment of the principles by which examination methods can be developed or existing ones revised.

1.5 The principal advantage of CT is that it nondestructively provides quantitative densitometric (that is, density and geometry) images of thin cross sections through an object. Because of the absence of structural noise from detail outside the thin plane of inspection, images are much easier to interpret than conventional radiographic data. The new user can learn quickly (often upon first exposure to the technology) to read CT data because the images correspond more closely to the way the human mind visualizes three-dimensional structures than conventional projection radiography. Further, because CT images are digital, they may be enhanced, analyzed, compressed, archived, input as data into performance calculations, compared with digital data from other NDE modalities, or transmitted to other locations for remote viewing. Additionally, CT images exhibit enhanced contrast discrimination over compact areas larger than 20 to 25 pixels. This capability has no classical analog. Contrast discrimination of better than 0.1 % at three-sigma confidence levels over areas as small as one-fifth of one percent the size of the object of interest are common.

1.6 With proper calibration, dimensional inspections and absolute density determinations can also be made very accurately. Dimensionally, virtually all CT systems provide a pixel resolution of roughly 1 part in 1000 (since, at presen...

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E1441 – 00 (Reapproved 2005)

Standard Guide for

Computed Tomography (CT) Imaging

This standard is issued under the fixed designation E1441; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope examination practices are generally part and application spe-

cific, and industrial CT usage is new enough that in many

1.1 Computed tomography (CT) is a radiographic method

instances a consensus has not yet emerged. The situation is

that provides an ideal examination technique whenever the

complicated further by the fact that CT system hardware and

primary goal is to locate and size planar and volumetric detail

performance capabilities are still undergoing significant evo-

in three dimensions. Because of the relatively good penetra-

lution and improvement. Consequently, an attempt to address

bility of X-rays, as well as the sensitivity of absorption cross

generic examination procedures is eschewed in favor of

sections to atomic chemistry, CT permits the nondestructive

providing a thorough treatment of the principles by which

physical and, to a limited extent, chemical characterization of

examination methods can be developed or existing ones

the internal structure of materials. Also, since the method is

revised.

X-ray based, it applies equally well to metallic and non-

1.5 TheprincipaladvantageofCTisthatitnondestructively

metallic specimens, solid and fibrous materials, and smooth

provides quantitative densitometric (that is, density and geom-

and irregularly surfaced objects. When used in conjunction

etry) images of thin cross sections through an object. Because

with other nondestructive evaluation (NDE) methods, such as

of the absence of structural noise from detail outside the thin

ultrasound, CT data can provide evaluations of material integ-

plane of inspection, images are much easier to interpret than

rity that cannot currently be provided nondestructively by any

conventionalradiographicdata.Thenewusercanlearnquickly

other means.

(often upon first exposure to the technology) to read CT data

1.2 This guide is intended to satisfy two general needs for

because the images correspond more closely to the way the

users of industrial CT equipment: (1) the need for a tutorial

human mind visualizes three-dimensional structures than con-

guide addressing the general principles of X-ray CT as they

ventional projection radiography. Further, because CT images

applytoindustrialimaging;and(2)theneedforaconsistentset

are digital, they may be enhanced, analyzed, compressed,

of CT performance parameter definitions, including how these

archived, input as data into performance calculations, com-

performance parameters relate to CT system specifications.

pared with digital data from other NDE modalities, or trans-

Potential users and buyers, as well as experienced CT inspec-

mitted to other locations for remote viewing.Additionally, CT

tors, will find this guide a useful source of information for

images exhibit enhanced contrast discrimination over compact

determining the suitability of CT for particular examination

areas larger than 20 to 25 pixels. This capability has no

problems, for predicting CT system performance in new

classicalanalog.Contrastdiscriminationofbetterthan0.1%at

situations, and for developing and prescribing new scan pro-

three-sigma confidence levels over areas as small as one-fifth

cedures.

of one percent the size of the object of interest are common.

1.3 This guide does not specify test objects and test proce-

1.6 With proper calibration, dimensional inspections and

dures for comparing the relative performance of different CT

absolute density determinations can also be made very accu-

systems;nordoesittreatCTinspectiontechniques,suchasthe

rately. Dimensionally, virtually all CT systems provide a pixel

bestselectionofscanparameters,thepreferredimplementation

resolution of roughly 1 part in 1000 (since, at present,

of scan procedures, the analysis of image data to extract

1024 31024 images are the norm), and metrological algo-

densitometricinformation,ortheestablishmentofaccept/reject

rithms can often measure dimensions to one-tenth of one pixel

criteria for a new object.

or so with three-sigma accuracies. For small objects (less than

1.4 Standard practices and methods are not within the

4 in. in diameter), this translates into accuracies of approxi-

purview of this guide. The reader is advised, however, that

mately 0.1 mm (0.003 to 0.005 in.) at three-sigma. For much

larger objects, the corresponding figure will be proportionally

This guide is under the jurisdiction ofASTM Committee E07 on Nondestruc-

greater. Attenuation values can also be related accurately to

tive Testing and is the direct responsibility of Subcommittee E07.01 on Radiology

material densities. If details in the image are known to be pure

(X and Gamma) Method.

homogeneous elements, the density values may still be suffi-

Current edition approved Dec. 1, 2005. Published February 2006. Originally

approved in 1991. Last previous edition approved in 2000 as E1441-00. DOI:

cient to identify materials in some cases. For the case in which

10.1520/E1441-00R05.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E1441 – 00 (2005)

no a priori information is available, CT densities cannot be graphic screening. One partial response to this problem is to

used to identify unknown materials unambiguously, since an use large slice thicknesses. This leads to reduced axial resolu-

infinite spectrum of compounds can be envisioned that will tion and can introduce partial volume artifacts in some cases;

yield any given observed attenuation. In this instance, the however, this is an acceptable tradeoff in many instances. In

exceptional density sensitivity of CT can still be used to principle, this drawback can be eliminated by resorting to full

determine part morphology and highlight structural irregulari- volumetric scans. However, since CT is to a large extent

ties. technology driven, volumetric CT systems are currently lim-

ited in the size of object that can be examined and the contrast

1.7 In some cases, dual energy (DE) CT scans can help

of features that can be discriminated.

identify unknown components. DE scans provide accurate

1.11 Complete part examinations demand large storage

electron density and atomic number images, providing better

capabilities or advanced display techniques, or both, and

characterizations of the materials. In the case of known

equipmenttohelptheoperatorreviewthehugevolumeofdata

materials, the additional information can be traded for im-

generated. This can be compensated for by state-of-the-art

proved conspicuity, faster scans, or improved characterization.

graphics hardware and automatic examination software to aid

In the case of unknown materials, the additional information

the user. However, automated accept/reject software is object

often allows educated guesses on the probable composition of

dependent and to date has been developed and employed in

an object to be made.

only a limited number of cases.

1.8 As with any modality, CT has its limitations. The most

1.12 The values stated in SI units are to be regarded as the

fundamental is that candidate objects for examination must be

standard. The values given in brackets are provided for

small enough to be accommodated by the handling system of

information only.

the CT equipment available to the user and radiometrically

1.13 This standard does not purport to address all of the

translucent at the X-ray energies employed by that particular

safety concerns, if any, associated with its use. It is the

system. Further, CT reconstruction algorithms require that a

responsibility of the user of this standard to establish appro-

full180degreesofdatabecollectedbythescanner.Objectsize

priate safety and health practices and determine the applica-

or opacity limits the amount of data that can be taken in some

bility of regulatory limitations prior to use.

instances. While there are methods to compensate for incom-

plete data which produce diagnostically useful images, the

2. Referenced Documents

resultant images are necessarily inferior to images from com-

2.1 ASTM Standards:

plete data sets. For this reason, complete data sets and

E1316 Terminology for Nondestructive Examinations

radiometrictransparencyshouldbethoughtofasrequirements.

E1570 Practice for Computed Tomographic (CT) Examina-

Current CT technology can accommodate attenuation ranges

tion

(peak-to-lowest-signal ratio) of approximately four orders of

magnitude. This information, in conjunction with an estimate

3. Terminology

of the worst-case chord through a new object and a knowledge

3.1 Definitions—CT, being a radiographic modality, uses

oftheaverageenergyoftheX-rayflux,canbeusedtomakean

much the same vocabulary as other X-ray techniques. A

educatedguessonthefeasibilityofscanningapartthathasnot

number of terms are not referenced, or are referenced without

been examined previously.

discussion, in Terminology E1316. Because they have mean-

1.9 Another potential drawback with CT imaging is the

ings or carry implications unique to CT, they appear with

possibility of artifacts in the data. As used here, an artifact is

explanation in Appendix X1. Throughout this guide, the term

anything in the image that does not accurately reflect true

“X-ray” is used to denote penetrating electromagnetic radia-

structure in the part being inspected. Because they are not real,

tion; however, electromagnetic radiation may be either X-rays

artifactslimittheuser’sabilitytoquantitativelyextractdensity,

or gamma rays.

dimensional, or other data from an image. Therefore, as with

3.2 Acronyms:Acronyms:

any technique, the user must learn to recognize and be able to

3.2.1 BW—beam width.

discount common artifacts subjectively. Some image artifacts

3.2.2 CDD—contrast-detail-dose.

canbereducedoreliminatedwithCTbyimprovedengineering

3.2.3 CT—computed tomography.

practice; others are inherent in the methodology. Examples of

3.2.4 CAT—computerized axial tomography.

the former include scattered radiation and electronic noise.

3.2.5 DR—digital radiography.

Examples of the latter include edge streaks and partial volume

3.2.6 ERF—edge response function.

effects. Some artifacts are a little of both. A good example is

3.2.7 LSF—line spread function.

the cupping artifact, which is due as much to radiation scatter

3.2.8 MTF—modulation transfer function.

(which can in principle be largely eliminated) as to the

3.2.9 NDE—nondestructive evaluation.

polychromaticityoftheX-rayflux(whichisinherentintheuse

3.2.10 PDF—probability distribution function.

of bremsstrahlung sources).

3.2.11 PSF—point spread function.

1.10 Because CT scan times are typically on the order of

minutes per image, complete three-dimensional CT examina-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

tions can be time consuming. Thus, less than 100% CT

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

examinationsareoftennecessaryormustbeaccommodatedby

Standards volume information, refer to the standard’s Document Summary page on

complementing the inspection process with digital radio- the ASTM website.

E1441 – 00 (2005)

4. Summary of Guide number and density of the absorbing medium; the Compton

scatteringispredominantlyafunctionoftheelectrondensityof

4.1 This guide provides a tutorial introduction to the tech-

the material. Photoelectric attenuation dominates at lower

nology and terminology of CT. It deals extensively with the

energies and becomes more important with higher atomic

physical and mathematical basis of CT, discusses the basic

number, while Compton scattering dominates at higher ener-

hardware configuration of all CT systems, defines a compre-

gies and becomes more important at lower atomic number. In

hensive set of fundamental CT performance parameters, and

specialsituations,thesedependenciescanbeusedtoadvantage

presents a useful method of characterizing and predicting

(see 7.6.2 and references therein).

system performance.Also, extensive descriptions of terms and

5.2.1 One particularly important property of the total linear

references to publications relevant to the subject are provided.

attenuation coefficient is that it is proportional to material

4.2 This guide is divided into three main sections. Sections

density, which is of course a fundamental physical property of

5 and 6 provide an overview of CT: defining the process,

all matter. The fact that CT images are proportional to density

discussing the performance characteristics of CT systems, and

isperhapstheprincipalvirtueofthetechnologyandthereason

describing the basic elements of all CT systems. Section 8

that image data are often thought of as representing the

addresses the physical and mathematical basis of CT imaging.

distribution of material density within the object being in-

Section 8 addresses in more detail a number of important

spected. This is a dangerous oversimplification, however. The

performance parameters as well as their characterization and

linearattenuationcoefficientalsocarriesanenergydependence

verification. This section is more technical than the other

that is a function of material composition. This feature of the

sections, but it is probably the most important of all. It

attenuation coefficient may or may not (depending on the

establishes a single, unified set of performance definitions and

materials and the energies of the X-rays involved) be more

relates them to more basic system parameters with a few

important than the basic density dependence. In some in-

carefully selected mathematical formulae.

stances, this effect can be detrimental, masking the density

5. Significance and Use differences in a CT image; in other instances, it can be used to

advantage, enhancing the contrast between different materials

5.1 This guide provides a tutorial introduction to the theory

of similar density.

and use of computed tomography. This guide begins with a

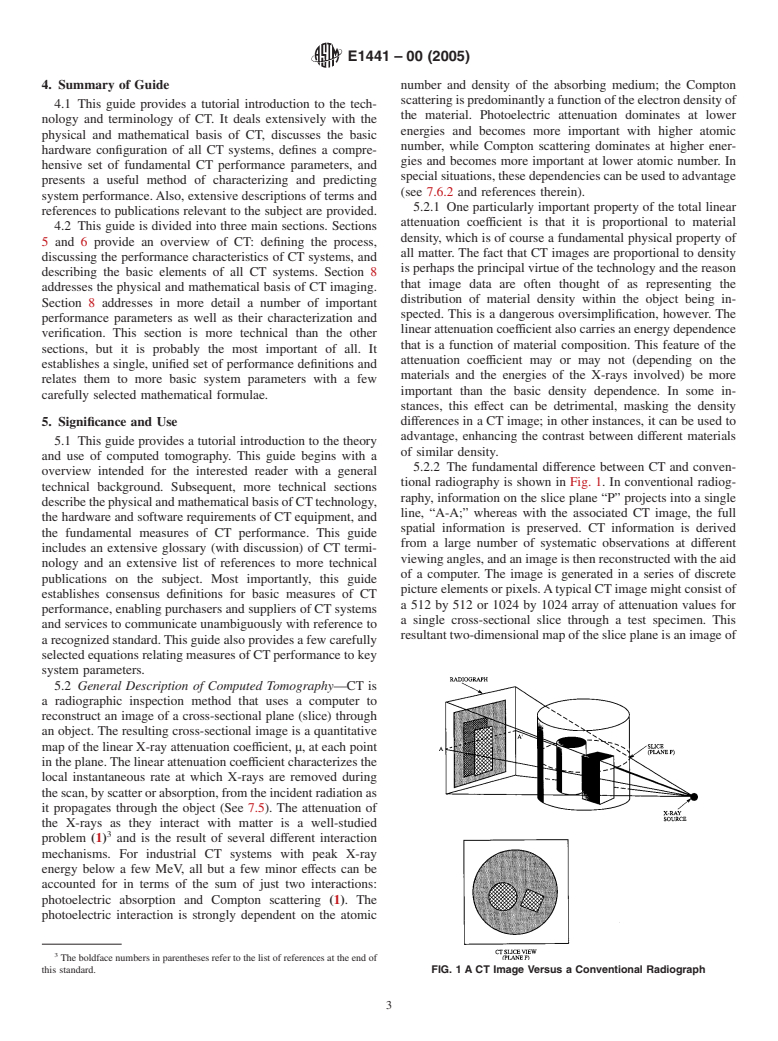

5.2.2 The fundamental difference between CT and conven-

overview intended for the interested reader with a general

tional radiography is shown in Fig. 1. In conventional radiog-

technical background. Subsequent, more technical sections

raphy, information on the slice plane “P” projects into a single

describethephysicalandmathematicalbasisofCTtechnology,

line, “A-A;”

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.