ASTM D1193-06(2011)

(Specification)Standard Specification for Reagent Water

Standard Specification for Reagent Water

ABSTRACT

This specification describes the required characteristics of reagent waters. Four types of waters have been specified, with three additional grades that can be applied to the four types. The grade specifications specifically address contaminants of microbiological origin. Historically, reagent water types I, II, III, and IV have been linked to specific processes for their production. Starting with this revision, these types of waters may be produced with alternate technologies as long as the appropriate constituent specifications are met. The electrical conductivity and resistance, pH, silica, sodium, chlorides, TOC, endotoxins, and microbiological contamination shall be tested to meet the requirements prescribed.

SCOPE

1.1 This specification describes the required characteristics of waters deemed suitable for use with the Standards under the jurisdiction of ASTM.

1.2 The alphanumeric characters ascribed to water types and grades are specified in the ASTM Format and Style Manual. These have been assigned in order of historical precedence and should not be taken as an indication of a progression in water purity.

1.3 Four types of waters have been specified, with three additional grades that can be applied to the four types. The grade specifications specifically address contaminants of microbiological origin.

1.4 All applicable ASTM Standards are expected to reference one or more of these reagent water types where reagent water is needed as a component of an analytical measurement process. Where a different water type or grade is needed for an ASTM Standard, it may be added to this Specification through the ASTM Standard revision process.

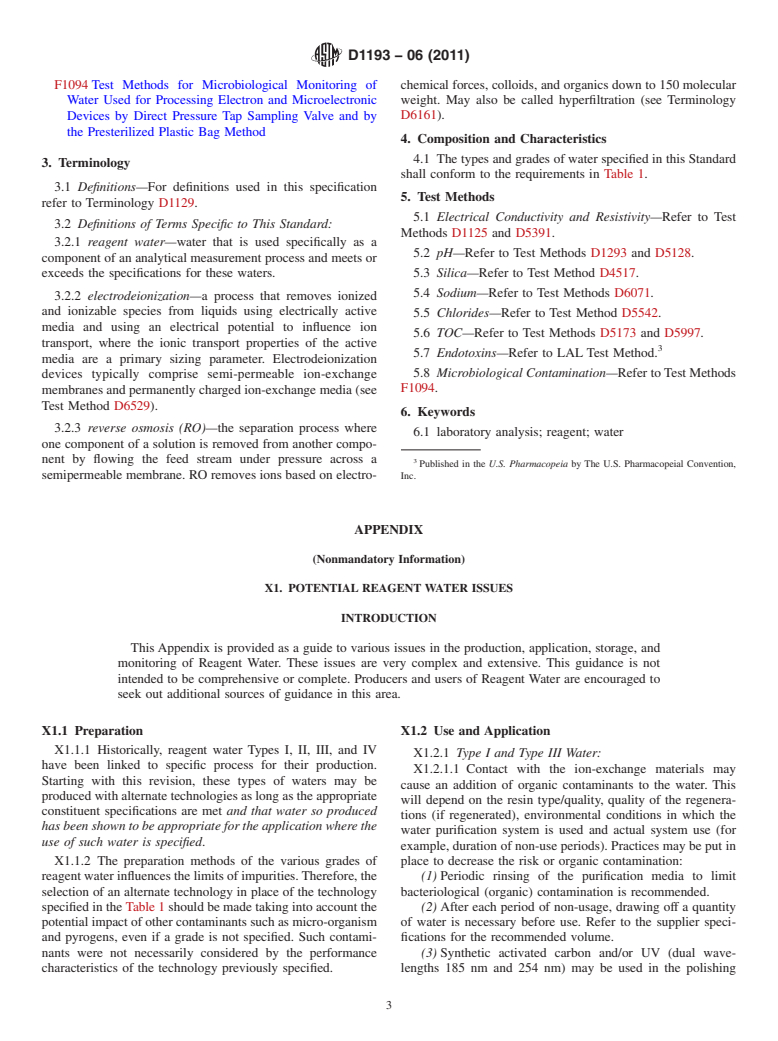

1.5 Although these water types and associated grades have been defined specifically for use with ASTM Standards, they may be appropriate for other applications. It is the responsibility of the users of this standard to ensure that the selected water types or grades are suitable for their intended use. Historically, reagent water Types I, II, III, and IV have been linked to specific processes for their production. Starting with this revision, these types of waters may be produced with alternate technologies as long as the appropriate constituent specifications are met and that water so produced has been shown to be appropriate for the application where the use of such water is specified. Therefore, the selection of an alternate technology in place of the technology specified in Table 1 should be made taking into account the potential impact of other contaminants such as microorganism and pyrogens. Such contaminants were not necessarily considered by the performance characteristics of the technology previously specified.

1.6 Guidance for applications, the preparation, use and monitoring, storage, handling, distribution, testing of these specified waters and validation of the water purification system is provided in Appendix X1 of this document.

1.7 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D1193 −06 (Reapproved 2011) Federal Test Method

Standard No. 7916

Standard Specification for

Reagent Water

This standard is issued under the fixed designation D1193; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope contaminants were not necessarily considered by the perfor-

mance characteristics of the technology previously specified.

1.1 This specification describes the required characteristics

of waters deemed suitable for use with the Standards under the 1.6 Guidance for applications, the preparation, use and

jurisdiction of ASTM. monitoring, storage, handling, distribution, testing of these

specified waters and validation of the water purification system

1.2 Thealphanumericcharactersascribedtowatertypesand

is provided in Appendix X1 of this document.

grades are specified in the ASTM Format and Style Manual.

These have been assigned in order of historical precedence and 1.7 The values stated in SI units are to be regarded as

should not be taken as an indication of a progression in water standard. No other units of measurement are included in this

purity. standard.

1.8 This standard does not purport to address all of the

1.3 Four types of waters have been specified, with three

safety concerns, if any, associated with its use. It is the

additional grades that can be applied to the four types. The

responsibility of the user of this standard to establish appro-

grade specifications specifically address contaminants of mi-

priate safety, health, and environmental practices and deter-

crobiological origin.

mine the applicability of regulatory limitations prior to use.

1.4 All applicable ASTM Standards are expected to refer-

1.9 This international standard was developed in accor-

ence one or more of these reagent water types where reagent

dance with internationally recognized principles on standard-

water is needed as a component of an analytical measurement

ization established in the Decision on Principles for the

process. Where a different water type or grade is needed for an

Development of International Standards, Guides and Recom-

ASTM Standard, it may be added to this Specification through

mendations issued by the World Trade Organization Technical

the ASTM Standard revision process.

Barriers to Trade (TBT) Committee.

1.5 Although these water types and associated grades have

been defined specifically for use with ASTM Standards, they

2. Referenced Documents

may be appropriate for other applications. It is the responsi-

2.1 ASTM Standards:

bility of the users of this standard to ensure that the selected

D1125 Test Methods for Electrical Conductivity and Resis-

water types or grades are suitable for their intended use.

tivity of Water

Historically, reagent water Types I, II, III, and IV have been

D1129 Terminology Relating to Water

linked to specific processes for their production. Starting with

D1293 Test Methods for pH of Water

this revision, these types of waters may be produced with

D4453 Practice for Handling of High Purity Water Samples

alternate technologies as long as the appropriate constituent

D4517 Test Method for Low-Level Total Silica in High-

specifications are met and that water so produced has been

Purity Water by Flameless Atomic Absorption Spectros-

shown to be appropriate for the application where the use of

copy

such water is specified. Therefore, the selection of an alternate

D5128 Test Method for On-Line pH Measurement of Water

technology in place of the technology specified in Table 1

of Low Conductivity

should be made taking into account the potential impact of

D5173 Guide for On-Line Monitoring of Total Organic

other contaminants such as microorganism and pyrogens. Such

Carbon in Water by Oxidation and Detection of Resulting

Carbon Dioxide

This specification is under the jurisdiction ofASTM Committee D19 on Water

and is the responsibility of Subcommittee D19.02 on Quality Systems,

Specification, and Statistics. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved May 1, 2011. Published June 2011. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1951. Last previous edition approved in 2006 as D1193 – 06. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D1193-06R11. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D1193−06 (2011)

TABLE 1 Processes for Reagent Water Production

Total

K

TOC Sodium Chloride Endotoxin,

E F HBC

Silica

µS/cm MΩ·cm

A,B,C,D G

H I J L

Type Grade Production Process pH µg/L µg/L µg/L cfu/mL EU/mL

(max) (min)

µg/L

(max) (max) (max) (max) (max)

(max)

I Purify to 20 µS/cm by dist. or 0.0555 18 50 1 1 3

equiv., followed by mixed

A

bed DI, 0.2 µm filtration

I A Purify to 20 µS/cm by dist. or 0.0555 18 50 1 1 3 10/1000 0.03

equiv., followed by mixed

A

bed DI, 0.2 µm filtration

I B Purify to 20 µS/cm by dist. or 0.0555 18 50 1 1 3 10/100 0.25

equiv., followed by mixed

A

bed DI, 0.2 µm filtration

I C Purify to 20 µS/cm by dist. or 0.0555 18 50 1 1 3 100/10

equiv., followed by mixed

A

bed DI, 0.2 µm filtration

B

II Distillation 1.0 1.0 50 5 5 3

B

II A Distillation 1.0 1.0 50 5 5 3 10/1000 0.03

B

II B Distillation 1.0 1.0 50 5 5 3 10/100 0.25

B

II C Distillation 1.0 1.0 50 5 5 3 100/10

III Distillation, DI, EDI, and/or 0.25 4.0 200 10 10 500

RO, followed by 0.45 µm

C

filtration.

III A Distillation, DI, EDI, and/or 0.25 4.0 200 10 10 500 10/1000 0.03

RO, followed by 0.45 µm

C

filtration.

III B Distillation, DI, EDI, and/or 0.25 4.0 200 10 10 500 10/100 0.25

RO, followed by 0.45 µm

C

filtration.

III C Distillation, DI, EDI, and/or 0.25 4.0 200 10 10 500 1000/100

RO, followed by 0.45 µm

C

filtration.

IV Distillation, DI, EDI, and/or 5.0 0.2 5.0 to 8.0 50 50

D

RO.

IV A Distillation, DI, EDI, and/or 5.0 0.2 5.0 to 8.0 50 50 10/1000 0.03

D

RO.

IV B Distillation, DI, EDI, and/or 5.0 0.2 5.0 to 8.0 50 50 10/100 0.25

D

RO.

IV C Distillation, DI, EDI, and/or 5.0 0.2 5.0 to 8.0 50 50 100/10

D

RO.

A

Type I grade of reagent water shall be prepared by distillation or other equal process, followed by polishing with a mixed bed of ion-exchange materials and a 0.2-µm

membrane filter. Feed water to the final polishing step must have a maximum conductivity of 20 µS/cm at 298K (25°C). Type I reagent water may be produced with alternate

technologies as long as the appropriate constituent specifications are met and that water so produced has been shown to be appropriate for the application where the use

of such water is specified.

B

Type II grade of reagent water shall be prepared by distillation using a still designed to produce a distillate having a conductivity of less than 1.0 µS/cm at 298 K (25°C).

Ion exchange, distillation, or reverse osmosis and organic adsorption may be required prior to distillation, if the purity cannot be attained by single distillation. Type II reagent

water may be produced with alternate technologies as long as the appropriate constituent specifications are met and that water so produced has been shown to be

appropriate for the application where the use of such water is specified.

C

Type III grade of reagent water shall be prepared by distillation, ion exchange, continuous electrodeionization, reverse osmosis, or a combination thereof, followed by

polishing with a 0.45-µm membrane filter. Type III reagent water may be produced with alternate technologies as long as the appropriate constituent specifications are met

and that water so produced has been shown to be appropriate for the application where the use of such water is specified.

D

Type IV grade of reagent water may be prepared by distillation, ion exchange, continuous electrodeionization, reverse osmosis, electrodialysis, or a combination thereof.

Type IV reagent water may be produced with alternate technologies as long as the appropriate constituent specifications are met and that water so produced has been

shown to be appropriate for the application where the use of such water is specified.

E

Electrical conductivity at 25°C.

F

Electrical resistivity at 25°C.

G

pH at 25°C, not applicable to higher resistivity waters.

H

Total organic carbon.

I

Sodium.

J

Chloride ion.

K

Heterotrophic bacteria count.

L

Endotoxin in endotoxin units per mL.

D5245 Practice for Cleaning Laboratory Glassware, fate Oxidation, and Membrane Conductivity Detection

Plasticware, and Equipment Used in Microbiological D6071 Test Method for Low Level Sodium in High Purity

Analyses Water by Graphite Furnace Atomic Absorption Spectros-

D5391 Test Method for Electrical Conductivity and Resis- copy

tivity of a Flowing High Purity Water Sample D6161 Terminology Used for Microfiltration, Ultrafiltration,

D5542 Test Methods for Trace Anions in High Purity Water Nanofiltration and Reverse Osmosis Membrane Processes

by Ion Chromatography D6529 Test Method for Operating Performance of Continu-

D5997 Test Method for On-Line Monitoring of Total ous Electrodeionization Systems on Feeds from 50–1000

Carbon, Inorganic Carbon in Water by Ultraviolet, Persul- µS/cm

D1193−06 (2011)

F1094 Test Methods for Microbiological Monitoring of chemical forces, colloids, and organics down to 150 molecular

Water Used for Processing Electron and Microelectronic weight. May also be called hyperfiltration (see Terminology

D6161).

Devices by Direct Pressure Tap Sampling Valve and by

the Presterilized Plastic Bag Method

4. Composition and Characteristics

4.1 The types and grades of water specified in this Standard

3. Terminology

shall conform to the requirements in Table 1.

3.1 Definitions—For definitions used in this specification

5. Test Methods

refer to Terminology D1129.

5.1 Electrical Conductivity and Resistivity—Refer to Test

3.2 Definitions of Terms Specific to This Standard:

Methods D1125 and D5391.

3.2.1 reagent water—water that is used specifically as a

5.2 pH—Refer to Test Methods D1293 and D5128.

component of an analytical measurement process and meets or

5.3 Silica—Refer to Test Method D4517.

exceeds the specifications for these waters.

5.4 Sodium—Refer to Test Methods D6071.

3.2.2 electrodeionization—a process that removes ionized

and ionizable species from liquids using electrically active

5.5 Chlorides—Refer to Test Method D5542.

media and using an electrical potential to influence ion

5.6 TOC—Refer to Test Methods D5173 and D5997.

transport, where the ionic transport properties of the active

5.7 Endotoxins—Refer to LAL Test Method.

media are a primary sizing parameter. Electrodeionization

5.8 Microbiological Contamination—Refer to Test Methods

devices typically comprise semi-permeable ion-exchange

F1094.

membranes and permanently charged ion-exchange media (see

Test Method D6529).

6. Keywords

3.2.3 reverse osmosis (RO)—the separation process where

6.1 laboratory analysis; reagent; water

one component of a solution is removed from another compo-

nent by flowing the feed stream under pressure across a 3

Published in the U.S. Pharmacopeia by The U.S. Pharmacopeial Convention,

semipermeable membrane. RO removes ions based on electro- Inc.

APPENDIX

(Nonmandatory Information)

X1. POTENTIAL REAGENT WATER ISSUES

INTRODUCTION

This Appendix is provided as a guide to various issues in the production, application, storage, and

monitoring of Reagent Water. These issues are very complex and extensive. This guidance is not

intended to be comprehensive or complete. Producers and users of Reagent Water are encouraged to

seek out additional sources of guidance in this area.

X1.1 Preparation X1.2 Use and Application

X1.1.1 Historically, reagent water Types I, II, III, and IV

X1.2.1 Type I and Type III Water:

have been linked to specific process for their production.

X1.2.1.1 Contact with the ion-exchange materials may

Starting with this revision, these types of waters may be

cause an addition of organic contaminants to the water. This

produced with alternate technologies as long as the appropriate

will depend on the resin type/quality, quality of the regenera-

constituent specifications are met and that water so produced

tions (if regenerated), environmental conditions in which the

has been shown to be appropriate for the application where the

water purification system is used and actual system use (for

use of such water is specified.

example, duration of non-use periods). Practices may be put in

X1.1.2 The preparation methods of the various grades of place to decrease the risk or organic contamination:

reagent water influences the limits of impurities.Therefore, the (1) Periodic rinsing of the purification media to limit

selection of an alternate technology in place of the technology bacteriological (organic) contamination is recommended.

specified in the Table 1 should be made taking into account the (2) After each period of non-usage, drawing off a quantity

potential impact of other contaminants such as micro-organism of water is necessary before use. Refer to the supplier speci-

and pyrogens, even if a grade is not specified. Such contami- fications for the recommended volume.

nants were not necessarily considered by the performance (3) Synthetic activated carbon and/or UV (dual wave-

characteristics of the technology previously specified. lengths 185 nm and 254 nm) may be used in the polishing

D1193−06 (2011)

stages to decrease the level of organic contaminants (to reach water listed with a validated filter may also produce sterile

Type I water specifications), and/or to reach lower organic water when performed in aseptic conditions. The user should

levels. choose the appropriate sterilization technique for the intended

X1.2.1.2 The quality of the water produced depends upon use.

the type, age, and method of regeneration of the ion exchange

materials (if regenerated). Likewise, the flow rate through the X1.3 Monitoring

ion exchange resin bed will change the conductivity of the

X1.3.1 The limits of Table 1 apply to the water sampled at

product water.The manufacturer’s instructions for resins or the

the point of use or, when for practical reasons and/or to avoid

resin cartridge bed should be followed.

contamination (for example connection of an equipment after a

X1.2.1.3 The use of the membrane filter in the preparation

0.2 µm filter), as close as possible to the point of use and with

of Type I and Type III water may add a sma

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.